Page 4 | ENG

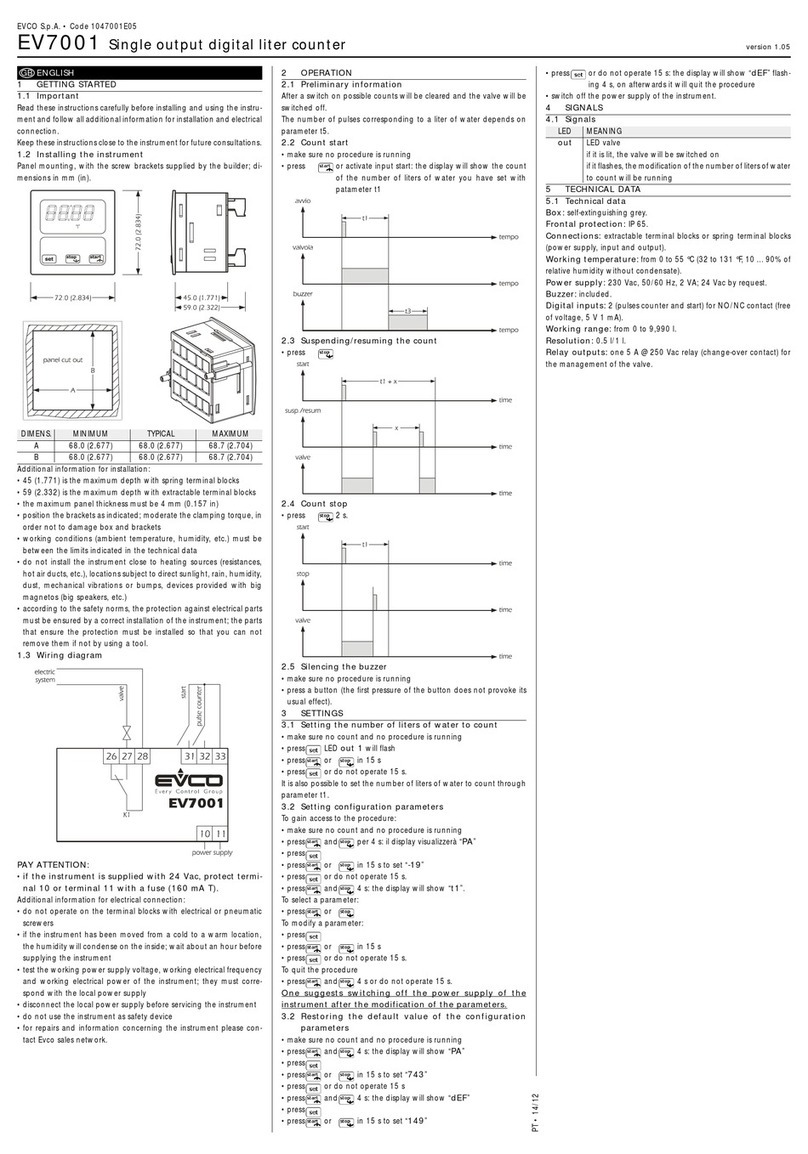

2.2 Counting input (Start input) terminal 5

Input damped to 25 Hz for pulse counting with

the pulse preset counter or static start input with

the time preset counter (time counting active

when input is active, time indicator located on

top left flashes when time counting is active).

Note: The reset input (terminal 6) and the coun-

ting input (terminal 5) are inputs with a common

connection (terminal 7) and must be controlled

wit the same polarity.

2.3 Key lock input

Tre front keys (including the set key) are locked

when this input (terminal 2) is set to +3 VDC

(terminal 1).

3. Output

Relay with potential-free contact, contact pro-

grammable as normally open or normally closed

(terminal 3 and terminal 4). For the adding count,

the relay is activated when > preset value, for

the subtracting count, it is activated when < 0.

The output signal is programmable as a fugitive

signal between 0.1 and 99.9 seconds or as a

bistable signal with the setting 0.0 (Loop OFF) no

automatic repetition. When the relay is active, a

colon symbol is displayed on the left end of the

lower row. The output relay shall not exceed a

switching frequency of 4 Hz.

4. Setting the operating mode and the

operating parameters

4.1 New installation

In case of a new installation of the counter, after

a battery replacement that lasted more than 20

seconds, or if the counter switched over to the

„NoFunc“ safety mode because of a too low

battery voltage, the preset counter switches

automatically to the programming mode. All

parameters must then be input again (see 4.2).

Parameter modification is also possible during

operation. For safety reasons, to access the

programming mode, the reset key and the keys

of the 5th and 6th decades must be pressed

simultaneously. The lower display line then dis-

plays the message INIT. If these 3 keys remain

pressed, a countdown from 5 to 0 takes place

in one-second intervals. If the keys are released

during this countdown, the device switches back

to the previous operating mode. If the keys are

released after 0 is reached, parameter setting is

activated and the first parameter is displayed.

4.2 Setting the parameters

The key of the 1st decade allows switching

among the available parameters (e.g. add-sub)

and the key of the 6th decade allows switching

over to the following function. The duration of the

fugitive pulse is set using the keys of decades

1-3. After the last input (dP), the key of the 6th

decade allows jumping back to the start of the

programming routine; pressing simultaneously

the reset key and the keys of the 5th and 6th

decades allows saving the parameters.

Note: Every time the programming routine is

called up, the counter switches back to the

basic parameter setting, i. e. the previous pro-

gramming is lost and the counter and preset

values are reset to zero.

4.3 Parameters description

(see also the function sequence)

Funct.Count: Pulse preset counter operating

mode

Funct.Time: Time preset counter operating

mode

tMode: Programmable time range (only

for Funct.Time), SEC=seconds,

Min=minutes, hour=hours

Count Add: Adding counting mode

Count Sub: Subtracting counting mode

LooP off: Automatic repetition off

When parameter LooP is „off“ and

dELAY time is 0.0, the output is

activated when the preset value

is reached and remains activated

until reset is performed.

LooP on: Automatic repetition on

When parameter „LooP is „on“, the

counter is reset automatically and

the output emits a fugitive pulse

for the time of the duration set in

dELAY.

rELAY no: Normally open contact

rELAY nc: Normally closed contact

dELAY: Output signal duration: fugitive

signal programmable from 0.01