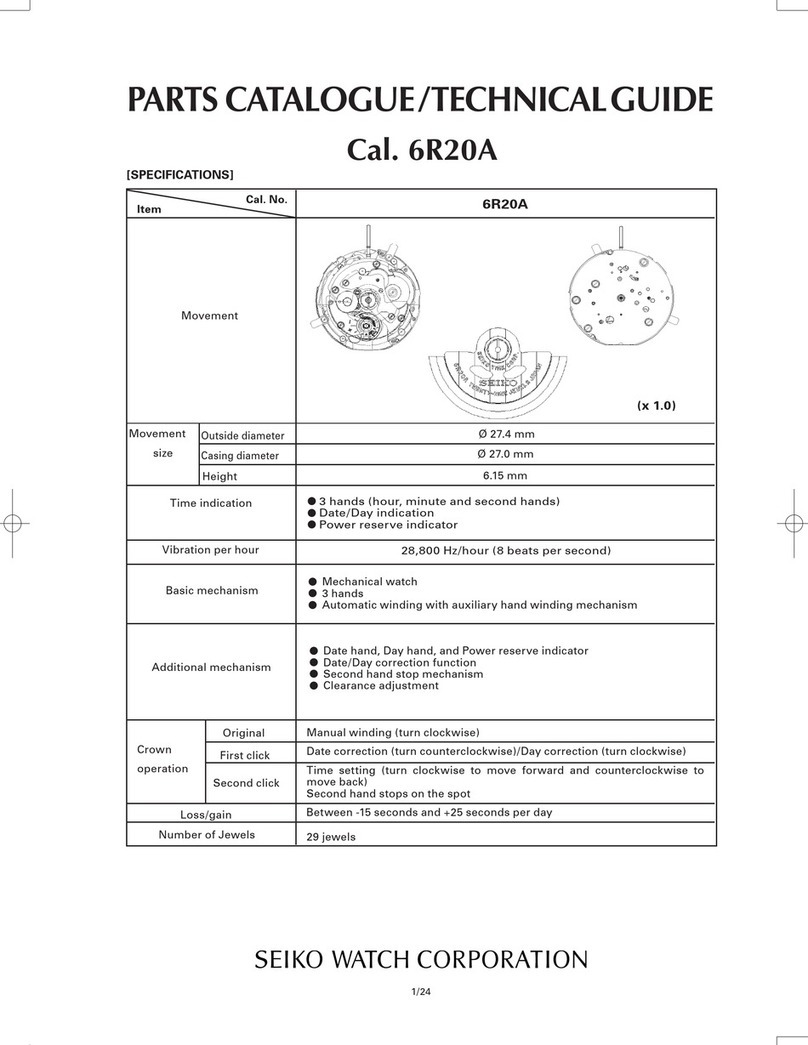

SPECIFICATIONS

/18

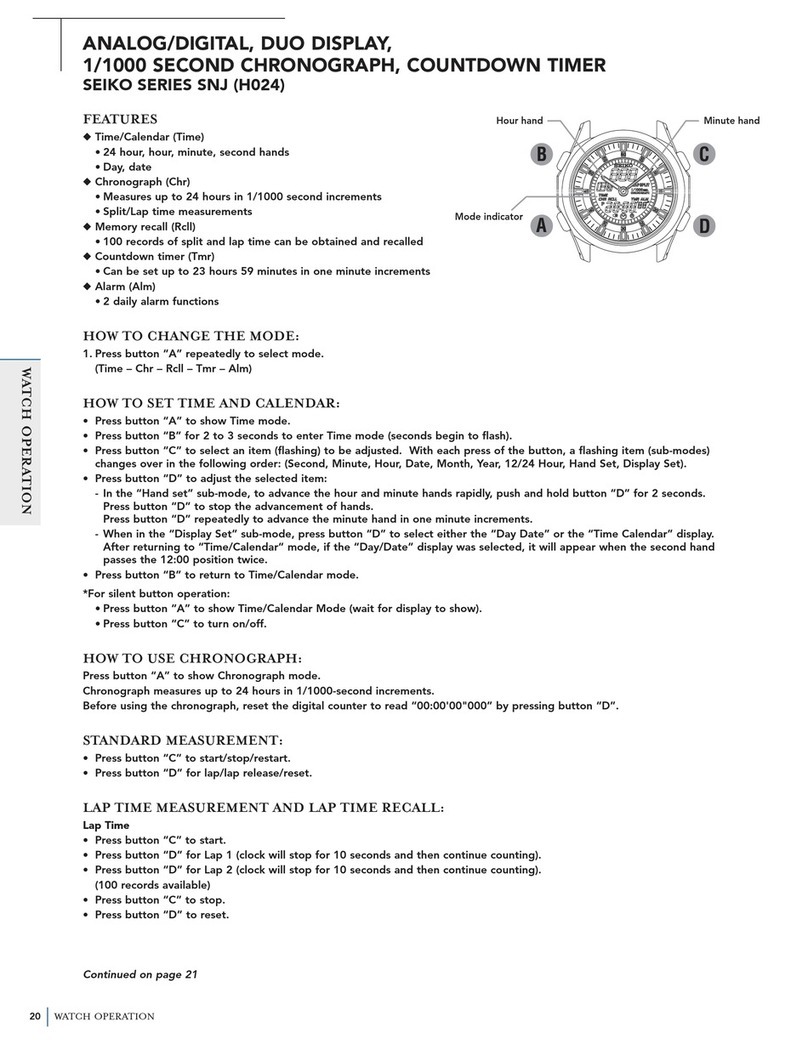

●Measurement functions

Accumulated elapsed time measurement and split time measurement are available.

Cal. 7T11A

●Standard measurement

Button A

START →Button A

STOP →Button B

RESET

●Split (intermediate) time measurement

Button A

START →Button B

SPLIT

Button B

SPLIT RELEASE

→ → → Button B

RESET

Button A

STOP

●Accumulated elapsed time measurement

Button A

START →Button A

STOP

Button A

STOP →Button B

RESET

→Button A

RESTART … →

