Seiwa LZLA Series User manual

Thank you very much for purchasing our LED lighting fittings.

Please read this instruction manual to use the product properly.

1) Prior to installing the fitting, check if the product is as per your order.

2) Check for a loose or damaged part due to an accident in transit, etc.

1)

<1>

<2>

<6>

<1,1H>

<0>

<4>

<4,5> -

<1>

<2>

-

<6>

<1,1H>

<0>

<4>

<4,5>

<1>

<2>

<6>

<1,1H>

<0>

<4>

<4,5>

The figure(s) in brackets ([ ]) denotes electrical characteristic data on DC power.

2) Usable in hazardous sreas of zone 1 or zone 2 hazardous areas where there are hydrogen gas.

- Installation work should be done properly by a qualified electrician in accordance with the related laws and the instruction manual.

- For safety, Installation work should be done by at least two workers.

■

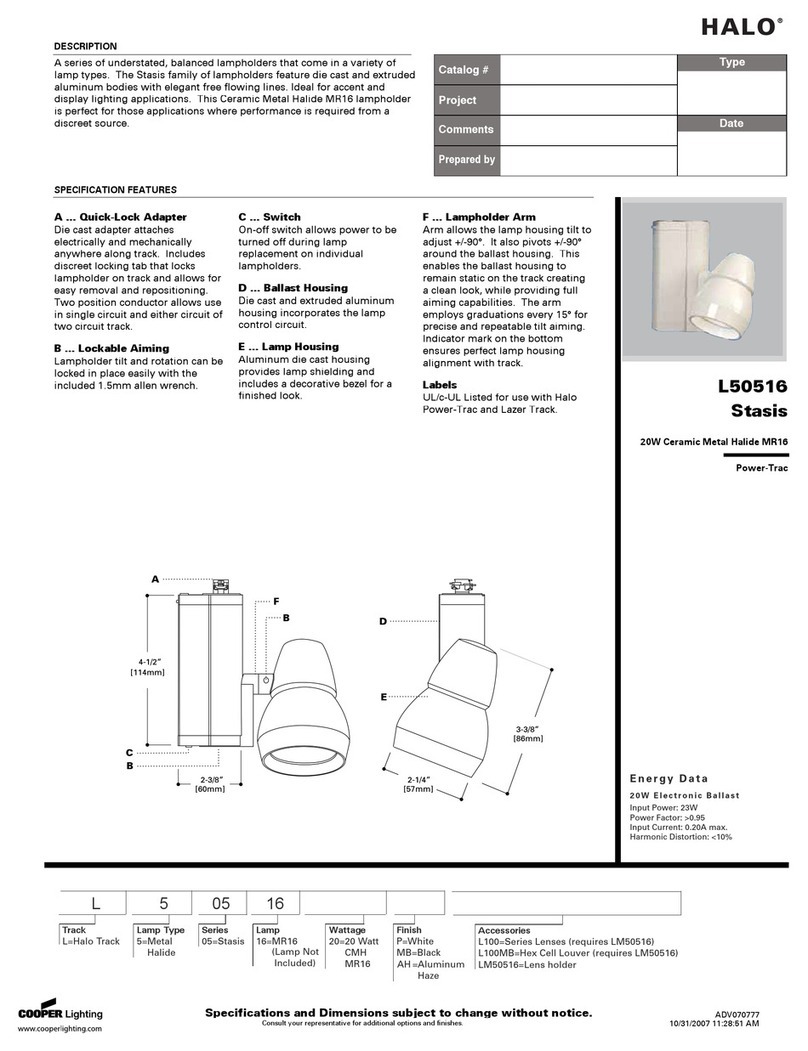

Direct Mount Type, Pipe Pendant Type, Bracket Type (Fig. 1: Example LZLA110141)

NB: For the bracket type, fix it on a vertical mounting surface securely.

Screw the pipe into the lamp house.

Screw the terminal box cover into the pipe.

Fasten the terminal box and its cover with four cross recessed hexagon bolts.

NB1:

NB2: Caulk the threaded connections.

NB3:

The lamp house may be installed within an angle range of 0 ° (down) to 45 °

(oblique).

The pipe, locking screws and cross recessed hexagon blots should be tightened

securely. Otherwise, the lamp house might fall.

Explosion proof type LED Lighting Fittings

LZLA

IP

rating

15.5-16W

[15.5W]

After installing the product, be sure to hand this manual over to the user of the product.

Lift the lamp house and hook the suspension hook onto the suspension hook hole

of the terminal box.

Performance

Model

Installation Type

LZLA11015

After connection of the electric wires (white and black: power wires, green:

grounding wire), remove the suspension hook and put it in the terminal box cover.

After adjusting the positions of the lamp house and terminal box, tighten the three

locking screws.

0.16-0.07A

[0.16-0.14A]

0.20-0.09A

[0.20-0.18A]

32.5-31.5W

0.33-0.14A

100-242V AC

(50/60Hz)

[100-110V DC]

100-242V AC

(50/60Hz)

Fix the terminal box on a horizontal mounting surface securely with M6 bolts or

equivalent bolts.

