Sehan Electools SCOUT II User manual

2010. 01. 15 2nd addition /Measuring mode added

2010.01.27 rev /I/O Pin configuration correction

2010.02.05 additional parameter 33,34,35,36

2010.03.26 page 21_ Added 7.8 Connecting to Hybrid HDC controller

2010.04.07 page 31-33_ Added 11.1-3 Protocol, data saving and monitoring

2010.04.15 page 30 _ Cable USB-RS232 code no. corrected

2010.05.11 page 23,24 pin 20 spare1 --> Mid-count signal correction

SCREW COUNTER MANUAL

SCOUT II

- 1 -

INDEX

Contents Page

1. Specification Main features 3

2. Main features 3

3. LAY OUT 4

4. Caution 5

5. Accessaries 6

6. Operation 7

6.1 Mode 7

6.2 Work mode 8

6.3 Log-in mode 8

6.4 Parameter mode 9

6.5 Measuring mode 10

6.6 Program ¶meters 11

6.7 Parameters 12

7. Interface 14

7.1 25P I/O interface 14

7.2 Input (Negative common wiring )15

7.3 Input (Positive common wiring )16

7.4 Output (Positive common wiring )17

7.5 Output (Negaitivecommonwiring)18

7.6 I/O Wiring example #1 - tower lamp, sol valve 19

7.7 I/O Wiring example #2 - Inter-Lock of two driver 20

7.8 Connecting to Hybrid HDC controller 21

8. Timing chart 23

9. Timing chart details for OK /NG setup 24

9.1 Fastening OK 24

- 2 -

Contents Page

9.2 Fastening NG (Time Lapse )24

9.3 Fastening NG (Time Over )25

9.4 Fastening NG (No Torqeu Up )25

10. Cycle Start /Stop in the various operating condition 26

10.1 Auto start 26

10.2 Start (Continuous ON )26

10.3 Start (pulse) +Stop by time limit (Optional) 27

10.4 Start (pulse) +Stop (pulse) 29

11. RS-232C &USB COM port 30

11.1 Protocol details 31

11.2 Parameter change and save 32

11.3 Monitoring data output 33

12. PC software, SCOUT II Manager 34

12.1 Software install 34

12.2 How to use 34

- 3 -

1. Specification

No Description Specification

1Input power 1. 30~40VDC from KT-38D(FT-40D)

2. External power of 24VDC, 1A

for Hybrid controller

2Available tools KT-38D, FT-40D, HDC-30i, HDC-40i

3No of Program 8programs

4Count number 99 for each program

5Screwdriver port 4ports for KT-38D(FT-40D)

1port for HDC-30i, HDC-40i

6Com port RS232C, USB(B)

7I/O Input 15, Output 7

8PC software Scout Manager (on Windows)

9Parameter setting on front panel or PC software

10 Program share

Maximum 4screwdrivers (with KT-38D v4.3 or FT-40D)

can share one program

※Only one(1) KT-38D with the version lower than v4.3

can be connected to Scout II.

2. Main features of SCOUT II

-Maximum 5screwdrivers can share one program of Scout

(4of KT-38D v4.3 or FT-40D through A,B,C,D port +1extra one through 25P I/O )

-OK /NG judgment for each fastening

-Display of the remained screw number to be fastened

-Variable signal type of the cycle start and stop

-Error display with beep sound

-Display of the fastening error information

-Built in Fastening time measurement function

-No extra power is required for KT-38D, FT-40D

-External power (24VDC) is required for HDC or other tools through 25P I/O

- 4 -

3. LAY OUT

25P I/O port Hybrid screwdriver port

Numeric LED for the number of fastening screw

Power Input

24VDC,1A

for HDC controller

Menu LCD

Key

Fastening result by NG /OK

RS232C Com port

USB

Com port

A

B

C

D

126.5 mm

dia. 5mm

33 mm

136.5 mm

RJ-11(6P) Screwdriver port

KT-38D, FT-40D

55.5 mm55.5 mm

- 5 -

1) The power is supplied from KT-38D or FT-40D controller to Scout through RJ-11 "A"

screwdriver port. The screwdriver port "A" works for power feeding from the

connected controller KT-38D or FT-40D additionally.

If the screwdriver port "A" is empty (not used), then external power (24VDC, 1A) is

required.

2) Scout II have 4screwdriver port for direct connecting of KT-38D and FT-40D.

