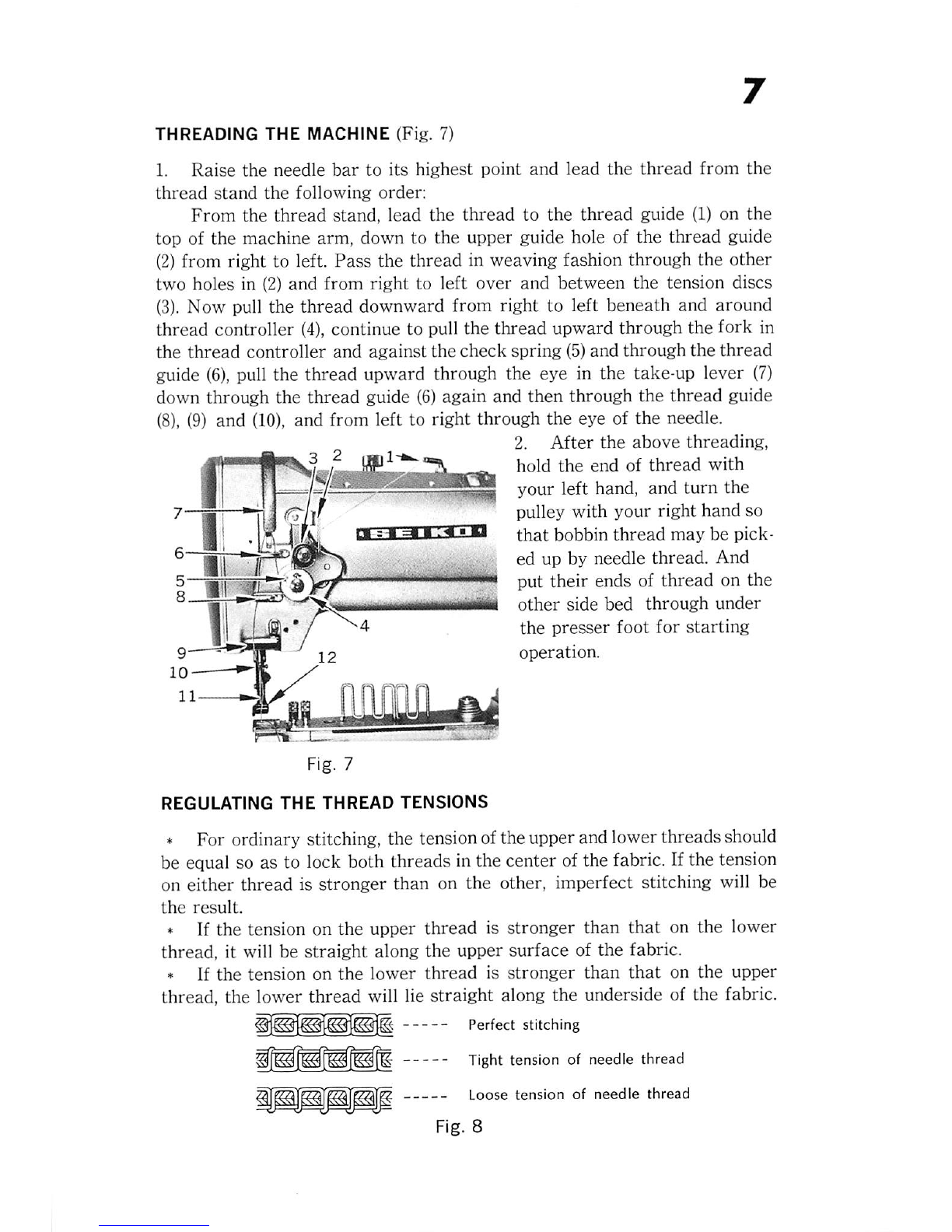

THREADING

THE

MACHINE (Fig. 7)

1. Raise the needle

bar

to

its

highest point

and

lead

the

thread

from

the

thread

stand

the

following

order:

From

the

thread

stand,

lead

the

thread

to

the

thread

guide (1) on

the

top of the machine arm, down to the upper guide hole of the thread guide

(2)

from right to left.

Pass

the

thread

in weaving fashion through the

other

two

holes in (2)

and

from

right

to

left

over

and

between

the

tension discs

(3).

Now pull the thread downward from right to left beneath and around

thread

controller

(4),

continue to pull the thread upward through the fork in

the

thread

controller

and

against

the

check

spring

(5)and

through

the

thread

guide

(6),

pull the thread upward through the eye in the take-up lever

(7)

down through the

thread

guide

(6)

again and then through the

thread

guide

(8),

(9) and

(10),

and from left to right through the eye of the needle.

2.

After

the

above

threading,

hold

the

end

of

thread

with

I t

your

left

hand,

and

turn

the

7—4—^1

pulley

with

your

right

hand

so

• '

.0

-1%

El

=•

=1

i ^

that

bobbin

thread

may

be

pick-

® ed up by

needle

thread.

And

put their ends of

thread

on the

®rii

i--

ifri'i

other

side

bed

through

under

1

iJ-JB**/

^

the

presser

foot

for

starting

9—12

operation.

DETQcrmii

Fig. 7

REGULATING

THE

THREAD

TENSIONS

* For ordinary stitching, the tension ofthe upper and lower threadsshould

be equal so as to lock both threads in the center of the fabric. If the tension

on either

thread

is stronger

than

on

the

other, imperfect stitching will be

the

result.

* If the tension on the upper

thread

is stronger

than

that

on the lower

thread, it will be

straight

along the upper surface of

the

fabric.

* If

the

tension

on

the

lower

thread

is

stronger

than

that

on

the

upper

thread, the lower

thread

will lie

straight

along the underside of

the

fabric.

Perfect

stitching

Tight tension of needle thread

Loose

tension

of

needle

thread

Fig. 8