Sefa iSPRAY PRO User manual

User guide

Manuel utilisateur

ENGLISH

FRANÇAIS

iSPRAY PRO

HEAT TRANSFER TECHNOLOGIES

www.sefa.fr 3

EnglishFrançais

INDEX

INDEX

INDEX������������������������������������������������������������������������������������������������������������������������������������������������������������������� 3

WARRANTY TERMS ������������������������������������������������������������������������������������������������������������������������������������4

TECHNICAL DATA����������������������������������������������������������������������������������������������������������������������������������������� 5

SAFETY ����������������������������������������������������������������������������������������������������������������������������������������������������������������6

INSTALLATION������������������������������������������������������������������������������������������������������������������������������������������������7

FIRST START���������������������������������������������������������������������������������������������������������������������������������������������������10

BASIC FUNCTIONS�������������������������������������������������������������������������������������������������������������������������������������12

GARMENT LOADING��������������������������������������������������������������������������������������������������������������������������������14

PRODUCTION MODE�������������������������������������������������������������������������������������������������������������������������������15

TANK PROCEDURE����������������������������������������������������������������������������������������������������������������������������������� 16

SERVICING������������������������������������������������������������������������������������������������������������������������������������������������������ 17

TROUBLESHOOTING TIPS ��������������������������������������������������������������������������������������������������������������������21

CONDITIONS DE GARANTIE���������������������������������������������������������������������������������������������������������������23

CARACTERISTIQUES ������������������������������������������������������������������������������������������������������������������������������� 24

SECURIT���������������������������������������������������������������������������������������������������������������������������������������������������������25

INSTALLATION��������������������������������������������������������������������������������������������������������������������������������������������� 26

PREMIER DÉMARRAGE������������������������������������������������������������������������������������������������������������������������ 29

FONCTIONS DE BASE������������������������������������������������������������������������������������������������������������������������������31

CHARGEMENT DES VÊTEMENTS����������������������������������������������������������������������������������������������������33

MODE DE PRODUCTION���������������������������������������������������������������������������������������������������������������������34

PROCÉDURE DU RÉSERVOIR�����������������������������������������������������������������������������������������������������������35

MAINTENANCE������������������������������������������������������������������������������������������������������������������������������������������� 36

CONSEILS DE DÉPANNAGE ��������������������������������������������������������������������������������������������������������������40

MAINTENANCE LOG �������������������������������������������������������������������������������������������������������������������������������42

2021-03-25

4 www.sefa.fr

English

WARRANTY TERMS

The warranty period shall come into effect on the day on which the equipment is

brought into service at the user’s premises, as attested on the returned warranty certif-

icate and the delivery note, and shall run for two years, based on a standard equipment

operating schedule of 8 hours per day, i.e. 3,000 hours.

The warranty is strictly limited to our equipment, and covers faulty materials and work-

manship,

which the purchaser shall be required to substantiate.

Our liability shall be limited to making good or replacing free of charge parts that are

acknowledged by us to be defective, and no claims for damages for any reason may be

made against us.

Parts replaced under warranty shall:

- Remain our property

- Be invoiced on consignment

A credit note will be issued upon return of the faulty parts.

Returns must be made NO LATER THAN ONE MONTH after the work is performed un-

der warranty.

THIS WARRANTY DOES NOT COVER :

Commercially sourced consumables such as:

- Fuses, LEDs, seals, hoses, nozzles, filters, etc.

- Material and equipment not manufactured wholly by us, which are covered by the

warranty of the manufacturer thereof.

THIS WARRANTY DOES NOT EXTEND TO :

Replacements or repairs arising from fair wear and tear of the appliances or machines,

damage or accidents arising from negligence, lack of supervision or maintenance, im-

proper use or alterations made without our written consent.

Defects arising from material provided by the purchaser or mandatory design require-

ments issued by the purchaser.

Repairs made necessary by damage or accidents arising during carriage.

Normal maintenance and adjustment procedures required during use of the machine,

as set out in the maintenance instructions, such as:

- adjustment of intermediate components

- tightening of pipes, hoses, etc.

Any traces of detergent oil in the air system of pneumatic machines

shall invalidate the aforementioned warranty terms.

Quote the machine reference and serial number when making technical enquiries

or ordering spare parts.

