4

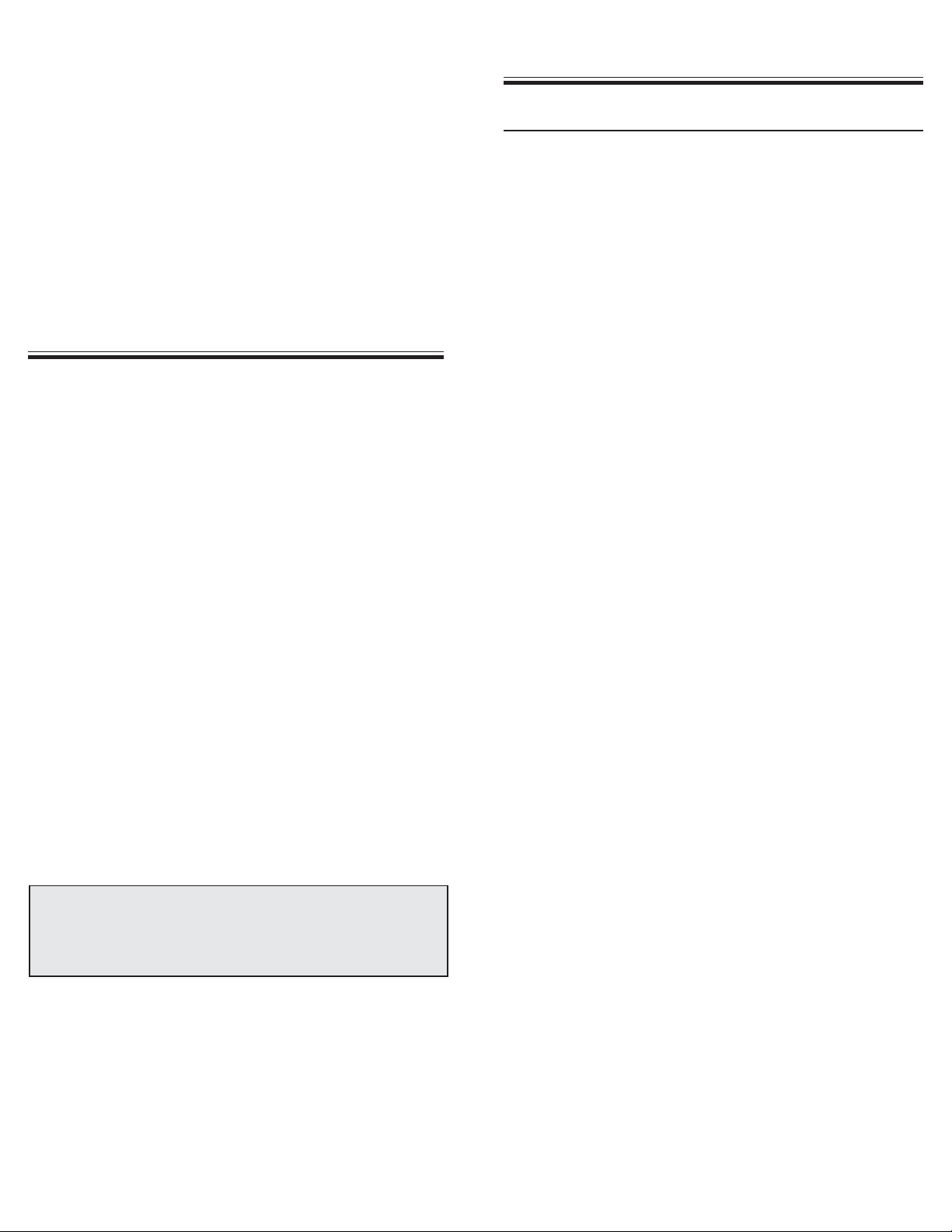

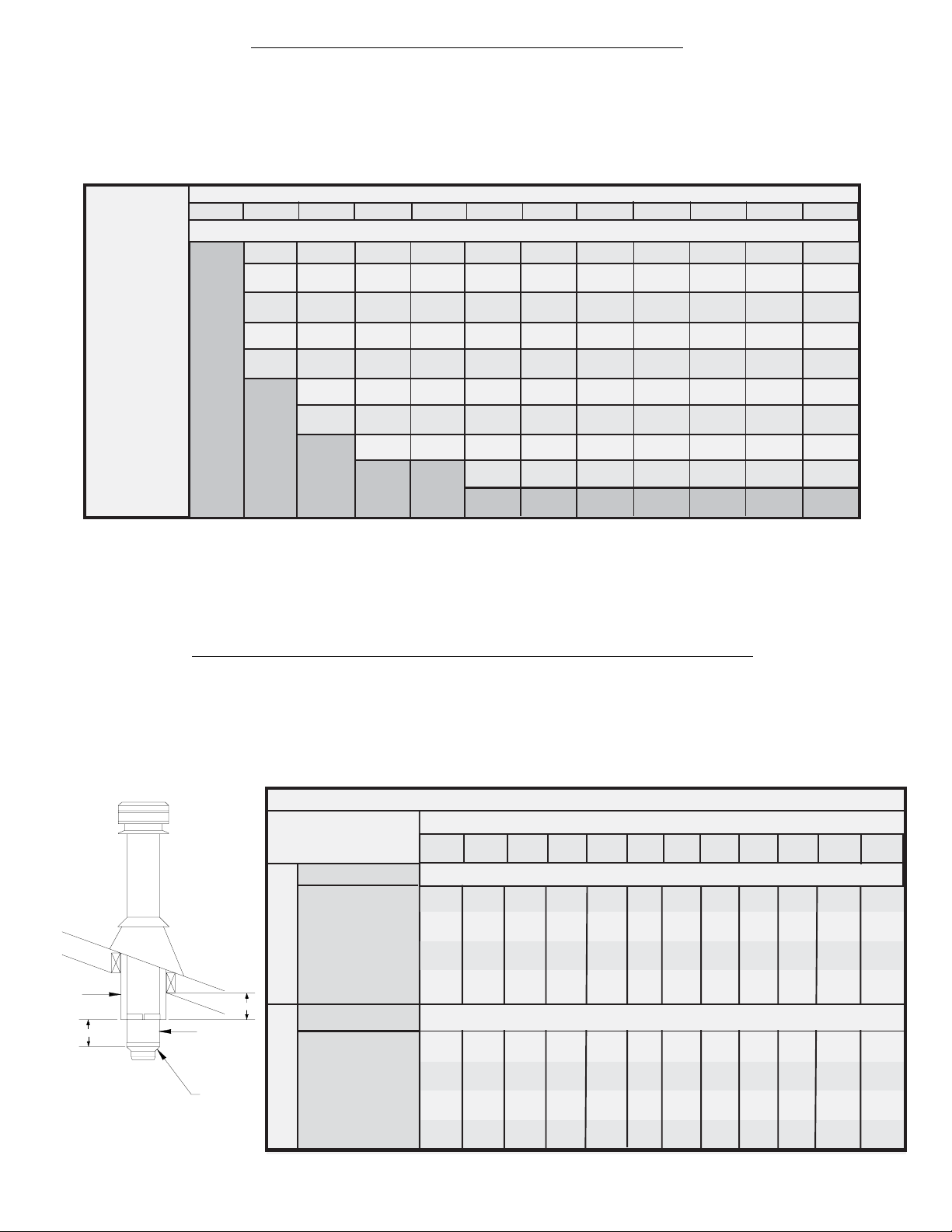

Plan your installation carefully. Lay out and frame in all openings

ensuring the specified 2” (50 mm) clearance to combustibles is

maintained. Seetable1. All openings should be square, plumb and

inperfectalignmentwitheachother. Seefigure2. Forslopingroofs,

ensure that the framing dimension is measured in the horizontal

plane. See figure 3.

