Selec ATSEL FD300 User manual

High Performance

AC Drives

Selec Subsidiaries: www.selecusa.com | www.selec-europe.com | www.selecaustralia.comSelec USA: Selec GmbH: Selec Australia:

Selec Controls Pvt. Ltd.

EL-27-1, Electronic Zone, TTC Industrial Area, MIDC, Mahape, Navi Mumbai 400710, INDIA.

Tel.:+91-22-4141 8468 / 452. Fax: +91-22-41418 408. Email: [email protected] | www.selec.com

User Manual Preface

This manual provides you with relevant instructions and precautions

for installation, wiring, function parameter setting, routine maintenance,

troubleshooting and troubleshooting of the inverter.

In order to fully utilize the functions of the product and ensure the safety of

users and equipment, please read this manual carefully before using the

inverter. Improper use may cause the inverter to operate abnormally,

malfunction, reduce the service life, and even cause equipment damage,

personal injury and other accidents!

Please pay special attention to the following safety precautions when

handling this product.

•Please ensure to turn off the power when wiring.

•The AC power cord must never be connected to the inverter output

terminals U, V, W.

•The inverter must be properly grounded.

•There is a high voltage circuit inside the inverter. It is strictly forbidden

to touch the internal parts by hand.

•Only qualified electricians can install, wire, repair and repair the

inverter.

•Install the inverter in a suitable environment to prevent direct exposure

to high temperatures and sunlight, and to avoid splashing of moisture

and water droplets.

•Please perform at least five minutes after the power is turned off

during inspection and maintenance.

•Never modify the parts or circuits inside the inverter by yourself.

•Do not test the voltage inside the inverter.

•This series of products cannot be used in situations that endanger

personal safety.

PREFACE

User ManualUser Manual

1-1 Inspection

Each inverter is subjected to strict quality control before being

shipped from the factory, and is made of enhanced anti-collision packaging.

After the customer unpacks, please check the following items:

1-2 Illustrations for nameplate of FD300

Chapter 1

PRODUCT INFORMATIONCONTENTS

Contents

1

8. Inspection and maintenance

8-1 Maintenance

8-2 Inspection and replacement of consumable parts

8-3 Storage

8-4 Inverter warranty

9. Appendix

Appendix A Modbus communications

Appendix B Brake resistor selection

Appendix C Appearance dimensions and installation dimensions

4. Keypad operation

4-1 Description of the keyboard panel

4-2 Function code modification, view instructions

7. Faults and Solutions

7-1 Fault alarm and Solutions

7-2 Common faults and solution

6. Parameter Instruction

P0 Basic function

P1 First motor parameter

P2 Vector control parameter

P3 V/F control parameter

P4 Input terminal

P5 Output terminal

P6 Start and stop control

P7 Keyboard and display

P8 Accessibility

P9 Failure and protection

PA Process control PID function

PB Swing frequency, fixed length and counting

PC Multi-segment instruction and simple PLC function

PP User password

A0 Torque Control Function

A5 Control optimization parameter

A6 Group AI curve setting

AC AIAO Correction

1. Production information

1-1 I nspection

1-2 Name plate

1-3 Specification of inverter

2. Installation

2-1 Installation environment

2-2 Installation method and space

3. Wiring

3-1 Peripheral device connection

3-2 Standard wiring diagram

3-3 Main circuit terminal description

5. Function parameter

5-1 Basic function parameter

5-2 Monitoring parameter

•Check the package for instructions (with certificate and warranty card).

•Check the inverter nameplate and confirm that it is the product model

you ordered.

•If you ordered any option for the drive, please check to confirm.

•Check if the inverter is damaged during transportation.

MODEL : FD300–3–100-C-CE

POWER : 10HP/7.5KW

INPUT : 10PH 415V ±15% 50/60Hz

OUTPUT : 0–400Hz 17 A

019059037

HIGH POWERED INVERTER

Selec Control Pvt. Ltd

BAR CODE

Product Model

Power

Output Power Specification

Input Power Specification

Item Number

Illustrations for product model of FD300

MODEL : FD300 - 3 - 100 - C- CE

Product Series 3 Phase 10.0HP

RS485

Certification

User ManualUser Manual

Chapter 1 Chapter 1

3

2

Rated

Power kW

Output

current A

45

Rated

voltage V Three-phase 415V

1-3 Name plate

Rated

Power kW

Output

current A

Rated

voltage V Three-phase 415V

Vector control: 0~3200Hz V/F control:0~500Hz

0.5kHz~16kHz (The carrier frequency is

automatically adjusted based on the load features.)

Digital setting: 0.01 Hz

Analog setting: maximum frequency x 0.025%

Standard

functions

Maximum

frequency

Input frequency

resolution

Carrier frequency

Specification

Item

Sensor-less flux vector control (SFVC)

Closed-loop vector control (CLVC) (+PG Card)

Voltage/Frequency (V/F) control

Control mode

0.5Hz/150% (SVC); 0Hz/180%(FVC)

Startup torque

Speed stability

accuracy

1 : 100 (SVC)

Speed range 1 : 1000 (FVC)

±0.5% (SVC) ±0.02% (FVC)

Torque control

accuracy ±5% (FVC)

G type: 60s for 150% of the rated current,

3s for 180% of the rated current

P type: 60s for 120% of the rated current,

3s for 150% of the rated current

Overload capacity

Torque boost Auto boost;

Manual boost: 0.1%~30.0%

Standard

functions

Specification

Item

V/F curve

Straight-line V/F curve

Multi-point V/F curve

N-power V/F curve (1.2-power, 1.4-power,

1.6-power, 1.8-power, square)

V/F separation 2 types: complete separation; half separation

Acc./dec. curve

Straight-line ramp

S-curve ramp

Four groups of acceleration/deceleration time

with the range of 0.00s~65000s

DC braking

DC braking frequency: 0.00 Hz ~ max. frequency

Braking time: 0.0~100.0s

Braking trigger current value: 0.0%~100.0%

JOG control

JOG frequency range: 0.00Hz~50.00 Hz

JOG acceleration/deceleration time: 0.00s~65000s

Built-in PLC,

multiple speeds

It realizes up to 16 speeds via the simple

PLC function or combination of DI terminal states

Built-in PID It realizes closed loop control system easily.

Auto voltage

regulation (AVR)

It can keep constant output voltage automatically

when the mains voltage fluctuation.

Over voltage/Over

current stall

control

The current and voltage are limited automatically

during the running process so as to avoid

frequently tripping due to over voltage/over current.

Rapid current

limit function

It can auto limit running current of frequency

inverter to avoid frequently tripping.

Torque limit and

control

(Excavator characteristics) It can limit the torque

automatically and prevent frequently over current

tripping during the running process.

Torque control can be implemented

in the VC mode.

Indivi-

dualized

functions

High performance

Control of asynchronous motor is implemented

through the high-performance current vector

control technology.

Instant power

off not stop

The load feedback energy compensates the

voltage reduction so that the frequency inverter

can continue to run for a short time.

Rapid current limit To avoid frequently over current faults of the

frequency inverter.

9 13 17 25 32 38 45 60 75 90

55 75 90 110 132 147

110 150 176 210 250 300

3.7 5.5 7.5 11 15 18.5 22 30 37

Specification

Item

Indivi-

dualized

functions

User ManualUser Manual

Chapter 1 Chapter 1

5

4

Virtual IO Five sets of virtual input and output for simple

logic control

Timing control Time range: 0.0~6500.0 minutes

Multi-motor

switching

Four sets of motor parameters for four motor

switching control

Multiple

communication

protocols

Currently supports communication bus via

Modbus-RTU and later will support

PROFIBUS-DP, CAN open, etc.

Motor overheat

protection

The optional I/O extension card enables AI3 to

receive the motor temperature sensor input

(PT100, PT1000) so as to realize motor overheat

protection.

Multiple encoder

types

It supports incremental encoder and encoders such

as differential encoder, open-collector encoder,

resolver, UVW encoder, and SIN/ COS encoder.

Running

command

giving

key panel

Control terminals

Serial communication port

You can switch between these giving in various ways.

Frequency giving

There are 10 kinds frequency giving: digital

setting, analog voltage setting, analog current

setting, pulse setting, serial communication port

setting, panel potentiometer, etc.

You can switch between these giving in various ways.

Run

Auxiliary

frequency

giving

There are 10 kinds auxiliary frequency giving.

It can implement tiny tuning of auxiliary

frequency and frequency synthesis.