User guide - SEFA iSPRAY PRO

www.sefa.fr 5

English

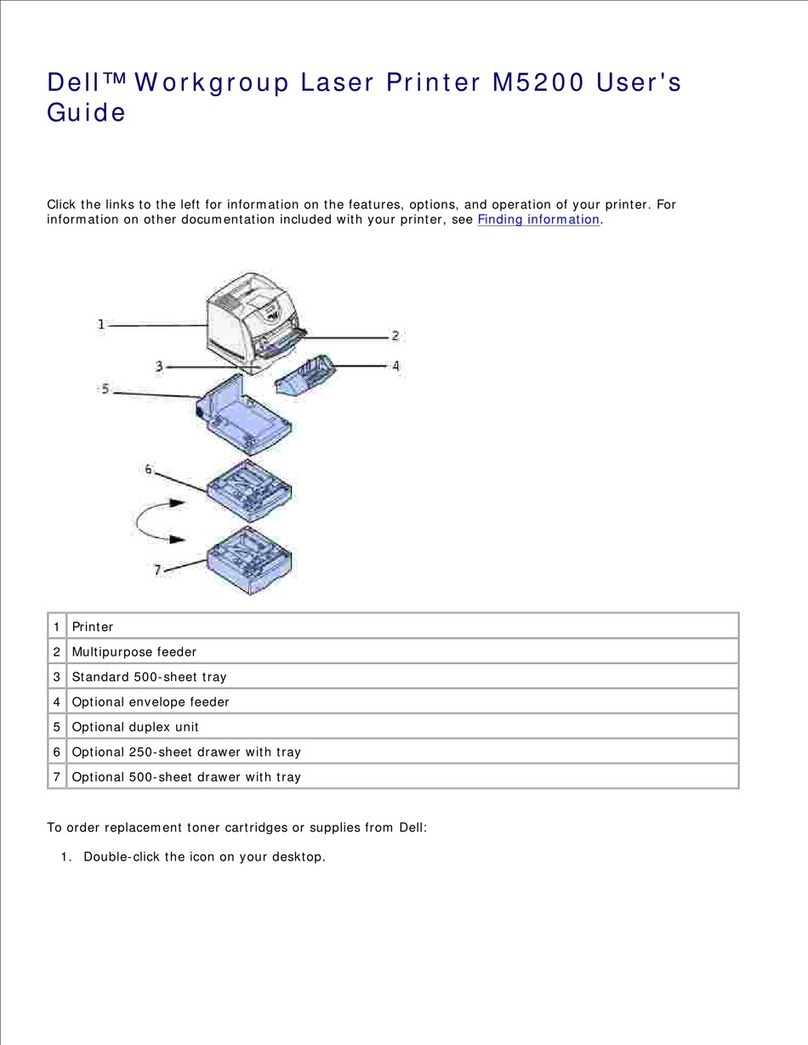

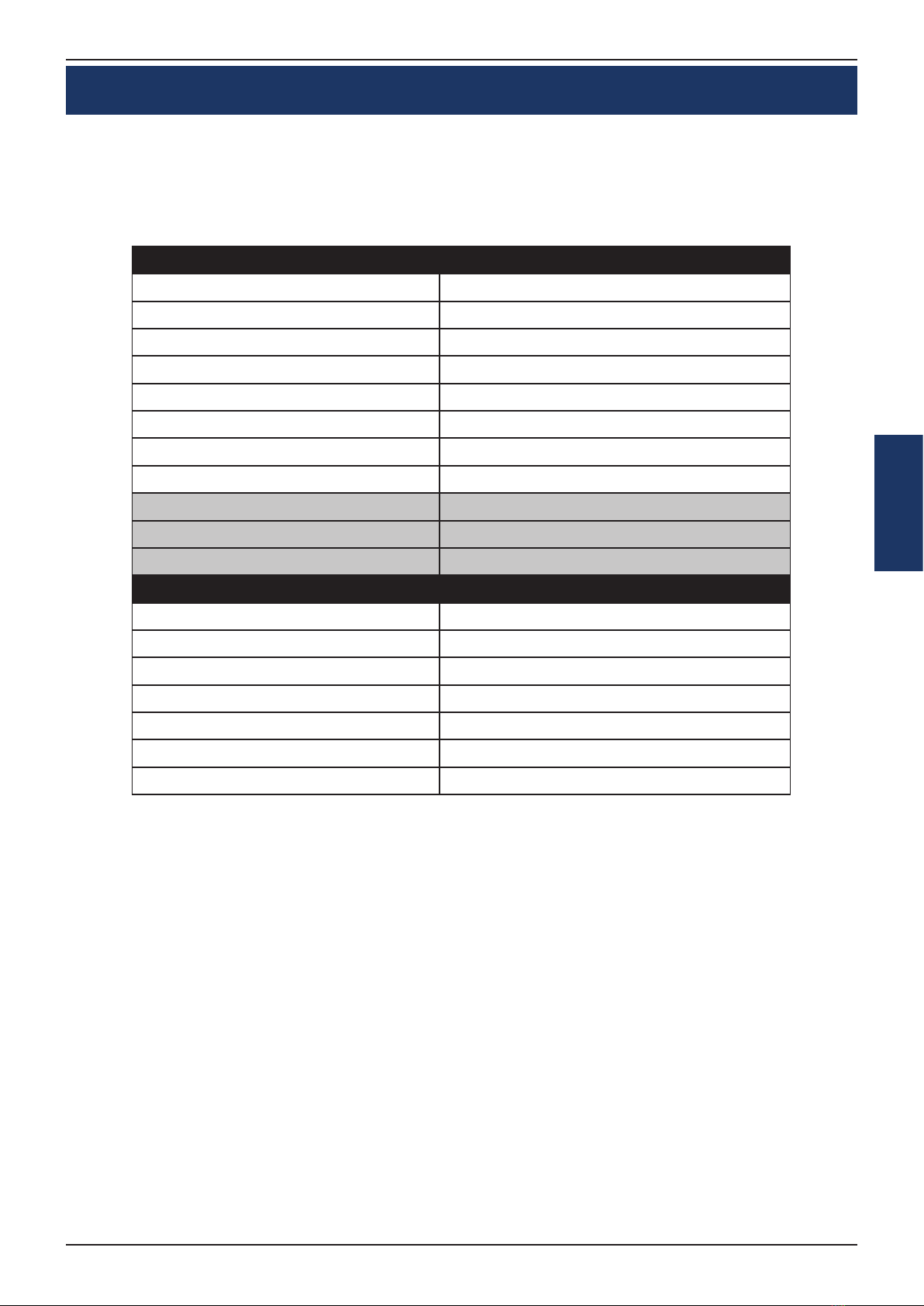

TECHNICAL DATA

Technical data

Weight in working order 104 kg

Height 660 mm

Depth 1040 mm

Width 850 mm

Platen size 410 x 600 mm

Power supply 220/240 V single phase + ground 50/60 Hz

Power consumption 250 W

Amp rating 1 A

Power supply (US version) 110/120 V single phase + ground 50/60 Hz

Power consumption (US version) 250 W

Amp rating (US version) 2 A

Features

Spraying Method Y Axis movement precision spraying

Motor Stepper motor

Pumps 4x

Direction of Spraying Uni-directional

Nozzles 4x

Nozzle Pressure 6.8 bars max.

Tanks 4x (5L/unit)

Non-contractual document : we reserve the right to alter our product specifications in

line with advances in technology.

2021-03-25

6 www.sefa.fr

English

SAFETY

Please read the Operating Manual carefully before operating the machine.

The machine should be operated by a qualified person who is aware of the potential

dangers arising from improper use of the equipment. The factory-installed pneuma-

tic, electrical and mechanical settings programmed by our technicians and the safety

features must not be altered under any circumstances. SEFA accepts no liability for

problems that may be caused by the machine if such alterations are made.

Personal Protective Equipment (PPE) must be worn (e.g. gloves and

safety glasses).

Do not touch hot parts of the machine during use. Do not place hands

inside when the machine is switched on. Make sure the operator is

not exposed to risks of electrocution or other hazards when handling

the machine.

Check the machine each day before use. Make sure there is nobody in

the vicinity of the machine before starting work. If the machine mal-

functions, cut the power supply and look for the cause of the problem

(see the Servicing section of this manual).