Also one extra screwdriver can be connected through 25P I/O.

3) Cycle can be started by the signal from PLC, sensor or other equipment.

Also Scout gives the cycle complete signal to PLC or other equipment, too through

the 25P I/O port

4) The numeric LED shows the number of screws which should be fastened for acycle.

5) Power Input (24VDC,1A) is required when the Hybrid screwdriver is connected.

Don't connect both KT-38D (or FT-40D) and HDC controller together to Scout II.

6) Fastening results are displayed by NG or OK for every fastening. In order to use

NG/OK judgment, the different parameter setting can be saved on the program no.

from 1to 8.

7) Parameter setting is also possible on Scout Manager (pc software). It transmit

the settings to Scout II. The settings on programs can be saved in csv format file.

4. Caution

1) The screw counter SCOUT II should be used with KT-38D or FT-40D controller only.

Never use the screw counter with any other tools not specified by the manufacturer.

It can be dangerous by the electrical shock.

2) Be careful of right connecting cable between the screwdriver controller and Scout II.

3) Never use non specified cable by the manufacturer.

4) Don't connect both KT-38D (or FT-40D) and HDC controller together to Scout II.

5) Do not use the screw counter near fire and magnetic environment.

- 6 -

5. Accessaries (Option items )

2M

Connection Cable

RJ-45(8pin)-RJ11(6pin)

Scout -KT-38D(FT-40D)

(7000007)

USB cable[A-B] type 1.8M

(part no. PELZ943)

AC adapter(SMPS) model:PAG024M

24VDC,1A (part no. GCM6913)

RS232 cable /USB_A type

1.8M (part no. PELZ939)

FT-40D

KT-38D

25P I/O cable (M-M) 1.8M

(part no. PELZ944)

PLC

HDC Hybrid

controller

- 7 -

6. Operation

6.1 Mode

By pressing the MODE button, it circulate Work,

Log-in, Parameter and Measuring mode.

Work means operating.

Before parameter mode, password is required.

Every settings is possible in Parameter mode.

Once logged in, it circulate Work, Parameter

and Measuring mode, until the power is off

and on again. Fastening time is monitored on Measuring mode. Minimum and

Maximum measured time can be saved on the selected program #.

Factory setting password :"0"

Measuring Parameter

Work

(Log-in)

1WORK 【READY 】

<0000000 > 0000mS

[PARAMETER ]

PLEASE ENTER

[07] CNT NUMBER 7

[05]

[07] CNT NUMBER 7

[05]

RESET

RESET

MODE

MODE

[PASSWORD ]

[ 0000 ]

[PASSWORD ]

[LOGIN ]

Password

MODE

log in

untill re-boot

[MEASURING] [00]

[0000ms] [0000ms]

[MEASURING] [00]

[0000] [AVG:0000]

[MEASURING] [02]

[PROGRAM NO: 5]