Input terminal

Standard:

5 digital input (DI) terminals, one of which

supports up to 100 kHz high-speed pulse input

2 analog input (AI) terminals, support 0V~10 V

voltage input or 0 mA~20 mA current input

Expanding capacity:

5 DI terminals

1 AI terminal supports -10V~+10 V voltage input.

Output terminal

Standard

1 high-speed pulse output terminal (open-collector)

that supports 0–100 kHz square wave signal output

1 digital output (DO) terminal

1 relay output terminal

2 analog output (AO) terminals,

support 0 mA~20 mA current output or

0 V~10 V voltage output.

Expanding capacity:

1 DO terminals

1 relay output terminals

Display

LED display It displays the parameters.

Parameters copy It can implement copy parameters function by

PC software.

Key locking and

function selection

It can lock the keys partially or completely and

define the function range of some keys so as to

prevent disoperation.

Protection mode

Motor short-circuit detection at power-on,

input/output phase loss protection, overcurrent

protection, overvoltage protection, under-voltage

protection, overheat protection and overload

protection, etc.

Altitude Lower than 1000 m

Ambient

temperature

-10°C~ +50°C (If the ambient temperature is

between 40°C and 50°C, the power grade is

reduced for use)

Humidity Less than 95%RH, without condensing

Vibration 2

Less than 5.9 m/s (0.6 g)

Storage temperature

-20°C ~ +60°C

Run

Specification

Item

Indoor, no direct sunlight, dust, corrosive gas,

combustible gas, oil smoke, vapor, drip or salt.

Enviro-

nment

Installation

location

INSTALLATION

2-1 Installation environment

•Locations free of water droplets, vapors, dust and oily dust.

•Non-corrosive, flammable gas and liquid.

•No floating dust metal particles.

•The environment temperature is -10°C ~ 50°C. If the environment

temperature exceeds 40°C, please place it in a well ventilated place

and delete the inverter

•Strong and vibration-free place.

•Locations without electromagnetic noise interference.

2-2 Installation method and space

•The inverter should be installed on a structure that does not burn, such

as metal, otherwise a fire accident may occur.

•The inverter should be installed vertically and securely with screws. Do

not flip, tilt or install horizontally. When the inverter runs, heat is

generated. To ensure the passage of the cooling air, a certain space is

left during installation (as shown in the figure).

•When installing the inverter in the control cabinet, consider ventilation

and heat dissipation to ensure that the ambient temperature of the

inverter does not exceed the specified value. Do not install the inverter

in a closed box with poor ventilation.

•When installing multiple inverters in the same control cabinet, it is

recommended to install them side by side in order to reduce the

thermal impact between each other. If it is necessary to install up and

down, a partition plate must be provided to reduce the influence of heat

generated in the lower part on the upper part (as shown in the figure).

•Do not allow foreign matter such as various fibers, paper sheets, chips

(chips) or metal fragments to enter the inverter.

50mm 50mm

≥100mm

≥100mm

UP

Right

CONVERTER

CONVERTER

CONVERTER

User ManualUser Manual

Chapter 2 Chapter 3

7

6

Installation size

Power level

≤15kw

18.5~30kw

≥37kw ≥50mm ≥300mm

≥50mm ≥200mm

≥20mm ≥100mm

A B

WIRING

In order to ensure the safety of operators and inverters, it is

necessary to be operated by qualified professional electricians. The

following are special considerations when wiring :

3-1 Peripheral device connection

•Make sure the input power is off before wiring.

•The ground terminal of the inverter must be reliably grounded.

•Verify that the rated voltage of the inverter matches the AC power

supply voltage.

•The power cable must be connected to the R, S, and T terminals of the

inverter. The motor cable should be connected to the U, V, and W

terminals. Do not connect the fault. Otherwise, the inverter will be

damaged internally.

•Confirm that the terminals and wires are reliably connected, and the

screws of the main circuit terminals are secured.

•Do not touch the main circuit terminals, otherwise there is danger of

electric shock.

Breaker AC reactor Electromagnetic

contactor Noise Filter Braking Unit Noise Filter

Name

Select the

appropriate

model, the

rated current

is not less than

1.5 times the

rated current

of the inverter

Used to

improve

input power

factor

Instruction

Configuration

Three-phase

power

Braking

unit

(+) (-)

R U

SV

T W

M

Used to

control power

on and off

Used to

reduce the

radio

interference

generated

by the

inverter

It is optional when

the braking torque

can’t meet the

requirements

of use. It is

suitable for large

inertia load and f

frequent start and

stop.

It is used to

reduce the

radio

interference

on the output

side of the

inverter.

MC

Braking unit AC output reactor

Braking resistor

Motor

Use within the allowable power supply

specification of the AC drive

Select a proper breaker to resist large

in-rush current that flows into the AC drive

at power-on.

To guarantee safety, use an electromagnetic

contactor. Do not use it to start or stop

the AC drive because such operation reduces

the service life of the AC drive.

Suppress the high order harmonic to improve

the power factor.

Three-phase AC

power supply

Moulded case circuit

breaker (MCCB) or earth

leakage circuit breaker

(ELCB)

Electromagnetic

contactor

AC input

react or

Noise filter on

input side

Reduce the

electromagnetic

interference on

the input side

Reliably ground the motor and

the AC drive to prevent electric

shock.

Braking unit AC output reactor

Braking resistor

Motor

Use within the allowable power supply

specification of the AC drive

Select a proper breaker to resist large

in-rush current that flows into the AC drive

at power-on.

To guarantee safety, use an electromagnetic

contactor. Do not use it to start or stop

the AC drive because such operation reduces

the service life of the AC drive.

Suppress the high order harmonic to improve

the power factor.

Three-phase AC

power supply

Moulded case circuit

breaker (MCCB) or earth

leakage circuit breaker

(ELCB)

Electromagnetic

contactor

AC input

react or

Noise filter on

input side

Reduce the

electromagnetic

interference on

the input side

Reliably ground the motor and

the AC drive to prevent electric

shock.

User ManualUser Manual

Chapter 3 Chapter 3

3-2-1 Standard wiring diagram for FD300

9

8

Braking resistor

QF MC

R/L1

S/L2

T/L3 T

S

R

B1 B2

U

W

V

PE

M

FWD

External fault

REV

Multi-phase

reference velocity 1

Common terminal

X1 Input terminal 1

X2 Input terminal 2

X3 Input terminal 3

X4 Input terminal 4

COM

PE

COM

X5 Input terminal 5

CN1

0-10V Input

0-20VmA Input

Potentio-

meter

3-5K

+10V Frequency setting

power supply

AI1 Multi-functional

Analog input

AI2 Jumper 3

GND

PE

0-20mA

AI2

0-10V

Jumper 4

0-20mA

AO

0-10V

AO

GND

Analog output

Default setting:

operating frequency

0-10V/0-20mA

15V

485+

485-

GND

485 communication

+24V

port

Y1

8

Default setting:

Run command

ROA

ROB

ROC

Default setting:

Fault output

Output of relay

FD100

BR

RY1

3 phase power supply

Single phase 220V inverter

input connect with L N

415V±15%, 50/60Hz

Frequency given

0-10V

MC

R/L

S/N

T

R

S

T

X1

X2

X3

X4

X5

COM

PE

+10V

AI1

AI2

GND

PE

Input 0-20mA

Input 0-10V

W

V

U

PE

QF

B1 B2

AO out

RY1

ROA

ROB

ROC

M

J3

0-10V

AI2

0-20mA

+24V

Y1

J5

Default setting

Three-wire control

mode

3-5K

AO

GND

PE

Motor

grounding

Grounding of

power measurement

J4

0-10V

AO

0-20mA

COM

Main

circuit

Control circuit

1

3

5

7

485+

485-

FWD

REV

Multi-phase

reference velocity 1

Multi-phase

reference velocity 2

Input terminal 1

Input terminal 2

Input terminal 3

Input terminal 4

Default setting:

operating frequency

0-10V / 0-20mA

Default setting:

Run indication

Output of relay

Current is less than 30mA

Output of relay

Default setting:

Fault output

Potentiometer

Preset frequency

0-10V

Power for

frequency

setting

Multi-functional AI

Three-phase source 415V ±15%

Single-phase source 220V ±15%

50/60Hz

3-3 Main circuit terminal description

Terminal

symbol (code) Functional descriptions

Power input terminal for three-phase 380V inverter.

(Power input terminal for single-phase 220V inverter)

The inverter output terminal is connected to a 3phase AC motor.

Braking resistor connection terminal (optional)

External brake unit connection terminal (optional).

Ground terminal.

R, S, T

L,N

U, V, W

B1, B2

(+), (-)

When wiring, please follow the electrical regulations to ensure the safety.

3-3-1 Power input terminal R, S,T

ŸIn order to prevent the high voltage and high current input into the power

supply circuit and damage the rectifier part, it is necessary to connect the

AC reactor on the input side, and also improve the power factor of the

input side.

