Seiko 4R35A Quick start guide

Other Seiko Watch manuals

Seiko

Seiko Conceptual SNE527P User manual

Seiko

Seiko Spectrum SVRD001 G510 User manual

Seiko

Seiko 8M25 User manual

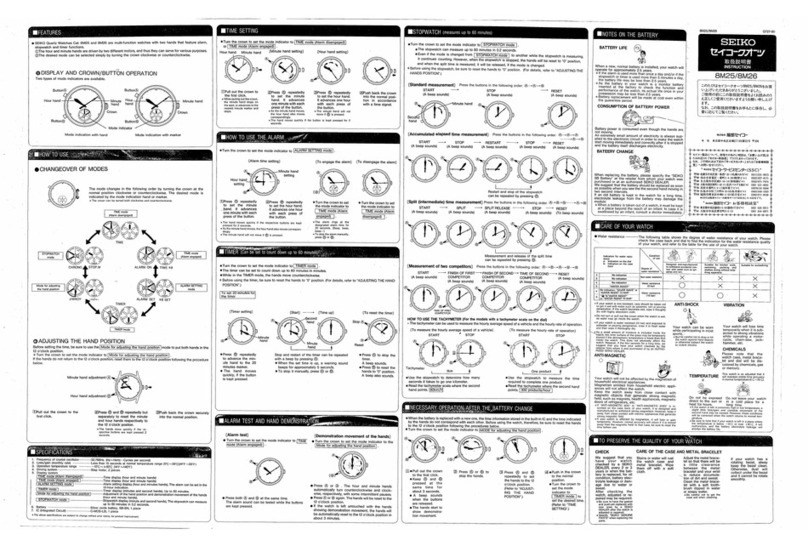

Seiko

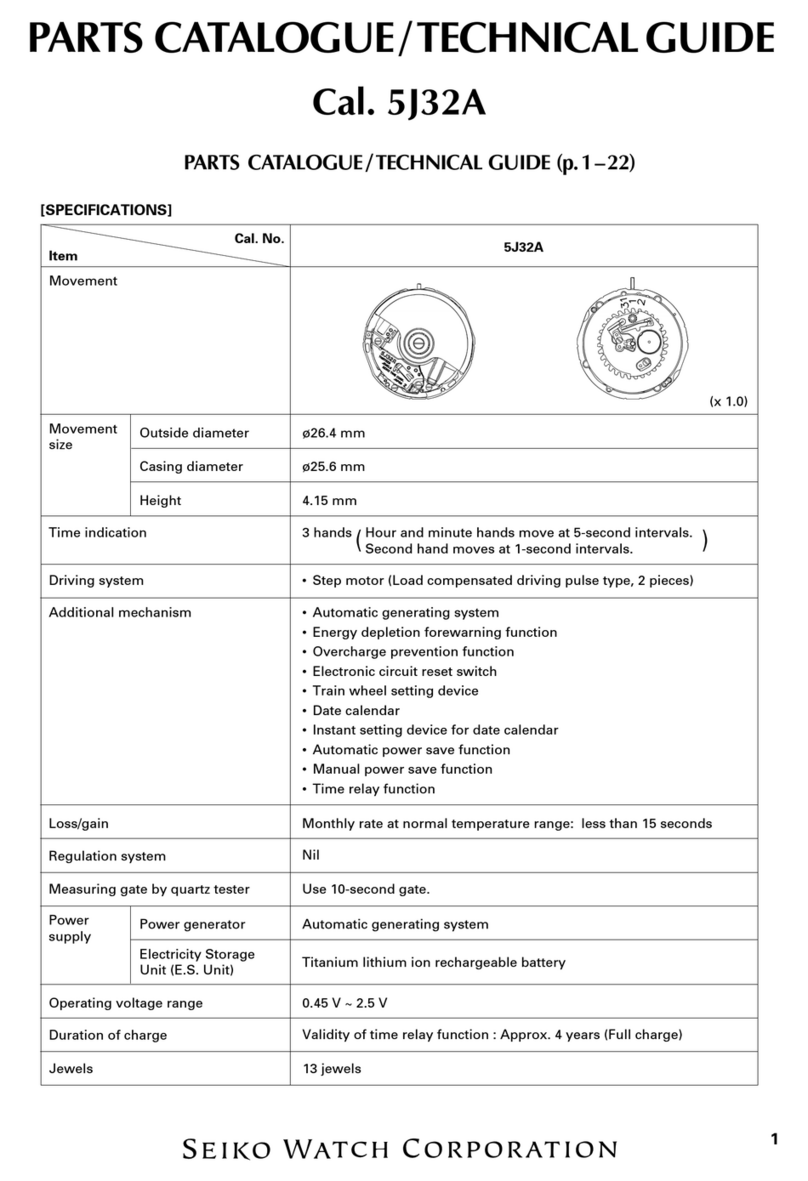

Seiko 5J32A Installer manual

Seiko

Seiko SSJ015J User manual

Seiko

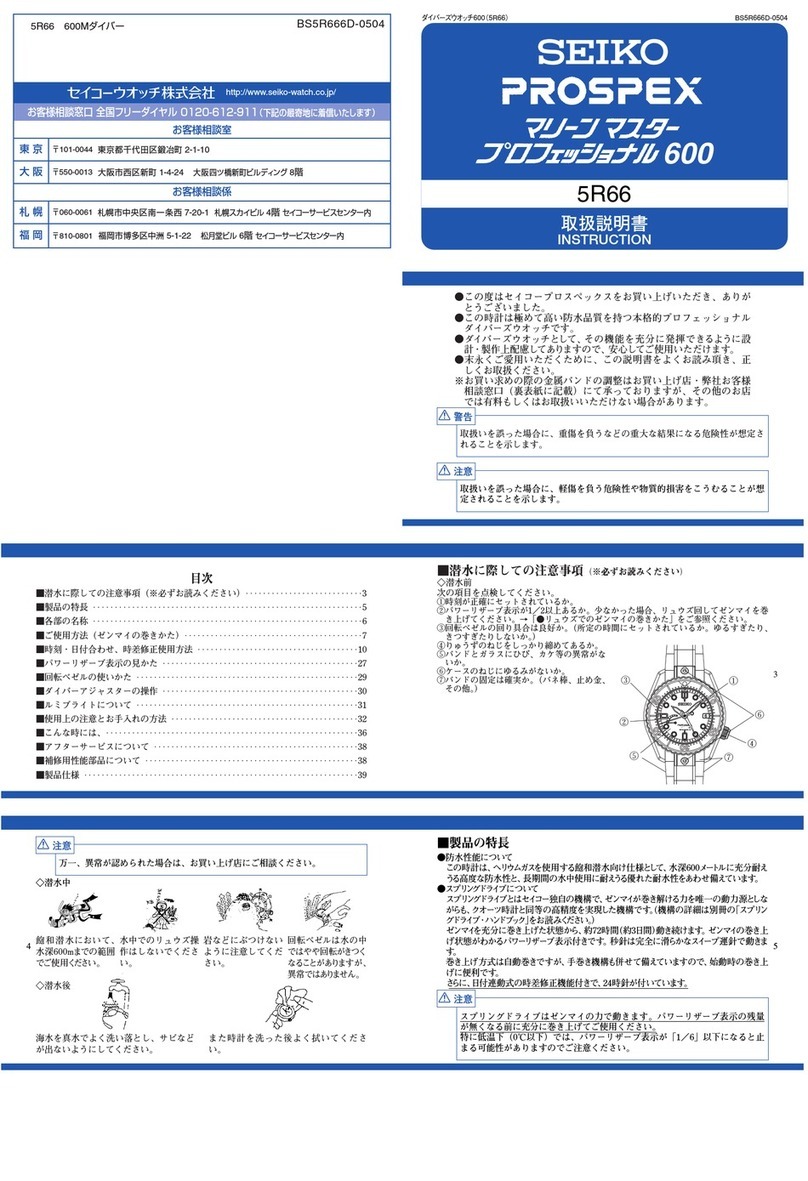

Seiko 5R66 User manual

Seiko

Seiko Conceptual SUR380P User manual

Seiko

Seiko 6R21 User manual

Seiko