11E0001021D11

To be conserved

The electrical characteristic data is given below (the figure in angle brackets < > in the Installation Type column is asign placed at the end of

each model code to represent the type of installation.)

Instruction Manual

LZLA15011

LZLA15012

Bracket

Stanchion

Horizontal pole mount

Prior to use

LZLA27015

LZLA27012

LZLA27014

LZLA27011

Lamp house replacement

Direct mount

Horisontal pipe mount

Lamp house replacement

Special direct mount

LZLA11012

LZLA15015

LZLA15014

Pipe pendant

LZLA11011

LZLA11014

Lamp house replacemen

Direct mount

Horizontal pole mount

Pipe pendant

Direct mount

Pipe pendant

Bracket

Stanchion

Special direct mount

20W

[20W]

Input Voltage

(Frequency)

Rainproof cover for

direct mount, pipe

pendant, and

bracket types

Type of

protection

ExdeⅡB+H2T6X

Input

Current

Option

Special direct mount

Names of the Components and Installation Method

Bracket

Stanchion

Power

Consumption

Guard

IP65

Terminal box

Suspension hook

Pipe

3-Locking screws

Lamp house

4-φholesfor M6 olts

Suspension hook hole

Cover gasket

Cover gasket

Terminal box cover

4-Cross recessed

hexagon bolts

Fig. 1

- -

■

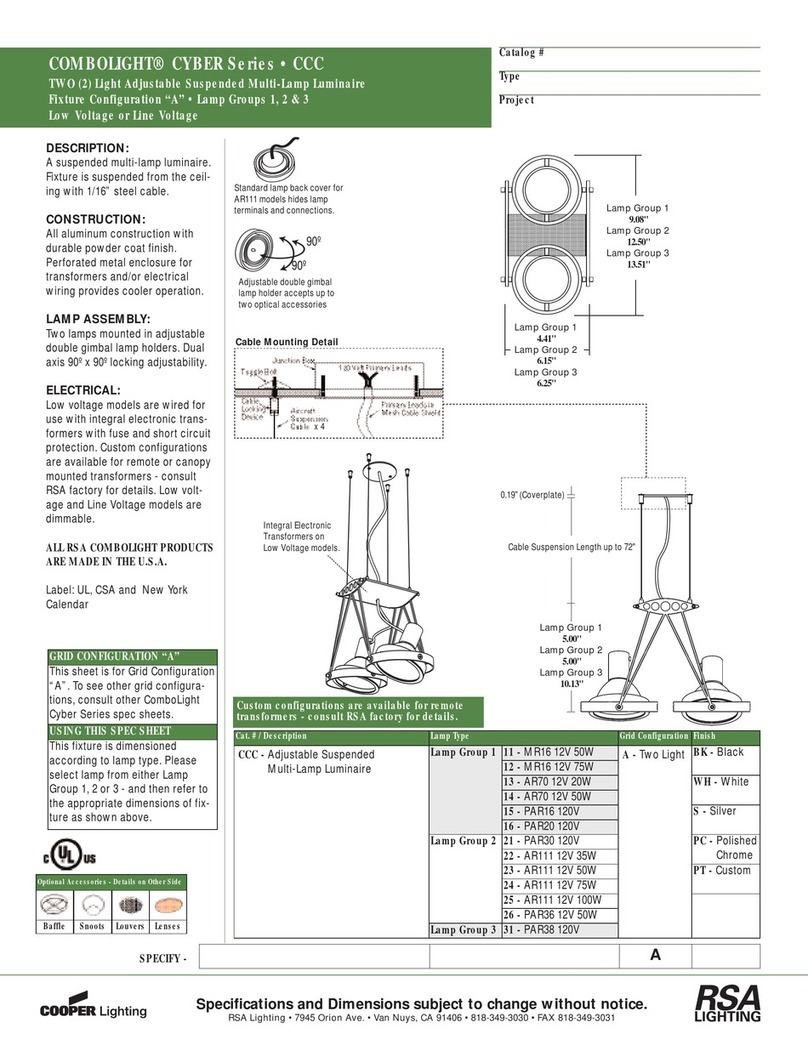

Stanchion Type (Fig. 2: Example LZLA110151)

NB:

NB: The lamp house should be installed within an angle range from 0° (down) to 15°.

■

Special Direct Mount Type (Fig. 3: Example LZLA110110)

Connect the electric wires in the terminal box.

Adjust the angle of the lamp house using the mounting bracket.

NB:

■

Horizontal Pole Mount Type (Figs. 4 and 5: Example LZLA110114)

Connect the electric wires in the terminal box.

Adjust the angle of the lamp house using the mounting bracket.

NB:

Keeping the support horizontal, fix the mounting band and the

support securely with the pole between them using the two

hexagon bolts and two hexagon nuts on the mounting band.

Pass the electric wires (white and black: power wires, green:

grounding wire) through the flexible fitting and attach the flexible

fitting to the retainer (lamp house).

The lamp house is installed within an angle range from 0 to 70

degrees in the left and right directions. For angle adjustment,

loosen the two hexagon socket head bolts on the retainer.

After adjustment, be sure to tighten the hexagon socket head

bolts.

