– 1 –

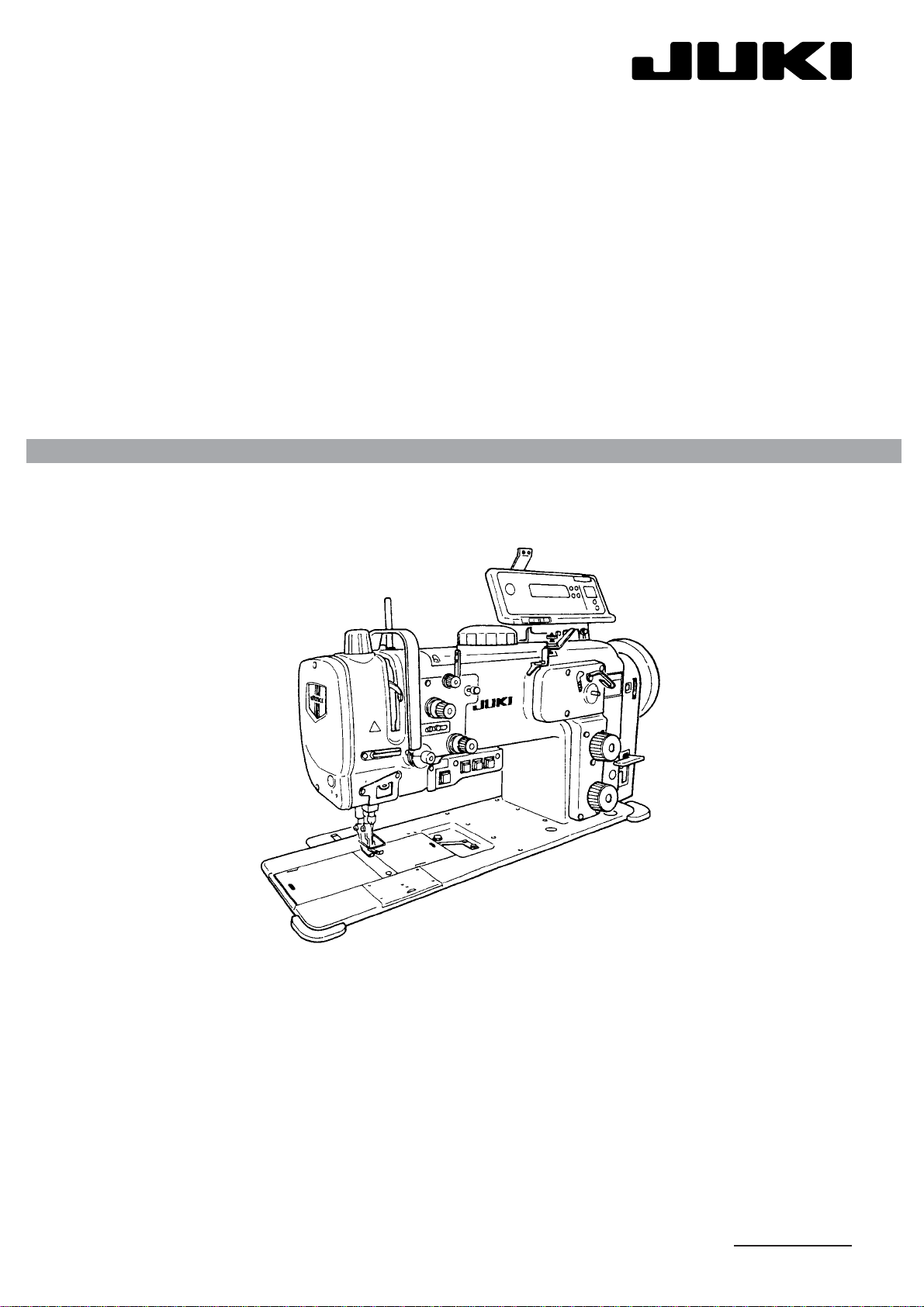

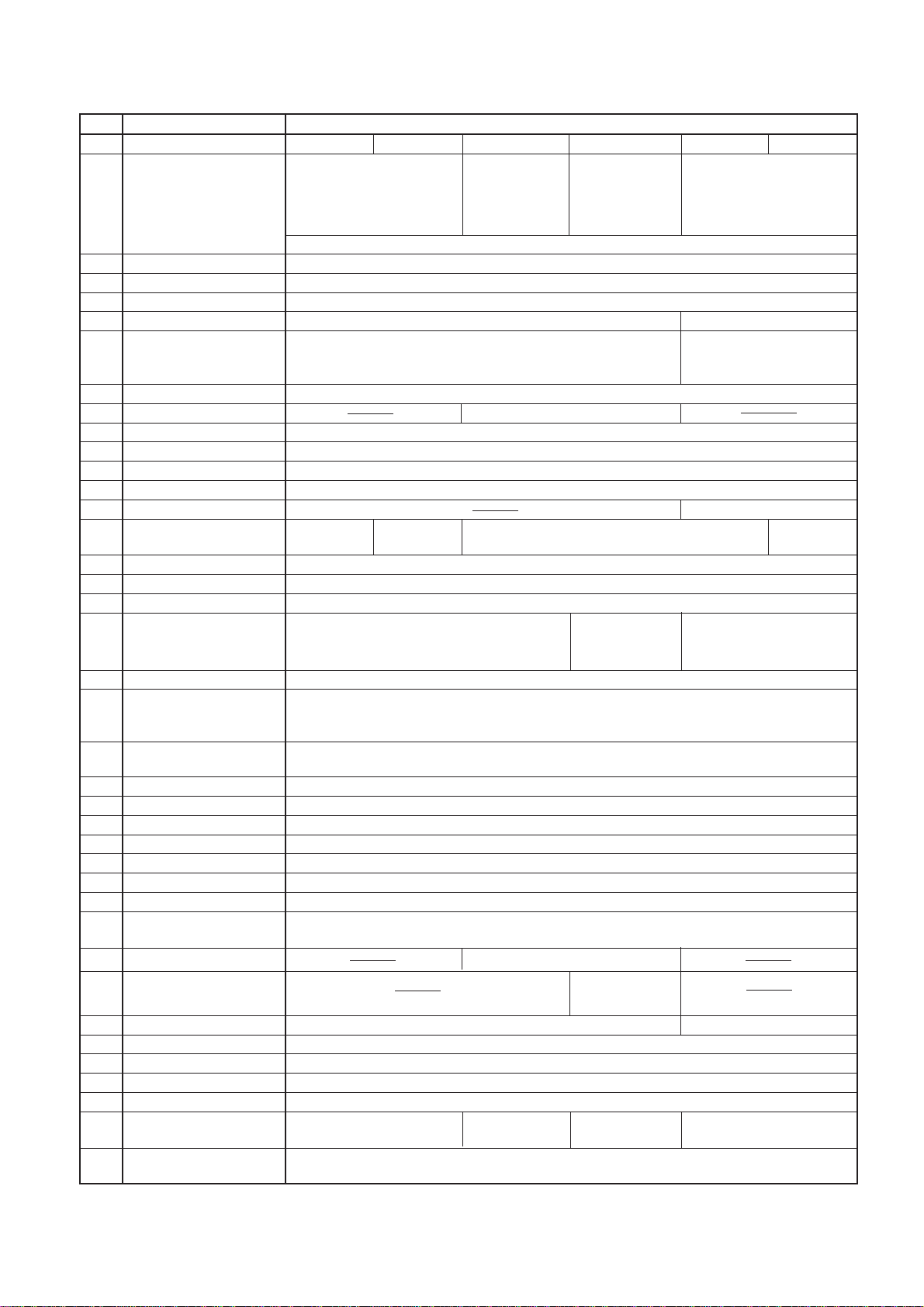

1. Specifications

No. Item Specification

1Model LU-2210N-7 LU-2210W-7 LU-2212N-7 LU-2220N-7 LU-2260N-7 LU-2260W-7

2Model name

(Touch-back unit, auto-lifter device, with lifting device)

3Applications For medium-weight materials, car seats and furniture

4Sewing speed Max. 3,500 rpm (Varies according to sewing conditions).