RESET

MODE

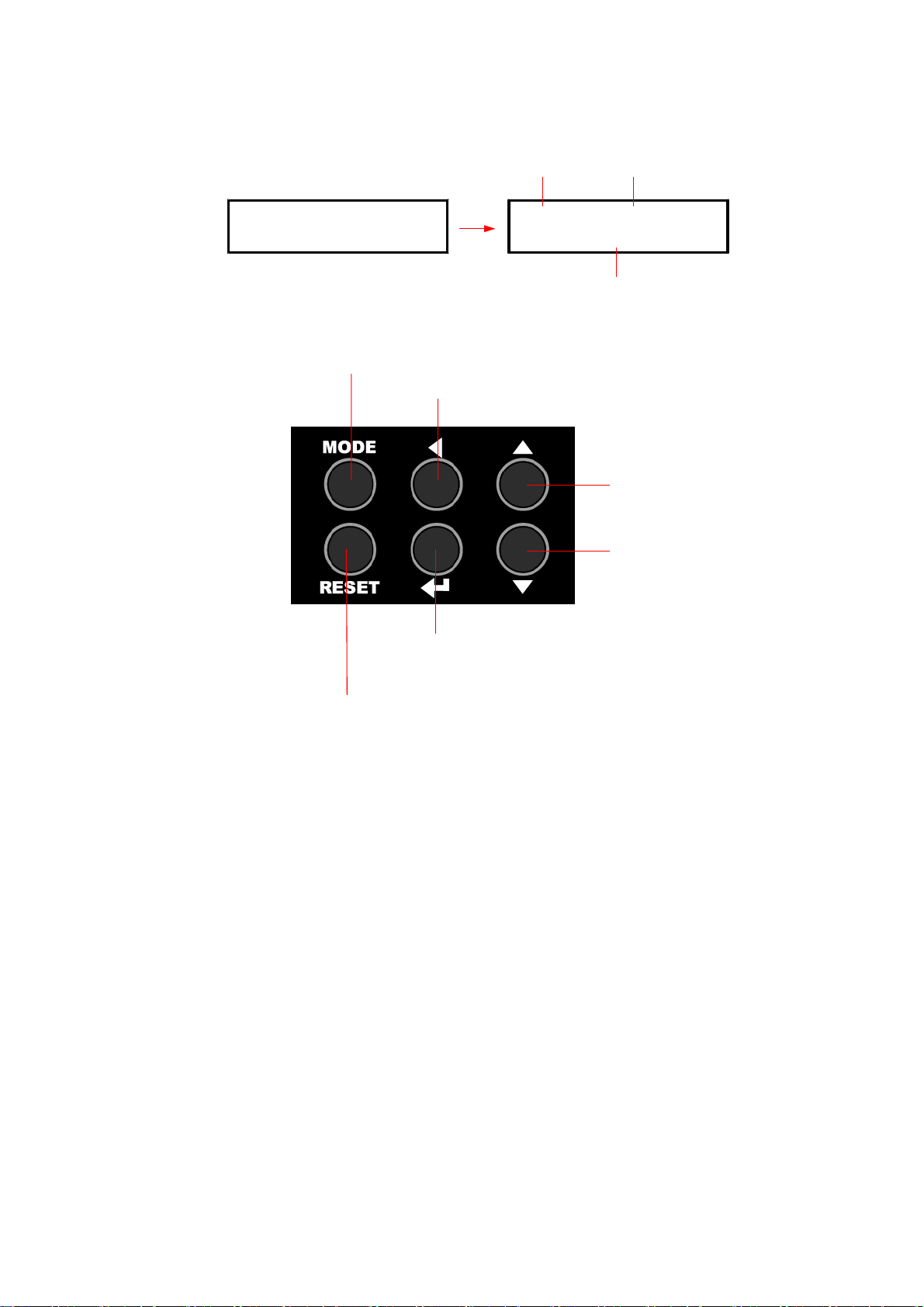

MODE ▲

▼

- 8 -

6.2 Work mode

6.3 Log-in mode

1WORK 【READY 】

<0000000 > 0000mS

Program #1to 8

Judgement (READY /OK /NG )

Total fastened screw number

Fastenting time

Mode

Program #UP (1 to 8)

Program #DOWN

Error and Cycle RESET

Move to next MODE when only cycle reset

Number UP (0 to 9)

Number DOWN

Log-in enter

Move the cursor left

1. Move back to work MODE without password login

2. Move to next Parameter MODE after password login

[PASSWORD ]

[0000] [PASSWORD ]

[LOGIN ]

Factory setting password "0000" can be changed in P33 parameter.

Decrease count number (-1)

- 9 -

6.4 Parameter mode

[PARAMETER ]

PLEASE ENTER [01] CNT NUMBER 1

[05]

Parameter #Description

setting data

Number UP

(Parameter #, data)

Number DOWN

Select Parameter #&Save data

Move the cursor left

Move to next Work MODE on Mode display

Move back without saving data

- 10 -

6.5 Measuring mode

[MEASURING] [00]

[0000ms][0000ms][MEASURING] [02]

[PROGRAM NO: 1]

Total measured data Description

Program #to be linked and

saved with the current

Min/Max data

Number UP

(Parameter #, data)

Number DOWN

1. Move the cursor left

2. Cancel the last data in calculation

Move to next Work MODE on Mode display

[MEASURING] [00]

[0000] [AVG:0000]

Min time Max time

last data Average value

Display

select

▲

▼

▲

▼

Link and save the current data to the

selected Program #

Move back without saving data

- 11 -

6.6 Program #and parameters

The program numbers from 1to 8are effected together with parameter 1~8 for

number of screws, P9~16 for minimum tightening time, P17~24 for maximum

tightening time.