No changes must be made to the safety covers and safety systems.

They must be refitted if they are removed for servicing work.

They must be kept in place and in good condition during normal use.

Technical parts documents are supplied with the machine. Please read them before

starting to use your SEFA machine.

a� International symbols

b� Important safety precautions

c� Safety features

THIS MACHINE IS DESIGNED FOR USE BY A SINGLE QUALIFIED OPERATOR

OFF ELECTROCUTION

HAZARD

ON

DANGER, WARNING

User guide - SEFA iSPRAY PRO

www.sefa.fr 7

English

Keep the machine away from direct sunlight and heat sources

TO BE PERFORMED BY QUALIFIED PERSONNEL

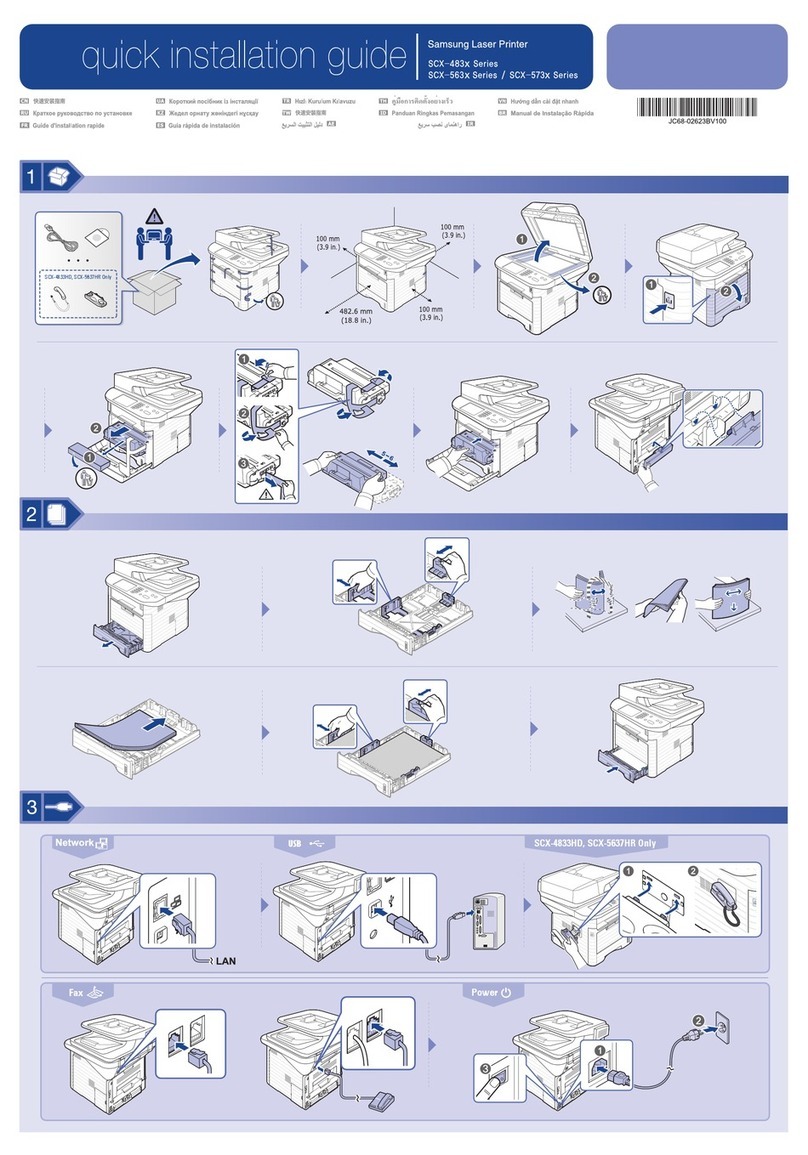

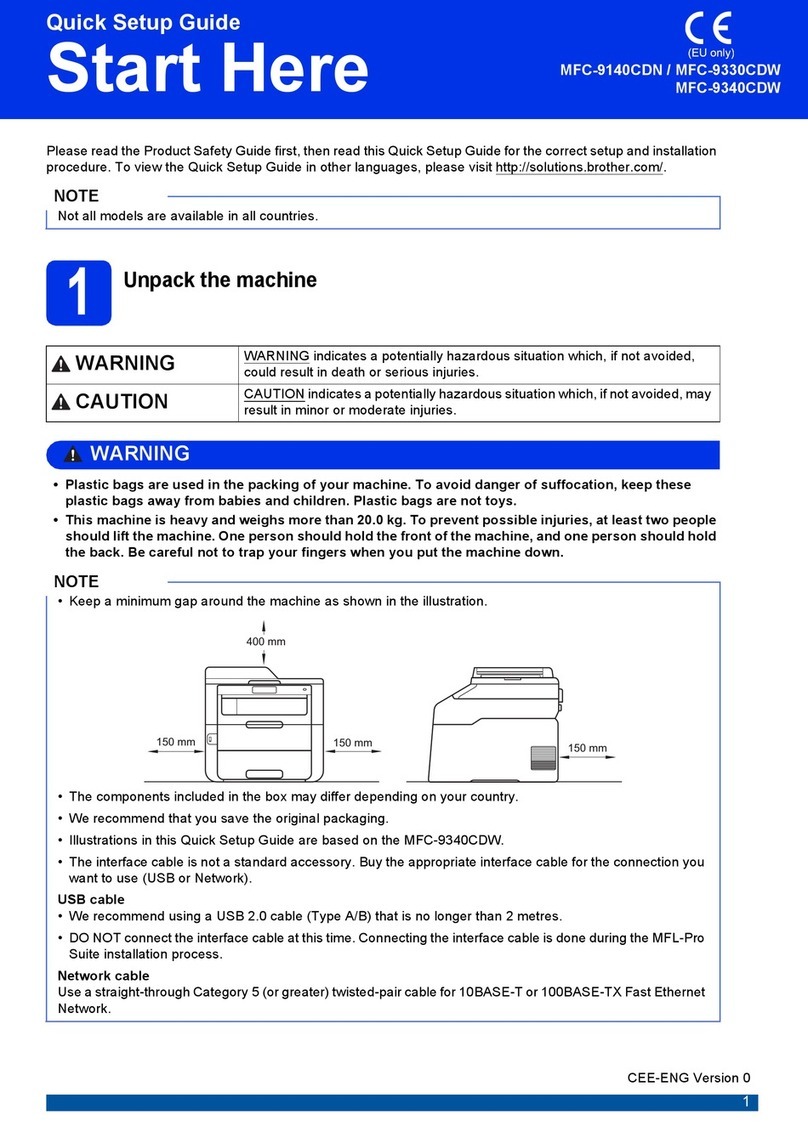

INSTALLATION

First remove the top cover from the carton box.