TYPES OF APPLIANCES

Your SuperVent/SuperPro Model FC chimney is intended as a

component for specific listed factory built fireplaces and for

connectionto liquidfuelorgasfiredresidentialtypeappliancesand

buildingheatingappliances,inwhichthemaximumcontinuousflue

gas temperatures do not exceed 540 oC. It has been tested and

approved to withstand temperatures of up to 1125oC.

PRE-INSTALLATION GUIDELINES

Your SuperVent/SuperPro chimney and connecting stove pipe

diameter should be sized in accordance with the appliance

manufacturer’srecommendations.

Plan the installation of your appliance and chimney in such a way

thatyourbothyourchimney,andyourchimneyconnector(stovepipe)

run is as short and straight as possible. By having too long and or

multiple bend installations you can reduce system draft which can

affect the operation, and or performance of your appliance and or

chimney system. The chimney should also be located within the

buildingsoastoavoidcuttingoralteringloadbearingmemberssuch

as joists, rafters, studs, etc. If you require to cut or alter an existing

loadbearingmember,specialreframingmethodsarerequiredwhich

often include doubling of adjacent members. If such a case arises,

contactyourlocalBuildingCodeOfficialregardinglocalregulations

and proper installation methods.

Sections of the SuperVent/SuperPro chimney which pass through

accessibleareasofthebuilding,mustbeenclosedinachasetoavoid

personal contact and damage to the chimney. The chase may be

fabricated using standard building materials. Drywall mounted on

2” x 4” studs is typically used in this situation.

MAINTAIN A 2" (50mm) MINIMUM AIR SPACE CLEARANCE

BETWEEN INSULATED CHIMNEY SECTIONS AND

COMBUSTIBLE MATERIALS.

