Seltron ACC40 User manual

ACC30, ACC40

ENG Constant temperature controller

DEU Festwertregler

SLO Regulator konstantne temperature

English

1

CONSTANT TEMPERATURE CONTROLLER

ACC30, ACC40

Controllers ACC30, ACC40 are modern designed, microprocessor-driven devices made

with digital and SMT technology.

The controller are provided as a constant temperature controller with actuator designed

for heating applications. The most common use is to control the return temperature in the

boiler. Controller ACC40 besides controlling the actuator also controls the circulating pump.

For initial setup see Initial controller setup, page 6!

INTRODUCTION

2 English

Contents

Introduction..................................................................................................................... 3

Appearance of the controller .......................................................................................... 5

Initial controller setup...................................................................................................... 6

Step 1 - Language selection................................................................................... 6

Step 2 - Hydraulic scheme selection ...................................................................... 6

Step 3 - Opening of the mixing valve...................................................................... 7

Graphic LCD display....................................................................................................... 8

Description and design of the main display............................................................ 8

Descpription of symbols on the display .......................................................................... 9

Controler mode symbols......................................................................................... 9

Temperature and other data symbols..................................................................... 9

Symbols for notices and warnings.......................................................................... 10

Display for help, notices and warnings........................................................................... 10

Menu entry and navigation ............................................................................................. 11

Menu structure and description ...................................................................................... 11

Temperature settings.............................................................................................. 13

Operation mode ..................................................................................................... 14

Manual mode:......................................................................................................... 14

Heating or cooling operation mode selector................................................................... 14

Basic settings ................................................................................................................. 15

Data overview................................................................................................................. 17

Controller parameter and auxiliary tools......................................................................... 18

Basic parameters.................................................................................................... 18

Service parameters ................................................................................................ 20

Factory settings ...................................................................................................... 23

Operation mode by sensor Failure ................................................................................. 24

Controller installation...................................................................................................... 25

Controller’s electric connection ...................................................................................... 25

Technical data................................................................................................................. 26

Disposal of old electrical & electronic equipment ........................................................... 27

Notes .............................................................................................................................. 28

Hydraulic schemes ......................................................................................................... 81