Seiko KINETIC AUTO RELAY 5J21 User manual

Seiko

Seiko KINETIC 7D56 User manual

Seiko

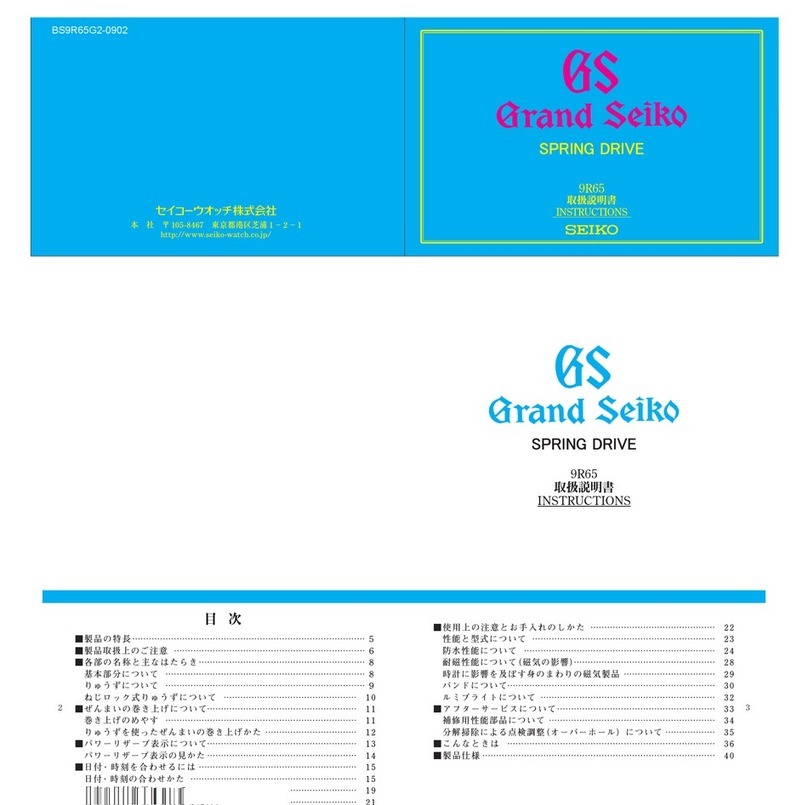

Seiko Grand Seiko SPRING DRIVE DIVERS 9R65 User manual

Seiko

Seiko 8J55 User manual

Seiko

Seiko 6G27A Quick start guide

Seiko

Seiko SRG019P2 User manual

Seiko

Seiko QM-11 User manual

Seiko

Seiko 4F56 User manual

Seiko

Seiko ASTRON GPS SOLAR 3x62 Assembly instructions

Seiko

Seiko 7T82 User manual

Seiko

Seiko Arctura SKA201 User manual

Seiko

Seiko 7002 User manual