Contents

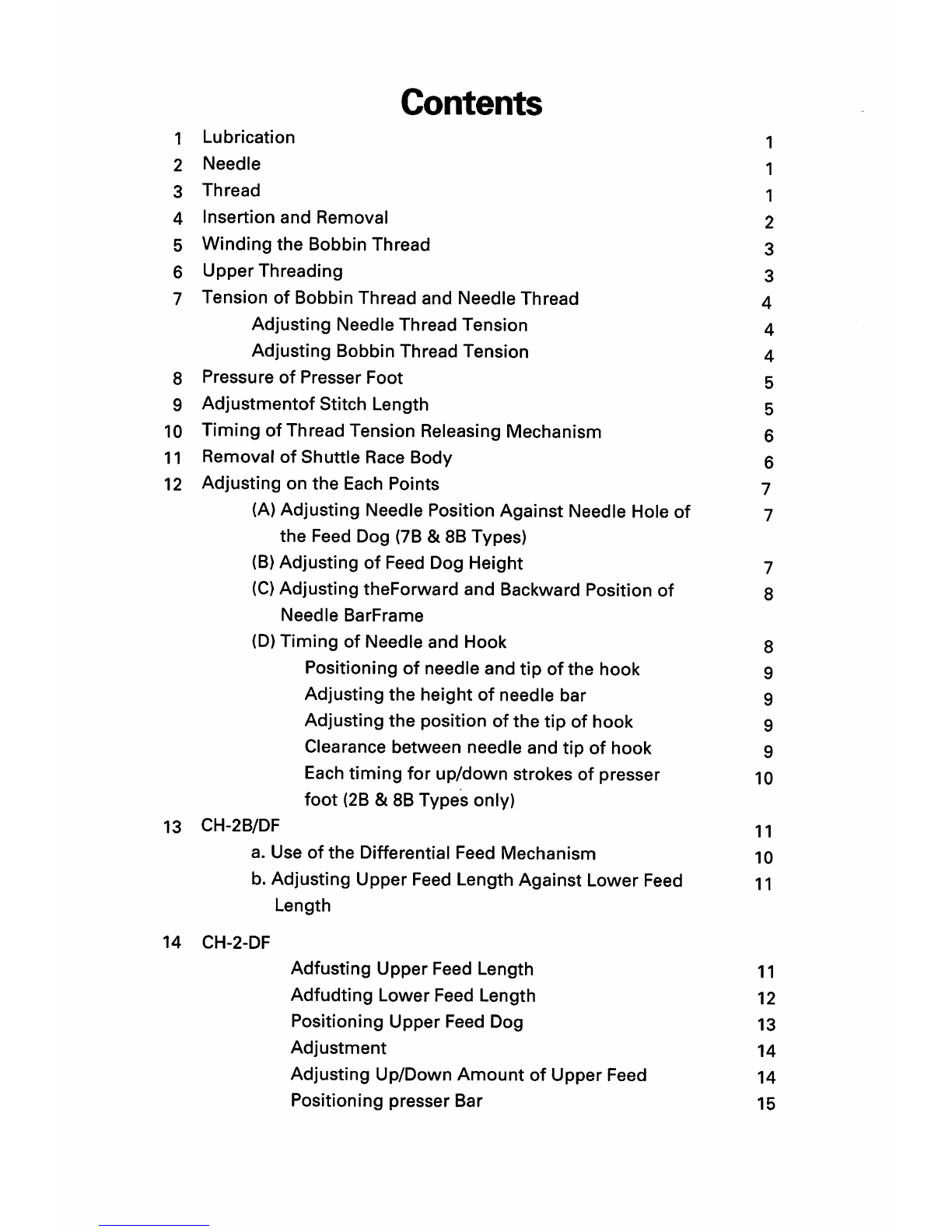

1Lubrication 1

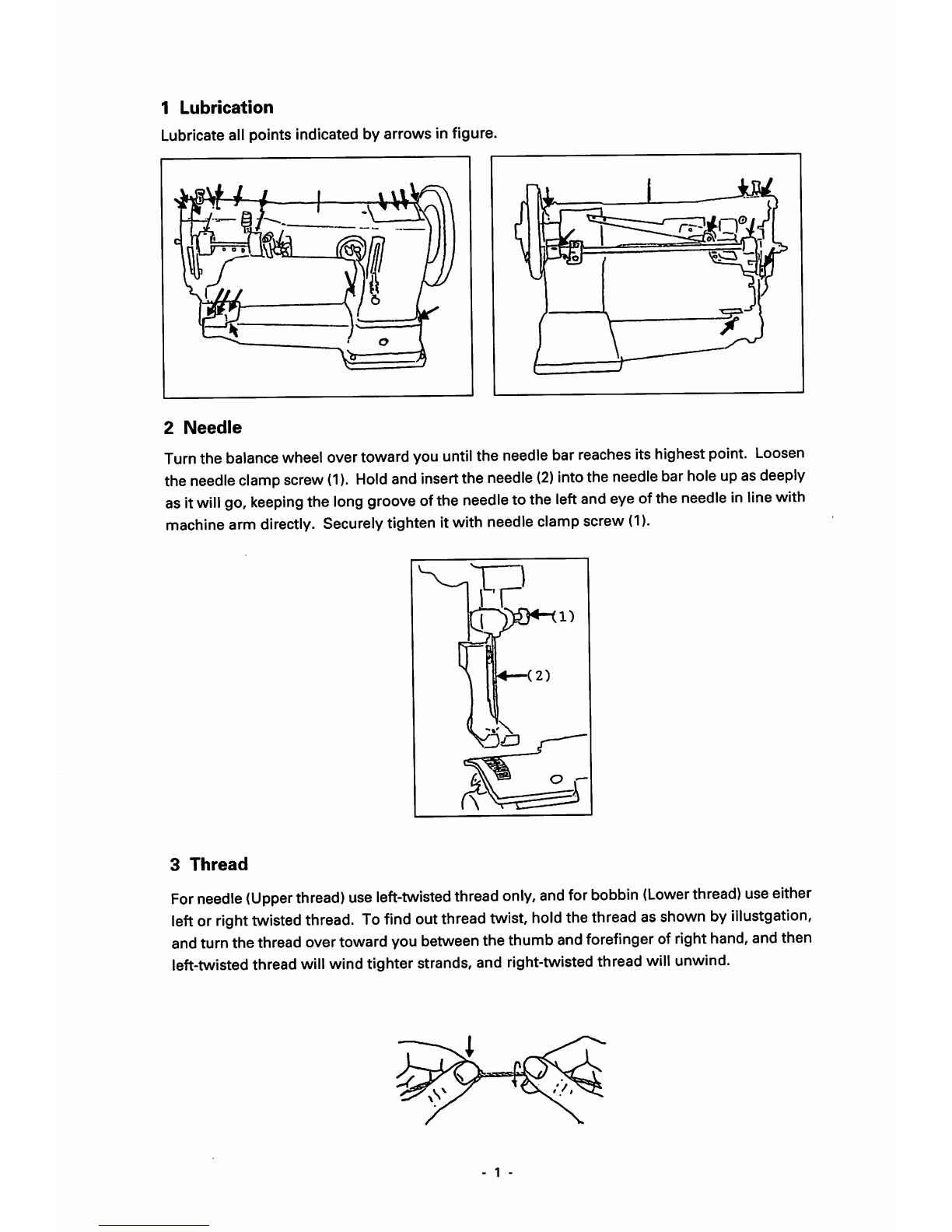

2Needle 1

3Thread 1

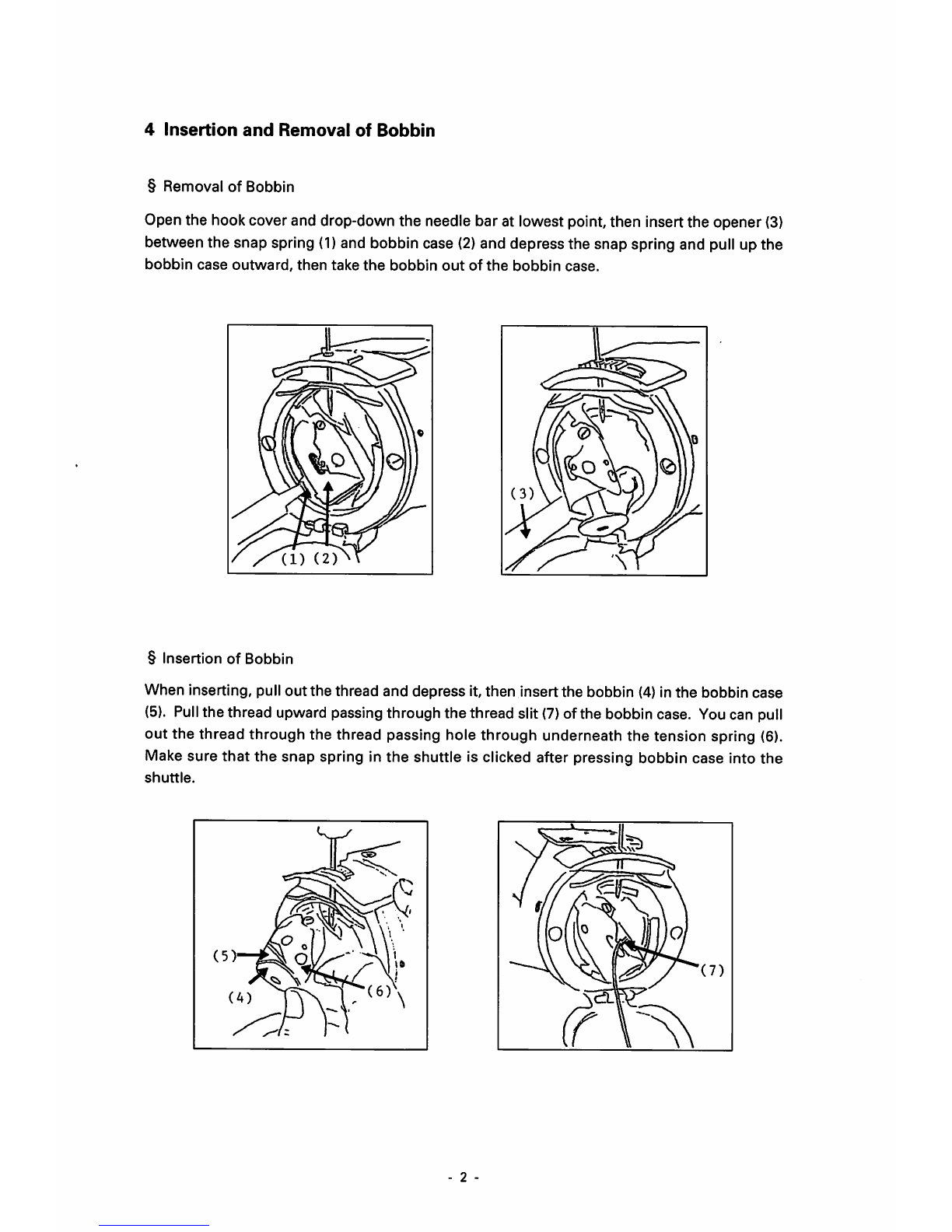

4Insertion

and

Removal 2