ŸDo not use the main circuit power ON/OFF method to control the

operation and stop of the inverter. The drive's operation and stop should

be controlled using the RUN and STOP keys on the keypad panel or the

control loop terminals. If the main power ON/OFF method must be used

to control the operation of the inverter, it can only be performed once per

hour.

ŸA circuit breaker is required between the three-phase AC input power

supply and the main circuit terminals (R, S and T). It is better to connect a

magnetic contactor (MC) in series to cut off the power supply when the

inverter protection function is activated (the R-C surge absorber is

required at both ends of the electromagnetic contactor).

ŸTo reduce the interference of the inverter to surrounding equipment, the

noise filter can be connected to the input side.

ŸIf the inverter is equipped with an earth leakage circuit breaker as a

leakage fault protection, in order to prevent the leakage circuit breaker

from malfunctioning, please select a sensitivity current of 200 mA or

more and an operation time of 0.1 second or longer.

ŸDo not connect the three-phase power supply to the single-phase power

supply.

Braking

unit

BR

BR

Three-phase source 380V±15%

50/60Hz

Single-phase source 220V±15%

R/L

S/N

T

QF MC

R

S

T

(+)/B1 B2 (-)

U

V

W

PE PE

Main Circuit M

Motor

grounding

Grounding of power

measurement

FWD

REV

Non-function

Default setting

X1

X2

X3

X4

X6

X5

COM

PE

AO

GND

+24V

Y1

COM

Y2

COM

ROA

Input terminal 1

Input terminal 2

Input terminal 3

Input terminal 4

Input terminal 6

Input terminal 5

AO out

RY1

RY2

Default setting :

Operating

frequency

0-10V / 0-20mA

Default setting :

Run indication

Default setting :

Direction

indication

Output of relay

Current is less than 30mA

Output of relay

Default setting :

Fault output

Non-function

Non-function

Non-function

ROB

ROC

Preset frequency

0-10V

Potentiometer

3-5K

Input 0-10V

Input 0-20mA

+10V

AI1

AI2

GND

PE

Control Circuit

Power for

frequency

setting

Multi-functional AI

J13

0-20mA

AO

0-10V

J1

0-20mA

AI2 J2

0-10V

User Manual Chapter 3

MC

R/L1

S/L2

T/L3

R

S

T

X1

X2

X3

X4

X5

X6

COM

Input terminal 1

+10V

AI1

AI2

GND

PE

Frequency given

0-10V

0-20mA Input

0-10V Input J4 jumper

Frequency setting

power supply

Multi-function

analog inout

W

V

U

PE

QF (+)/B1 B2 (-)

Braking unit

BR

Analog output 0-10V/0-20mA

RY1

ROA

ROB

ROC

Relay output

RY2

M

Breaker pull-in,

current less than 30A

0-10V

AI2

0-20mA

J5 jumper

0-10V

AO

0-20mA

+24V

Y1

Y2

BR

External keyboard port

J13

FWD

REV

External fault

Multi-pase reference

velocity 1

Default:Running

frequency

Default:

running

indication

Default:

Direction

indication

(Default: Fault output)

Potentio-

meter

3-5K

Common terminal

AO

GND

485+

485-

GND

RS485 communication

Braking resistor

Input terminal 2

Input terminal 3

Input terminal 4

Input terminal 5

Input terminal 6

Multi-pase reference

velocity 2

Multi-pase reference

velocity 3

Default

settings

3 phase power supply

Single phase 220V inverter

input connect with L N

415V±15%, 50/60Hz

PE

User Manual

Chapter 3

11

10

3-3-2 Connection of inverter output terminals U, V, W

ŸThe inverter output terminals are connected to the 3-phase motor in the

correct phase sequence. If the motor rotates in the wrong direction, the

wiring of any two phases of U, V, and W can be exchanged.

ŸThe output side of the inverter cannot be connected to the capacitor and

the surge absorber.

ŸWhen the wiring between the inverter and the motor exceeds 50 meters,

the distributed capacitance between the lines will generate a large

leakage current, which may cause the inverter to over-current trip. At the

same time, in order to avoid damage to the motor insulation, the output

reactor must be compensated. .

ŸIf the installation location of the inverter is quite sensitive to interference,

please install an output noise filter to reduce the carrier frequency of the

inverter and reduce interference.

3-3-3 Braking resistor and brake unit connection

ŸWhen the load inertia is large and it is necessary to stop frequently or stop

for a short time, when the braking capacity of the inverter is insufficient or

to increase the braking torque, etc., the braking resistor or the braking

unit may be selected as needed.

ŸWhen the inverter has no built-in braking unit, the main circuit (+) and (-)

terminals are connected to the external braking unit.

ŸDo not connect the main circuit (+) and (-) terminals to the braking

resistor.

ŸThe main circuit B1, B2 terminal is connected to the braking resistor

(there is B1, B2 terminal indicates that the inverter has built-in braking

unit).

3-3-4 Inverter Grounding Terminal PE

ŸFor safety and noise reduction, the ground terminal PE of the inverter

must be well grounded.

ŸUse the specified standard grounding wire and be as short and thick as

possible (grounding impedance 10Ω or less).

ŸThe grounding wire of the inverter must not be grounded together with

large current loads such as electric welders and high-power motors, but

must be grounded separately.

ŸThe power supply line generally adopts 5 core wires, of which 3 are fire

wires, 1 neutral wire, and 1 ground wire. It is strictly forbidden to use the

neutral wire as ground wire.

ŸWhen multiple inverters are installed together, all inverters must be

directly connected to the common ground.

(a) correct (b) not recommend (c) error

3-4 Control circuit terminal description

Terminal description &

default setting

Classification Mark Terminal name

Multi-functional

input

X1

X2

X3

X4

X6

COM

Multi-functional input

terminal 1 Default setting : Forward

Multi-functional input

terminal 2 Default setting : Reverse

Multi-functional input

terminal 3 Default setting : No function

Multi-functional input

terminal 4 Default setting : No function

Multi-functional input

terminal 6

Default setting : No function

can be used as a high

speed pulse input

Public terminal

Multi-functional input common

+24V power supply

reference groung

CN1

Needle base

COM

X5

RS485

485- 485+

8 7 6 543 21

6 543

Please refer to the following illustration:

+24V Y1 Y2 X1 X2 X3 X4 AO 485- 485+

ROA ROB ROC COM X5 X6 GND AI1 AI2 +10V

X5 Multi-functional input

terminal 5 Default setting : No function

PRG FUNC

ESC

JOG

REV

STOP

RESET

RUN

Hz V

A

RPM %

L/R F/R

RUN

-

+

Positive and negative

indicator

light on: reverse

light off: forward

Multi-function

selection button

Stop/reset button

Display information

and return button

Running

Increment button

Decrement button

Command source

Light on: terminal control

Light off: key pad control

Running indicator

Potentiometer

Shift button

Programming

button

Current

indication

Unit indicator

Voltage

indication

Unit indicator

Running indicator

Command source indicator

Light on: terminal control

Light off: key pad control

Blinking: communication control

Potentiometer

Programming button

Running

Tuning/torque control fault

indicator

Positive and negative indicator

Light on: reverse

Light off :forward

enter

Increment button

Shift button

Decrement button

Stop/reset button

Multi-function selection button

PRG FUNC

ESC

JOG

REV

STOP

RESET

RUN

Hz V

A

RPM %

L/R F/R

RUN

-

+

Positive and negative

indicator

light on: reverse

light off: forward

Multi-function

selection button

Stop/reset button

Display information

and return button

Running

Increment button

Decrement button

Command source

Light on: terminal control

Light off: key pad control

Running indicator

Potentiometer

Shift button

Programming

button

Current

indication

Unit indicator

Voltage

indication

User Manual Chapter 4

User Manual

Chapter 3

13

12

Terminal description &

default setting

Classification Mark Terminal name

AI1

AI2

+10V

Analog input

GND

Analog input 1 0~10V input

0~10V/0~20mA input

(J2 jumper is optional)

+10V DC 10mA

(potentiometer 3~5K)

Analog power

supply

Analog input-output reference

ground

Analog reference

ground

Multi-

functional

output

Y1

ROA

Default setting :

Inverter fault output

Relay output

ROA-ROB

(normally closed)

ROA-ROC

(normally opened)

ROB

ROC

Multi-functional output

terminal 1 Default setting : Running

Y2 Multi-functional output

terminal 2

Default setting : No output, can be

used as high speed pulse output

0~10V/0~20mA output (J1-

jumper is optional)

GND means ground

Analog output

Power supply

AO

+24V

Analog output terminal

+24V power +24V DC 100mA

COM power ground

Use a multi-core shielded cable or stranded wire to connect the

control terminals. When using a shielded cable (on one end of the drive), it

should be connected to the ground terminal PE of the drive. When wiring, the

control cable should be away from the main circuit and high-voltage lines

(including power lines, motor lines, relays, contactors, etc.) more than 20CM,

and avoid parallel placement. It is recommended to use vertical wiring to

prevent external interference from generating inverter errors action.