Then remove the protective styrofoam sheets.

Continue with removing the side carton cover.

The product is 104Kg and requires at least 4 people to lift it. Always carry the device

from the bottom. Never lift it utilizing the drawer handle, nor the Nozzle Access Cover.

Place this product on a flat, stable surface. The surface should be at least 670 x 790 mm

and capable of supporting more than 130kg. This product will not operate properly if it

is tilted or in an angle. The machine must only be used indoors. Do not install or store

the iSPRAY Pro, where it will be exposed to weather conditions. Avoid places subject to

shocks and vibrations. Before moving the machine to another position, ensure that the

tank caps are sealed and liquid cannot spill out. Do not tilt the pretreatment machine,

while the liquid tanks are full or inside the machine.

Remove the blue security tapes from the iSPRAY Pro covers.

Open the Nozzle Access Cover.

Remove the yellow safety bar from the Nozzle Carriage.

Open the drawer and check that the table is properly placed on it.

The height of the machine on the front side must be 660mm and on the backside

643mm. If not, adjust the feet accordingly.

a� Unboxing

b� Preparation

2021-03-25

8 www.sefa.fr

English

Open the Tank Access Cover to gain access to the Tank Storage Compartment.

There are 4 empty tanks in the slots L1, L2, CL, and MT. You can fill the empty tanks or

directly use a new pretreatment tank in its place.

Fill/Replace Tank L1 or/and L2 with the pretreatment liquid you are going to use.

In case of using 2 pretreatment liquids, fill/replace both Tanks L1 and L2 with the accor-

ding pretreatment liquid.

Fill the Tank CL with distilled water.

Tanks that you need to refill/replace in blue below.

Option 1:

Using 1 Pretreatment Liquid (L1 or L2) and

Distilled water in the (CL) Tank.

Option 2:

Using 2 of the same type Pretreatment Li-

quids (L1 +L2) to double your capacity and

Distilled water in the (CL) Tank.

Option 3:

Using 2 different Pretreatment Liquids (L1 /

L2) and Distilled water in the (CL) Tank.

c� Liquid installation

L1

L1

L1

L1

L2

L2

L2

L2

CL

CL

CL

CL

MT

MT

MT

MT

Shake the new tanks/bottles with the pretreatment well, before using them inside the

machine.

User guide - SEFA iSPRAY PRO

www.sefa.fr 9

English

Take the Tank out of the slot.

Open the cap of the Tank.

You can use the Tank Access Cover as extra workspace.

Take the tubes out of the Tank.

Shake the pretreatment bottles well, before filling the tanks.

Fill the tank with the pretreatment liquid. Ensure that it’s with the same pretreatment

liquid type.

Put the tubes inside the tank and close the cap. Ensure they are in place and properly

sealed.

Put the tank back into the slot.

Close the Tank Access Cover.

Take the Tank out of the slot.

Open the cap of the Tank.

You can use the Tank Access Cover for extra workspace.

Take the tubes out of the Tank.

Shake the pretreatment bottles well, before replacing the tanks.

Put the tubes inside the new tank and close the cap. Ensure they are in place and pro-

perly sealed.

Put the new tank inside the slot.

Close the Tank Access Cover.

d� Tank Filling Procedure

e� Tank Replacement

Before closing the Tank Access Cover, ensure that all the tubes are inside the tanks and

that the caps are in place and properly sealed.

Before closing the Tank Access Cover, ensure that all the tubes are inside the tanks and

that the caps are in place and properly sealed.

2021-03-25

10 www.sefa.fr

English

FIRST START

a� Preparation

b� Nozzle assembly steps

Plug in the power cord. Make certain that the source voltage is the same as the rated

voltage, listed on the serial number/rating plate. Power On the machine from the Main

switch, that is placed at the backside of iSPRAY Pro.

To initiate the machine, tap the screen.