English

3

USER MANUAL

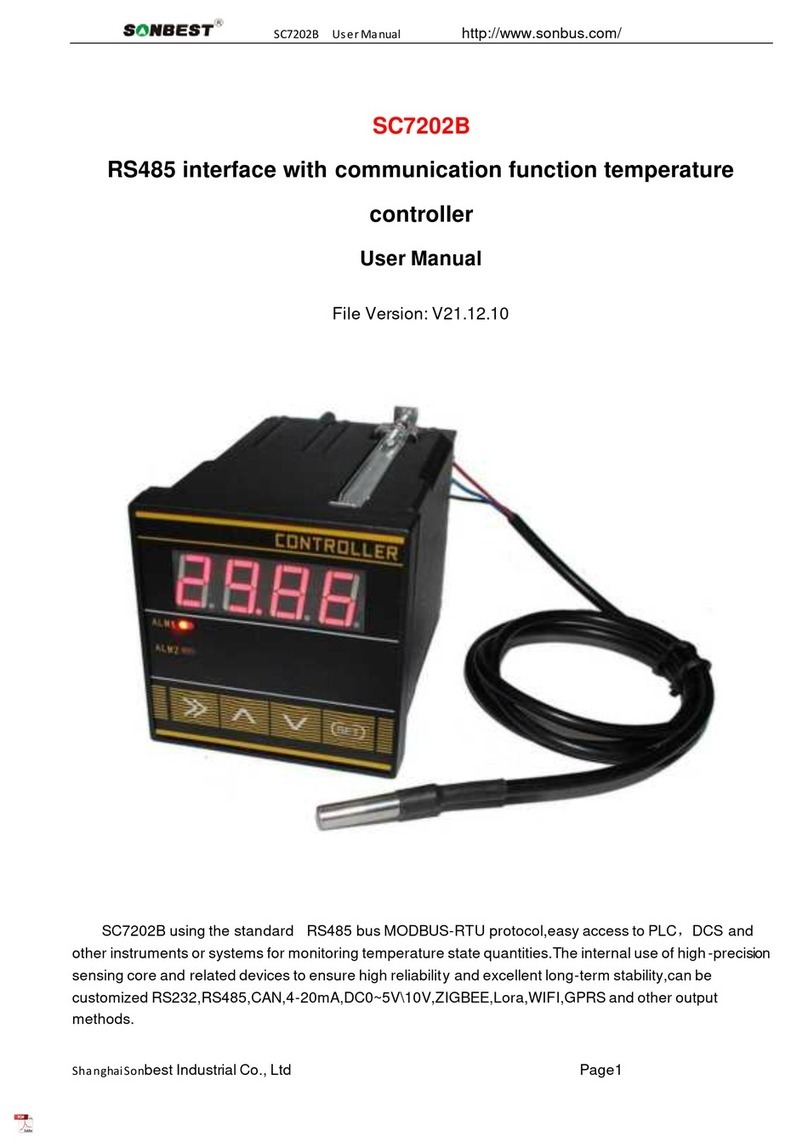

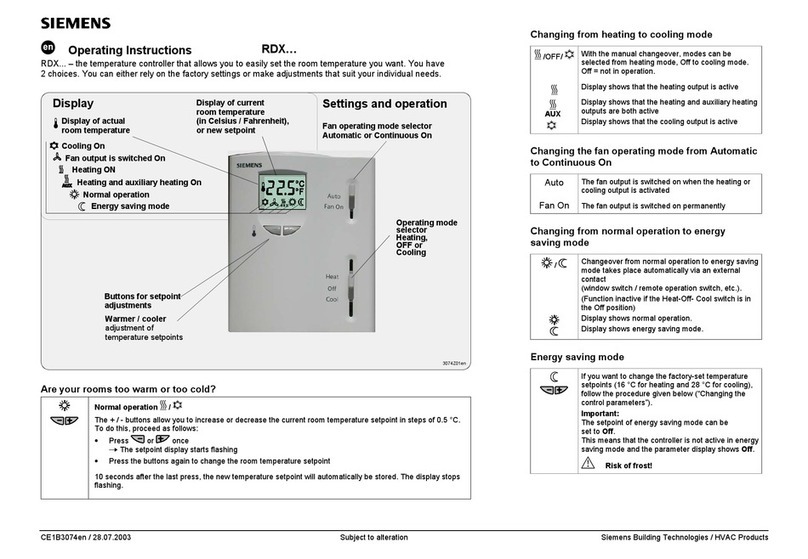

APPEARANCE OF THE CONTROLLER

1

2

3

4

5

8

9

10

6 7

1. Graphic display

2. Clutch for manual operation.

3. Button Return back.

4. Button Move to left, decreasing.

5. Button Menu entry, conrmation of selection.

6. Button Move to right, increasing.

7. Button Help.

8. LED indication - valve rotation right.

9. LED indication red - fault, error.

10. LED indication - valve rotation left.

4 English

INITIAL CONTROLLER SETUP

Constant temperature controllers are equipped with an innovative solution, which allows

initial setup of the controller in only three steps.

When you connect the controller to the power supply for the rst time, the software version

is shown. Next, the rst step appears on the screen.

STEP 1 - LANGUAGE SELECTION

Using buttons and you select the required

language.

Press the button to conrm the selected language.

After selecting the language, the controller requires

conrmation of the selection by pressing the

button .

If you accidentally selected the wrong language, go

back to reset the language by pressing button .

STEP 2 - HYDRAULIC SCHEME SELECTION

Next, you select a hydraulic scheme for the control-

ler function. Move between schemes by means of

buttons and .

Conrm the selected scheme by pressing the

button .

