10 TDST24M000SE 032635 190619

AFTER SELECTING PARAMETER P2 PRESS THE ‘ ‘

KEY.

USING THE ‘ OR ‘ ‘ ARROWS IT IS POSSIBLE TO

SCROLL CYCLICALLY THROUGH THE THERMAL DATA:

- Safety temperatures

- Differentials

- Hysteresis of the differentials

- Hysteresis of the safety thermostats

- Hysteresis of the thermostats

- Offset

- Maximum temperatures

- Integration temperature

- ABC (Automatic Boiler Control) temperature

PRESS THE ‘ ‘ TO MODIFY THE THERMAL DATA

SELECTED; THE DATA WILL START FLASHING.

SET THE DESIRED NUMERIC VALUE USING

THE ‘ ‘ OR ‘ ‘ ARROWS.

P2: SETTING THE THERMAL DATA

Using this parameter it is possible to set the thermal data

related to the selected installation:

Note: The control unit is supplied with pre-programmed

thermal data for optimal operation. Any change to

these values must be performed by qualied personnel

only.

When changing the hydraulic scheme by means of the

parameter P1, the thermal values (TS, TM, TAH and

TABC) already set will be reset at the default values.

PRESS THE ‘ ‘ KEY TO CONFIRM THE

PROGRAMMED SETTINGS OR PRESS THE ‘ esc ’ KEY

TO CANCEL THE CHANGES.

In the following the regulation ranges allowed for each

parameter are listed.

WARNING!

The thermal parameters to be set are displayed when

the relevant scheme is selected, this means the power

unit will only display the thermal parameters actually

activated for the selected hydraulic scheme.

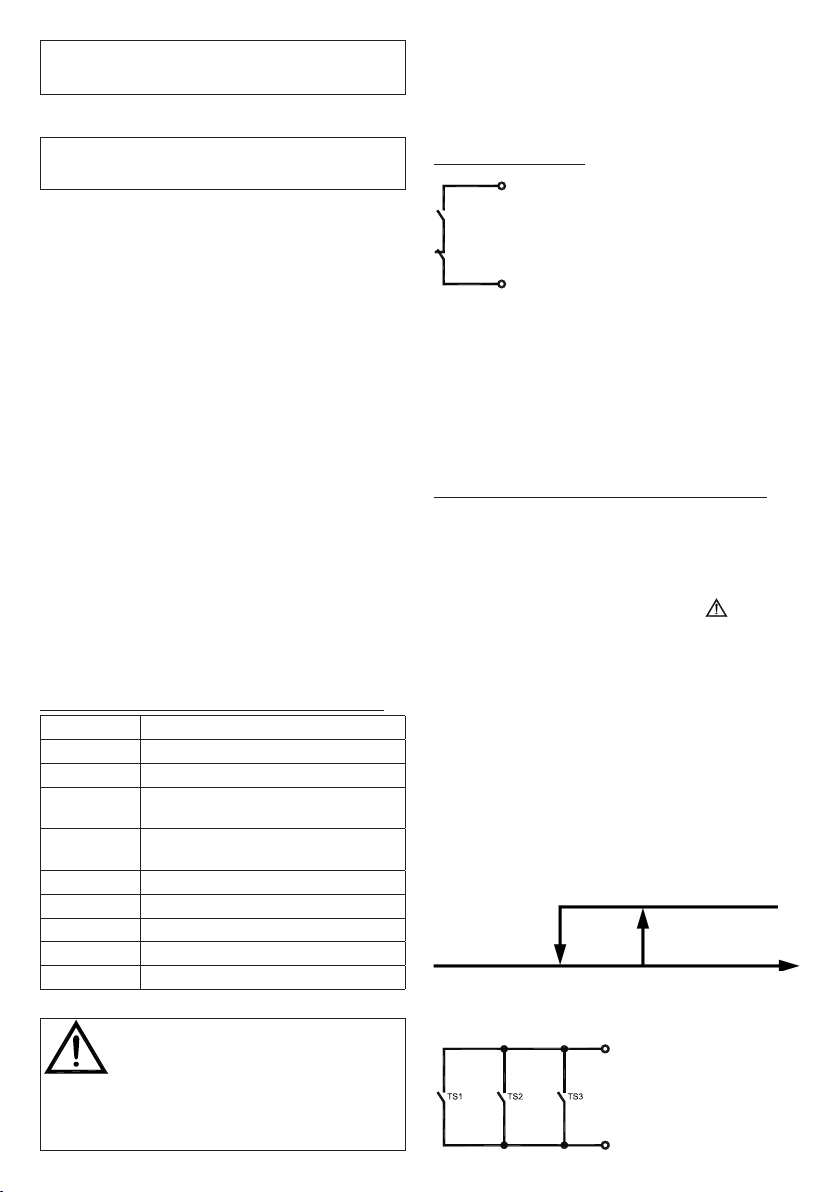

Probe safety temperatures

Data Regulation range Default

TS1 60.0 .. 240.0 °C 140.0 °C

TS2 20.0 .. 90.0 °C 80.0 °C

TS3 20.0 .. 90.0 °C 80.0 °C

WARNING!

It is not possible to set the Safety Temperatures TS2

and TS3 to a value lower than the relevant Maximum

Temperature, as the value of the Safety Temperature

is limited to the value of the Maximum Temperature

+5°C. To lower the Safety Temperature, it is rst

necessary to decrease the Maximum Temperature and

then set the Safety Temperature to the desired value.

If the Safety Temperature is displayed but the relevant

Maximum Temperature is not, then the Safety

Temperature will be limited according to the Maximum

Temperature operating in the current scheme (i.e. in

scheme no.1, the value of the TS2 safety temperature

will be limited according to the value of the TM3

maximum temperature). Should the hydraulic scheme

be changed and SCH5 scheme previously activated, all

the Safety and Maximum temperatures will be set at

the factory-set default values.

Differential between the probes S1-S2 (∆T12)

Data Regulation range Default

∆T12 1.0 .. 20.0°C 8.0 °C

WARNING!

It is not possible to set the Differential to a value lower

than the relevant hysteresis because the value of the

Differential is limited to the value of the hysteresis

+1°C. To lower the Differential it is rst necessary to

decrease the value of the hysteresis.

Hysteresis of the differential ∆12

Data Regulation range Default

HY12 1.0 .. 15.0°C 4.0 °C

WARNING!

It is not possible to set the Hysteresis (HY) to a value

higher than the relevant Differential (∆T), because

the value of the hysteresis is limited to the value of

the Differential -1°C. To increase the value of the

Hysteresis it is rst necessary to increase the value of

the Differential (∆T).