Control. Monitor. Protect

»Control. Monitor. Protect

»

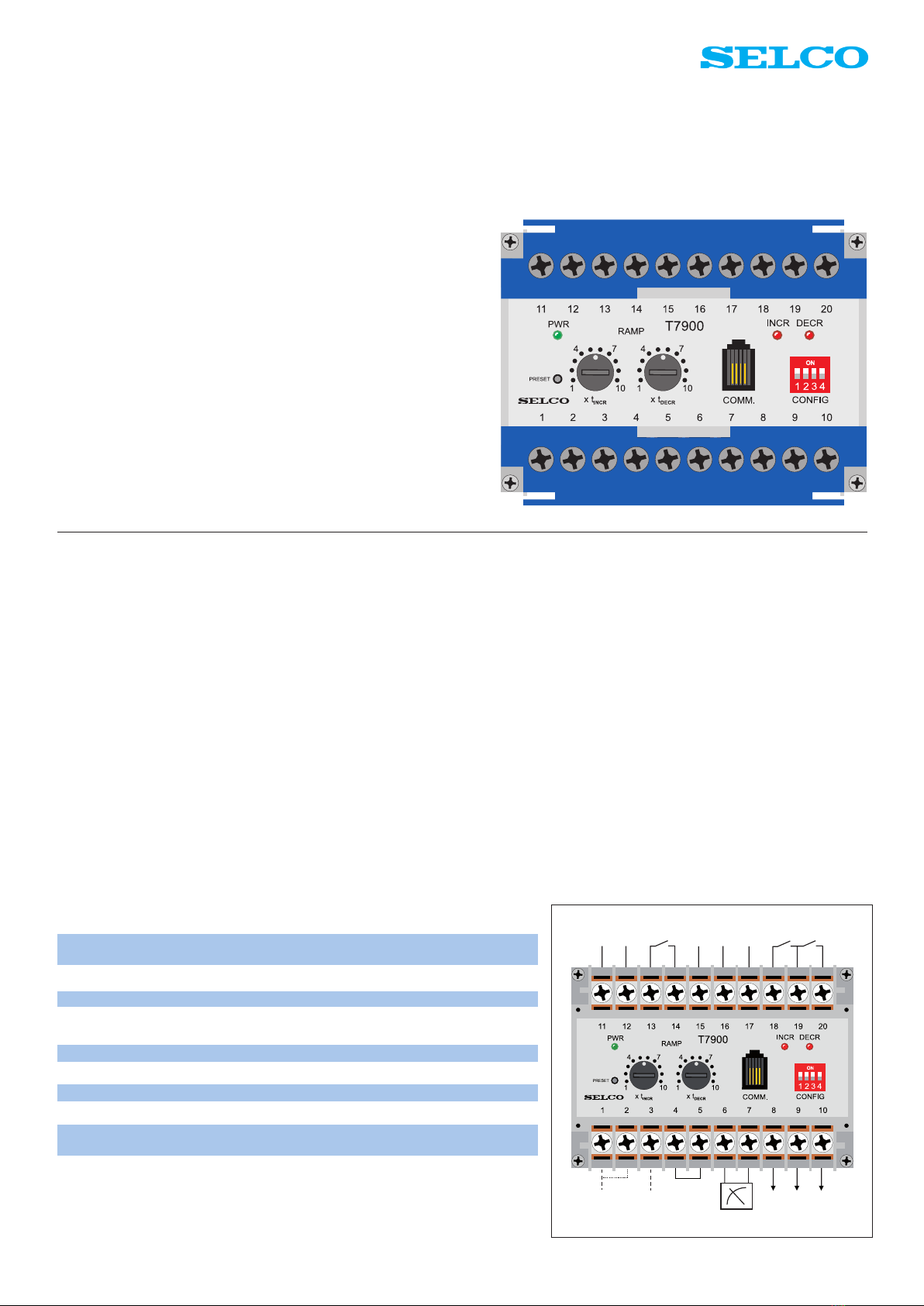

Electronic Potentiometer Function

When the CONFIG dipswitch no. 1 on the

front is OFF, the T7900 will act as an

electronic potentiometer. The output is a

variable voltage, current or pulse width

modulated signal (PWM).

