2020 Heli-Pump Operations Manual (Version F)

We Engineer Solutions

Table of Contents

Section 1: Heli-Pump Overview 1

Introduction ...................................................................................................................1

Description of Pump Systems ........................................................................1

Features and Options .....................................................................................1

Available Models ............................................................................................ 1

Model Specifications .....................................................................................................2

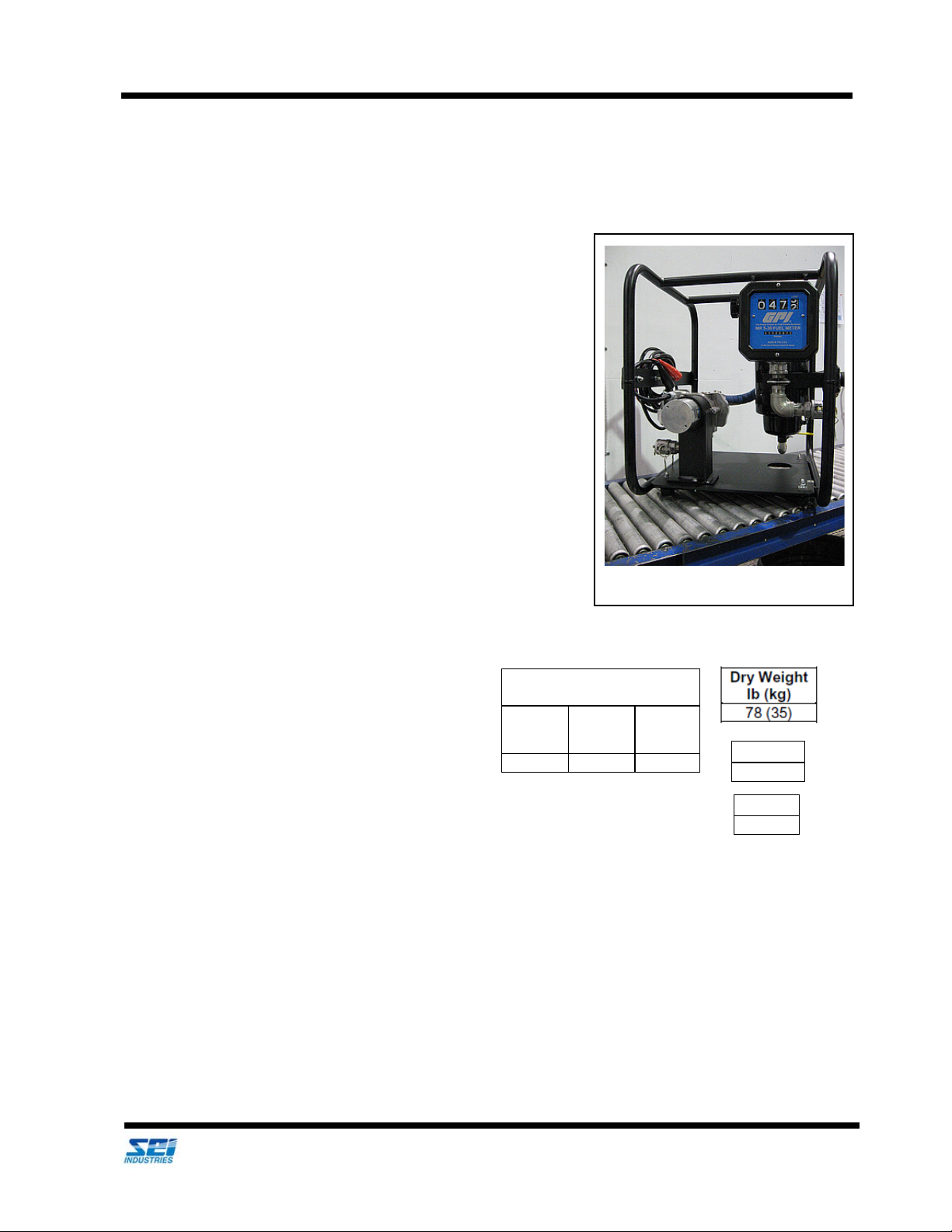

Model Slimline Pump, Part # 003530 .............................................................2