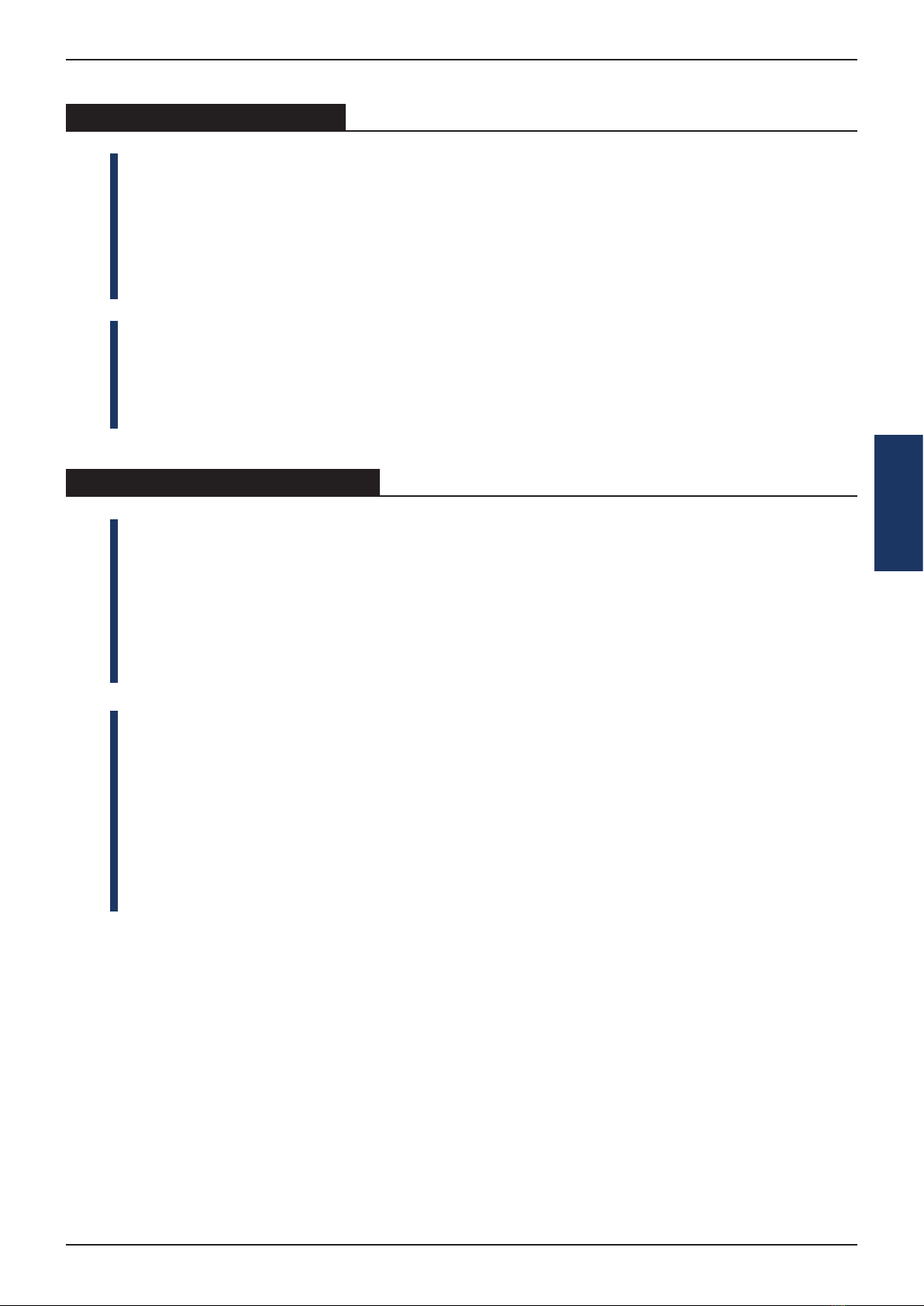

Check that the CL, L1 and/or L2 Tanks are full and that all four (4) nozzles are properly

placed into position.

Press Confirm to continue with the liquid charge.

In case you installed pretreatment liquid in L1 or L2 Tank, select the one you filled.

In case you installed pretreatment liquid in both L1, L2 Tanks, select the one you wish to

use first and press Confirm.

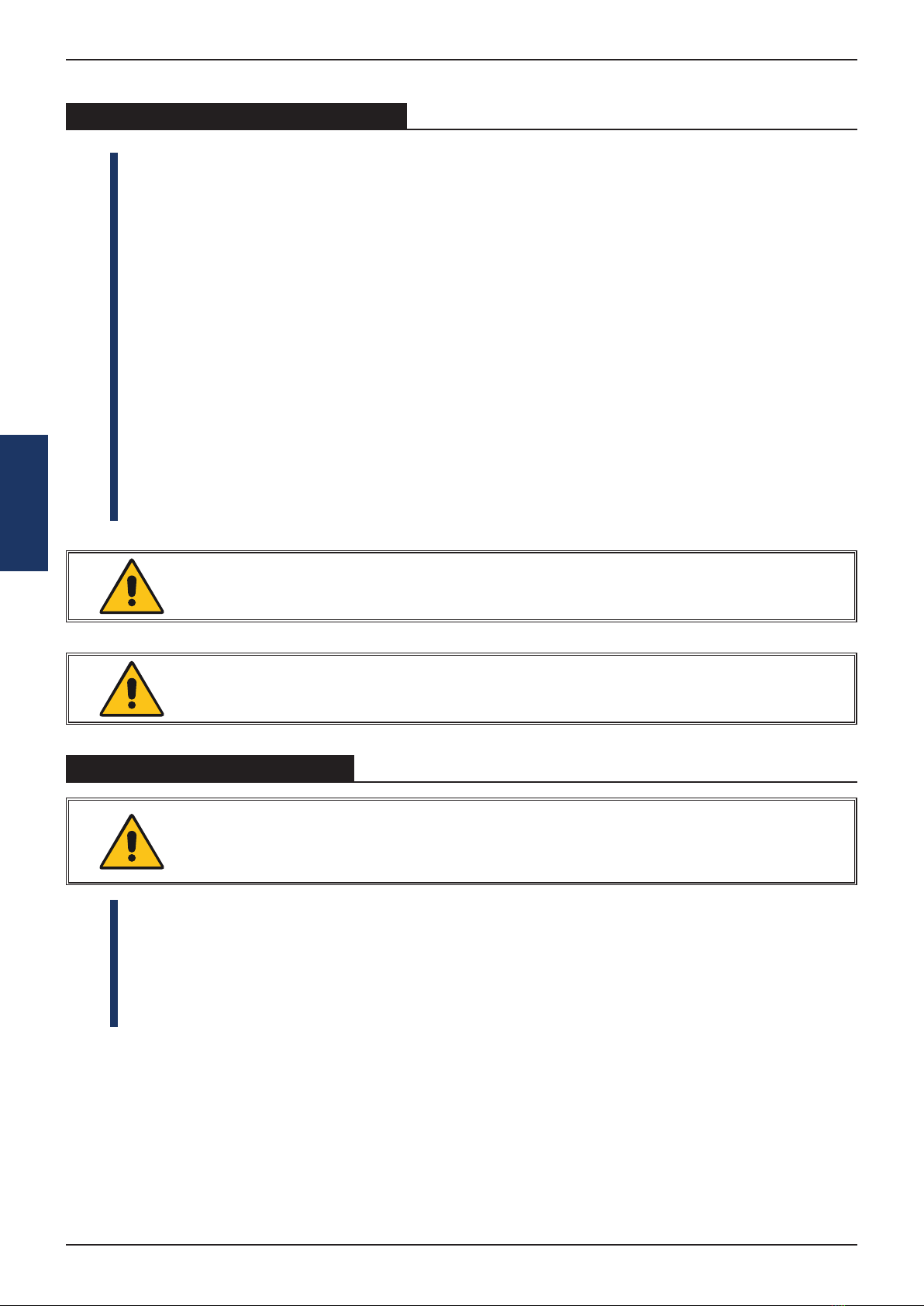

Place inside the Nozzle Carriage Chamber the nozzle assemblies, following the steps

below :

1. Open the Nozzle Access Cover

2. Insert the nozzle inside the blue nozzle holder.

3. Position the black gasket inside the blue nozzle holder and push it, in place, to tighten.

Finally, Attach the nozzle assembly to the carriage and turn it 90 degrees counterclo-

ckwise to lock it in position.

c� Initial Liquid Charge

User guide - SEFA iSPRAY PRO

www.sefa.fr 11

English

d� Nozzle Check

You should perform a nozzle check to see if all four nozzles are firing correctly.