The type and range of output can be

selected via dipswitches on the back of

the unit. This selection should be made in

order to match the input type and range

of the unit to control e.g. an electronic

speed controller. The following can be

selected on the dipswitches:

Setting all dipswitches to ON will put

the unit in programming mode. In

programming mode the unit can be

congured from a PC using a standard

ANSI terminal such as the Windows Hy-

perTerminal. In this case additional out-

put ranges, reference levels and

other parameters can be specied from

the PC. An optional programming kit

G0100 is available for this purpose.

The control inputs are the increase / de-

crease contact inputs on terminals 18

and

20. As long as no increase / decrease

in-

puts have been received, the output sig-

nal will stay at the reference level.

Fig. 2 illustrates the normal output

characteristic. When an increase signal is

applied to the T7900, the output signal

will increase until the increase signal is

interrupted. The ramping of the increase

is determined by the setting of tINCR in

such a way that lower settings will cause

faster ramps.

When a decrease signal is applied to the

T7900, the output signal will decrease

until the decrease signal is interrupted.

The ramping of the decrease is

determined by the setting of tDECR.

When using a PC for conguration, it is

also possible to select a different type of

output characteristic, a so called “rubber

band” output characteristic where the

output automatically goes back to the

reference level when the increase or

decrease signal is interrupted.

In this case, the ramping of the increase

and decrease is a little different. They are

both the same, determined by the setting

of tINCR, whe reas the ramping of going

back to the reference level is now

determined by the setting of tDECR. This

is illustrated in gure 3.

The ramping times tINCR and tDECR can be

set on the two dials on the front panel.

The ramping times have the following

ranges:

0.25 s / V – 2.5 s / V

0.25 s / mA – 2.5 s / mA

0.04 s / % – 0.4s / %

The ramping time tINCR can be multiplied

by 10 by setting the CONFIG dipswitch

3 to on and the ramping time tDECR can be

multiplied by 10 by setting the CONFIG

dipswitch 4 to ON.

2.5 s / V – 25 s / V

2.5 s / mA – 25 s / mA

0.4 s / % – 4s / %

The function of the CONFIG dipswitches

on the front is as follows:

SW1 ON: POWER REF

SW2 ON: INVERT

SW3 ON: INCR ramp*10

SW4 ON DECR ramp*10

Dipswitch no. 1 should be OFF when

T7900 is used as an electronic

potentiometer, and on when T7900 is

used as a power reference unit.

Dipswitch no. 2 can be used for inverting

the output, e. g. going from 10V to 0V

rather than from 0V to 10V. Dipswitches

nos. 3 and 4 are the dipswitches mentio-

ned previously for multiplying the ramp

times by 10.

The output reference level can be set or

changed by adjusting the output signal to

the desired level and then briey activate

the PRESET push button on the front of

the unit.

PWM Output (terminals 10 and REF)

This type of signal is used as input in

some speed controllers (e.g. Woodward

& Caterpillar) because the signal is found

Output signal

(e.g.voltage)

t

INCR

t

DECR

Input pulse signals

INCR

REF

DECR

SW1 SW2 SW3 SW4 Output Ref.