Analog input 2

485+ Standard RS-485 serial

communication interface

Please use twisted pair

or shielded wire

485 Positive signal

485-

Communi-

cation 485 Negative signal

KEYPAD OPERATION

4-1 Description of the keyboard panel

Keyboard panel

RUN When the light is off, the inverter is in the stop state. When the

light is on, the inverter is in the running state.

L/R

Keyboard operation, terminal operation and communication

operation indicator, the light off indicates the keyboard operation

control status, the light is on indicates the terminal operation

control status, and the light flashes to indicate that it is in the

communication operation control state.

F/R Positive and negative indicators, when the light is on, it indicates

that it is in reverse running mode.

Panel indicator description

TUNE

Tuning/torque control/fault indicator. When the light is on, it indicates

that it is in the torque control mode. When the light is flashing slowly,

it indicates that it is in the tuning state. If the light is flashing,

it indicates that it is in the fault state.

Hz

Lights indicate

frequency units

Lights up to indicate

current unit

The light is on to indicate

the voltage unit

A V

RMP The Hz lamp and the A lamp are simultaneously lit to indicate the

speed unit.

%The A and V lamps are lit at the same time to indicate the

percentage unit.

Positive and negative

indicator

light on: reverse

light off: forward

Multi-function

selection button

Stop/reset button

Display information

and return button

Increment button

Decrement button

Command source

Light on: terminal control

Light off: key pad control

Running indicator

Potentiometer

Date display

Voltage indication

Frequency indication

Current indication

Programming key

Shift key

RUN key

Running indicator

Potentiometer

Confirm key

Increment key

Multi-function key

Decrement key

Stop / Reset key

Command source

light on : terminal control

light off : Key pad control

light blinking : modus control

Positive & negative indicator

light off : forward

light on : reverse

User ManualUser Manual

Chapter 4 Chapter 4

3) Digital display area : A total of 5 LED displays, which can display the

set frequency, output frequency, various monitoring data and alarm codes,

etc.

Name

15

14

Positive and negative

indicator

light on: reverse

light off: forward

Multi-function

selection button

Stop/reset button

Display information

and return button

Running

Increment button

Decrement button

Command source

Light on: terminal control

Light off: key pad control

Running indicator

Potentiometer

Shift button

Programming

button

Current

indication

Unit indicator

Voltage

indication

Keyboard button description

Button Function

Programming

key Enter or exit menu level I.

Confirm key Enter the menu interfaces level by level,

and confirm the parameter setting.

Increasing

key Increase data or function code.

Decreasing

key Decrease data or function code.

Menu move

selection /

monitoring

key

Select the displayed parameters in turn in the stop or

running state, and select the digit to be modified

when modifying parameters.

Running key Start the frequency inverter in the operation panel

control mode.

Stop/Reset

key

Stop the operation when it is in the running state and

perform the reset operation when it is in the fault

state. The functions of this key are restricted by P7-02.

Multifunction

key

Perform function switch over (such as quick switch

over of command source or direction) according to

the setting of P7-01.

Potentio-

meter knob

Regulate the speed directly by panel potentiometer

when P0-03 is set to 4.