Pass the electric wires (white and black: power wires, green:

grounding wire) through the flexible fitting and attach the flexible

fitting to the retainer (lamp house).

Pass the electric wires through the terminal box and attach the

terminal box to the flexible fitting.

The product is mounted on a ceiling. The lamp house is

installed within an angle range from 0 to 70 degrees in the left

and right directions. For angle adjustment, loosen the two

hexagon socket head bolts on the retainer. After adjustment,

be sure to tighten the hexagon socket head bolts.

As shown in Fig. 5, put the mounting band onto the support and

insert the horizontal pole (handrail).

Pass the electric wires through the terminal box and attach the

terminal box to the flexible fitting.

Lift the lamp house and fix the lamp house mounting bracket to

the support securely with the two hexagon bolts and two

hexagon nuts on the mounting bracket.

Fit the top flange attached to the lamp house into the stand pole (in the arrow

direction).

Tighten the retaining screw and two locking screws supplied with the top flange

and confirm that the lamp house does not turn.

Don't remove the waterproof rubber pieces from the retaining screw and

locking screws.

Attach the short nipple and terminal box, referring to the short nipple installation

manual. For installation of the terminal box, see Fig. 2.

Completely fix the stand pole with the support (not supplied) and prescribed

terminal box mounting screws.

Bring the electric wires to the terminal box and connect the wires in the terminal

box.

Fix the mounting bracket on a horizontal mounting surface

securely with M6 bolts or equivalent bolts.

Pass the electric wires (white and black: power wires, green: grounding wire)

through the stand pole.

Stand pole

Support

(not supplied)

Adapter

(thread G3/4)

Short nipple

(w/ 2 O rings)

2-Locking screws

(w/ rubber piece)

Top flange

Retaining screw

(w/ rubber piece)

Lamp house

Terminal box

Fig. 2

Fig.3

2-φholes

(for M8 bolts)

Mounting bracket

Retainer

Lamp house

Terminal box

Flexible fitting

Mounting angle

(up to 70°left/right)

2-Hexagon socket head

bolts

Pole (handrail)

Mounting band

(not supplied)

Support

Retainer

Lamp house

Flexible fitting

Terminal box

2-Hexagon bolts

2-Hexagon bolts

2-Hexagon nuts

Mounting bracket

2-Hexagon nuts

Fig.4

Fig.5

Pole (handrail)

(not supplied)

Support

Mounting band

800 mm or more

- -

■

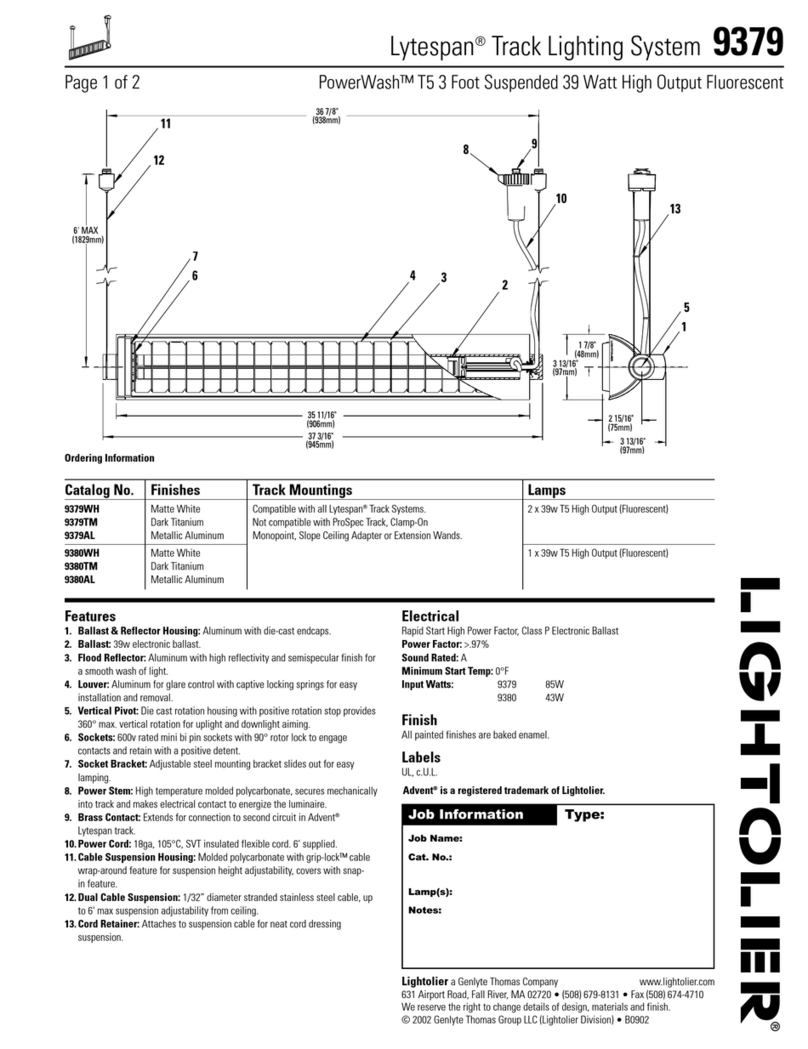

Lamp House Replacement Type (Fig. 6: Example LZLA110124)

Connect the electric wires in the existing junction box.