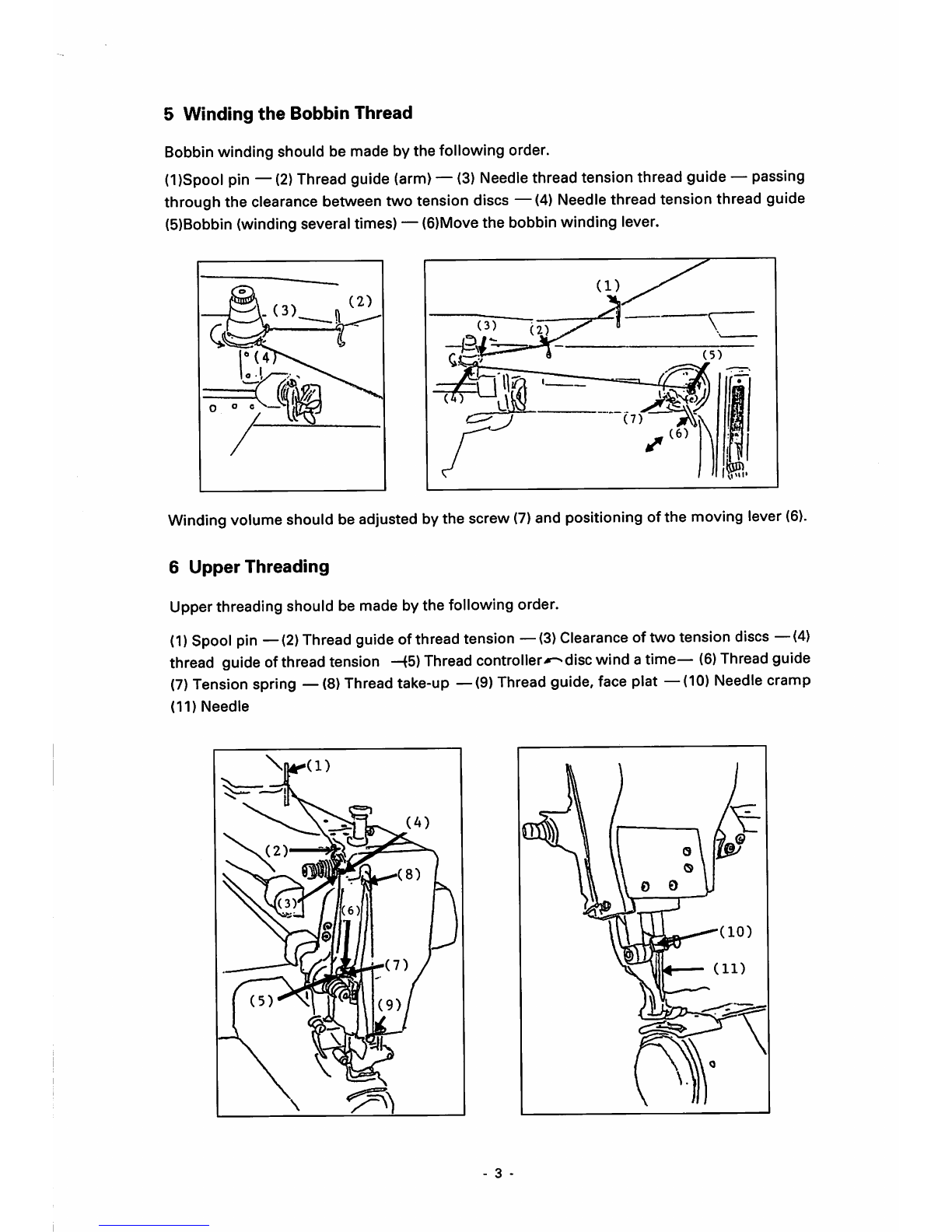

5 Winding the Bobbin Thread 3

6Upper Threading 3

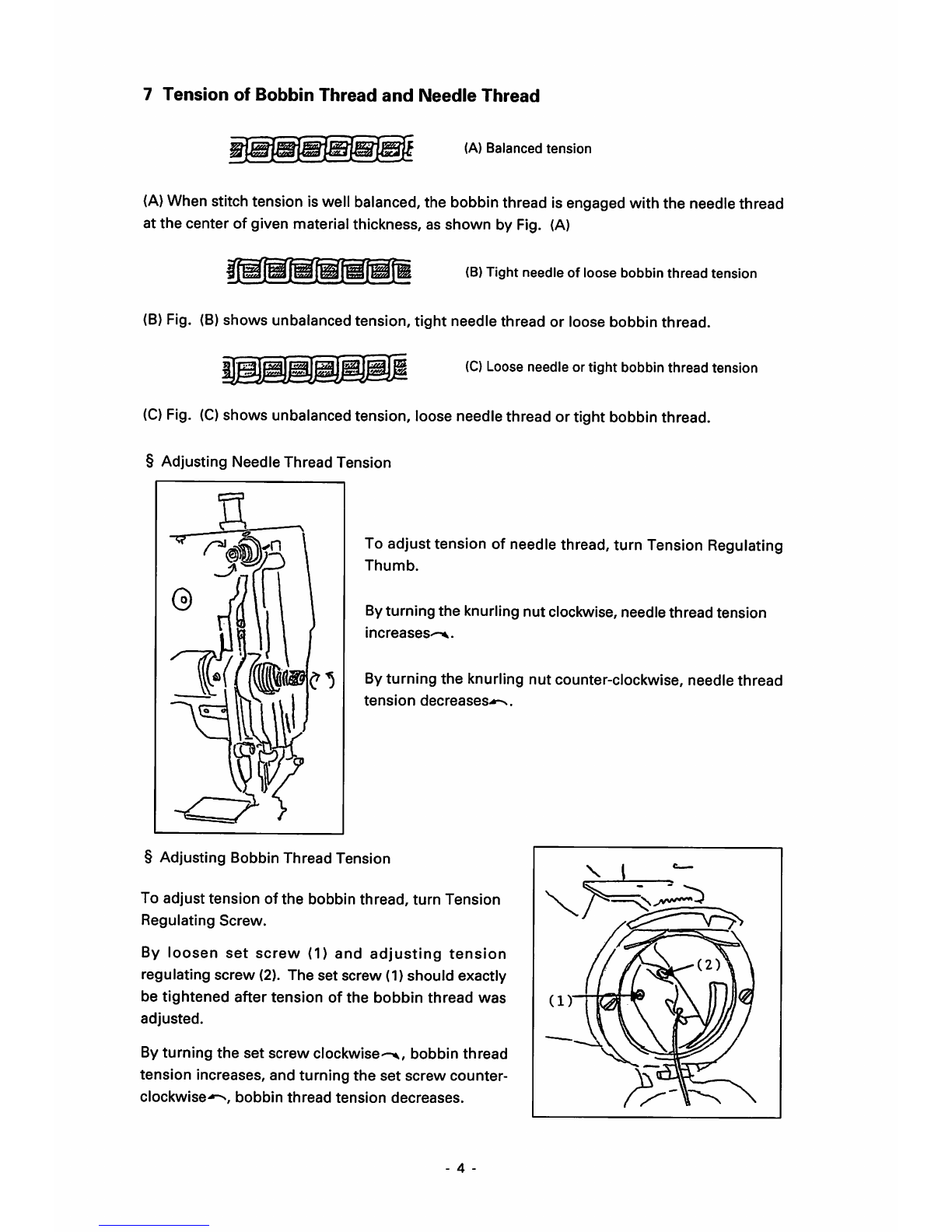

7Tension of Bobbin Thread and Needle Thread 4

Adjusting Needle Thread Tension 4

Adjusting Bobbin Thread Tension 4