1 2 4 8

OFF OFF OFF OFF -10V – +10V 0V

OFF OFF OFF ON 0V – +10V +5V

OFF OFF ON OFF -5V – +5V 0V

OFF OFF ON ON -10V – 0V -5V

OFF ON OFF OFF -1V – 0V 0V

OFF ON OFF ON 0V – +1V 0V

OFF ON ON OFF 0V – +3V 0V

OFF ON ON ON 0V – +5V 0V

ON OFF OFF OFF 0V – +6V 0V

ON OFF OFF ON -1V – +1V 0V

ON OFF ON OFF -3V -- +3V 0V

ON OFF ON ON

ON ON OFF OFF 10-90% 2.94KHz 50%

ON ON OFF ON 4mA – 20mA 12mA

ON ON ON OFF 10-90% 500Hz 50%PWM

ON ON ON ON PRG. MODE

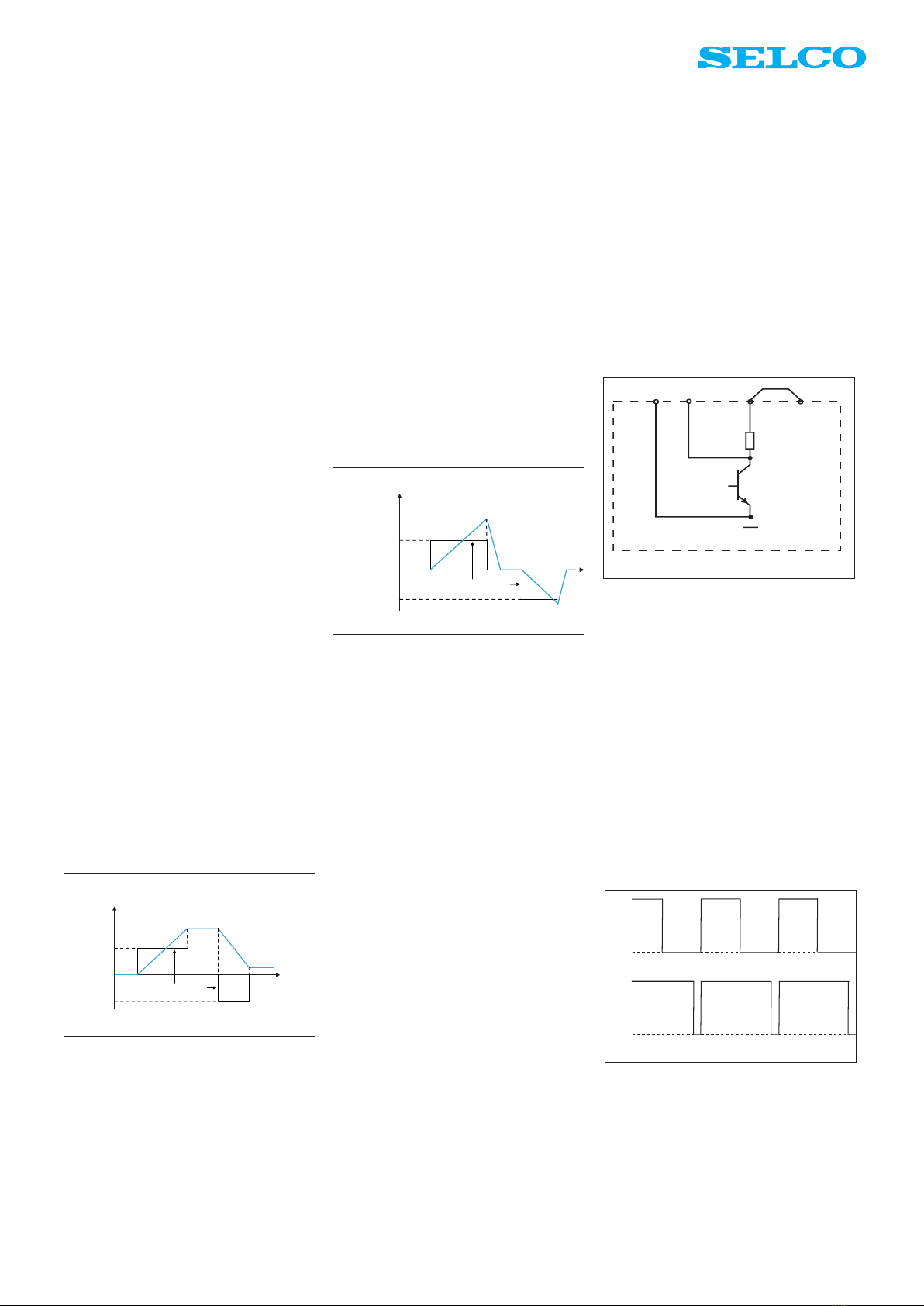

Fig. 2. Normal output characteristic.

Output signal

(e.g. voltage)

t

DECR

t

INCR

t

DECR

Input pulse signals

t

INCR

INCR

REF

DECR

Fig. 3. “Rubber band” output characteristic.