NB1:

NB2:

NB3: The external conductor should be heat-resistant to 80°C or more.

NB4:

Note:

■

Attachment of Cable Gland (Fig. 7: Example ZCGS-22B)

NB1:

NB2:

Screw in the lock nut on the body until it touches the body flange.

NB: Waterproof the threaded connection.

Fasten the cable retaining plate on the cable fixing member.

NB:

Confirm that the cable does not move.

NB1:

NB2: The cable gland should be a product as specified by SEIWA.

■

Option 1: Guard (Fig. 8: Example LZLA110141)

Place the guard on the lamp house.

Place the three guard holding pieces over the guard in prescribed positions.

NB: Confirm that the guard is fixed securely.

■

Option 2: Rainproof Cover (for the direct mount, pipe suspension, and bracket types)

See the rainproof cover installation manual supplied with the rainproof cover.

If the product is used in a place subject to water splashes, waterproof the

connection between the lamp house and the existing pipe.

Fasten the gland onto the entry of the terminal box (or the device

to which the gland is to be attached) until the body stops.

Separate the cable gland into parts as shown in Fig. 7 and pass

the cable through the cable gland in the following order: cover,

connecting member, cable fixing member, washer, rubber sleeve,

washer, body, and lock nut.

Tighten the three M4 mounting screws securely to fix the guard with the guard

holding pieces.

For lamp house replacement of the stand pole type (LZLA110125)

with G1 thread entry, see the supplied installation manual.

Attach the protective tube to the connecting member, then

screw the cover into the body securely.

Tighten the locking screw on the body to prevent the cable fixing

member from loosening.

Confirm that the cover is invisible from the O ring. If visible,

the waterproofness is not ensured.

Pass the electric wires (white and red: power wires, black: grounding wire)

through the pipe (existing or supplied pipe) and the existing junction box.

Pass the electric wires (white and red: power wires, black: grounding wire)

through the pipe (existing or supplied pipe) and the existing junction box.

Be sure to remove the locking screw on the cable gland body

before separating the cable gland into parts.

Tighten the lock nut toward the terminal box (or the device to

which the gland is to be attached).

The cable should be a round cable applicable to the rubber

sleeve. For information on cables applicable to the cable

gland, see the catalog.

Push the washer, rubber sleeve, and washer into the body and

pull out the cable to a sufficient length for cable connection.

Screw the cable fixing member into the body.

Before attaching the lamp house, check the existing piping (including the pipe

and junction box) for corrosion.

If the existing entry is of the G1/2 thread type, replace the existing pipe and

junction box cover as well (marked with ☆in Fig. 6 if the existing junction

box is SEIWA's product).

For the G3/4 thread entry, remove the existing pipe and screw the supplied pipe

into the existing junction box. For the G1 thread entry, use the existing pipe as it

is.

Fig.6

Fig.7

Existing junction box

Supplied or existing pipe

Junction box

cover☆

Power cable

Built-in

terminal box

Lamp house

Lock nut

2-Washers

O ring

Terminal box

Locking screw

Body

Rubber sleeve

Cable fixing member

2-Cable fixing screws

Cable retaining plate

O ring

Connecting member

Cable gland (ZCGS)

Cover

Cable (round)

Fig.8

3-Guard holding screws

Lamp house

Guard

3-Guard mounting pieces

- -

The LED lamp is turned on by applying the rated voltage to the power cable of the product.

■

Inspection 1)

2) Prior to maintenance, be sure to turn off the power.

3) Carry out maintenance properly in accordance with the related law and regulations.

4) If a repair is needed, consult us.

1) In the period when the product is in use, never disassemble it.

2) For disposal of the product, follow the regulations and rules of your local government.

When reordering, please let us know:

・Drawing or drawing No. for the delivered product

・Manufacturing lot number on the nameplate

1.

2. Prior to maintenance or inspection, be sure to turn off the power.

3. Confirm that the screws and bolts are fastened properly and tightly.

4. In the case of the stanchion type, be sure to provide a support at least 800 mm above the bottom of the pole.

5.

6.

7. When handling the product, be very careful not to scratch the glass globe. Scratching may break the glass globe.

8.

9. The supply voltage variation should be within ±6% of the rating.

10. Close unused entries of the terminal box with plugs.

11.

NB: For LZLA1101 and LZLA1501, the allowable ambient temperature range is -20°C to +50°C.

12.

13.

Prior to maintenance or inspection, be sure to turn off the power.

14. To prevent shortening of the service life, avoid turning on the fitting in direct sunlight.

15. To avoid noise or malfunctioning, don't use a radio, television or wireless infrared remote control near the fitting.

16.

17.

18.

19.

20. After turning off the power, allow 3 minutes before opening the lamp house. Otherwise, an explosion might occur.

21. The cable gland must be a product specified by SEIWA.

22.

23.

24. The LED lamp and the power supply unit cannot be replaced.

25. Do’t look straight at the LED lap. It a daage your eyes.

26.

27.

