Version No. 1-5 - 09.11.2022 Doc. No. 9984120001-BZBG 4 / 28

3. Safety instructions

Upon delivery the unit is already meeting current technical standards and can therefore be safely taken into

operation. Only authorised personnel is allowed to work on the unit. Unauthorised personnel must be prohibited

from working on the unit. Operating personnel must inform their superiors immediately of any malfunction of

the unit.

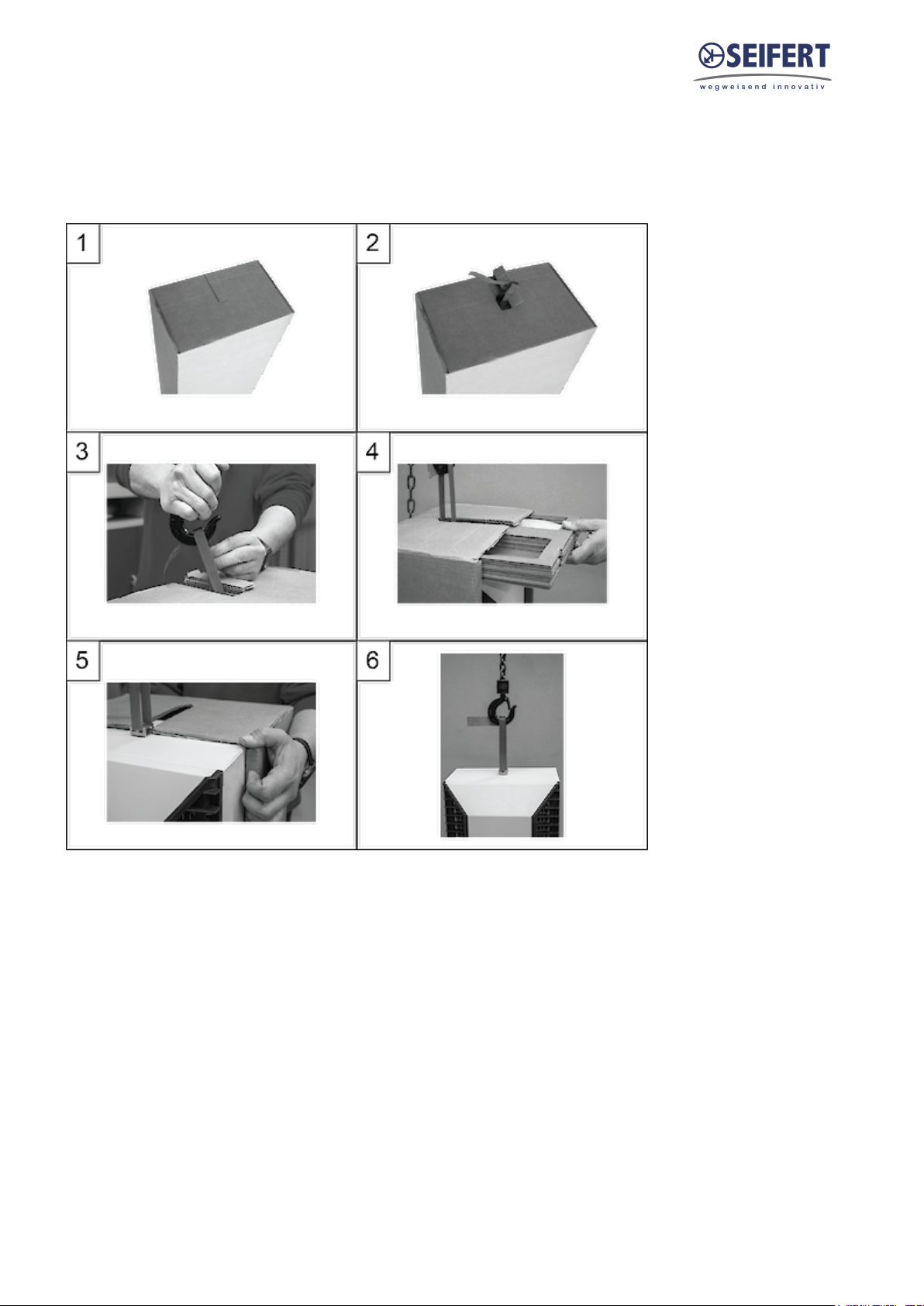

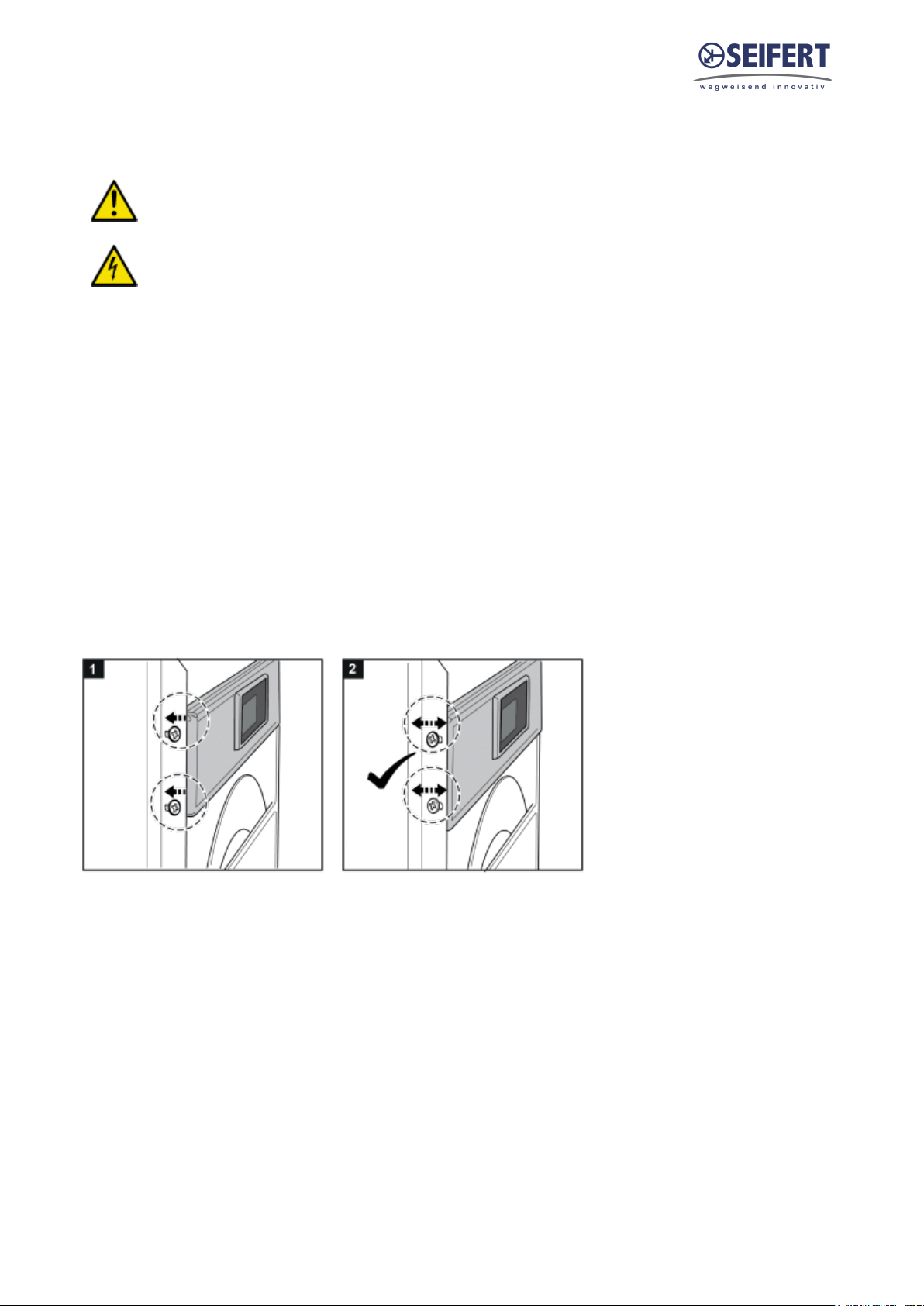

Please note that before starting to work on or with the unit, a procedure must be carried out inside the cabinet

on which the unit is to be mounted.

Before commencing work inside the cabinet, the control cabinet manufacturer's instruction must be read with

regards to:

Safety instructions.

Instructions on taking the cabinet out of operation.

Instructions on the prevention of unauthorised cabinet reconnection.

The electric equipment meets the valid safety regulations. One can find dangerous voltages (above 50 V AC or

above 100 V DC)

Behind the control cabinet doors.

On the power supply in the unit housing.

The unit has to be operated according to the type plate and the wiring diagram, and must be protected

externally from overloading and electrical faults via suitable protective devices.

Danger through incorrect work on the unit

The unit can only be installed and maintained by technical competent and qualified

personnel, using only supplied material according to the supplied instructions.

Danger from electrical voltage

Only specialised personnel are allowed to maintain and clean the unit. The personnel must

ensure that for the duration of the maintenance and cleaning, the unit is disconnected from

the electrical supply.

Attention

Damage to the unit through the use of inappropriate cleaning materials. Please do not use

aggressive cleaning material.

Instruction

Damage to the environment through unauthorised disposal. All spare parts and associated

material must be disposed according to the environmental laws.