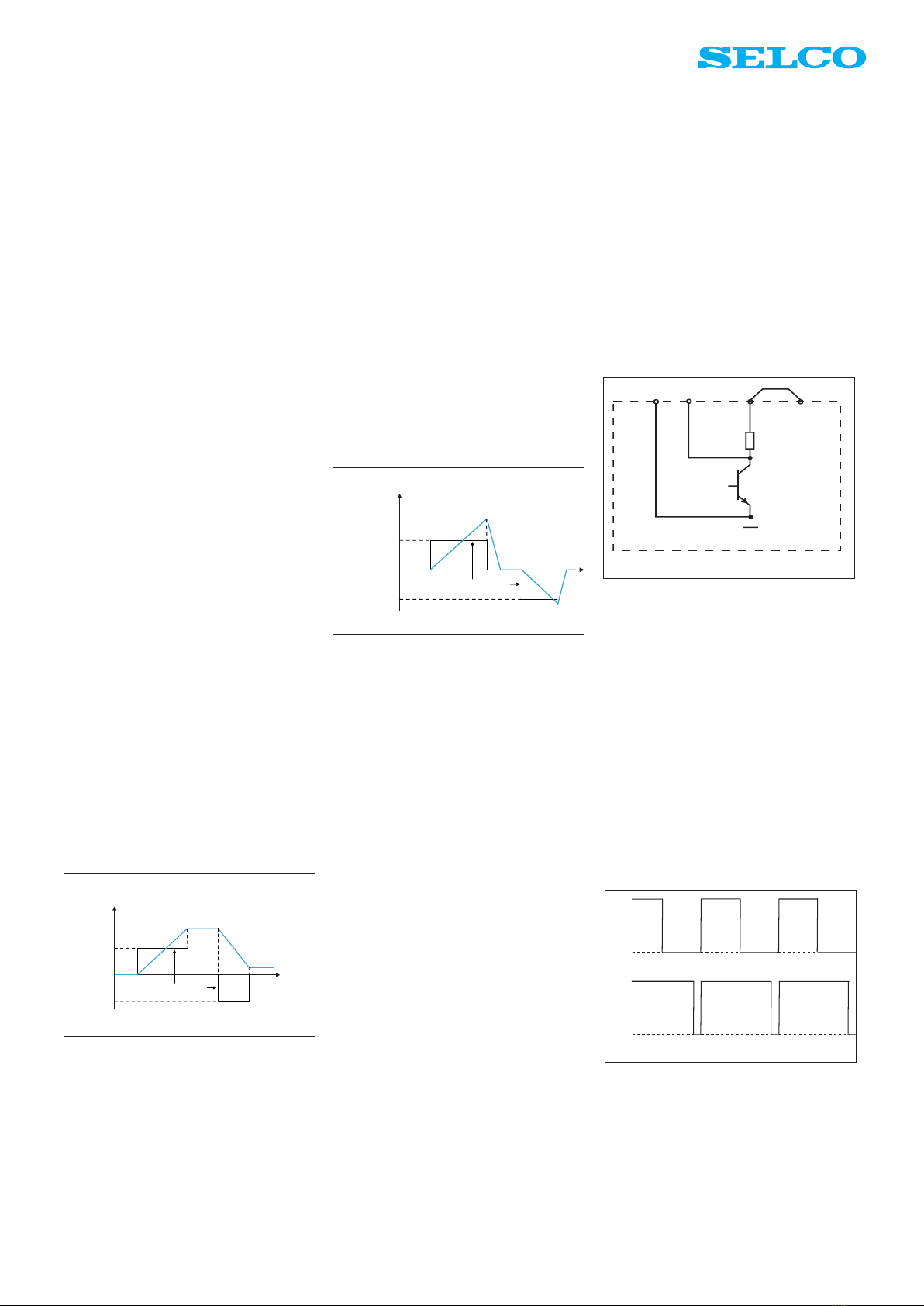

Fig. 5. Pulse width modulated signal (PWM).

The range of the pulse width is 10% - 90%

in default conguration. The reference

point is 50%. Voltage, pulse and REF can

be altered via PC conguration.

Figure 5 illustrates a PWM signal of 50%

and 90%. The default reference is 50%.

However, this can be changed using PC

conguration or by using the PRESET

push button.

Fig. 4. T7900 PWM Output

less sensitive to noise rather than a volta-

ge or current input.

The PWM output of T7900 is an open col-

lector output with a 1kΩ pull up resistor

as shown in gure 4. In factory default

this output gives +10V when the transis-

tor is closed and 0V (REF) when open. Ex-

ternal voltages can be used by removing

the bridge between terminals 4 and 5 and

connecting and external voltage (max. 24

V DC) between terminals 5 and REF.

The frequency of the PWM signal is

500HZ or 2,94 KHz dependending on the

dip switch settings.