The fastening bolts on the control unit chamber housing the control unit have a tensile strength level of A2-50. Don ’t remove the

fastening bolts. Removal of the bolts might cause a fire, electric shock or explosion.

Don't clean the flexible fitting with a dry cloth since it may be electrified. Be sure to clean it with a wet cloth. Otherwise, ignition of

flammable gas might occur due to static sparks.

For white LED lamps, the luminescent color and brightness may vary with individual LEDs because of their nature. Also note that the rate

of attenuation with time varies with individual LED lamps.

The product must be mounted on a sturdy wall surface or structure which is vibration-free and less susceptible to damage. Otherwise, it

might fall or be damaged.

The ambient temperature should be within the range of -20°Cto +40°C. The use of the product out of this range may shorten the service

life.

In grounding work, be sure to follow the technical standards for electrical equipment and explosion-protected equipment of your country.

Inadequate grounding might cause an explosion, fire or electric shock.

Don’t open the globe. The internal components such as the LED lamp become very hot. Don’t touch the LED lamp since a malfunction or

lighting failure might occur.

For use in an unfavorable location (a very hot, cold or humid place or a place in which there is strong

wind or vibration, a salt damage environment or a dusty or corrosive gas atmosphere), a special

The product must be used in a location where it can be used safely according to its explosion protection type (indicated on the body).

For the lamp house replacement type (in which some existing components are used as they are), the external conductor should be heat-

resistant to 80°C or more.

For the lamp house replacement type with G3/4 thread entry, be sure to use the supplied pipe. If the entry is of the G1/2 thread type, be

sure to use the supplied pipe and the supplied junction box cover. Otherwise, the lamp house might fall or be damaged.

How to Use

In cleaning the fitting, gently wipe with water or mild detergent. Don ’tuse thinner, benzene or alkaline detergent. Such

chemicals might cause discoloration or deterioration in quality and strength, resulting in a damage.

Reordering

If the above information is unavailable, give us any material showing the appearance of the product or details of the product specification

(dimensions, mounting interval, lamp type, etc.).

For outdoor use, waterproof the screwed portion of the conduit, the cable entry fittings and the joint with the stand pole to prevent

rainwater infiltration.

Disassembly and Disposal

Maintenance

The product must be installed so that the angle of the lamp house is within a prescribed range from its downward oriented position (0°).

If the angle is out of the range, an insulation failure or electric shock might result.

When installing the fitting, be sure to connect external wires inside a specified part of the fitting. Don't open any other part of the fitting

unless necessary.

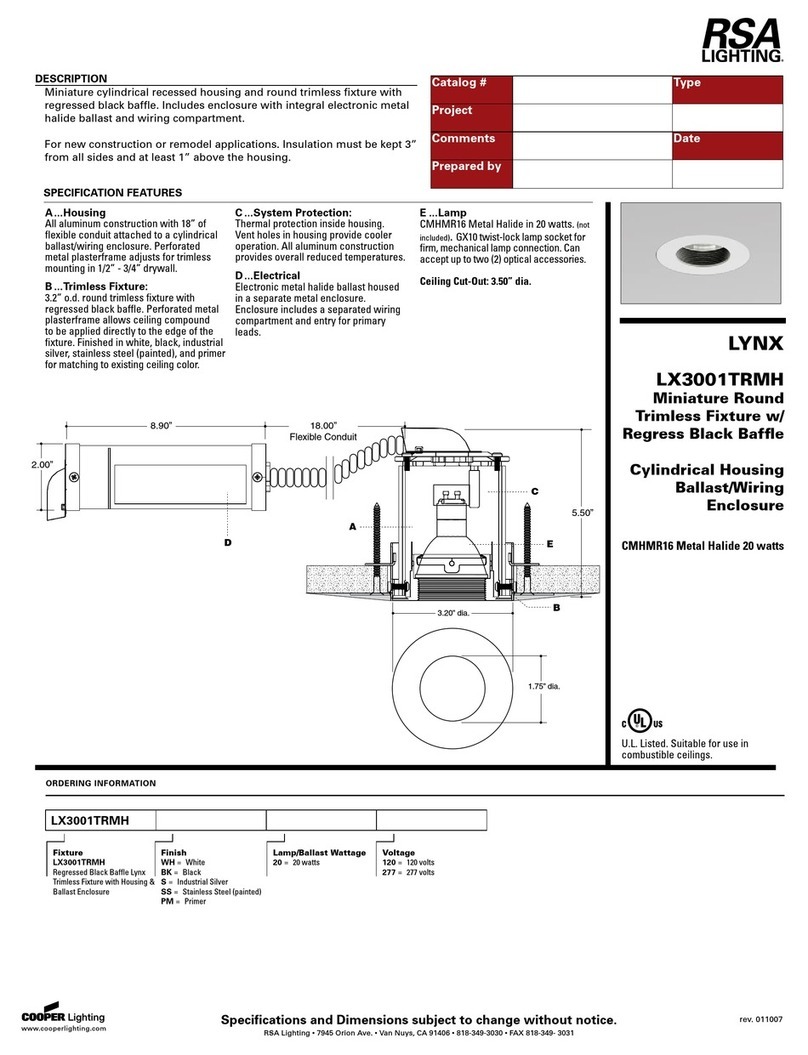

Fig.9

Nameplate

CAUTIONS

- -

- Prior to use, please read the safety precautions and instruction manual thoroughly to use the product properly.