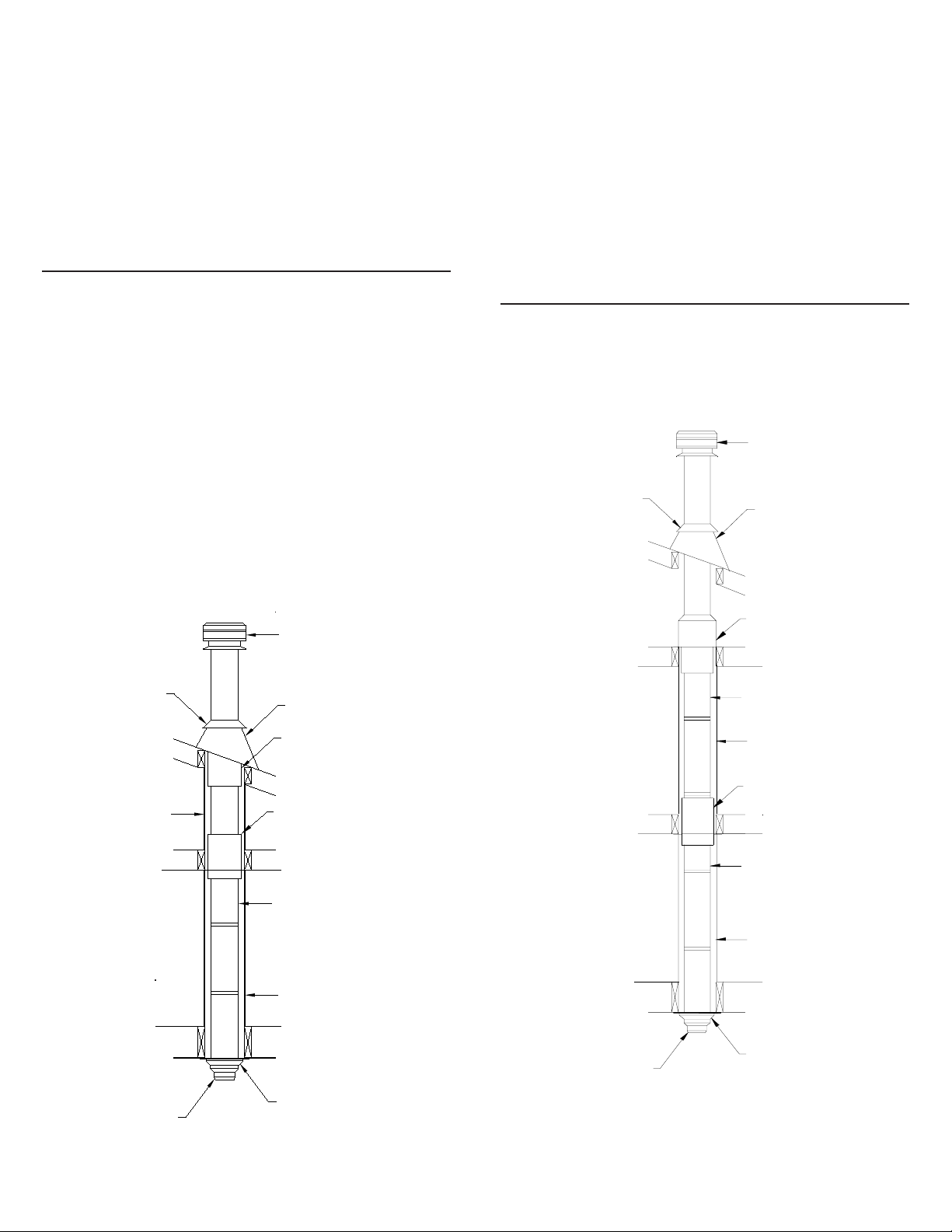

Authoritiesrequirethatthechimneyextendnotlessthan3feetabove

the highest point where it passes through the roof of a building and

notlessthan2feet(600mm)aboveanyportionofthebuildingwithin

10 feet (3m). See figure 1.

Theuseof Locking Bandsatall chimney jointsisrecommended for

added safety and stability when exposed to high winds and as a

precautionagainstaccidentalunlockingoflengthswhenthesystem

is inspected and swept.

The ideal location for your chimney system is within the building

envelope. Incold climates, theuse ofexternal chimneys mayresult

inoperationproblemssuchaspoor draft, excessivecondensationof

combustion products and rapid accumulation of creosote. Under

these circumstances, the installation of the chimney within the

building is strongly recommended.

If the chimney must be installed on an exterior wall it is highly

recommendedto enclose the chimney belowthe roof line to protect

itfromcoldoutdoortemperatures,thismayhelpreducecondensation,

creosote formation and enhance draft.

Do not install the chimney directly at the outlet of the appliance.

Interconnecting smoke pipe is required unless the appliance is

specifically approved for that type of installation.

Use only with an appliance listed by a recognized testing authority

such as Underwriters Laboratories Inc., Underwriters Laboratories

of Canada, Intertek Testing Services or Warnock Hersey.

The flue diameter of gas or oil fired appliances should comply with

theappropriateCSAorCGAInstallationCodes;/CAN/CSAB139.00,

CAN/CSA-B149.1-00 or CAN/CSA-B149.2-00.

YOUR CHIMNEY HAS BEEN TESTED, AND LISTED USING

ALL OF THE SUPPORTS, SHIELDS, ETC., DESCRIBED

HEREIN. DELETION OR MODIFICATION OF ANY OF THE

REQUIRED PARTS OR MATERIALS MAY SERIOUSLY

IMPAIR THE SAFETY OF YOUR INSTALLATION, AND

VOID THE CERITFICATION AND OR WARRANTY

OF THIS CHIMNEY

YourSuperVent/SuperProchimneysystemisdesignedforinstallation

using standard building materials and procedures. The following

tools will be required:

-safety gloves -screwdriver and pliers

-safety goggles -plumb line and level

-hammer and nails -square

-tin snips -spoke saw or power jig saw

Other tools or equipment may be required, depending on your

chimney location and the structure in which it is to be installed.

