After

the

bobbin

is filled

with

thread,

release

will

cause

wheel

to

disengage

from the belt and winding will stop. Cut the thread and remove the bobbin

from

the

spindle.

Adjustment screw (5) can be turned in or out to increase or decrease the

amount

of

thread

wound

on

the

bobbin.

When fine thread is wound on bobbins, use light tension, it is regulated

by turning the knurled nut (6) on the tension bracket at the rear of the

bobbin

winder.

Bobbin can be wound while the machine is sewing.

If the thread does not wind evenly on the bobbin, loosen the screw (4)

in the tension bracket and move the bracket to right or left as may be

required, then tighten the screw.

THREADING

THE

MACHINE

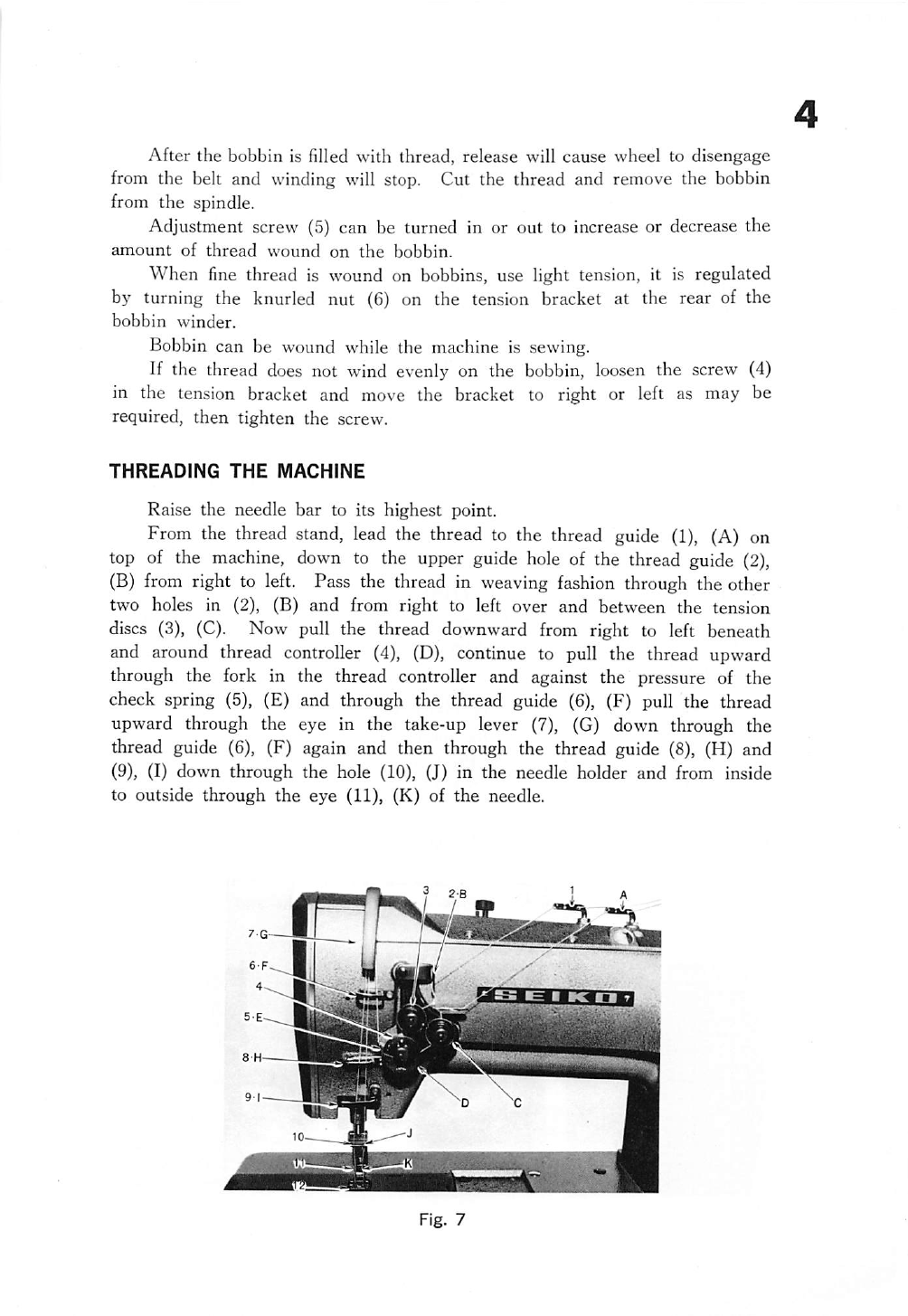

Raise the needle bar to its highest point.

From the thread stand, lead the thread to the thread guide

(1),

(A) on

top of the

machine,

down

to the upper

guide

hole

of the thread

guide

(2),

(B)

from right to left. Pass the thread in weaving

fashion

through the other

two holes in (2), (B) and from right to left over and between the tension

discs (3), (C). Now pull the thread downward from right to left beneath

and around thread controller (4), (D), continue to pull the thread upward

through the fork in the thread controller and against the pressure of the

check spring (5), (E) and through the thread guide (6), (F) pull the thread

upward through the eye in the take-up lever (7), (G) down through the

thread guide (6), (F) again and then through the thread guide (8), (H) and

(9), (I) down through the hole (10), (J) in the needle holder and from inside

to outside through the eye (11), (K) of the needle.

?

28

ltj

Fig.

7

From the library of: Superior Sewing Machine & Supply LLC