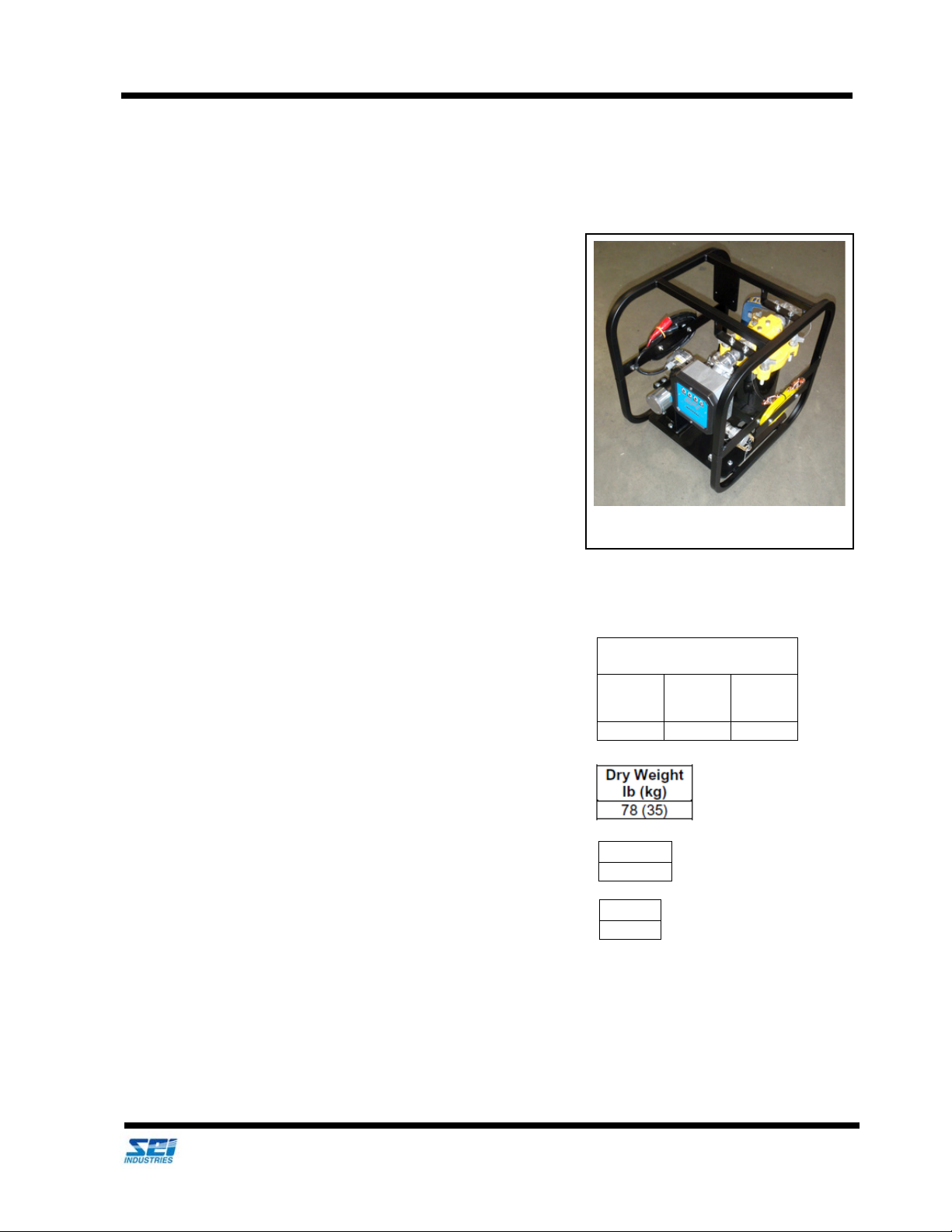

Model PSHR 1210 Heli-Pump, Part # 003595 ...............................................3

Model PSHR 2410 Heli-Pump, Part # 003594 ...............................................4

Model PSHR 2420 Heli-Pump, Part # 003687 ...............................................5

Model PSHR 2420-2 Heli-Pump, Part # 009923 ............................................6

