Seiko 6N23A User manual

Other Seiko Watch manuals

Seiko

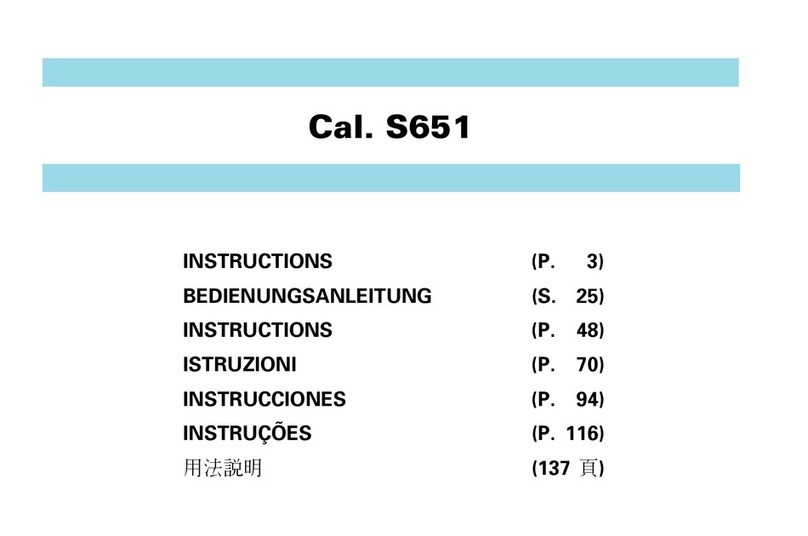

Seiko S651 User manual

Seiko

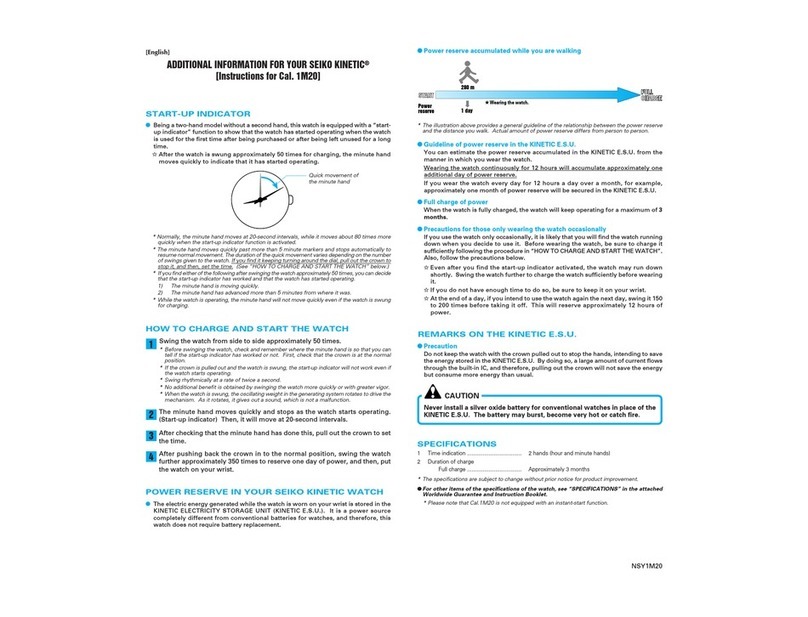

Seiko KINETIC 1M20 Installation manual

Seiko

Seiko S610A Installer manual

Seiko

Seiko 7T94 User manual

Seiko

Seiko Pulsar 7T32 User manual

Seiko

Seiko 5M54A Quick start guide

Seiko

Seiko 6N76A Quick start guide

Seiko

Seiko H024A Quick start guide

Seiko

Seiko 6R15 User manual

Seiko

Seiko 7K52 User manual

Seiko

Seiko SSA392J1 User manual

Seiko

Seiko ASTRON GPS SOLAR 3x62 Assembly instructions

Seiko

Seiko wiredwena N857 User manual

Seiko

Seiko Cal. 6T63 User manual

Seiko

Seiko Cal. 9R84 User manual

Seiko

Seiko T001 User manual

Seiko

Seiko 7F22 User manual

Seiko

Seiko V116A Quick start guide

Seiko

Seiko 3B51 User manual

Seiko

Seiko 5M45 User manual