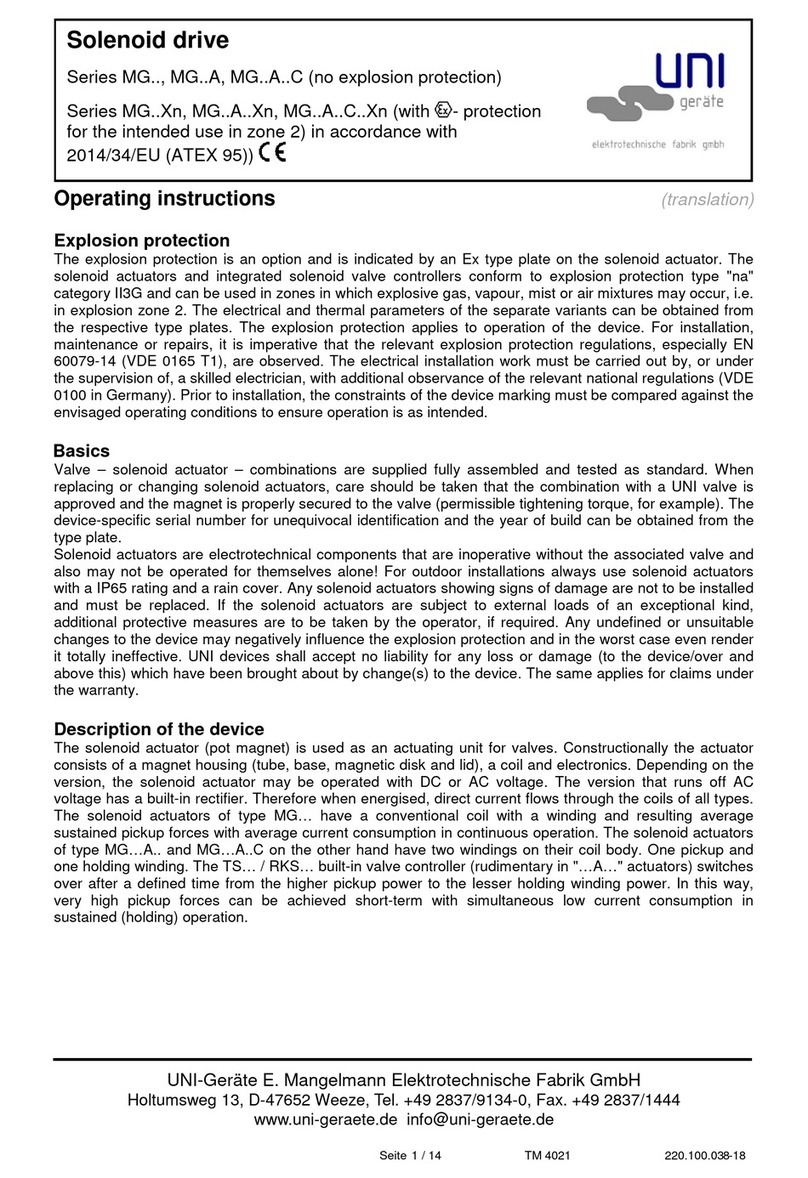

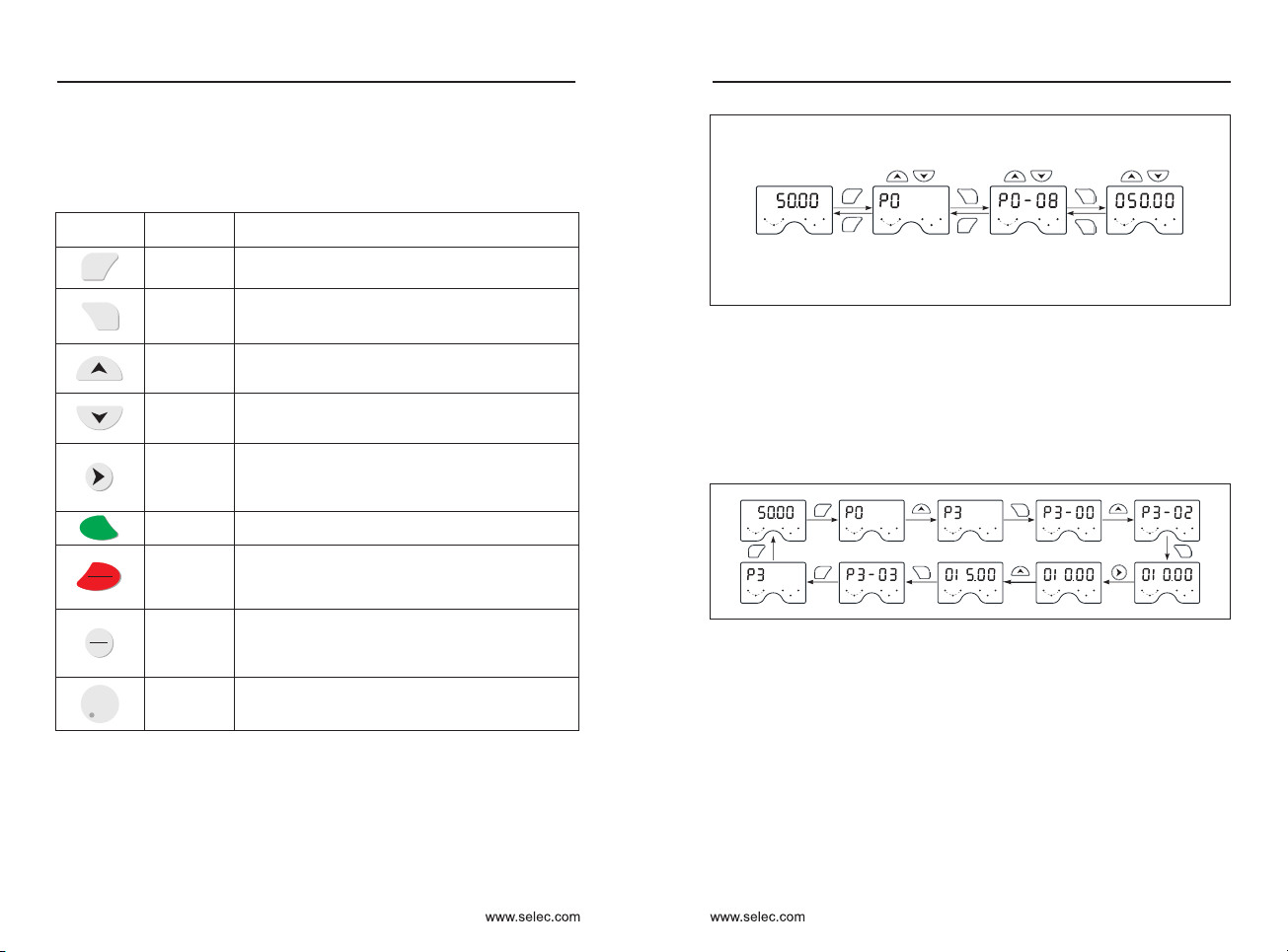

4-2 Function code modification, view instructions

Function code modification instructions

The operation panel of the inverter adopts a three-level menu structure for

parameter setting and other operations. The three levels of menu are:

function parameter group (first level menu) → function code

(second level menu) → function code setting value (third level menu).

The operation process is shown in Figure 4-2.

Status parameter

(default display)

Select the function

code group

Select the

function code

Set the value of

the function code

Level-I menu Level-II menu Level-III menu

Example: An example of changing the function code P3-02 from 10.00 Hz to

15.00 Hz. (black mark indicates flashing bit)

Note: When operating in a three-level menu, press the PRG or ENTER key to

return to the secondary menu. The difference between the two is: press the

ENTER key to save the set parameters and return to the second level menu,

and automatically transfer to the next function code; press the PRG key to

return directly to the second level menu, do not store the parameters, and

return to the current function code .

In the third level menu, if there is no flashing bit in the parameter, it means that

the function code cannot be modified. The possible reasons are as follows:

a) The function code is an unmodifiable parameter. Such as the actual

detection parameters, operating record parameters.

b) The function code cannot be modified in the running state, and can be

modified after it needs to be stopped.

How to view status parameters

In the stop or running state, the shift key can be used to switch between

displaying various status parameters. The function code P7-03 (operation

parameter 1), P7-04 (operation parameter 2), P7-05 (stop parameter) is

selected according to the binary bit to display whether the parameter is

displayed.

PRG

FUNC

ESC

JOG

REV

STOP

RESET

RUN

PRG

PRG

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN PRG

Enter

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

Enter

Enter

50.00 050.00P0 P0-08

Change

parameter group

Change function

parameter selection

Change function

parameter value

PRG Enter Enter

Enter

PRG

PRG

PRG Menu

level1

Menu

level2

Menu

level3

Figure 4-2 Three-level menu operation flow Chart

PRG

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

PRG

PRG

Hz V

A

RPM %

L/R F/R

RUN

Enter

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

Enter

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

Enter

Hz V

A

RPM %

L/R F/R

RUN

Hz V

A

RPM %

L/R F/R

RUN

ENTER

User Manual Chapter 4

User Manual

Chapter 4

17

16

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

PRG PRG PRG PRG

FUNC

ESC

PRG

FUNC

ESC PRG

Basic information

Main Menu

Secondary Menu

Date

Setting

Frequency

Operating

Frequency

Output

current Bar voltage Other

information

Data storage

and return

Basic information

Main Menu

Secondary Menu

Data

Setting frequency Operating frequency Output current Bar voltage Other information

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

FUNC

ESC

PRG PRG PRG PRG

PRG

PRG

PRG

data storage and return

- - -

-+

-+

-+

-+

-+

-+

4-2 Illustrations of keyboard operation

FUNC

ESC

Other

information

FUNC

ESC

Bar voltage

FUNC

ESC

Output

current

Operating

frequency

FUNC

ESC

Setting

frequency

Basic information

PRG

PRG

FUNC

ESC

PRGPRG

FUNC

ESC

PRG

PRG

Main Menu

Secondary Menu

Data

P7-05=0000 0000 0011 0011B=33.

For example, in the stop state, P7-05 (stop parameter) is set to 33.

In the running state, P7-03 (operation parameter 1) is set to 7F.

The 7 status parameters of Bit00/Bit01/Bit03/Bit03/Bit04/Bit05/Bit06 are

selected: running frequency, set frequency, bus voltage, output voltage,

output current, output Power, output torque, key sequence switching to

display the selected parameters,

The four status parameters of Bit00/Bit01/Bit04/Bit05 are selected: set

frequency, bus voltage, AI1 voltage, AI2 voltage, and the key sequence

switches to display the selected parameter.

P7-05=0000 0000 0111 1111B=7F

After the inverter is powered off and then powered on, the displayed

parameters are defaulted to the parameters selected before the inverter is

powered down.

P7-03

LED

Running

display

parameters1

Bit12: Count value Bit13: Length value

Bit14: Load speed display Bit15: PID set up

Bit8: Output status Bit9: AI1 Voltage(V)

Bit10: AI2 Voltage (V) Bit11: AI3 Voltage(V)

0000~FFFF

Bit0: Operating frequency 1 (Hz)

Bit1: Setting frequency(Hz)

Bit2: bus voltage (V) Bit3: The output voltage(V)

Bit4: Output current(A) Bit5: Output Power(KW)

Bit6: Output current(%) Bit7: Input status

LED

Running

display

parameters2

LED Stop

display

parameter

P7-04

0000~FFFF

Bit4:Remaining running time

Bit6:AI2 Pre-correction voltage(V)

Bit0:PID Feedback

Bit7:AI3 Pre-correction voltage(V)

Bit10:Current running time(Min)

Bit2:Pulse input frequency(kHz )

Bit11:PULSE Input pulse frequency(Hz)

Bit1:PLC Stage

Bit9:Current power-on time(Hour)

Bit8:Line speed

Bit13:Encoder feedback speed(Hz)

Bit12:Communication setting

Bit14:Main frequency X display(Hz)

Bit15:Auxiliary frequency Y display(Hz)

Bit3:Operating frequency 2(Hz)

Bit5:AI1 Pre-correction voltage(V)

Bit10: Load speed Bit11: PID set

Bit08: Length value Bit09: PLC stage

Bit06: AI3 Voltage (V) Bit07: Count value

0000~FFFF

Bit12: PULSE Input pulse frequency (kHz)

Bit04: AI1 Voltage (V) Bit05: AI2 Voltage (V)

Bit00: Setting frequency (Hz) Bit01: bus voltage (V)

Bit02: X Input status Bit03: DO Output status

P7-05

User password setting

The inverter provides the user password protection function. When PP-00 is

set to non-zero, it is the user password. Exiting the function code editing

status password protection takes effect. Press PRG again, “-----” will be

displayed. Enter the user password correctly to enter the normal menu,

otherwise you will not be able to enter, so you must remember the password

after setting the user password.

To cancel the password protection function, only enter with a password and

set PP-00 to 0.

User Manual Chapter 5

5-1 Function parameters table

P0: Basic function parameters

Function

Code

Parameter

Name

Setting Range Default Proper-

ty

Modbus

Address

P0-00

GP type

1 : G (Constant torque

load model)

2 : P (Fan, pump type

load model)

1

P0-01

0 : Speed sensorless vector

control (SVC)

1 : Speed sensor vector

control (FVC)

2 : V/F control

0●

P0-02 0

P0-03

0 : Digital setting (non-retentive

at power failure)

1 : Digital setting (retentive at

power failure)

2 : AI1

3 : AI2

4 : panel potentiometer

5: Pulse setting (X6)

6 : Multi-segment instruction

7 : Simple PLC

8: PID

9 : Communication given

0

0 : Operation panel command

channel(LED close)

1 : Terminal command channel

(LED open)

2 : Communication command

channel(LED Flashing)

Converter must be switched off immediately by pushing the button

STOP/RESET if there is anything goes wrong with converter or motor; meanwhile,

please refer to Chapter 7 Fault Correcting to find out the reason why it

malfunctions. Even it is shut off, output terminals (U, V, W) may still cause electric

shock to anyone who touches them unless power ports (R, S, T) are disconnected

from main circuit.

