ZD340_07d_e.doc / Apr-17 Page 3 / 50

Table of Contents

1. Available Models................................................................................................................4

2. Introduction.........................................................................................................................6

3. Electrical Connections.........................................................................................................7

3.1. Power Supply ...................................................................................................................9

3.2. Auxiliary Outputs for Encoder Supply..............................................................................9

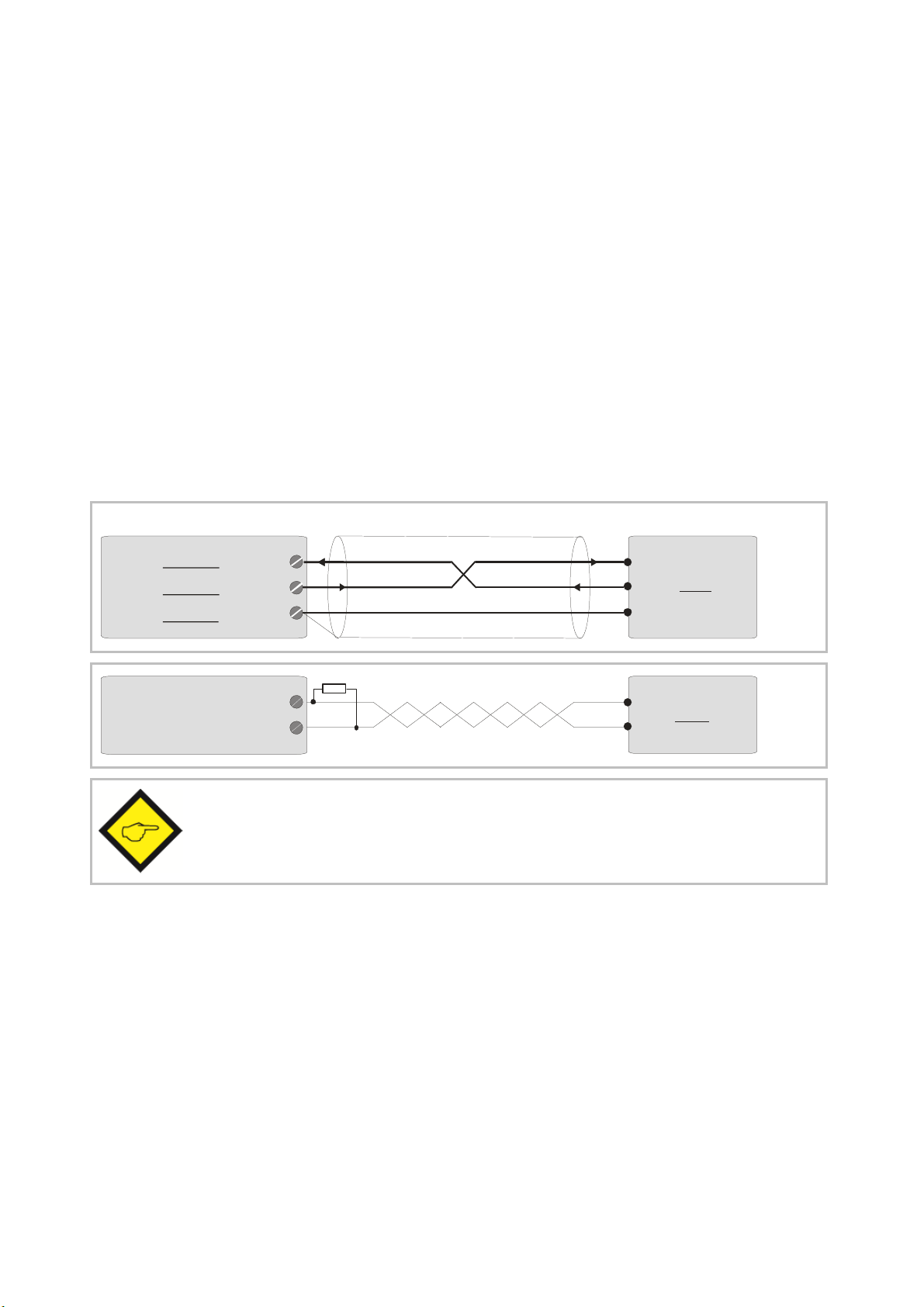

3.3. Impulse Inputs for Incremental Encoders ........................................................................9

3.4. Control Inputs Cont.1 – Cont.4 ........................................................................................9

3.5. Switching Outputs K1 – K4............................................................................................10

3.6. Serial Interface ..............................................................................................................10

3.7. Fast Analogue Output ....................................................................................................10

4. Operating Modes of the Counter.......................................................................................11

4.1. “Single Mode” (Encoder 1 only): F07.062 = 0 ...............................................................12

4.2. “Sum Mode” (Encoder 1 + Encoder 2): F07.062 = 1 ......................................................13

4.3. Differential Mode (Encoder 1 – Encoder 2): F07.062 = 2 ..............................................14

4.4. Master Counter and Integrated Batch Counter: F07.062 = 3 ........................................15

4.5. Evaluation of the Real Cutting Length: F07.062 = 4......................................................16

4.6. Diameter Calculation with Winding Rolls: F07.062 = 5 ................................................17

4.7. Radius Calculation with Winding Rolls: F07.062 = 6 ....................................................18

4.8. Cut-to-Length Control Counter: F07.062 = 7 or 8 ..........................................................19

4.9. Monitor for Slip, Torsion, Skew Position, Shaft Fracture: F07.062 = 9.........................21

4.10. Dual Counter, Two Independent Counters for Encoders 1 and 2: F07.062 = 10 ..........22

5. Keypad Operation .............................................................................................................23

5.1. Normal Operation ..........................................................................................................23

5.2. General Setup Procedure...............................................................................................23

5.3. Direct Fast Access to Presets ........................................................................................24

5.4. Change of Parameter Values on the Numeric Level .....................................................25

5.5. Code Protection against Unauthorized Keypad Access ................................................26

5.6. Return from the Programming Levels and Time-Out Function ......................................26

5.7. Reset all Parameters to Factory Default Values ...........................................................26

6. Menu Structure and Description of Parameters ................................................................27

6.1. Summary of the Menu ...................................................................................................27

6.2. Description of the Parameters.......................................................................................30

6.3. Clarification of the Counter Setting Functions..............................................................39

7. Appendix for models ZD 6xx and ZA 6xx ...........................................................................40

7.1. Relay Outputs.................................................................................................................40

7.2. Front Thumbwheel Switches .........................................................................................40

7.3. Specific Parameters for Units with Thumbwheel Switches .........................................41

8. Appendix: Serial Communication Details ..........................................................................43

8.1. Setup of the Counter by PC............................................................................................43

8.2. Automatic and Cyclic Data Transmission......................................................................44

8.3. Communication Protocol................................................................................................44

8.4. Serial Register Codes ....................................................................................................46

9. Specifications ...................................................................................................................48

10. Dimensions.......................................................................................................................49