To perform the nozzle check, start from the Home screen.

Press the Nozzle button.

You can, also, open the Nozzle Access Cover to have a better view.

Enable all the nozzles, one-by-one, (or only the nozzles you want to check).

Press the Spray button. Each nozzle should be firing in an 80O angle.

Exit the Nozzle Check screen, by pressing the back arrow, to return to the Home screen.

After a couple of seconds, the initial liquid charge will finish.

The machine is now filled with liquid and ready for operation.

If there is no liquid flowing, then check that all the tubes are inside the tanks and that

the caps are in place and properly sealed.

If you get any error messages, for further information, check the topic: Troubleshooting>

General Problems in the Operational Manual.

If the nozzles are not firing correctly, for further information, check the topic:

Troubleshooting> Spraying problems.

2021-03-25

12 www.sefa.fr

English

BASIC FUNCTIONS

a� Spraying modes

b� Grid edit

On the Home screen, tap on Edit.

Edit the spray area. There are two spraying selection modes. You can use your preferred

method, by switching between Grid Edit and Linear Edit.

Select the direction you want the garment to have, on the drawer plate. You can rotate

it 180°, by pressing the icon.

The entire spray area (41x60cm / 16x23.6in) has been divided into 4 columns and 4 rows

(4x4=16 boxes). Specifically, select the boxes in the Grid Box selection area that you want

to enable.

Select the liquid spraying amount per ml, for the max spray area (41x60cm / 16x23.6in),

from the slide bar. Tap on the Calculate button, to check the actual liquid amount

sprayed on the selected area. When finished, tap on the Confirm button.

User guide - SEFA iSPRAY PRO

www.sefa.fr 13

English

c� Linear Edit

Select the direction you want the garment to have, on the drawer plate. You can rotate

it 180°, by pressing the icon.

Select the nozzles you want to enable. You are able to choose from 1 up to all 4 nozzles.

The nozzles spray, exactly as shown on the screen, in the Nozzle Carriage Chamber.

e.g. If you select the second nozzle from the left on the screen, the same nozzle will

spray in the Nozzle Carriage Chamber.

Select the Spray Length by changing the value with the +/ - buttons.

Select the distance from the top, by changing the Neck Offset value with the +/ -

buttons.

Select the liquid spraying amount per ml, for the max spray area (41x60cm / 16x23.6in),

from the slide bar. Tap on the Calculate button, to check the actual liquid amount

sprayed on the selected area. When finished, tap on the Confirm button.

On the Home screen, you can save your job preference, by holding for 3 seconds on any

of the ten custom job preset buttons.

d� Save custom presets

2021-03-25

14 www.sefa.fr

English

GARMENT LOADING

Open the drawer and place the garment on the plate, in the direction of the preselec-

ted position.

Place the garment on the platen. Make sure that the garment is flat.

Carefully tuck in/ position, any excess textile, below the platen.

Close the drawer.

In humid environment, it is often beneficial to pre-press the shirt (using the protection

paper as a barrier from the press) for 5 to 10 seconds prior to applying the pretreatment.

This removes some of the water that is naturally trapped in the fibers.

User guide - SEFA iSPRAY PRO

www.sefa.fr 15

English

PRODUCTION MODE

To spray the garment, either press the Blue button on the front side of the iSpray Pro,

or activate the Spray option on the Home screen.

Production Mode allows you to start the spraying procedure, as soon as, the drawer is

closed, without pressing a button.

Activate the Production Mode on the Home screen to start the automatic spraying

function, once the drawer is closed.

If drawer is closed, when enabling the Production Mode, open and close the drawer to

start spraying procedure.

When spraying finishes, open the drawer and take out the garment.

Once you have finished spraying your last garment, before closing the drawer, deacti-

vate the Production Mode on the Home screen.

