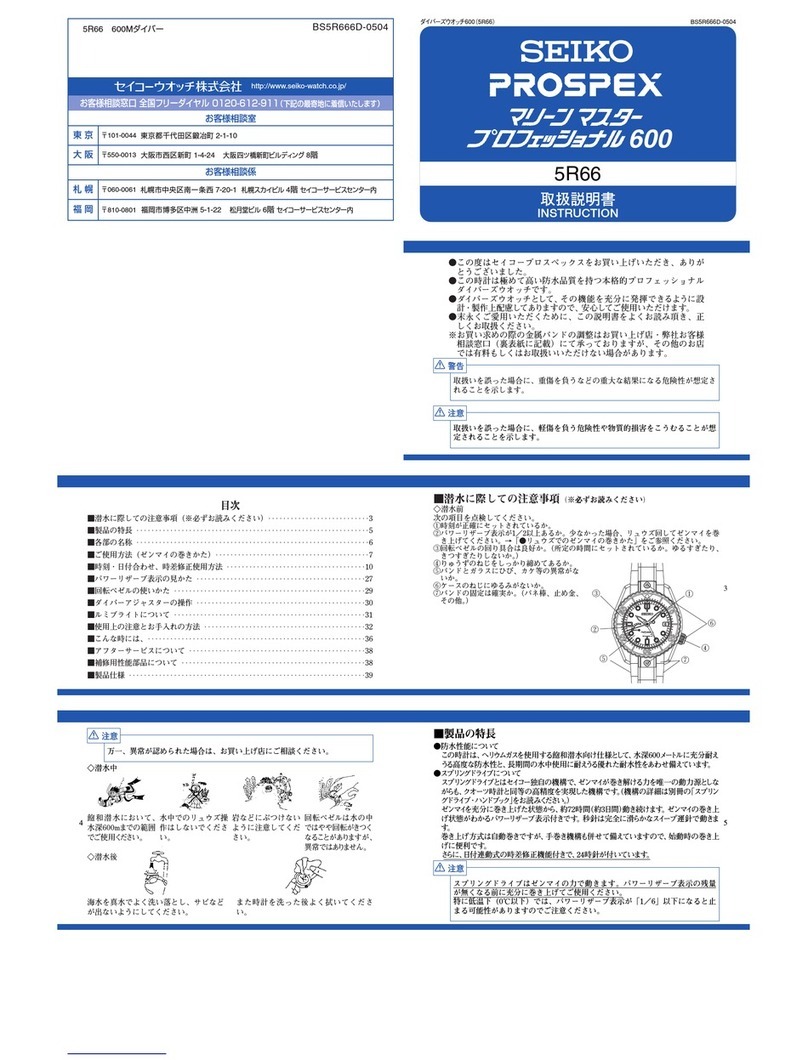

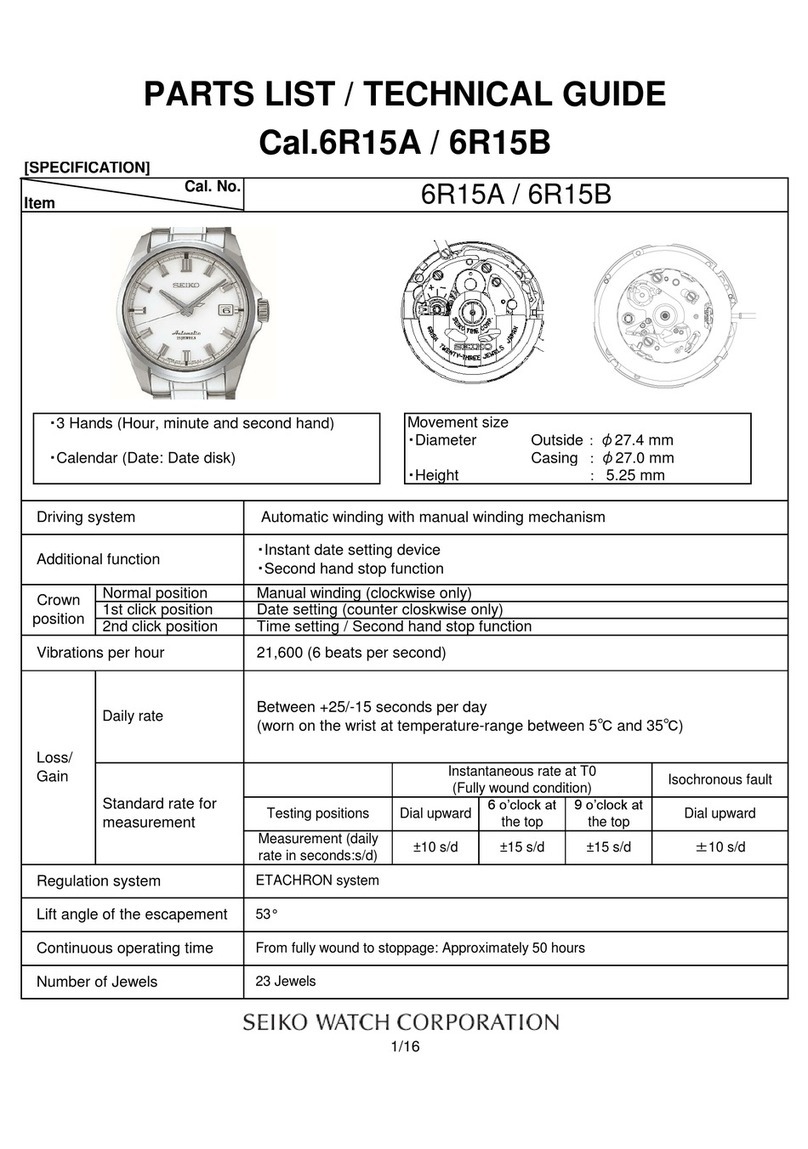

SPECIFICATIONS

2/19

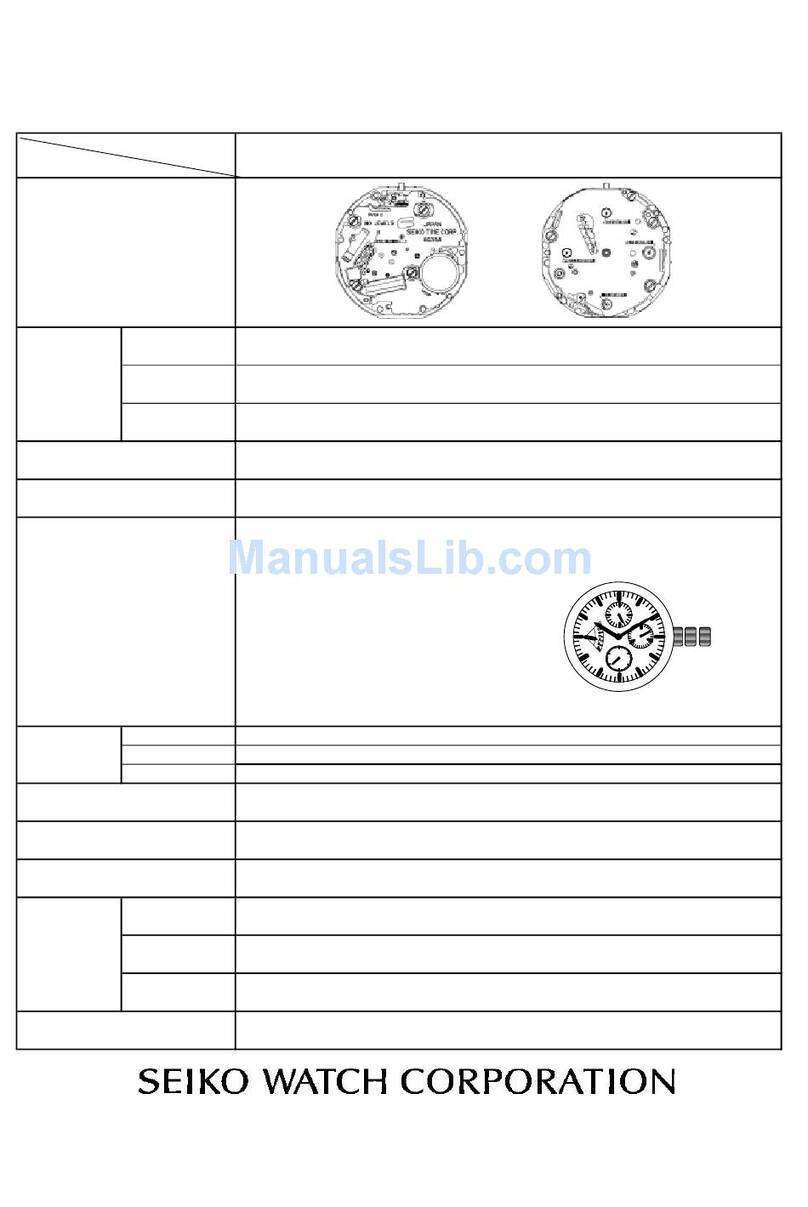

Cal. 4R15A/4R15B/4R16A/4R16B

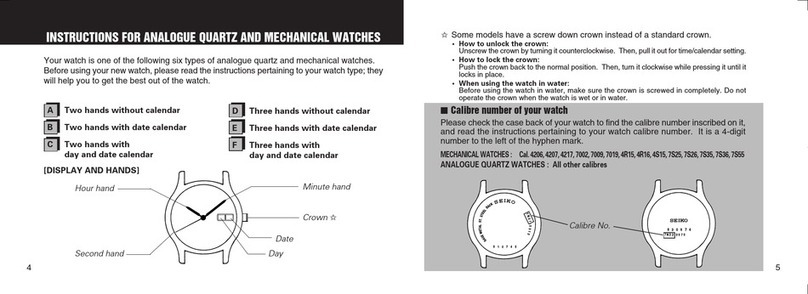

FEATURES

CHARACTERISTICS OF A MECHANICAL WATCH