Measurement and release of the split time can be repeated by pr essing button B.

Restart and stop of the stopwatch can be repeated by pressing b utton A.

●Measurement of two competitors

Button A

START

Button B

RESET

Button B

FINISH TIME OF FIRST

RUNNER

Button A

SECOND RUNNER

FINISH

→ →

Button B

FINISH TIME OF

SECOND RUNNER

→ →

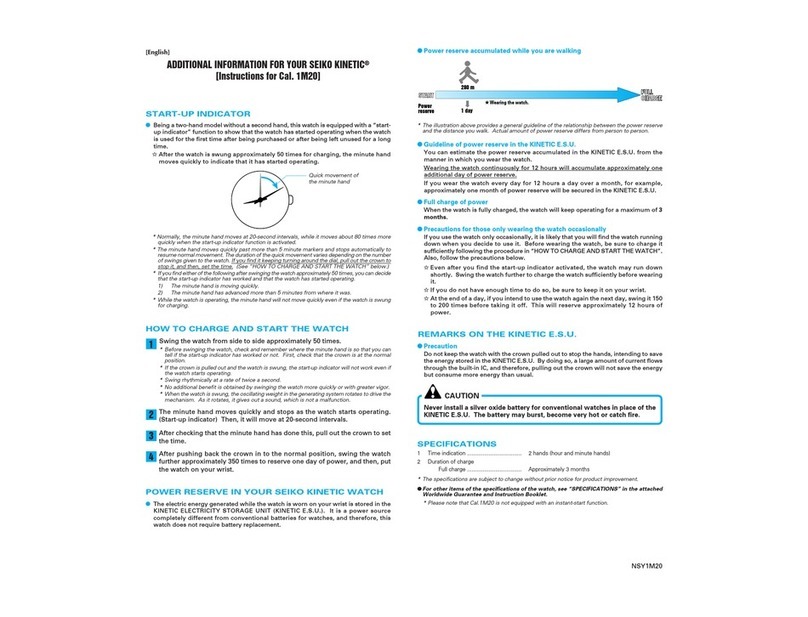

After installing the battery, pull out the crown to the second click position. And then follow the

instructions below to correct the hand positions and set the time.