Additionally, it will take some times for filter capacitor to discharge because

there is still charging voltage stored in the filter capacitor even main power source

is shut off. Charging indicator will be off if main power source is shut off; voltage in

the middle DC circuit must be tested by voltmeter. Only after it's confirmed that the

voltage is lower than specified value can internal circuit be touched.

5-2 Quick debugging

Start

Select preset

frequency (P0~01)

Select running &

control mode (P0~02)

Select Starting

mode (P2-00~04)

Select Acc-Dec time

(P0-04/P0-05)

Select running

direction (P0-06)

Select half mode

(P2-05~08)

Starting & Observing

Optimization of

parameters

P0-01

0 : Preset frequency

1 : Preset panel potentiometer

2 : Preset external Ai1

3 : Preset external Ai2

0 : Keyboard control

1 : Running by terminal,

effective control by STOP key

2 : Running by terminals,

ineffective control by STOP key

3 : Controlled by communication

0 : Starting directly

1 : Starting after DC braking

P0-02

P2-00

P0-06 0 : Default direction

1 : Reverse direction

P2-05

0 : Freely stopping

1 : Stopping by decelerating

2 : Decelerating-DC braking

stopping

User Manual

Chapter 5

19

18

“●”: Indicates that this parameter cannot be changed while the inverter is running.

“○”: Indicates that this parameter can be changed while the inverter is running or

stopped.

“×”: Indicates that this parameter is only the actual detected record value and

cannot be changed.

PP-00 is set to a non-zero value, that is, the parameter protection password is set.

The parameter menu must be entered after the password is entered correctly. To

cancel the password, set PP-00 to 00000.

FUNCTION PARAMETER

×

Speed

control

mode

selection

Run

command

source

selection

Main

frequency

source

X selection

Preset

frequency

0.00Hz~Maximum frequency

(P0-10) 50.00Hz

Rotation

direction 0

Maximum

frequency 50.00Hz〜500.00Hz 50.00Hz

Source of

frequency

upper limit

Frequency

upper limit

Frequency lower limit P0-14~

Maximum frequency P0-10 50.00Hz

●

Auxiliary

frequency

source

Y selection

Frequency

offset of

auxiliary

frequency

source for

X operation

0%~150% 100%

Frequency

source

overlay

selection

00

P0-04

Same as P0-03 (main frequency

source X selection)

0

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

●

P0-05

0 : relative to the maximum

frequency

1 : relative to the frequency

source X

0○

○

Frequency

offset of

auxiliary

frequency

source for

Y operation

P0-06 ○

Ones place : frequency source

selection

0 : main frequency source X

1 : X and Y operation (operation

relationship determined by

Tens position)

2 : Switchover between X and Y

3 : Switchover between X and

"X and Y operation"

4 : Switchover between Y and

"X and Y operation"

Tens place: frequency source

primary and secondary

operation relationship

0 : main + auxiliary

1 : main - auxiliary

2 : the maximum of the two

3 : the minimum of the two

P0-07 ○

P0-08 ○

P0-09

0 : Same direction

1 : Reverse direction

○

P0-10 ●

0 : Set by P0-12 1 : AI1

2 : AI2 3 : AI3

4 : Pulse setting

5 : Communication setting

P0-11 ●

0

P0-12 ○

61441

61442

61443

61444

61445

61446

61447

61448

61449

61450

61451

61452

61453

P1: Motor parameter

21

20

Frequency

upper

limit offset

0.00Hz~Maximum frequency

(P0-10) 0.00Hz

0.00Hz~Upper limit frequency

(P0-12)

Carrier

frequency 0.5kHz~16.0kHz

Model

dependent

Carrier

frequency

is adjusted

with

temperature

Acceleration

time 0

0.00s~65000s

0 : 1S 1 : 0.1S 2 : 0.01S

P0-21

Frequency

offset of

auxiliary

frequency

source for

X and Y

operation

0.00Hz~Maximum frequency

(P0-10) 0.00Hz

Frequency

reference

resolution

Digital

setting

frequency

shutdown

memory

selection

Motor

parameter

group

selection

Base frequency

for UP/DOWN

modification

during

running

Binding

command

source to

frequency

source

0000

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P0-13 ○

Frequency

lower limit 0.00Hz

P0-14 ○

P0-15 ○

P0-16 ○

0 : no

1 : yes 1 : Yes

Model

dependent

P0-17 ○

Deceleration

time 0

0.00s~65000s

Model

dependent

P0-18 ○

P0-19

1

●

Acceleration/

deceleration

unit

○

P0-22

2

●

1 : 0.1Hz

2 : 0.01Hz

P0-23

0

0 : Not retentive

1 : Retentive

○

P0-24

0

●

0 : motor parameter 1

1 : motor parameter 2

P0-25

0

●

0 : Maximum frequency (P0-10)

1 : Setting frequency

2 : 100Hz

Acceleration/

deceleration

time base

frequency

P0-26

0 : running frequency

1 : setting frequency

0

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

●

P0-27

Single digit : Operation panel

command binding frequency

source selection

0 : No binding

1 : Digital setting frequency

2 : AI1 3 : AI2

4 : AI3 5 : Pulse X6

6 : Multi-speed 7 : Simple PLC

8 : PID

9 : Communication given

Tens place: terminal command

binding frequency source

selection Hundreds place :

communication command binding

frequency source selection

Thousands : automatic operation

binding frequency source selection

○

Motor type

selection

P1-00

0 : Ordinary asynchronous motor

1 : Variable frequency

asynchronous motor

1

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

●

Motor rated

power 0.1kW~1000.0kW

Motor rated

voltage 1V~2000V

Motor rated

current 0.1A~655.35A

Motor rated

frequency 0.01Hz~Maximum frequency

Motor rated

speed 1rpm~65535rpm

Asynchronous

motor stator

resistance

0.001Ω~65.535Ω

Tuning

parameter

P1-01 ●

Model

dependent

P1-02 ●

Model

dependent

P1-03

P1-04

P1-05

●

●

●

Model

dependent

Model

dependent

Model

dependent

P1-06 ●

User Manual Chapter 5

User Manual

Chapter 5

61454

61455

61456

61457

61458

61459

61460

61462

61463

61464

61465

61466

61467

61468

61697

61698

61699

61700

61701

61702

61703

23

22

Synchronous

motor stator

resistance

0.001Ω~65.535Ω

Tuning

parameter

Leakage

inductive

reactance

(asynchronous

motor)

0.01mH~655.35mH

0.1mH~6553.5mH

0.01A~P1-03

Encoder

line

number

1~65535 1024

0

A/B phase

sequence of

ABZ

incremental

encoder

Encoder

mounting

angle 0.0~359.9° 0.0°

UVW

incremental

encoder

UVW

Encoder

offset angle 0.0~359.9° 0.0°

Rotary

transformer

pole pair 1~65535 1

Speed

feedback PG

disconnection

detection time

0

Tuning

selection

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P1-07 ●

Tuning

parameter

P1-08 ●

Tuning

parameter

P1-09 ●

Mutual

inductive

reactance

(asynchronous

motor)

Tuning

parameter

P1-10 ●

No-load

current

(asynchronous

motor)

P1-27 ●

Encoder

type

P1-28 ●

0 : ABZ Incremental encoder

1 : UVW Incremental encoder

2 : Resolver

0

P1-30 ●

0 : forward

1 : reserve

P1-31 ●

0 : forward

1 : reserve 0

P1-32 ●

P1-33 ●

P1-34 ●

0.0 : no act

0.1s~10.0s

P1-36 ●

P1-37

0 : No auto-tuning

1 : Static auto-tuning

2 : Complete auto-tuning

3 : Static full auto-tuning

0

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

●

P2: Motor vector control parameter

P2-00

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

Speed loop

proportional

gain 1

1~100 30

Speed loop

integration

time 1

0.01s~10.00s 0.50s

Switchover

frequency 1 0.00~P2-05 5.00Hz

Speed loop

proportional

gain 2

1~100 20

Speed loop

integration

time 2

0.01s~10.00s 1.00s

Switchover

frequency 2 P2-02~Maximum frequency 10.00Hz

Vector control

slip gain 50%~200% 100%

Time constant

of speed

loop filter

0.000s~0.100s 0.050s

Vector

controlled over-

excitation gain

0~200 64

Torque upper

limit source in

speed control

mode

0

○

P2-01 ○

P2-02 ○

P2-03 ○

P2-04 ○

P2-05 ○

P2-06 ○

P2-07 ○

P2-08 ○

P2-09 ○

0 : Function code P2-10 set

1 : AI1 2 : AI2

3 : AI3 4 : Pulse setting

5 : Communication given

6 : MIN(AI1,AI2) 7 : MAX(AI1,AI2)