After you selected the scheme, the controller re-

quires conrmation of the selection by pressing the

button .

If you accidentally selected the wrong scheme, go

back to reset the scheme by pressing button .

Selected hydraulic scheme can be later changed with service parameter

S1.1.

English

5

STEP 3 - OPENING OF THE MIXING VALVE

Press icon which indicates the proper direction of

mixing valve opening direction. Between icons you

can move with buttons and .

After you selected the correct direction, the controller

requires conrmation of the selection by pressing the

button .

If you accidentally selected the wrong mixing valve

opening direction, go back to reset the the selection

by pressing button .

Selected mixing valve opening direction can be later changed with service

parameter S1.4.

6 English

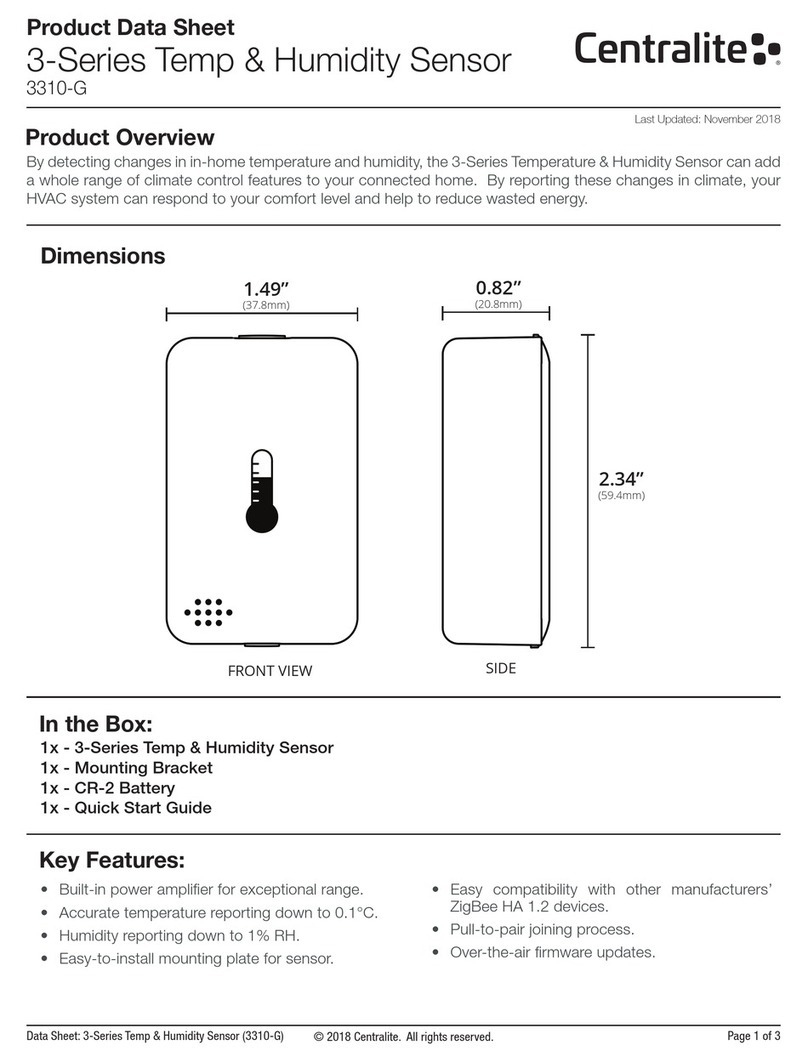

GRAPHIC LCD DISPLAY

All important data of controller operation are shown on the graphic LCD display.

DESCRIPTION AND DESIGN OF THE MAIN DISPLAY

Notications

and warnings.

Controller mode. Controller mode.

Temperature, protection functions and over-

view of other data.

Display of information on the screen:

The controller mode, notications and warnings are displayed in the upper third of the

display. For switching between basic display and display of the hydraulic scheme use the

button .