Program #Number of

fastening Min. time Max. time

1P1P9P17

2P2P10 P18

3P3P11 P19

4P4P12 P20

5P5P13 P21

6P6P14 P22

7P7P15 P23

8P8P16 P24

1st data 2nd data 3rd data

- 12 -

6.7 Parameters

P# Name Specification Default

P01-

P08 Program #Save total number of screws on P1-8. 1

P09-

P16 Minimum tightening

time Minimum screw tightening time

Input : 0.000 - 9.999 sec ("0":No use )0

P17-

P24 Maximum tightening

time Maximum screw tightening time

Input : 0.000 - 9.999 sec ("0":No use )0

P25 Type of cycle start

and stop

Select one of 4types of Cycle Start signal

input

0:Auto

1:Start (continuous ON)

2:Start (pulse ON) +Stop (timer on P27)

3:Start (pulse ON) +Stop (pulse ON)

0

P26 Input signal type

Select one of 2signal type

0:Active High ( 0 --> 1 )

1:Active Low ( 1 --> 0 )

※When Active Low is selected, the only

one(1) screwdriver ("A") can be connected.

0

P27 Timer setting for

Cycle start/stop type

2of P25

Input screw tightening time limit after Cycle

start signal

Input :0.0-9.9sec ("0":No use )0

P28 Minimum time to

judgement

Set the minimum time to judgement of

OK/NG

Input :0-99(x0.1s) ("0":No use )0

P29 Com port select Select one of two com ports.

0:USB

1:RS-232C 0

P30 Hybrid HDC connect Select one of two condition

0:Not Connected (not use)

1:Connected (used) 0

- 13 -

P# Name Specification Default

P31 Fastening buzzer

Select one of followings

0:Not use

1:OK only

2:NG only

3:OK +NG

0

P32 Cycle buzzer

Select one of followings

0:Not use

1:OK only

2:NG only

3:OK +NG

0

P33 Reset key control Select Reset key Enable /Disable

0:Disable 1:Enable 0

P34 Program key control Select Program key Enable /Disable

0:Disable 1:Enable 0

P35 Program Select Input

with Binary code

Program Select Input by Binary code with

Pin no. 1~3

0:Disable 1:Enable 0

P36 Monitoring data

output setting

Select Enable /Disable of monitoring data

output through RS-232C port

0:Disable 1:Enable 0

P37 Mid-Count signal

setting

Count complete signal come out after the set

number of Mid-Count signal during the cycle

0:

No use

1~99 : Count number

0

P38 Password

Key in the password in 4numbers.

Initial factory setting password is "0000"

If the password is forgot, click the "PInit "

menu on Scout manager control bar with

password "77", then all parameters

are changed to the factory setting.

Once again, the factory setting password is

"0000"

P39 Parameter initial All parameter are initialized to the factory

setting. Key in "77" on P34 and press

Enter button.

P40 Version information It is not allowed to change. 052

- 14 -

7. Interface

7.1 25P I/O interface details

The configuration of 25P I/O port for remote control is as below

PIN no. Configuration IN /OUT

1External Motor Run signal

INPUT

(to Controller)

2External Torque Up signal

3Cycle Start

4Cycle Stop

5Cycle Reset

6Driver Lock

7Spare 1

8PS1 (Program selecting) PS1(P35 Enable)

9PS2 (Program selecting) PS2(P35 Enable)

10 PS3 (Program selecting) PS3(P35 Enable)

11 PS4 (Program selecting) spare

12 PS5 (Program selecting) spare

13 PS6 (Program selecting) spare

14 PS7 (Program selecting) spare

15 PS8 (Program selecting) spare

16 Cycle complete OK

OUTPUT

(from controller)