-

- Please keep the manual in a handy place for later reference.

●The various marks have the following meanings:

11E0000712D11

Safety Precautions

To be conserved

L照6

Be sure to turn

off the power.

In grounding work, be sure to follow the technical standards for electrical equipment and explosion-protected equipment of

your country. Inadequate grounding might cause an explosion, fire or electric shock.

The parts once removed for cleaning should be replaced properly according to the instruction manual.

An improperly placed part might cause the product to explode or fall, resultng in an injury or property damage.

Do’t ope LED lap protetie oers suh as the frot glass ad glass gloe.

Do’t touh a LED lap, otherise a alfutio or lightig failure ight our.

Do’t ed, tist or pull the poer ale y fore.

Inadequate handling of the cable might damage it and result in a fire or electric shock.

Do’t oert the produt.

Conversion might cause the product to fall or result in a fire or electric shock.

When leading the power cable into the product through a conduit or the like, waterproof the connection and joint

adequately to prevent water infiltration. Inadequate waterproofing might cause a fire or electric shock.

WARNING

If you use a product in a hazardous location where there is a gaseous, steamy or dusty atmosphere, it should be of the

flameproof type suitable for the location. Use of an unsuitable type apparatus might cause an explosion or fire.

The ambient temperature should be within the operating temperature range specified in the instruction manual. If the

product should be used at a temperature higher than specified, an early lighting failure or malfunction might occur or an

explosion or fire might result.

If a product must be oriented in a specific manner for use, install it properly according to the marking on its body or the

instruction manual. Otherwise, an explosion, fire or electric shock might result.

Don’t touch.

Be sure to

ground.

Prohibited.

Be careful of

ignition.

After installing the product, be sure to hand the safety precautions and instruction manual over to the user of the product.

Caution

WARNING:

CAUTION:

Improper handling may lead to a human death or serious bodily injury.

Improper handling may lead to a bodily injury or property damage.

Disassembly &

conversion

prohibited.

Don’t use near

a water source.

Be sure to

follow the

instructions.

When leading the power cable into the product, be sure to follow the technical standards for electrical equipment and

explosion-protected equipment of your country. Inadequate cable connection or waterproofing might cause an explosion,

fire or electric shock.

For electrical connections, use crimp-type terminals, etc. to secure the connections and conduct insulation treatment. An

inadequate connection or inadequate insulation might cause an imperfect contact, leading to an explosion, fire or electric

shock.

Do’t oer the produt ith a iflaale aterial suh as loth or paper or put aythig i the produt.

Such a material or thing might cause an explosion or fire.

- 1/2 -

Ni-Cd

Ni-MH

L照6

Please note that the above addresses and phone numbers may be changed.

Installation of the product should be carried out by a qualified person.

Installation by an unqualified person is legally prohibited.

Don’t use the product in a strong corrosive gas atmosphere which contains hydrochloric acid or chlorine gases or the like.

Use in a corrosive gas atmosphere might cause the product to corrode and fall, resulting in an injury.

Do’t use the produt at a oltage other tha the rated oltage idiated o the aeplate.

Otherwise, breakage, fire or electric shock might result.

Before cleaning, be sure to turn off the power.

Otherwise, a fire or electric shock might result.

CAUTION

Any product not marked as a product for outdoor use should not be used outdoors or in a humid place or near a water

source. Its use in such a place might cause a fire or electric shock.

The product should be mounted on a surface robust enough to support its weight, properly according to the instruction

manual. Improper installation might cause the product to fall or result in an electric shock or injury.

CONTACT DETAILS

Never touch LED light sources and their surroundings.

The light sources and their surroundings are very hot, so an accidental touch might cause a burn.

A lighting fitting has a service life. A product which has been used for eight to ten years may have degraded internal parts

even if it looks normal. For safety and energy saving, we recommend you check and replace it. The LED module design life is

6,0000 hours (different from the lighting fitting life) when used at an ambient temperature of 30°C, 10 hours per day, 3,000

hours per year. If used at a higher temperature or more hours per year, the life would be shortened. Have a specialist

inspect the product every three years. If used for an extended period without inspection, a smoke, fire, or electric shock

might result.

Fax

2-19-6 Yanagibashi, Taito-ku, Tokyo 111-0052 Japan

+81 3 5833 8971

+81 774 58 2034

+81 3 5833 8946

Tokyo Branch

Fax

SEIWA ELECTRIC MFG.CO., LTD.

Phone

Phone

36 Shinike, Terada, Joyo, Kyoto Pref. 610-0192 Japan

Head Office

+81 774 55 8181

For further information on the product, contact any of our offices listed below (if you like to make an inquiry, let us know the model name

indicated on the product nameplate).

To ensure brightness and safety, carry out periodical cleaning and inspection.

If you find a problem, discontinue the use of the product and have it repaired by a specialist.

For a product marked with a frequency, don’t use the product at a frequency other than 50 or 60 Hz (local power supply

frequency). Use at a wrong frequency might cause a fire.