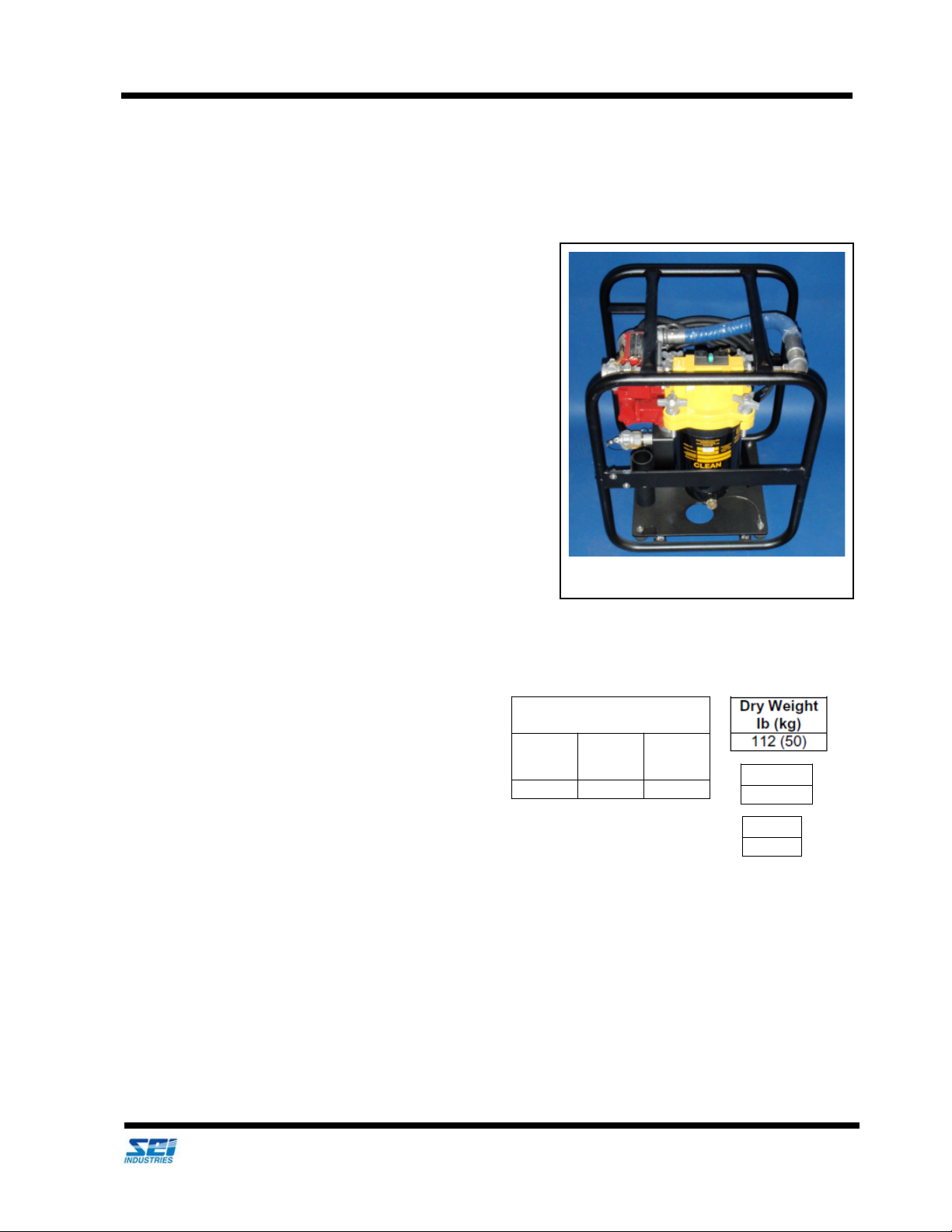

Model PSHR 23020 Heli-Pump AC, Part # 003687A .....................................7

Model PSHR 11020 Heli-Pump AC, Part # 003687B .....................................8

Model PSD 688 Maritime Pump, Part # 006647 .............................................9

Section 2: Pump Safety 10

Safety Procedures ......................................................................................................10

Installation .................................................................................................... 10

Operation ......................................................................................................10

Service ..........................................................................................................11

Section 3: Pump Operations 12

12/24 VDC and 110/230 VAC Operations ..................................................................12

Dispensing Fuel ............................................................................................13

Filter Instructions ........................................................................................................13

Filter Safety Precautions ..............................................................................14

Models Slimline, PSHR 2410 and 1210 Pumps .........................................................15

Priming .........................................................................................................15

Motor Protector .............................................................................................16

Pump Maintenance .......................................................................................16

Models PSHR 2420, 2420-2, 11020 and 23020 Pumps .............................................18

Model PSD 688 Pump ................................................................................................19

PSD 688 Maintenance ..................................................................................19

Priming All Pump Systems .........................................................................................21

Section 4: Fuel Meters 22

Operations and Maintenance .....................................................................................22

Meter Accuracy .............................................................................................22

Daily Operations ...........................................................................................22

Maintenance .................................................................................................23