24VDC, 50mA

max

17 Cycle complete NG

18 Tightening OK

19 Tightening NG

20 Mid-count complete signal

21 Driver Lock

22 Spare 2

23 No use

24 Input COM

25 Output COM

1

13

1425

- 15 -

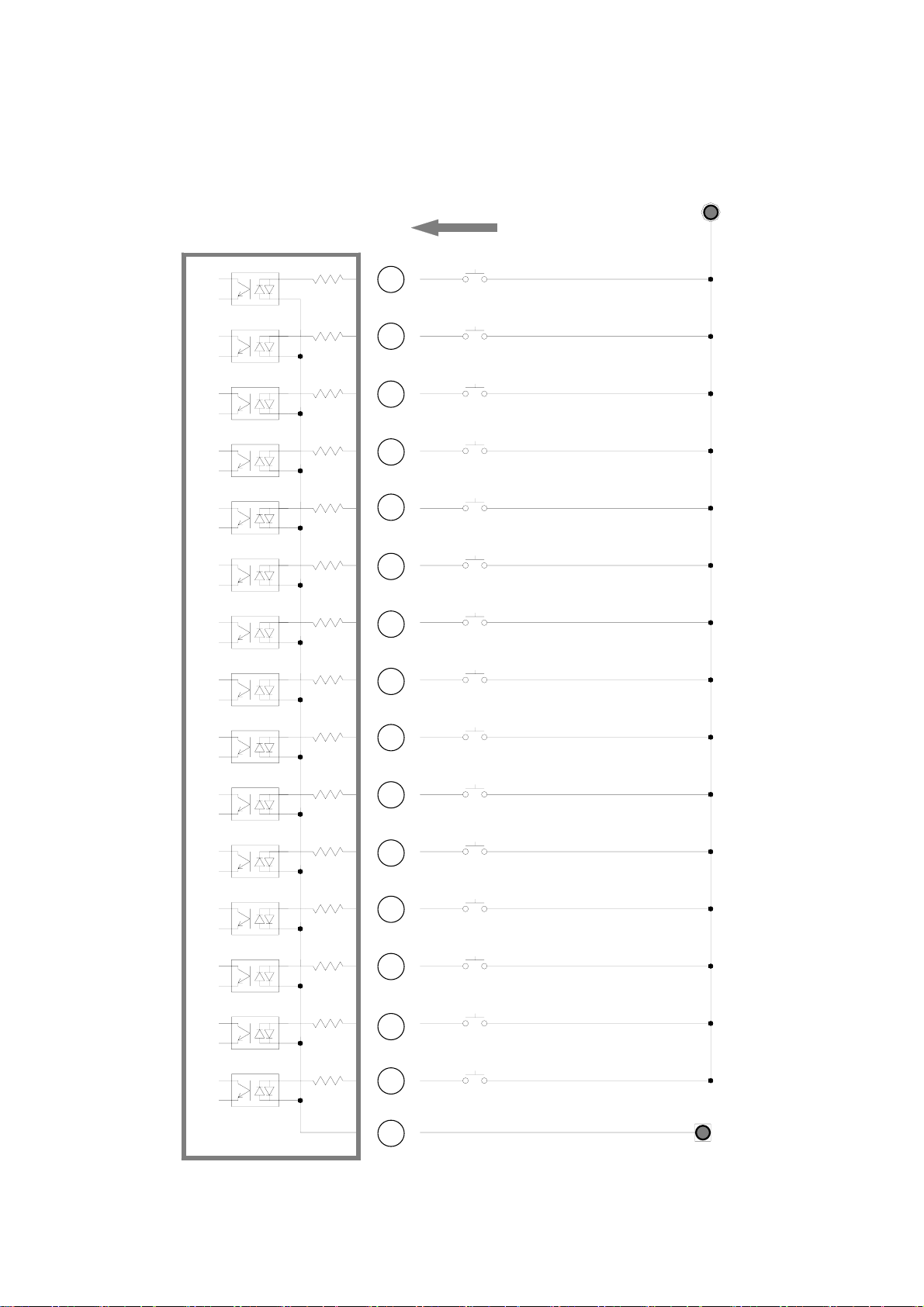

7.2 INPUT (Negative(-) Common wiring)

7

6

5

4

3

2

1

SCOUT II

External power (24VDC+)

Input COM

8

9

10

11

12

13

14

15

24

Cycle Start

Spare 1

PS1

PS2

PS3

PS4

PS5

PS6

PS7

PS8

Cycle Stop

Cycle reset

External torque up

External motor RUN

Driver Lock

Return 24V(-)