To check the temperature and other data, use buttons and . The number of sensors

and other data, which can be listed on the display, depends on the selected hydraulic sche-

me and controller settings.

If you would like to have a specic data display to appear after you stop using

the keyboard then select the desired data with buttons and . Conrm

the selected screen by pressing the button for 2 seconds.

When you press the button for 2 seconds, then the display of the tem-

perature will change from one to two rows and vice versa. On the two line

temperature display, the measured temperature is displayed in the rst row

and the required or calculated temperatire in the second row.

English

7

DESCPRIPTION OF SYMBOLS ON THE DISPLAY

Symbol Description

Heating.

Cooling.

Automatic mode.

Stand by.

Manual mode.

CONTROLER MODE SYMBOLS

TEMPERATURE AND OTHER DATA SYMBOLS

Symbol Description

Measured temperature.

Set point or calculated temperature.

Supply temperature.

Boiler temperature.

Stand- pipe temperature.

Stand- pipe temperature.

Boiler return temperature.

T1, T2 Temperature measured by the sensor T1, T2.

8 English

DISPLAY FOR HELP, NOTICES AND WARNINGS

By pressing the button the screen for help, messages and warnings will be oppened in

which the following icons are available.

Short manual

Short manual for use of the controller.

Controller version

Overview of controller type and software version.

Notications

Log of exceeded maximum temperatures and activated protection functions.

By pressing the buttons and move through the list of notications.

Press to exit the list.

Warnings

Log of sensors, pump or ow meter failures.

By pressing the buttons and move through the list of warnings.

Press to exit the list.

Delete warning and notication logs

By pressing the button will erase notication and warning log. All sensors

that are not connected will be deleted from the list of failures.

Note: Failures of sensors that are required for controller operation can not

be deleted.

Symbol Description

Notications

In case of exceeding the maximum temperature or activation of pro-

tection function, the controller indicates the event with ashing symbol

on the display. If the maximum temperature is no longer exceeded or

if the protection function is turned o, a lited symbol indicates a recent

event.

Press to open the screen to check notications.

Warning

In the event of sensor failure, the controller indicates the failure with

ashing symbol on the display. If the issue is resolved or no longer

present, a lited symbol indicates a recent event.

Press to open the screen to check warnings.

SYMBOLS FOR NOTICES AND WARNINGS

English

9

MENU ENTRY AND NAVIGATION

To enter the menu, press the button .

Move around the menu using the buttons and , with the button you conrm your

selection.

By pressing the button you return to the previous screen.

If some time no button is pressed, the backlight turns o or is reduced accor-

ding to the setting.

MENU STRUCTURE AND DESCRIPTION

TEMPERATURE SETTINGS

Set-point temperature.

OPERATION MODE

Automatic operation.

Switch-off.

Select Heating / Cooling mode.

Manual operation.

BASIC PARAMETERS

Language selection.

Time and date.

DISPLAY SETTINGS

Duration of active display illumination and menu autoexit.

10 English

DATA OVERVIEW

Diagrams of measured temperatures by days for last week.

Diagrams of measured temperatures for current day.

Output operation time counter.*

Special service data.

CONTROLLER PARAMETERS

Basic settings.

Settings for the heating circuit.*

Settings for heat source.*

SERVICE PARAMETERS

Basic settings.

Settings for the heating circuit.

Settings for heat source.

FACTORY SETTINGS

Reset of all controller parameters.

Reset of all controller settings and restart of initial setup.

Save user settings.

Load user settings.

* Not available

English

11

TEMPERATURE SETTINGS

In the menu only the temperatures are displayed, where you can set the set-point tempera-

ture by the selected hydraulic scheme.

By pressing buttons , and you choose the required temperature, and a new

window opens:

Set the set-point temperature with buttons , and conrm with button .

Exit the settings by pressing the button .

Default value

Graphic review

of settings

Setting range

Value of the last

conrmed setting

Current value

of set-point

temperature

(numeric mode)

Current value

of set-point temperature

(analogue mode)

12 English

OPERATION MODE

In this menu the operating mode of the controller is selected.