5Needle Schmetz 134 x 35R, Nm 110 to Nm 160 (Standard Nm 140)

6Thread #4 to #30 #5 to #20

Max. 6 mm for both normal

7 Stitch Length Max. 9 mm for both normal feed stitching and reverse feed stitching feed stitching and reverse feed

stitching

8 Presser foot lift Using hand lifter: 9 mm, Using knee lifter: 15.5 mm (equipped with a reversing device)

9

Stitch length regulating method

Using a dial

10

Stitch length regulating method for 2P

Using a dial

11 Reverse feed stitching Externally mounted air pressure cylinder (with a touch-back switch and hand lever)

12 Thread take-up lever Link type

13 Needle bar stroke 33.8mm

14 Needle gauge

15 Hook

1.6-fold horizontal axis hook 2-fold horizontall axis hook 1.6-fold horizontal axis hook 2-fold horizontall axis hook

(Automatic lubrication hook) (Automatic lubrication hook) (Automatic lubrication hook) (Automatic lubrication hook)

16 Opener

Opener shaft eccentric cam speed reduction system (The opener travels by one stroke while the hook rotates twice).

17 Feed mechanism Using an arc block slider

18 Hook driving system Screw gear

19 Thread trimmer

20 Tension release system Using the push solenoid for actuating together with the thread trimmer

Adjustment of the amount of

21

alternating vertical movement of

Using a dial (peripheral cam)

the walking foot and presser foot

22 Using a timing belt

23 Bobbin winder Built in the arm

24 Lubrication system Automatic lubrication system

25 Oil return flow Circulated with the plunger and felts

26 Lubricating oil JUKI New Defrix Oil No. 1 (Equivalent to ISO VG7)

27 Space under the needle 263.5 mm (Distance from the center of the presser bar to the bottom of the arm)

28 Bed size 517mm x 178mm

29 Automatic lifter Externally mounted pneumatic cylinder

30 Lifting device (DL)

31 2P DIAL unit Pneumatic cylinder sheathing system

32 Needle thread clamp device

33 Weight of machine head Approx. 55 kg Approx. 58 kg

34 Transmission belt HM V belt

35 Motor used SC-510 +M51

36 Motor pulley Engraved mark (outer periphery): 90 / Effective diameter: ø 85mm

37

Hand wheel (Effective diameter)

Effective diameter: ø 76.023mm

38 Air pressure/ 0.5MPa 0.5MPa 0.5Mpa 0.5Mpa

Air consumption 0.736dm3/min (ANR)

1.078dm

3

/min (ANR) 1.377dm

3

/min (ANR)

0.736dm3/min (ANR)

39 Single phase 100V / Three-phase 200V / 425VA

1-needle, high-speed, unison

feed lockstitch machine with

vertical-axis large hook and

automatic thread trimmer

(Needle thread clamp device/

2P DIAL)

Pneumatic cylinder with a built-in type speed controller to control the speed corresponding to the amount

of alternating vertical movement of the walking foot and presser foot

1-needle, high-speed, unison

feed lockstitch machine with

vertical-axis large hook and

automatic thread trimmer

1-needle, high-speed, unison

feed lockstitch machine with

vertical-axis large hook and

automatic thread trimmer

(Specially specified for 2P

DIAL)

2-needle, high-speed, unison

feed lockstitch machine with

vertical-axis large hook and

automatic thread trimmer

6mm•8mm•10mm(Standard)•12mm•20mm∗

Rocks around the hook

(peripheral cam and solenoid)

Rocks around the hook

(groove cam and

air cylinder system)

Rocks around the hook

(peripheral cam and solenoid)

Pneumatic cylinder

sheathing system

(with switch)

∗Needle Gauge:

The gauge from 4 mm up to 36 mm (for LU-2260N-7) or from 4 mm up to 30 mm (for LU-2260W-7) is available with special specifications.

Main shaft and hook driv-

ingshaft driving system

Source voltage/

Power consumption