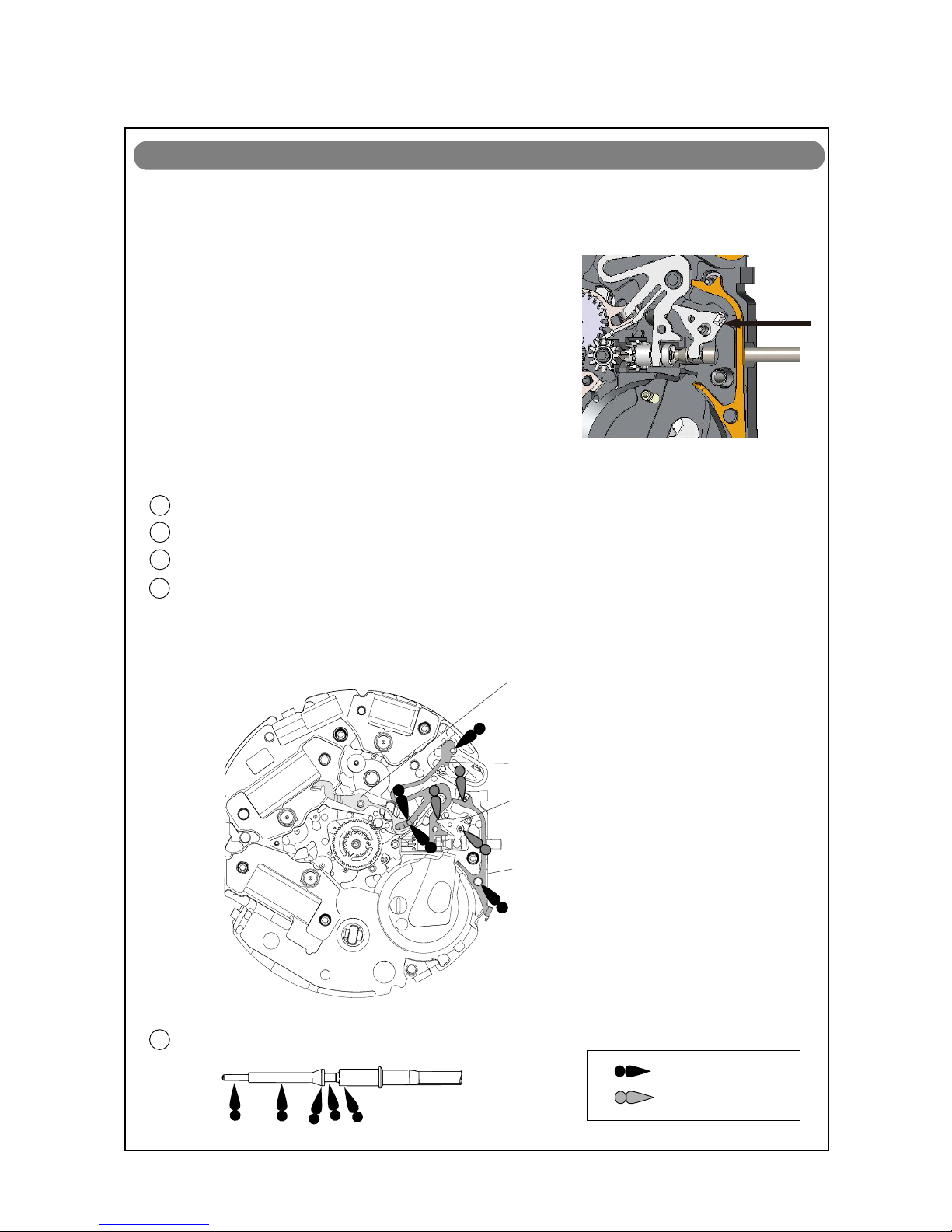

NECESSARY PROCEDURE AFTER BATTERY CHANGE

Pull out to the click position when the small second hand is at the

60 seconds position. The small second hand stops on the spot.

Turn to set the main time. * Check that AM/PM is correctly set.

Crown

Crown

Note*

Push back in to the normal position in accordance with a time signal.

Crown

Note* Pressing Button A for longer than 2 seconds here will allow you to resume the procedure again

Button A

Press Button A for longer than 2 seconds to ready for “0” position adjustment.

Button A

Press Button A for longer than 2 seconds.

The STOPWATCH second hand turns a full circle.

Button A

Press Button A for longer than 2 seconds.

The STOPWATCH hour and minute hand turns a full circle.

Button B

Press Button B to set the STOPWATCH second hand to the “0” position.

Button B

Press Button B repeatedly to reset the STOPWATCH

second hand to the “0”

if button B is kept pressed.

position. (12:00) It moves quickly

3