Select the operaion mode with buttons , and conrm with button .

Exit the settings by pressing the button .

Automatic operation

Controller switch-o

Heating or cooling operation mode selector

Manual mode

HEATING OR COOLING OPERATION MODE SELECTOR

Heating operation mode is active.

Cooling operation mode is active.

MANUAL MODE:

This mode is used for testing the system or in case

of malfunction. Every output can be manually activa-

ted or deactivated.

Move with the buttons and between the indi-

vidual outputs R1, M- or M +. The output, which you

want to change is selected by pressing the button

.

ON, OFF or AUTO starts ashing. Now the output

can be changed using the buttons und . The

setting is conrmed by pressing the button .

Exit the setup menu with the button.

English

13

BASIC SETTINGS

The menu is intended for language, time, date and display settings

Language selection

The required user language is selected by pressing buttons , and conrmed with

button .

Exit settings by pressing the button .

Time and date

You set the exact time and date in the following

manner:

By pressing buttons and move among

individual data. By pressing button you select

data that you want to change. When data ashes,

change it by pressing buttons , and conrm it

with the button .

Exit the settings by pressing the button .

14 English

The following settings are available:

Time of active screen illumination and autoexit from menu to the main screen.

DISPLAY SETTINGS

By pressing buttons , and you select and conrm required setting.

A new window opens:

Graphic

symbol

Werkseinstellung

Aktueller Einstellwert

Current value of

setting (graphic)

Einstellbereich

The last conrmed

value of setting

Current value of setting

(Numeric value)

You change settings by pressing buttons and and conrm by pressing

button .

Exit the settings by pressing button .

The change of settings is carried out when you conrm it by pressing button

.

English

15

To view the sensor-diagrams move with buttons and between the sen-

sors. By pressing the button the date of displayed temperature begins to

ash. Use buttons and to move between days.

Return to the temperature selection by pressing the button .

The range of the temperature display on the graph can be changed with the

the button .

Exit the diagram overview by pressing the button .

DATA OVERVIEW

In this menu there are icons to access the following data on controller performance:

DIAGRAMS OF MEASURED TEMPERATURES BY DAYS FOR LAST WEEK

The graphical representation of the temperature prole in days, for each sensor.

There are records of the temperatures for the last week of operation.

DIAGRAMS OF MEASURED TEMPERATURES FOR CURRENT DAY

Detailed graphic overview of temperature in current day for each sensor.

How often are temperatures logged is set with parameter P1.3.

OUTPUT’S OPERATION TIME COUNTERS*

Counters of controller’s outputs operation time.

SPECIAL SERVICE DATA

Intended for diagnostics for technical service.

* Not available

16 English

CONTROLLER PARAMETER AND AUXILIARY TOOLS

SERVICE MANUAL

All additional settings and adjustments of controller performance are carried out by means

of parameters. User-, Service- and parameters are found on the second menu screen.

BASIC PARAMETERS

The basic parameters are listed in one group P1 - basic parameters.

Content of basic parameters is displayed as follows:

Parameter mark

Parameter

description

Current parameter

value

Factory default

Setting range

The setting is changed by pressing the button .

The value will start blinking and can be changed with the and . The setting is conr-

med by pressing the button .

Move with buttons and to other parameters and repeat the procedure.

Exit the parameter settings by pressing the button .