Except for installation in one and two family dwellings, a factory

builtchimneythatextendsthroughanyzone abovethatonwhichthe

connected appliance is located is to be provided with an enclosure

havingafireresistanceratingequaltoorgreaterthanthatofthefloor

or roof assemblies through which it passes.

Obtain any necessary building permits.

Ensurethatyouobtainanynecessarybuildingpermits,andthatyour

installation will conform with all federal and municipal building

code requirements. Before commencing installation,

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

RESTRICTIONS AND INSTALLATION

INSPECTION IN YOUR AREA.

WARNING: DO NOT PLACE ANY INSULATING

MATERIALS OR RUN ANY ELECTRICAL WIRING

WITHIN THE REQUIRED AIR CLEARANCE SPACE

SURROUNDING THE CHIMNEY.

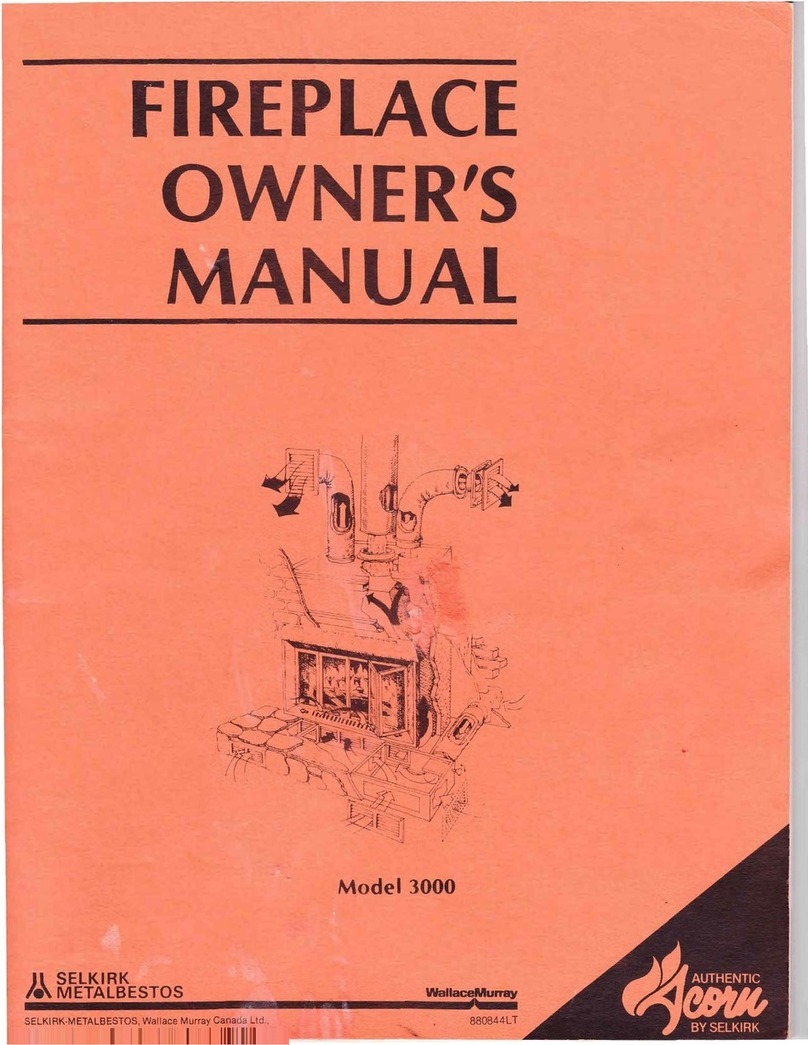

3 ft. (900mm)

min.

3 ft. (900mm)

min.

10 ft.

(3m)

2 ft.

(600mm)

2 ft.

(600mm)

FIGURE 1

TOOLS

FRAMING DETAILS