- 16 -

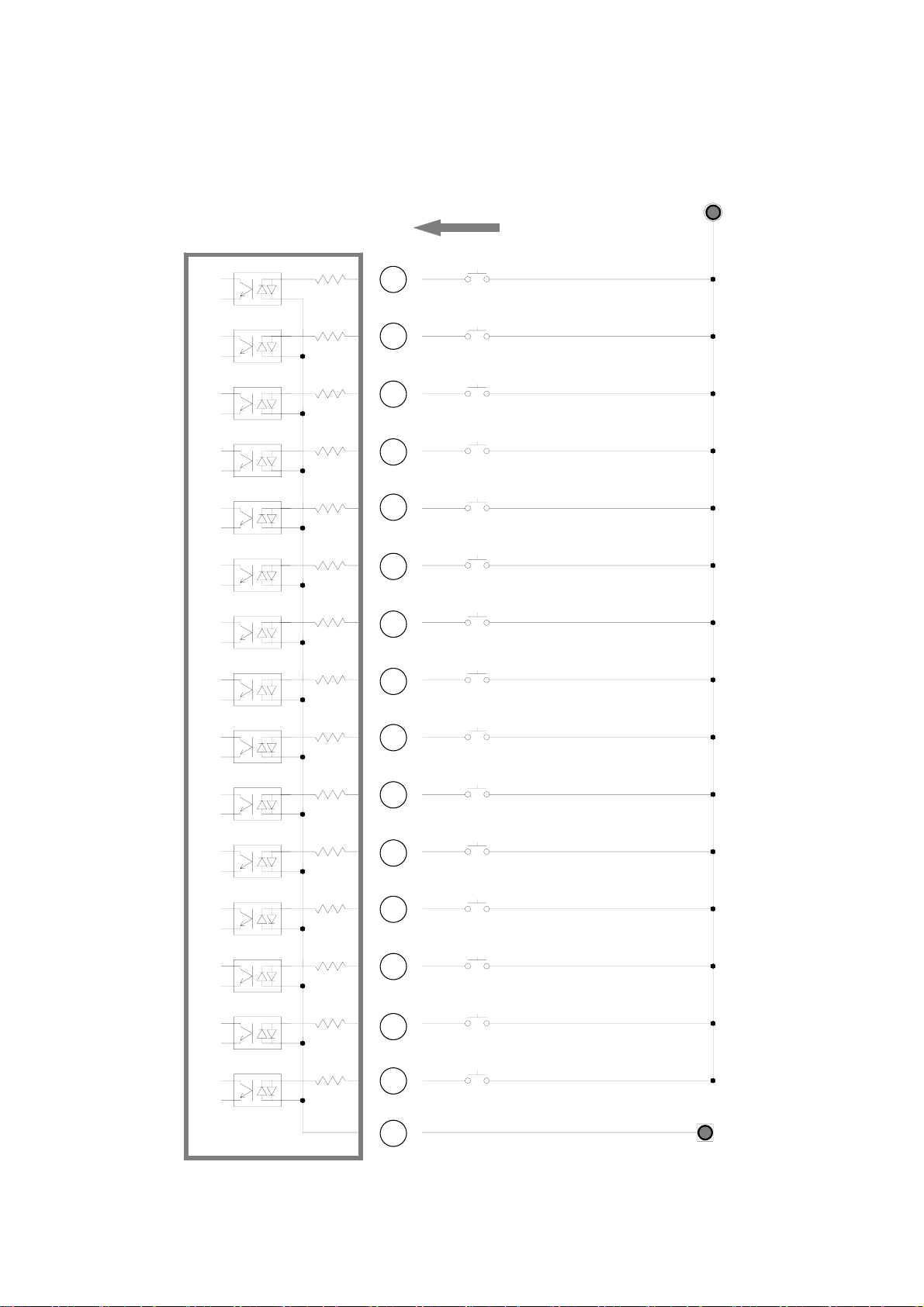

7.4 INPUT (Positive(+) Common wiring)

7

6

5

4

3

2

1

SCOUT II

External power (24VDC+)

Input COM

8

9

10

11

12

13

14

15

24

Return 24V(-)

Cycle Start

Spare 1

PS1

PS2

PS3

PS4

PS5

PS6

PS7

PS8

Cycle Stop

Cycle reset

External torque up

External motor RUN

Driver Lock

- 17 -

7.4 OUTPUT (Negative(-) Common wiring)

Cycle complete OK

Mid-count complete

No use

Driver Lock

24VDC, 100mA max

21

22

23

16

Return(24V-)

External power (24V+)

Output COM

SCOUT II

25

Tightening OK

Spare 2

17

18

19

20

Cycle complete NG

Tightening NG

- 18 -

7.5 OUTPUT (Positive(+) Common wiring)

Cycle complete OK

Mid-count complete

No use

Driver Lock

24VDC, 100mA max

21

22

23

16

Return(24V-)

External power (24VDC+)