a� Single

b� Production

2021-03-25

16 www.sefa.fr

English

TANK PROCEDURE

a� Filling / Replacment

b� Tank selection

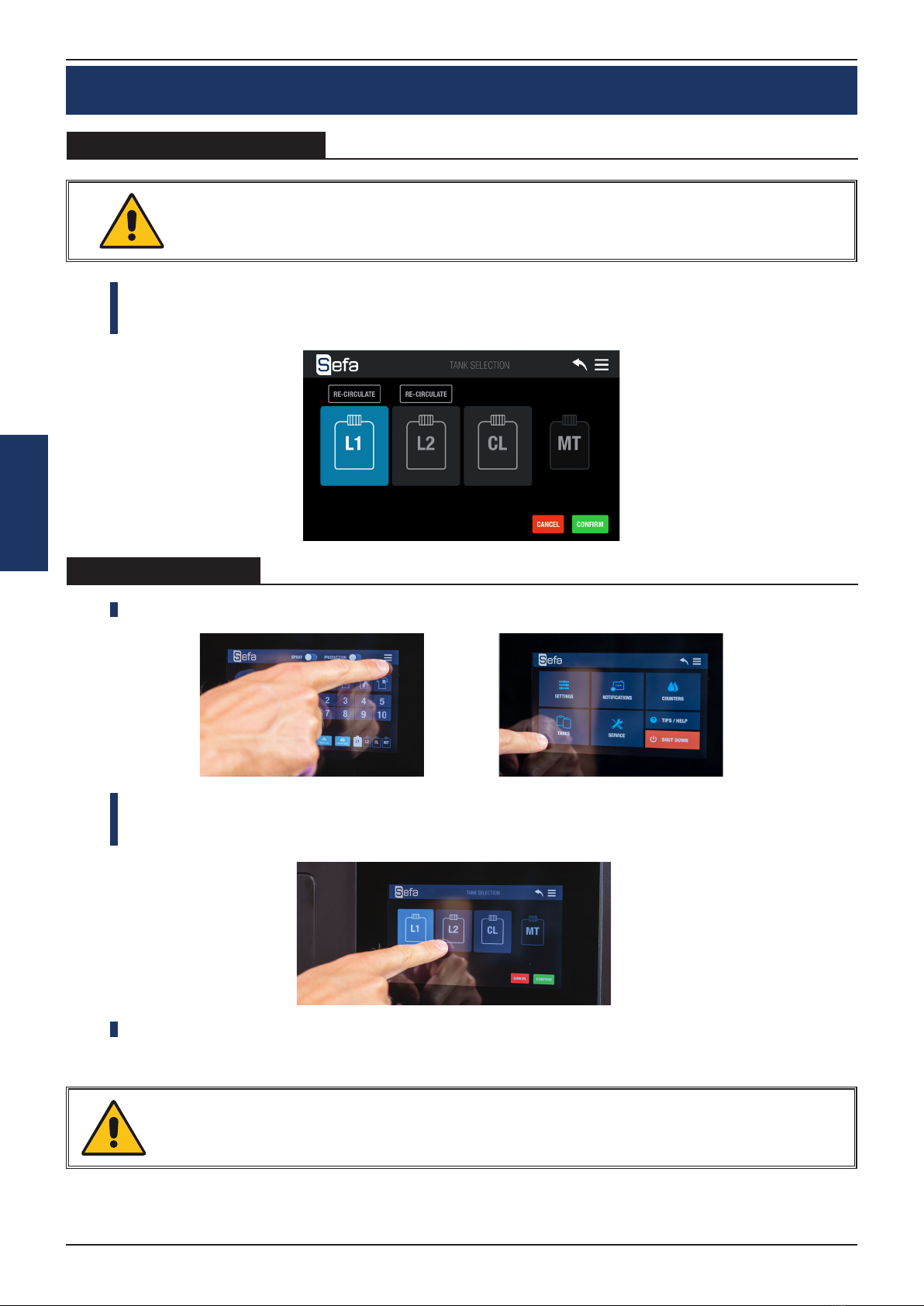

On the Home screen tap on the Menu button and select Tanks. Tap the Re-Circulate

button (of the tank you refilled previously) for three seconds to initiate the liquid re-cir-

culation process that will remove any air bubbles from the tank tubes.

In this Tank Selection screen, you can check, which tank you have, currently, selected.

If you wish to select a different tank to spray, tap on that tank you want, and press

Confirm. iSpray Pro will automatically switch to your preferred tank.

You can, also, tap on the CL Tank, to manually perform the shutdown maintenance.

On the Home screen tap on the Menu button. Select Tanks.

CHECK «LIQUID INSTALLATION» IN THE INSTALLATION MENU.

Choosing CL will clean, only the basic line to the nozzles, and will not bring the machine

into a shipping state. For further instructions, check the topic: Transporting iSPRAY Pro.

User guide - SEFA iSPRAY PRO

www.sefa.fr 17

English

1. Open the Tank Storage Compartment Cover.

2. Check the liquid level in the L1, L2, CL tanks and if needed, follow the instructions to

refill / replace them.

3. Empty the Maintenance tank.

1. Open the Nozzle Access Cover.

2. Take the 4 nozzles out of the ultrasonic device and insert the nozzles inside the blue

nozzle holder.

3. Position the black gasket inside the blue nozzle holder and push it in place to tighten.

SERVICING

TO BE PERFORMED BY QUALIFIED PERSONNEL

Maintenance Schedule

Daily Liquid Check

• Check the Tanks for enough

Pretreatment liquid and Water

• Empty the Maintanance Tank

Daily Wake Up

• Place the 4 nozzles on the Nozzle Carriage

• Initiate iSpray Pro

• Liquid Charge

Daily Shutdown

• Flush the main tube with

distilled water

• Remove the 4 nozzles from the Nozzle Carriage

• Place the 4 nozzles in the

ultrasonic device

Monthly Maintenance

• Check and clean the L1, L2

tank filters

• Clean the Liquid Collecting Mat

Two Month Maintenance • Check and clean the Nozzle Filter

• Clean the Waste Collector

Long Inactivity-

Storage Condition

• Flush all the tubes with

distilled water

• Shutdown iSpray Pro

• Remove the 4 nozzles from the Nozzle Carriage

• Place the 4 nozzles in the

ultrasonic device

• Clean the Waste Collector

• Empty all the Tanks

a� Daily Liquid Check

b� Daily Wake Up Procedure

2021-03-25

18 www.sefa.fr

English

Attach the nozzle assembly to the Nozzle Carriage and turn it 90 degrees counterclo-

ckwise, to lock it in position.

To initiate the machine, tap the screen.

Select the tank you want to use. Follow the instructions of Tank Selection.