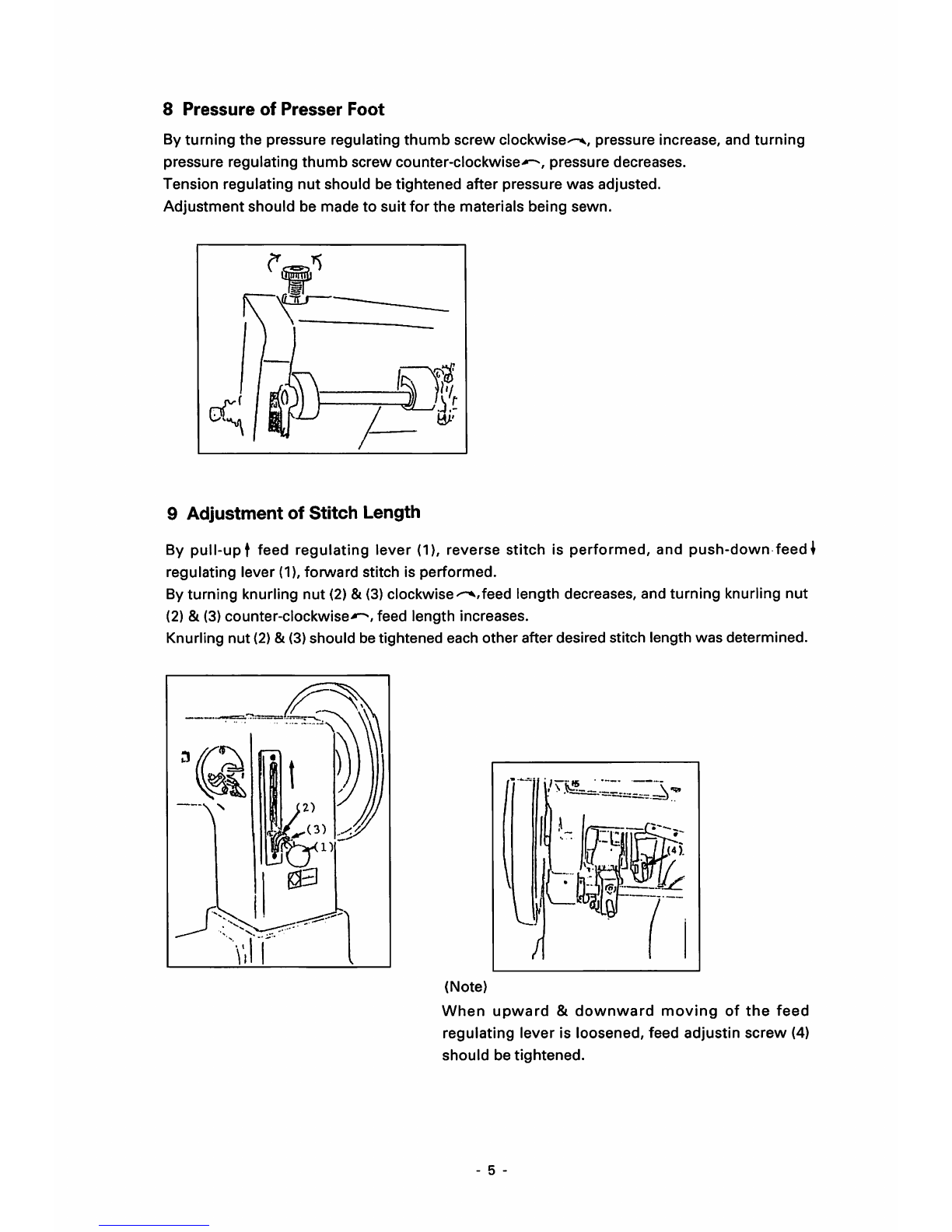

8Pressure of Presser Foot 5

9Adjustmentof Stitch Length 5

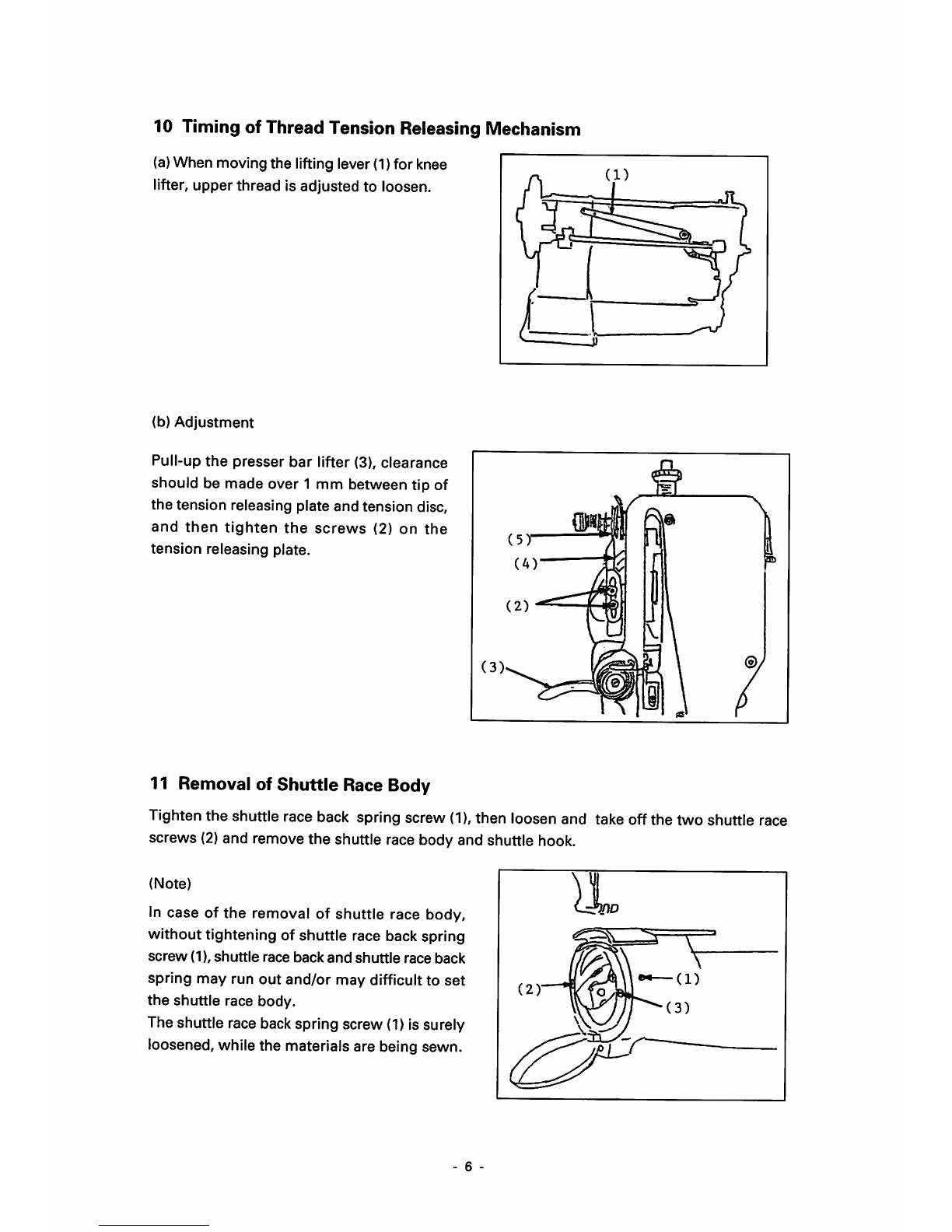

10 Timing of Thread Tension Releasing Mechanism 6

11

Removal of Shuttle Race Body 6

12 Adjusting on

the

Each Points 7

(A)

Adjusting Needle Position Against Needle Hole of 7

the

Feed

Dog

{7B & 8B

Types)

(B)

Adjusting of Feed Dog Height 7

(C)

Adjusting theForward and Backward Position of q

Needle

BarFrame

(D)

Timing of Needle and Hook 8

Positioning of

needle

and

tip of

the

hook 9

Adjusting

the

height of needle bar 9

Adjusting

the

position of

the

tip of hook 9

Clearance between needle

and

tip of hook 9

Each timing for up/down strokes of

presser

10

foot

(2B & SB

Types

only)

13

CH-2B/DF

11

a. Use of

the

Differential Feed Mechanism 10

b. Adjusting Upper Feed Length Against Lower Feed 11

Length

14

CH-2-DF

Adfusting

Upper

Feed

Length

11

Adfudting

Lower

Feed

Length 12

Positioning

Upper

Feed

Dog 13

Adjustment

14

Adjusting

Up/Down

Amount

of

Upper

Feed

14

Positioning

presser

Bar

15