Output COM

SCOUT II

25

Tightening OK

Spare 2

17

18

19

20

Cycle complete NG

Tightening NG

- 19 -

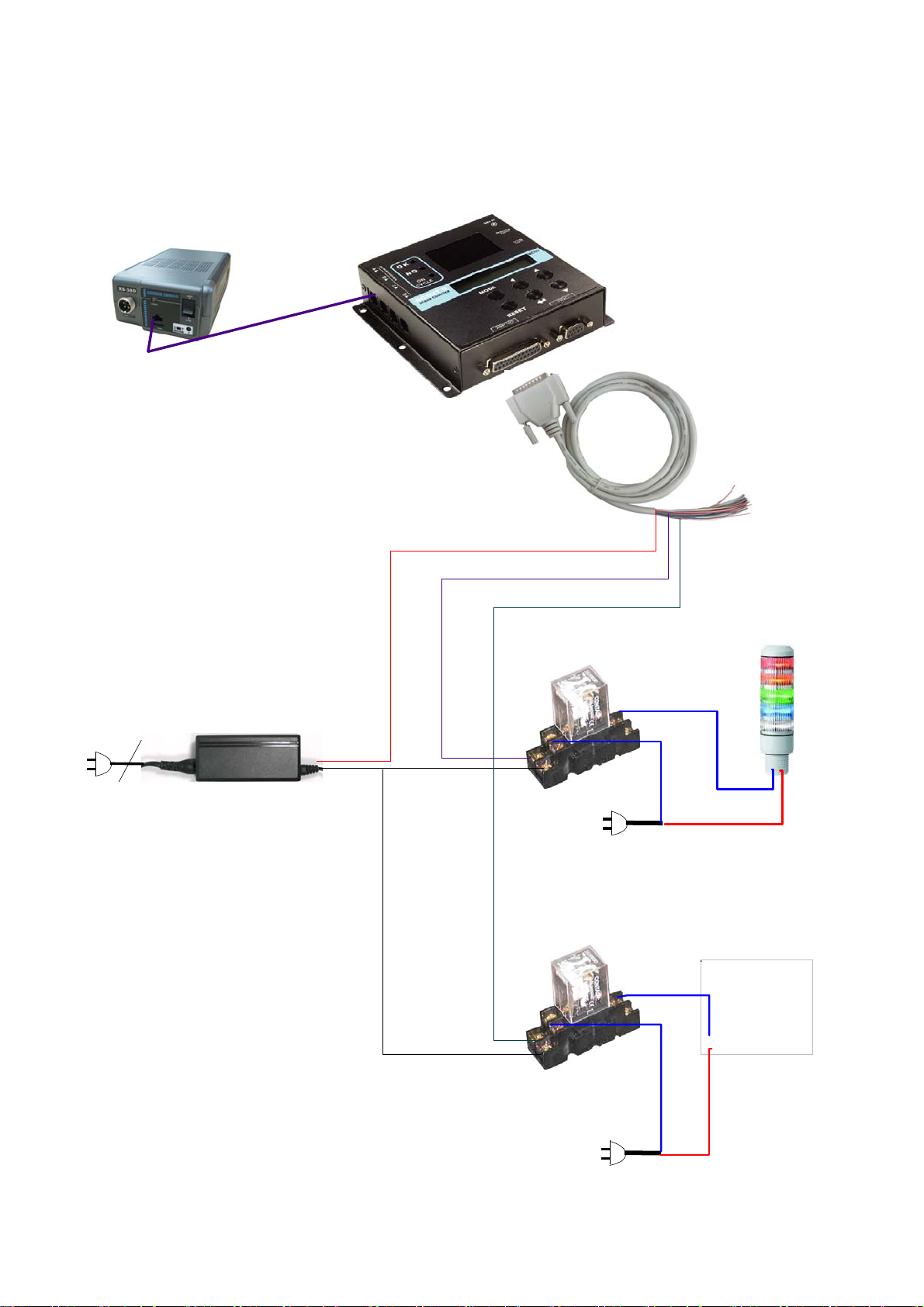

7.6 Wiring example #1 - Tower lamp, solenoid valve, sensors, switch

D:₩sehan1₩해외업체₩DOGA₩Position controller₩sol valve.jpg

AC220V

Solenoid valve

AC220V

Tower lamp

NG

DC12~24V Adapter

Pin 25 Output com

+Positive

-Negative

Pin 17 Cycle complete NG

Pin 16 Cycle complete OK

DC12~24V Relay

DC12~24V Relay

COM

N.O

COM

N.O

Table of contents