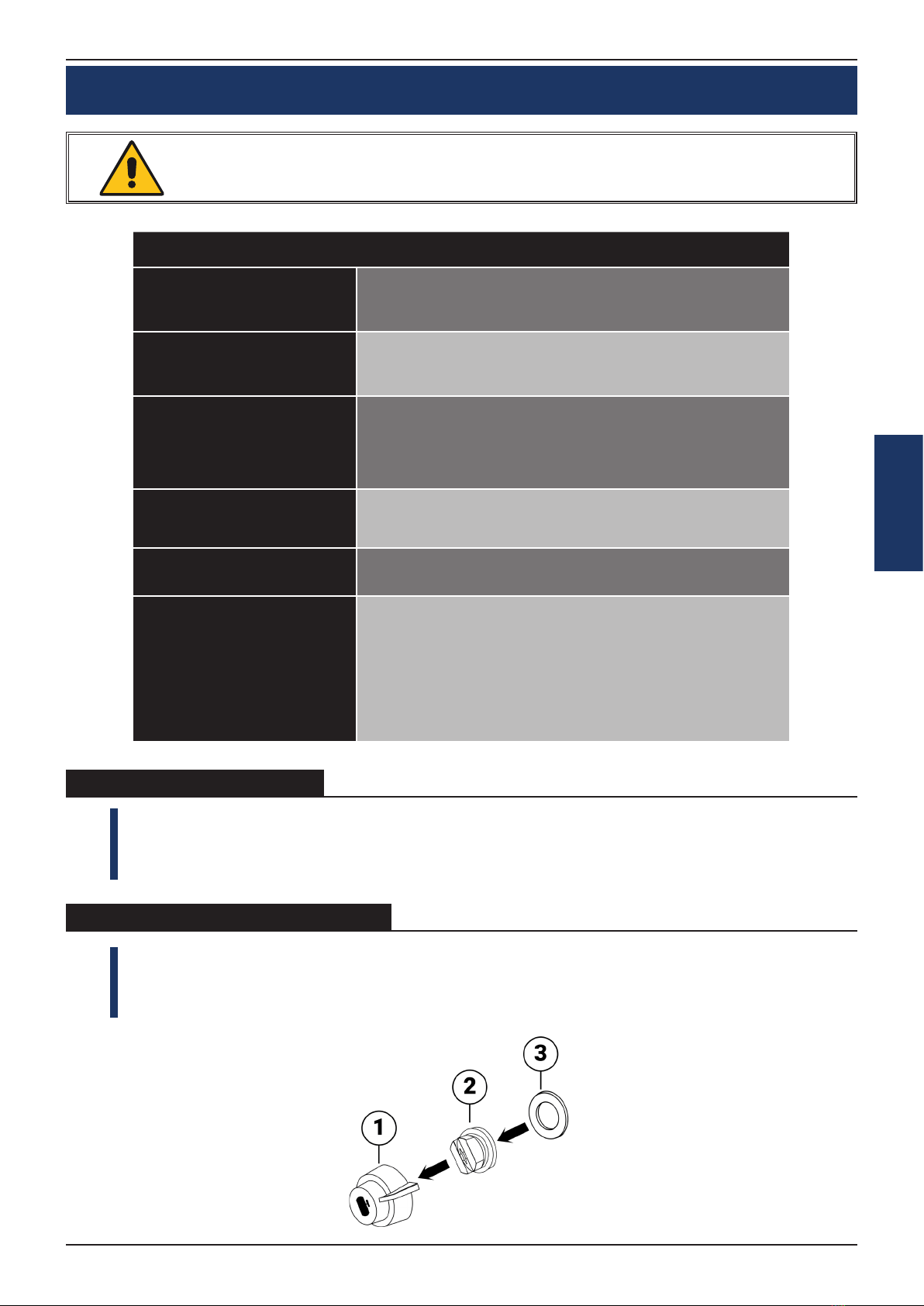

Tap on the Menu button.

Tap the Shutdown button.

To flush the main tube with distilled water, select YES on the screen that appears.

Remove the 4 nozzles from the Nozzle Carriage and disassemble them. Place the 4

nozzles into the ultrasonic device and start the cleaning process for 1 min.

c� Daily Shutdown Procedure

User guide - SEFA iSPRAY PRO

www.sefa.fr 19

English

Check and clean the L1, L2 tank filters :

1. The two filters are located in the Tank Compartment.

2. Unscrew the filter cap to remove them.

3. Clean them with water.

4. Reposition them. Make sure they are, in their initial place.

There is no need to empty the tubes from liquid to do this procedure.

Check and clean the Nozzle Filter :

The 3rd filter (nozzle filter) is located in the Nozzle Carriage Chamber. To clean it, you

need to, firstly, discharge the liquid from the main tube. To do that, you have to bring

the machine to service condition. For further instructions, check the topic: Service

Condition in the Operational Manual.

When iSpray Pro is in service condition, you can safely remove the filter cap and take it

out to be cleaned.

Clean the Waste Collector :

1. Power Off the machine, from the Main Power switch before cleaning the Waste

Collector.

2. Open the Nozzle Carriage Cover and pull it outwards.

3. Remove the screws holding the left metal cover and pull it out.

4. Remove the top plastic cover of the Isolation Chamber.

5. Clean the Waste Collector with paper or a towel.

6. Place back, into initial position, the top plastic cover of the Isolation Chamber.

7. Place the screws back on the left metal cover and tighten it into place.

8. Move the Nozzle Carriage back to Home position and close the Nozzle Carriage Cover.

Clean the Liquid Collecting Mat :

1. Open the Nozzle Access Cover.

2. Remove the Liquid Collecting Mat.

3. Clean it with water.

4. Reposition it. Make sure it is, in its initial place.

d� Monthly Maintenance

e� Two Month Maintenance

2021-03-25

20 www.sefa.fr

English

Storage Condition :

1. Empty the L1, L2 Tanks from the pretreatment liquid.

2. Fill the L1, L2 Tanks with distilled water.

3. Check that the CL Tank is full of / contains distilled water.

4. In one step: On the Home screen, tap on the Menu Button and then, select

Tanks.

5. Perform a Liquid Charge, by selecting L1, L2, CL, one-by-one, in any order. This

will flush all the lines with distilled water.

6. Go back and in the main Menu screen, tap on Service.

7. Set the Initial Charge Flag to ON.

8. Tap on the back icon and select the Shutdown button.

9. Click Yes to flush with distilled water the main line and nozzles.

10. When finished, iSpray Pro will Shutdown. Close the main switch at the back of

the machine and remove the power cable.

11. Remove the 4 nozzles from the Nozzle Carriage.

12. Place the 4 nozzles in the ultrasonic device.

13. Clean the Waste Collector, as described on page 23.

14. Empty all Tanks from liquids and place them back, empty. Place the tubes back

into the Tanks and seal the caps.

Perform the Maintenance Long Inactivity Storage Condition.

For further information check the topic: Maintenance>Long Inactivity> Storage Condi-

tion.

1. Lock the Nozzle Carriage in position with a tire up.

2. Ensure that the Tanks are empty.

3. Place tape to all covers to keep them properly secured into place.

f� Long Inactivity Maintenance

g� Transporting iSpray Pro

When the machine has been maintained for Long Inactivity Storage Condition,

there is no need to follow up with the maintenance schedule.

Before moving the machine to another location/position, ensure that the tank caps

are in place and sealed, so liquid cannot spill out. Do not tilt iSpray Pro while the

liquid tanks are full or inside the machine and the waste collector is not properly

cleaned.

To restore iSPRAY Pro after the Long Inactivity- Storage Condition state, follow the

instructions in the Installation Guide.

Table of contents

Languages:

Other Sefa Printer manuals