JBRC Japan Portable Rechargeable Battery Recycling Center

Phone +81 3 6403 5763

Resycling

Please bring used Secondary batteries to the recycling station for effective use of precious

resources and global environment conservation.

If you continue to use the product in an abnormal condition (smoke, odor, etc.), an explosion, a fire or electric shock might

result. If you detect an abnormality, immediately turn off the power switch. Confirm that the abnormal condition has been

eliminated and make a repair call.

WARNING

- 2/2 -

This manual suits for next models

12

Table of contents

Popular Light Fixture manuals by other brands

Xtralite

Xtralite omni XL20717 instruction manual

Lightolier

Lightolier Lytespan 9379 specification

PROEL

PROEL SG CLSPOT user manual

RSA Lighting

RSA Lighting LYNX LX3001TRMH Specification sheet

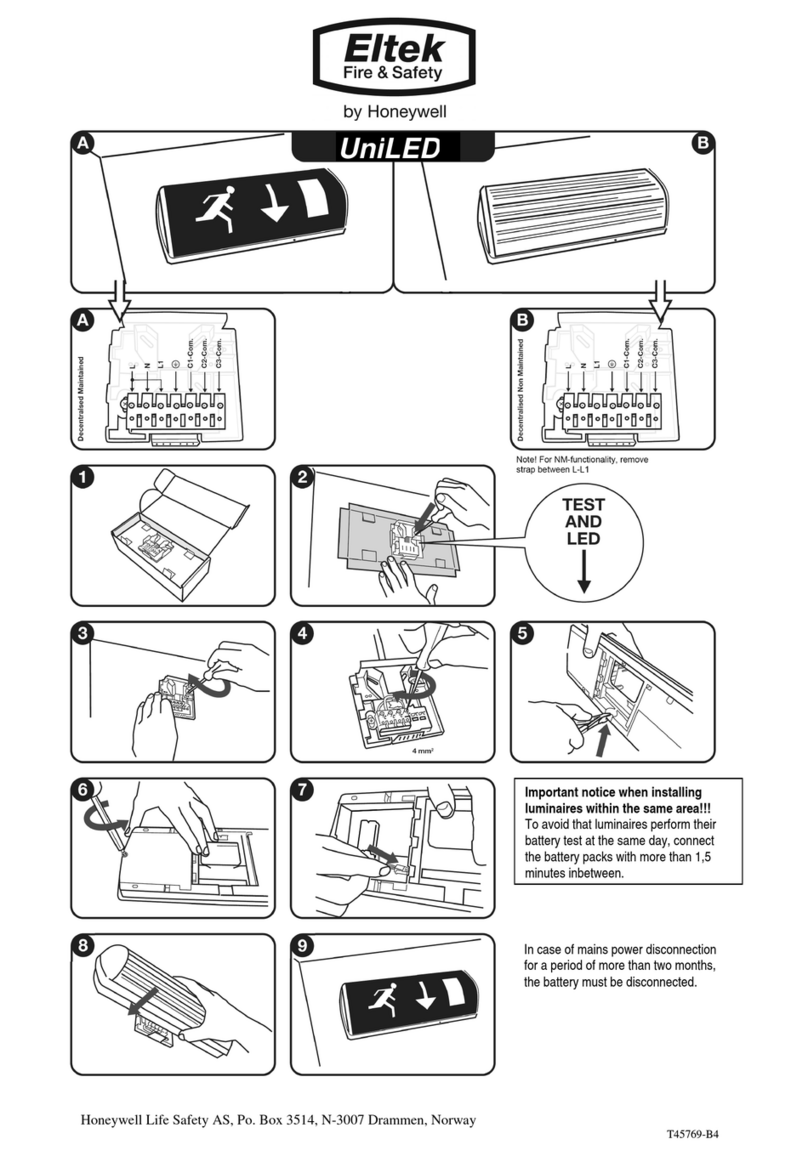

Honeywell

Honeywell Eltek UniLED quick start guide

Cooper Lighting

Cooper Lighting all-pro mst27920les instruction manual

LDR

LDR Nota f1000 plus 120V operating instructions

MELINERA

MELINERA HG02026A-BS Operation and safety notes

YELLOWRIVER

YELLOWRIVER YR-IP1024Q user manual

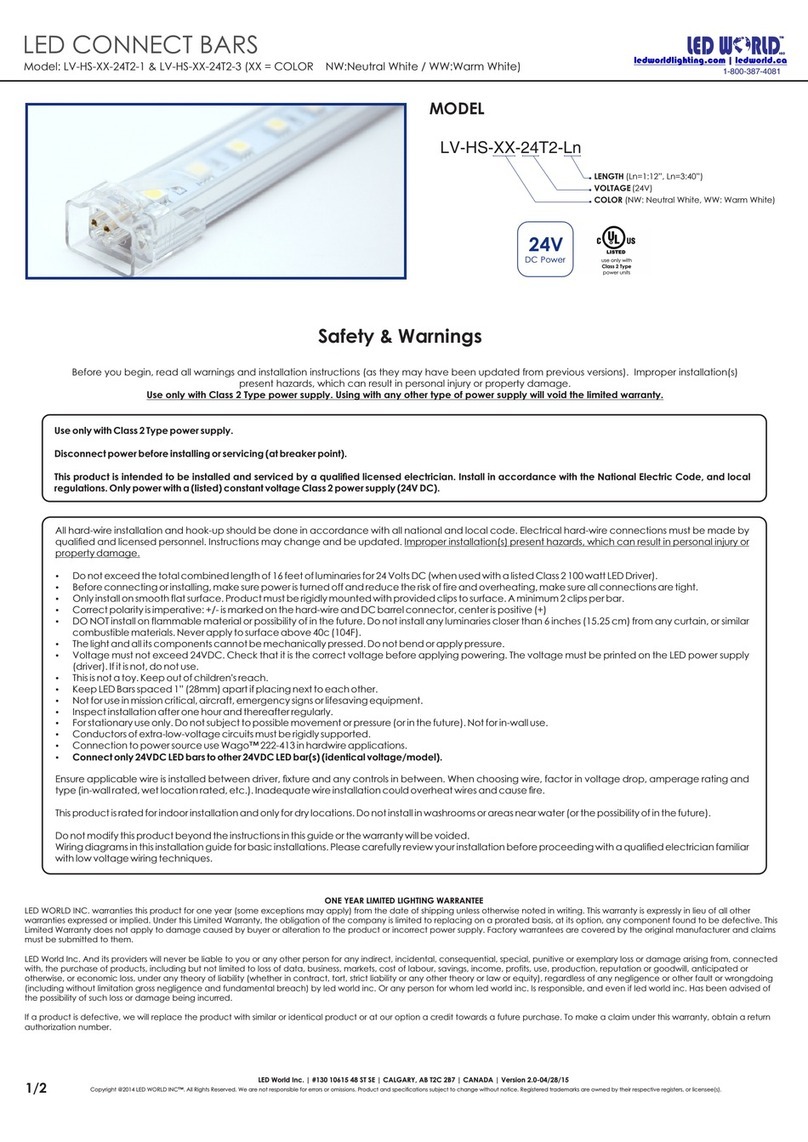

LED World

LED World LV-HS 24T2-1 Series quick start guide

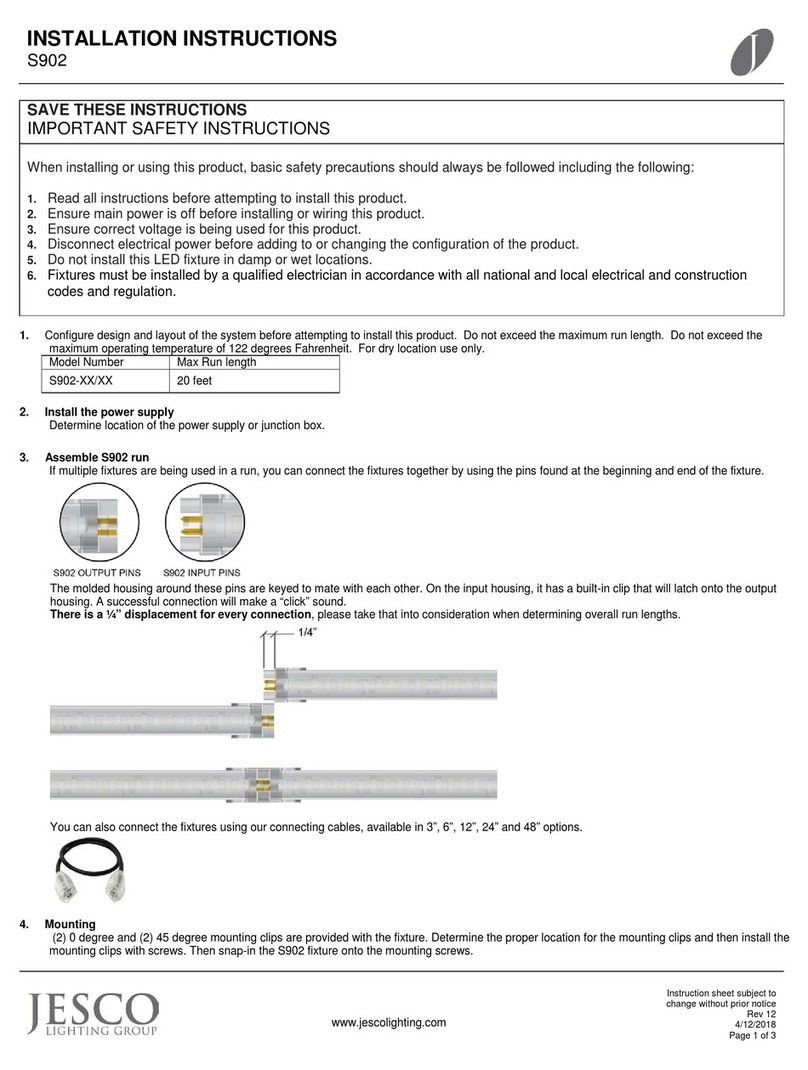

Jesco

Jesco Sleek Plus S902 installation instructions

UltraPro

UltraPro ESCAPE LED Rope Light user manual