English

17

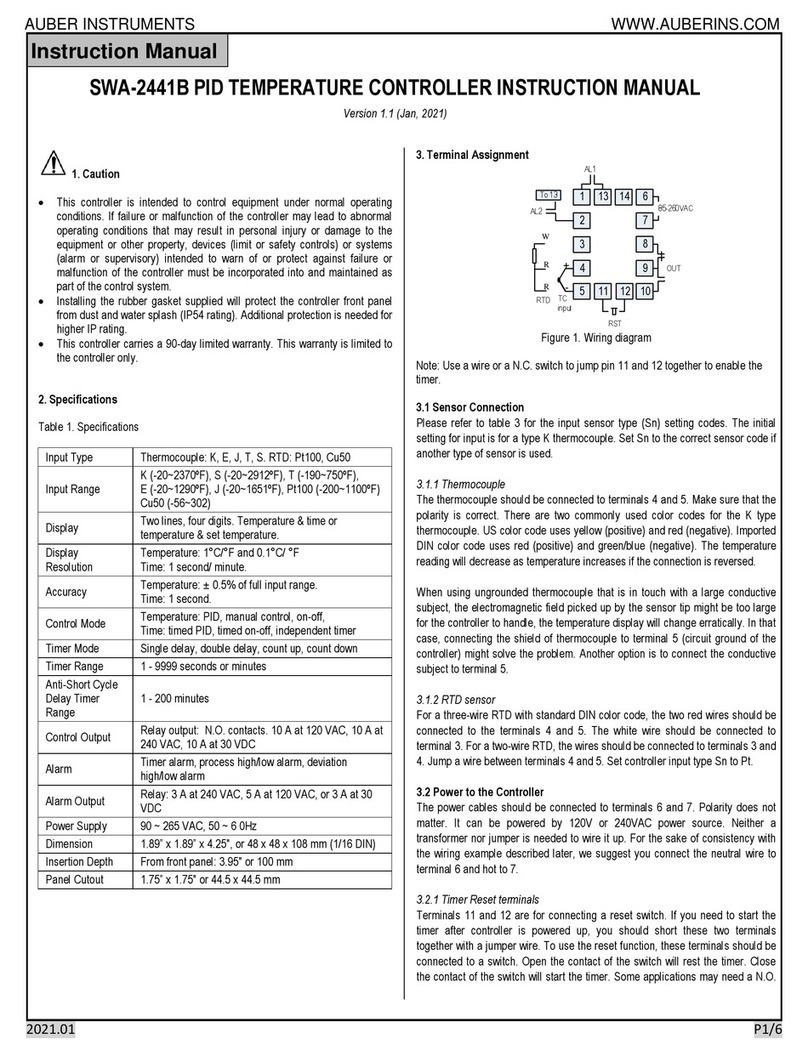

Basic parameters:

Para-

meter

Function Parameter description Setting range Default

value

P1.1 TEMPERATURE ROUND

UP

You set the accuracy of displayed temperatures. 0- 0.1 °C

1- 0.2 °C

2- 0.5 °C

3- 1 °C

2

P1.2 AUT. SHIFT OF CLOCK

TO SUMMER/WINTER

TIME

With the help of a calendar, the controller carries out

the automatic changeover between summer and winter

time.

0- NO

1- YES 1

P1.3 PERIOD OF TEMPERAT.

LOGGING

By setting this eld you dene how often the measured

temperatures are saved.

1 ÷ 30 min 5

P1.4 TONES By setting this eld you dene sound signals of the

controller.

0- OFF

1- KEYPAD

2- ERRORS

3- KEYPAD AND

ERRORS

1

P1.5 ADVANCED TEMPERA-

TURE SCREEN

Advanced screen means that while checking

temperatures you can see measured and required or

calculated temperature.

0- NO

1- YES 1

18 English

SERVICE PARAMETERS

Service parameters are arranged in groups S1 - Basic parameters, S2 - Parameters for the

heating circuit. With service parameters it is possible to activate or select many additional

functions and adaptations of controller performance. When you select the required para

meter group in the menu, a new screen opens:

Parameter

mark

Parameter

description

Parameter value

Hydraulic scheme

The setting is changed by pressing the button . Because the parameters are factory

locked, a new screen appears. Here you have to enter the unlock code.

Setting range

Default value

This manual suits for next models

1

Table of contents

Languages:

Other Seltron Temperature Controllers manuals