1-7 option correspond to P2-10

User Manual Chapter 5

User Manual

Chapter 5

61704

61705

61706

61707

61724

61725

61727

61728

61729

61730

61731

61733

61734

61953

61954

61955

61956

61957

61958

61959

61960

61961

61962

25

24

Digital setting

of torque

upper limit

in speed

control mode

0.0%~200.0% 150%

Excitation

adjustment

proportional

gain

0~60000 2000

Excitation

regulation

integral gain

0〜60000 1300

Torque

adjustment

proportional

gain

0〜60000 2000

Torque

adjustment

integral gain

0〜60000 1300

Speed loop

integral

separation

0 : Invalid

1 : Valid 0

Maximum

output

voltage

coefficient

100%~110% 105%

Weak

magnetic

zone

maximum

torque factor

50%~200% 100%

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P2-10

P2-13

P2-14

P2-15

○

○

○

○

P2-16 ○

P2-17 ○

P2-20 ●

P2-21 ○

P3: V/F Control parameters

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P3-00

V/F Curve

setting 0

Torque boost 0.0%(Auto) 0.1%〜30.0%

Cut-off

frequency of

torque boost

0.00Hz〜Maximum frequency 50.00Hz

Multi-point

V/F frequency 1

0.00Hz〜P3-05 0.00Hz

Multi-point

V/F voltage 1 0.0%〜100.0% 0.0%

Multi-point V/F

frequency 2 P3-03〜P3-07 0.00Hz

0.0%〜100.0% 0.0%

P3-05〜Motor rated frequency

(P1-04)0.00Hz

0.0%〜100.0% 0.0%

V/F Slip

compensation

gain 0.0%〜200.0% 0.0%

0〜200 64

V/F oscillation

suppression

gain 0〜100

Oscillation

suppression

mode selection

0~4 3

Voltage source

for V/F

separation 0

Voltage digital

setting for V/F

separation

0 V~rated motor voltage 0V

Voltage rise

time of V/F

separation 0.0s~1000.0s 0.0s

0 : Linear V/F 1 : V/F

2 : Square V/F

3 : 1.2-power V/F

4 : 1.4-power V/F

6 : 1.6-power

8 : 1.8-power V/F

9 : Reserved

10 : V/F complete separation

11 : V/F half separation

●

P3-01

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

Model

dependent

P3-02 ●

P3-03 ●

P3-04 ●

P3-05 ●

Multi-point V/F

voltage 2

P3-06 ●

Multi-point V/F

frequency 3

P3-07 ●

Multi-point V/F

voltage 3

P3-08 ●

P3-09

V/F over-

excitation gain

P3-10

P3-11

Model

dependent

P3-12

P3-13

0 : Digital setting(P3-14) 1 : AI1

2 : AI2 3 : AI3

4 : Pulse setting(HDI)

5 : Multi-function

6 : Simple PLC 7 : PID

8 : Communication setting

Note:100.0% corresponds to the

rated motor voltage

P3-14

P3-15

○

○

○

○

●

○

○

○

User Manual Chapter 5

User Manual

Chapter 5

61963

61966

61967

61968

61969

61970

61973

61974

62209

62210

62211

62212

62213

62214

62215

62216

62217

62218

62219

62220

62221

62222

62223

62224

27

26

Voltage

decline time

of V/F

separation

0.0s 〜 1000.0s

Note:Indicates the time from

0V changes to the rated

voltage of the motor

0.0s

V/F Separate

shutdown

mode

selection

0

50~200% 150%

Over-current

suppression

0:Invalid

1: Valid 1

Over current

stall gain 0~100 20

Double

speed overrun

speed action

current

compensation

coefficient

50~200% 50%

Overvoltage

stall

operating

voltage

200.0V~2000.0V

0:Invalid

1:Valid 1

Overvoltage

stall

suppression

frequency

gain

0~100 30

Overvoltage

stall

suppression

voltage gain

Overvoltage

stall

maximum

rising

frequency

limit

0~50Hz 5Hz

Slip

compensation

time constant

0.1~10.0s 0.5

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P3-16 ○

P3-17 ○

0 : frequency / voltage is

independently reduced to 0

1 : After the voltage is reduced

to 0, the frequency is reduced

again.

Overcurrent

stall

operating

current

P3-18 ●

P3-19 ●

P3-20 ○

P3-21 ●

P3-22 ●

Model

dependent

220V:380V

380V:760V

480V:850V

Overvoltage

stall enable

P3-23 ●

P3-24 ●

0~100 30

P3-25 ●

P3-26 ●

P3-27

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

○

P4: Multi functional inputs parameters

P4-00

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

X1 Terminal

function

selection

1

4

9

●

P4-01

X2 Terminal

function

selection

●

P4-02

X3 Terminal

function

selection

●

12

P4-03

X4 Terminal

function

selection

●

User Manual Chapter 5

User Manual

Chapter 5

P3-34

Water supply

mode

selection

0: Turn off water supply mode

1: Turn on the water supply mode

0

P3-35

Remote

transmission

of pressure

gauge range

0.00〜5.00MPa 1.00MPa

P3-36 Demand target

pressure 0.00~P3-39 0.5MPa

P3-37 Dormancy

frequency 0.00 Hz~P0-10 25.00Hz

P3-38 Sleep latency 0.0~3600.0s 0.0s

P3-39 Wake up the

pressure 0.0~100.0% 80%

P3-40 Wake up time

delay 0.0~3600.0s 0.0s

●

○

0 : No function

1 : Forward RUN (FWD)

2 : Reverse RUN (REV)

3 : Three-line control

4 : Forward JOG (FJOG)

5 : Reverse JOG (RJOG)

6 : Terminal UP

7 : Terminal DOWN

8 : Coast to stop

9 : Fault reset (RESET)

10 : RUN pause

11 : Normally open (NO) input of

external fault

12: Multi-speed 1

13: Multi-speed 2

14: Multi-speed 3

15: Multi-speed 4

16 : Acceleration/deceleration

time selection 1

○

○

○

○

○

62225

62226

62227

62228

62229

62230

62231

62232

62233

62234

62235

62236

62243

62244

62245

62246

62247

62248

62249

62465

62466

62467

62468

29

28

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

Input terminal

filter time

P4-10

0.000s〜1.000s 0.010

Terminal

command

mode

0

Terminal

UP/DOWN

rate of

change

0.001Hz/s〜65.535Hz/s 1.00Hz/s

AI Curve

1 minimum

input 0.00V〜P4-15 0.00V

AI Curve 1

minimum

input

corresponding

value

-100.0%〜+100.0% 0.0%

AI Curve 1

maximum input P4-13〜+10.00V 10.00V

AI Curve 1

maximum

input

corresponding

value

-100.0%〜+100.0% 100.0%

AI1 Filtering

time 0.00s〜10.00s 0.10s

AI Curve 2

minimum input

0.00V〜P4-20 0.00V

AI Curve 2

minimum

input

corresponding

value

-100.0%〜+100.0% 0.0%

AI Curve 2

maximum input

P4-18〜+10.00V 10.00V

○

P4-11 ●

0: Two-wire mode 1

1: Two-wire mode 2

2: Three-wire mode 1

3: Three-wire mode 2

P4-12 ●

P4-13

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

○

P4-14 ○

P4-15 ○

P4-16 ○

P4-17 ○

P4-18 ○

P4-19 ○

P4-20 ○

User Manual Chapter 5

User Manual

Chapter 5

0

17 : Acceleration/deceleration

time selection 2

18 : Frequency source switchover

19 : Keyboard UP/DOWN setting

is cleared (terminal\keyboard)

20 : Command source switchover

terminal

21 : Acceleration/deceleration

prohibition

22 : PID pause 23 : PLC reset

24 : swing frequency pause

25 : counter input

26 : Counter reset

27 : Length count input

28 : Length reset

29 : Torque control prohibited

30 : Pulse frequency input

32 : Immediate DC braking

33 : Normally closed (NC)

input of external fault

34 : If this terminal is valid,

frequency modification is allowed;

if The terminal status is invalid, &

frequency modification is

prohibited.

