6

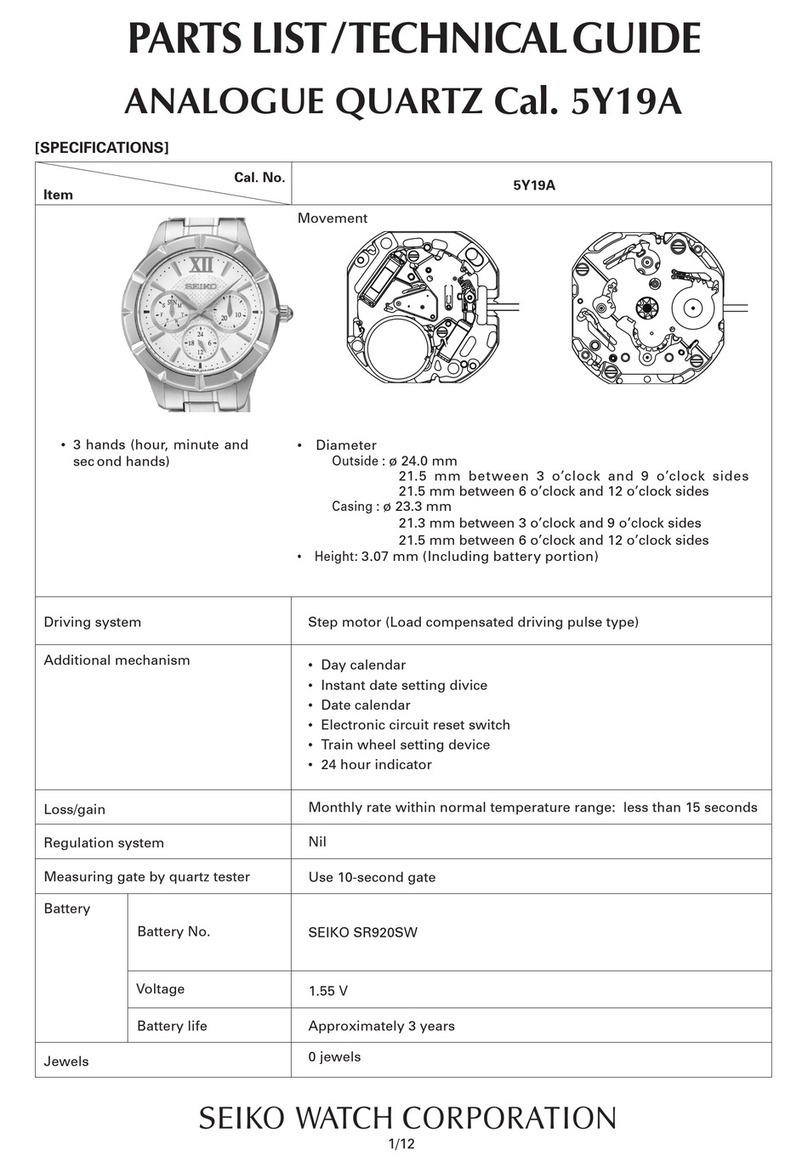

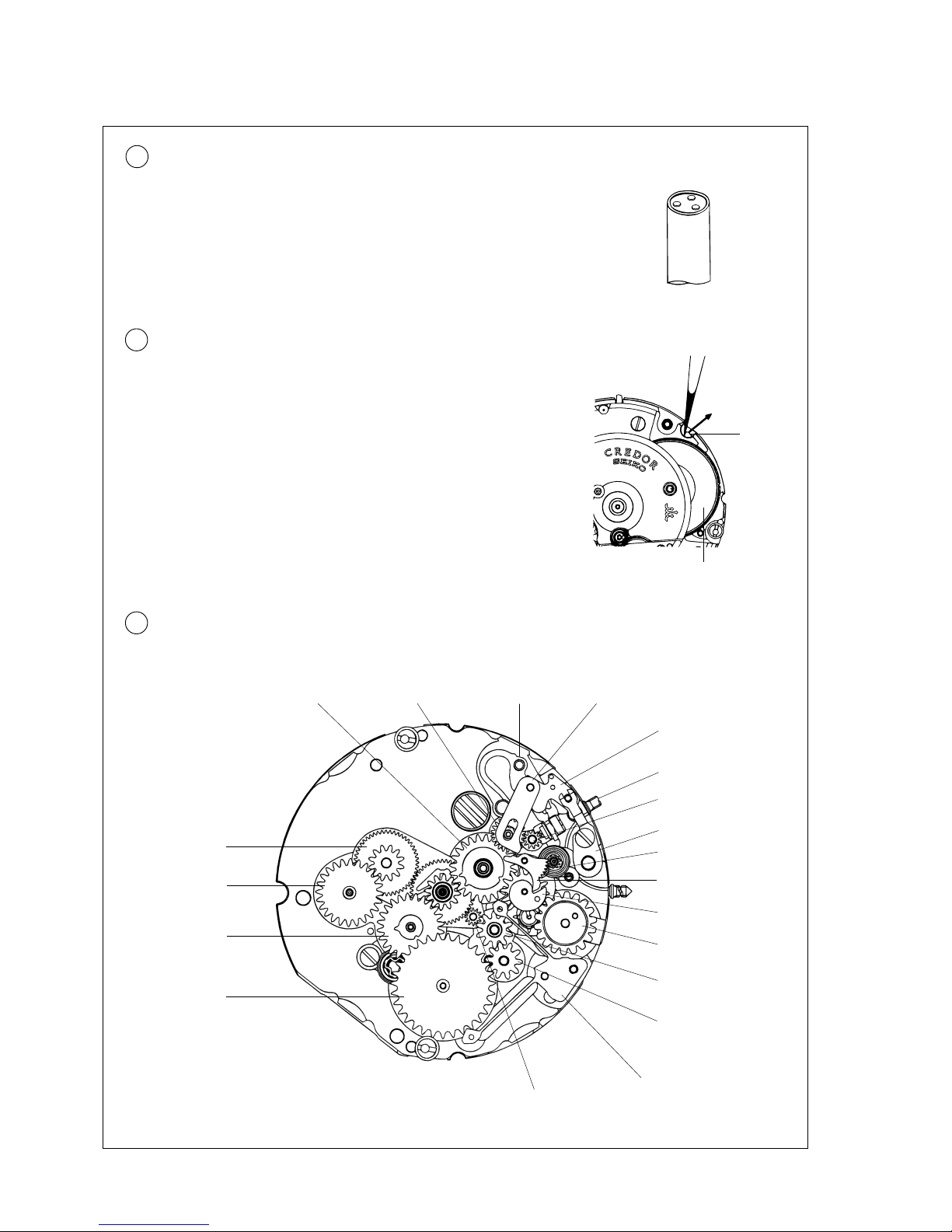

PARTS CATALOGUE Cal. 4S77A

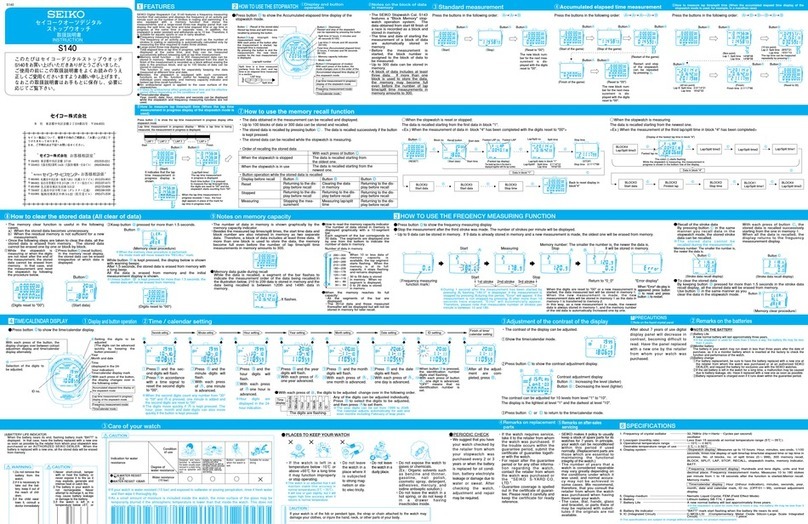

•List of jewels

0011 540

• Lower hole jewel for fourth wheel

and pinion

0011 505

0011 541

0011 151

0011 422

0011 157

•List of tubes and pins

0032 165

Part No. Name Part No. Name

Part No. Name Part No. Name

• Diashock upper/lower cap jewel

• Diafix upper cap jewel for fourth

wheel and pinion

• Diafix upper/lower cap jewel for

escape wheel and pinion

0011 221 • Upper/lower hole jewel for third

wheel and pinion

• Upper hole jewel for complete

barrel with mainspring

0011 398

• Upper hole jewel for center wheel

and pinion

0011 715

• Lower hole jewel for center wheel

and pinion

0011 146

0013 934 • Micro adjuster pin

• Dial leg pin

0013 975

• Upper/lower hole jewel for jewelled

pallet fork and staff

• Upper/lower hole jewel for first

reduction wheel and pinion

• Upper hole jewel for differential

wheel and pinion

• Lower hole jewel for differential

wheel and pinion

0013 481 • Pin for second reduction wheel

and pinion

0032 166 • Tube for auxiliary train wheel bridge

• Tube for balance cock (B)

0344 080

Part No. Part No. NameName

•Other parts

• Regulator pointer

0345 010 • Stud holder

0468 003 • Lower hole jewel with frame for

jewelled pallet fork and staff

0014 603 • Diashock upper frame

0341 016 • Regulator

0014 605 • Diashock upper/lower hole jewel

with frame

0014 317 • Diashock upper/lower spring

0014 417 • Diafix upper spring for fourth wheel

and pinion

• Diafix upper spring for escape

wheel and pinion

0014 634 • Diashock lower frame

0015 513 • Diafix lower spring for escape

wheel and pinion

0015 721 • Diafix upper hole jewel with frame

for fourth wheel and pinion

0015 161 • Diafix upper hole jewel with frame

for escape wheel and pinion

0015 531 • Diafix lower hole jewel with frame

for escape wheel and pinion