35 : PID action direction is

reversed

36 : External STOP terminal 1

37 : Command source

switchover terminal 2

38 : PID integral pause

39 : Switchover between main

frequency source X and preset

frequency

40 : Switchover between

auxiliary frequency source Y

and preset frequency

43 : PID parameter switchover

44 : User-defined fault 1

45 : User-defined fault 2

46 : Speed control/Torque

control switchover

47 : Emergency stop

48 : External STOP terminal 2

49 : Deceleration DC braking

50 : Clear the current running

time

13

P4-04

X6 Terminal

function

selection

●

P4-05

X5 Terminal

function

selection

●

0

P4-06

X7 Terminal

function

selection

●

0

P4-07

X8 Terminal

function

selection

●

0

P4-08

X9 Terminal

function

selection

●

62469

62470

62471

62472

62473

62475

62476

62477

62478

62479

62480

62481

62482

62483

62484

62485

51 : Switchover between two-

line mode and three-line mode

52 : Reverse rotation is

prohibited

31

30

AI Curve 1

maximum

input corresp-

onding value

-100.0%〜+100.0% 100.0%

AI3 Filtering

time 0.00s〜10.00s 0.10s

Pulse

minimum input

0.00kHz〜P4-30 0.00kHz

Pulse

minimum input

corresponding

value

-100.0%〜100.0% 0.0%

Pulse

maximum input

P4-28〜100.00kHz 50.00kHz

P4-31

Pulse

maximum input

corresponding

value

-100.0%〜100.0% 100.0%

P4-32 Pulse input

filtering time

Unit: AI1 curve selection

1 : Curve 1 (2 points, P4-13

to P4-16)

2 : Curve 2 (2 points, P4-18

to P4-21)

3 : Curve 3 (2 points, P4-23

to P4-26)

0.10s

P4-33 AI Curve

selection 321

P4-34

AI Below the

minimum

input

setting

selection

000

P4-35 Input terminal

X1 delay time 0.0s〜3600.0s 0.0s

P4-36 Input terminal

X2 delay time 0.0s〜3600.0s 0.0s

P4-37 Input terminal

X3 delay time 0.0s〜3600.0s 0.0s

P4-38

Input terminal

valid mode

selection 1

00000

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

P4-26 ○

P4-28

P4-27

P4-29

P4-30

○

○

○

○

○

○

○

0.00s〜10.00s

Unit digit : AI1 is lower than

the minimum input setting

selection

0 : corresponding to the

minimum input setting 1:0.0%

Ten digit : AI2 is lower than

the minimum input setting

selection, the same as above

Hundreds : AI3 is lower than

the minimum input setting

selection, the same as above

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

●

●

●

●

Unit's digit: X1 Ten's digit: X2

Hundred's digit: X3

Thousand's digit : X4

million: X6

0 : The X terminal is connected

to COM and the disconnection is

invalid.

1 : X terminal and COM

connection are invalid, the

disconnection is valid.

P4-39

Input terminal

valid mode

selection 1

00000

●

Unit's digit: X1 Ten's digit: X2

Hundred's digit: X3

Thousand's digit: X4

million: X6

0 : The X terminal is connected

to COM and the disconnection is

invalid.

1 : X terminal and COM

connection are invalid, the

disconnection is valid.

User Manual Chapter 5

User Manual

Chapter 5

AI Curve 3

minimum input -10.00V〜P4-25 -10.00V

AI Curve 3

minimum input

corresponding

value

-100.0%〜+100.0% -100.0%

P4-23〜+10.00V 10.00V

P4-23 ○

P4-24 ○

AI Curve 3

maximum input

P4-25 ○

○

62488

62489

62490

62491

62492

62493

62494

62495

62496

62497

62498

62499

62500

62501

62502

62503

62504

AI Curve 2

maximum

input

corresponding

value

-100.0%〜+100.0% 100.0%

AI2 Filtering

time 0.00s〜10.00s 0.10s

P4-21 ○

P4-22 ○

62486

62487

4 : Curve 4 (4 points, A6-00

to A6-07)

5 : Curve 5 (4 points, A6-08

to A6-15)

Tens place : AI2 curve

selection, ibid.

Hundreds place : AI3 curve

selection, ibid.

33

32

P5: Output terminal

Function

Code

Parameter

Name

Setting Range Default Prope-

rty Modbus

Address

P5-00

Y2 Output

mode

selection

0: Pulse output

1: Switch signal output 0

P5-01

Y2 Switch

output

function

selection

0

P5-02

Relay output

function

selection

2

P5-03

Relay output

function

selection 2

(Optional)

0

P5-04

Y1 output

function

selection

1

P5-05

Y3 output

function

selection

(optional)

4

P5-06

Y2 Pulse

output

function

selection

0

P5-07

AO Output

function

selection

0

P5-08

AO2 Output

function

selection

(optional)

1

P5-09

Y2 Pulse

output Maxi-

mum frequency

0.01kHz〜100.00kHz 50.00kHz

P5-10 AO Zero offset

coefficient -100.0%〜+100.0% 0.0%

P5-11 AO Gain -10.00〜+10.00 1.00

P5-12

Extended AO2

zero offset

coefficient

-100.0%〜+100.0% 0.0%

P5-13 Extended AO2

gain -10.00〜+10.00 1.00

Y2 output

delay time 0.0s〜3600.0s 0.0s

P5-18 Relay output

delay time 0.0s〜3600.0s 0.0s

○

○

○

○

○

0 : No function

1 : Inverter running

2 : Fault output (stop)

3 : Frequency-level detection

FDT1 output

4 : Frequency reached

5 : Zero-speed running

(no output at stop)

6 : Motor overload pre-warning

7 : Inverter overload pre-

warning

8 : Set count value reached

9 : Designated count value

reached

10 : Length reached

11 : PLC cycle completed

12 : Accumulative running time

reached

13 : Frequency limited

14 : Torque limited

15 : Ready to RUN

16 : AI1>AI2

17 : Frequency upper limit

reached

18 : Frequency lower limit

reached (no output at stop)

19 : Under voltage status

output

20 : Communication setting

23 : Zero-speed running 2

(having output at stop)

24 : Accumulative power-on

time reached

25 : Frequency level

detection FDT2 output

26 : Frequency 1 reached

27 : Frequency 2 reached

28 : Current 1 reached

29 : Current 2 reached

30 : Timing reached

31 : AI1 input limit exceeded

32 : Load becoming 0

33 : Reverse running

34 : Zero current state

35 : IGBT temperature reached

36 : Software current limit

exceeded

○

37 : Frequency lower limit

reached (having output at stop)

38 : Alarm output

39 : Motor overheat warning

40 : Current running time

reached

41 : Fault output (There is no

output if it is the coast to stop

fault and under voltage occurs.)

Fun-

ction

Code

Parameter

Name Setting range Default Prope-

rty

Modbus

Address

0 : Running frequency

1 : Set frequency

2 : Output current

3 : Output torque

(absolute value)

4 : Output power

5 : Output voltage

6 : Pulse input (100.0%

corresponds to 100.0kHz)

7 : AI1 8: AI2

9 : AI3 (extended) 10: Length

11 : Count value

12 : Communication setting

13 : Motor speed

14 : output current 55KW &

below 100% corresponds to

100.0A, 75KW and above 100%

corresponds to 1000.0A

15 : (100% of the output voltage

corresponds to 1000.0V) actually

(1000.0V corresponds to 100%

of the bus voltage)

○

○

○

○

○

○

○

P5-17

○

○

User Manual Chapter 5

User Manual

Chapter 5

○

62721

62722

62723

62724

62725

62726

62727

62728

62729

62730

62731

62732

62733

62734

62738

62739

35

34

P5-21

Y3 Delay

time

(expansion) 0.0s〜3600.0s 0.0s

P5-22

Output

terminal

valid mode

selection

00000

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

○

○

Ones place:Y2

Tens place: Relay

Hundreds place : Relay 2

Thousands place : Y1

Ten thousand: Y3

0: The output terminal is

connected to COM and the

disconnection is invalid.

1: The output terminal is not

connected to COM, and the

disconnection is valid.

P6: Start and stop control mode

Function

Code

Parameter

Name

Setting Range Default Prope-

rty

Modbus

Address

○

P6-00 Start mode 0

P6-01 0 ●

P6-02

Rotational

speed

tracking

speed

1〜100 20

P6-03 Startup

frequency 0.00Hz〜10.00Hz 0.00Hz

P6-04

Startup

frequency

holding time

0.0s〜100.0s 0.0s ●

P6-05

Startup DC

braking

current/Pre-

excited

current

0%〜100% 0%

P6-06

Startup DC

braking

time/Pre-

excited time

0.0s〜100.0s 0.0s

P6-07

Acceleration/

Deceleration

mode

0●

P6-08

Time proportion

of S-curve

start segment

0.0%〜(100.0%-P6-09)30.0% ●

P6-09 0.0%〜(100.0%-P6-08)30.0% ●

P6-10 Stop mode 0

P6-11

Initial frequency

of stop DC

braking