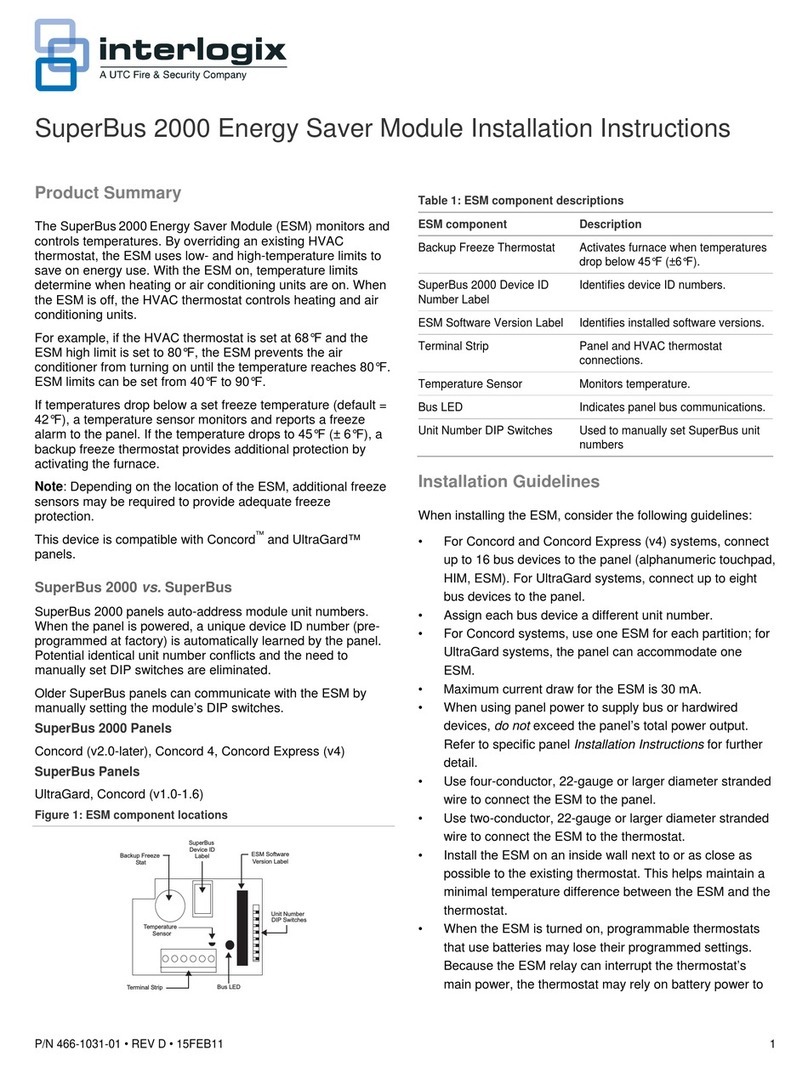

Eliwell EWPC 902/S Series User manual

GENERAL DESCRIPTION

The EWPC 902/S is a new series of micro-

processor based and fully programmable

process controllers for single setpoint ap-

plications.

The front keypad of these controllers offers

several alpha-numeric menu prompts to

configure the controller for each specific

application.

Furthermore, the instrument is equipped

with a RS-485 port for the purpose of con-

necting it into a Televis system; is compat-

ible with Televis software rel 2.4 or greater.

In case its use with different software re-

leases is required contact your supplier or

Eliwell Customers’ Service.

Three different versions of this controller

are available: EWPC 902/T/S for

Temperature, EWPC 902/R/S for Relative

humidity and EWPC 902/P/S for Pressure

control.

The EWPC 902/S is supplied in the popu-

lar “32x74” ELIWELL housing.

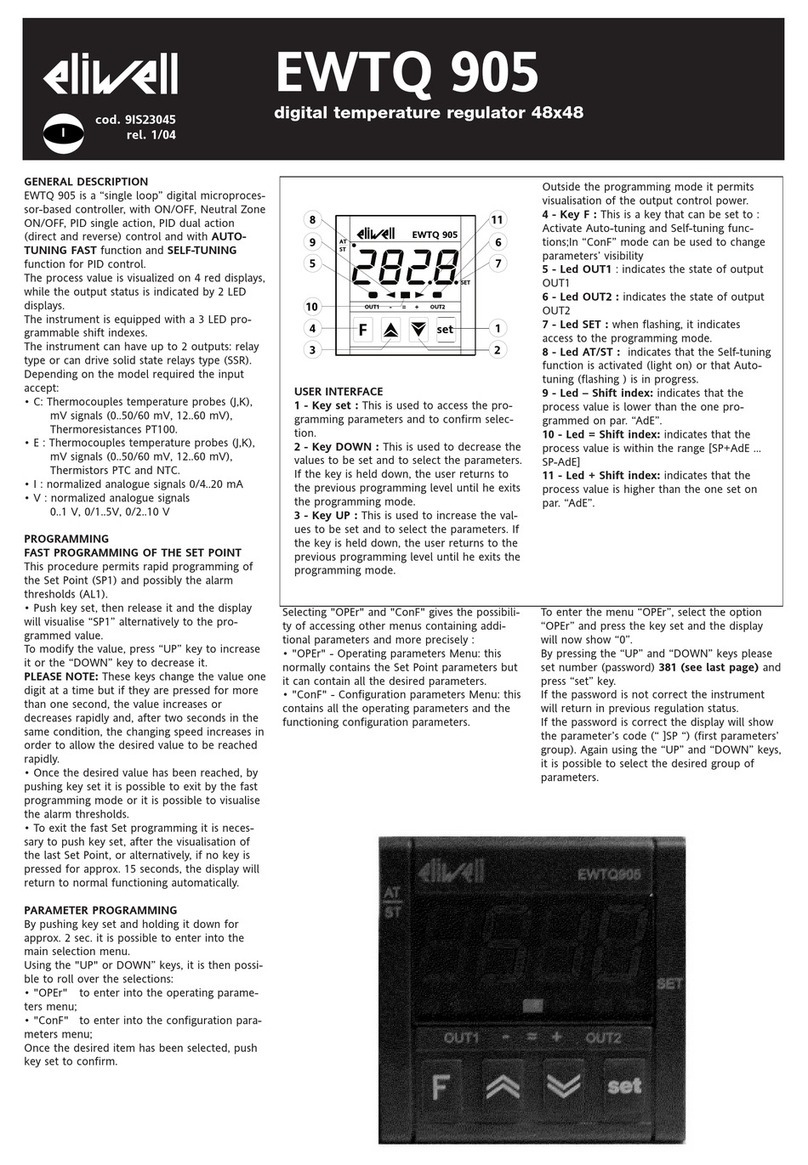

FRONT KEYPAD

SET: push to display the setpoint value.

The setpoint can be changed within 5 sec-

onds with the “UP” or “DOWN” button.

The control will automatically switch back

to normal operating mode within 5 sec-

onds; the last entered setpoint will stay in

memory.

UP: used to increase the setpoint value, as

well as the parameter when in program-

ming. When held down for a few seconds,

the change rate accelerates.

DOWN: used to decrease the setpoint val-

ue, as well as the parameter when in pro-

gramming. When held down for a few

seconds, the change rate accelerates.

Led “SET”: on during setpoint

display/change or blinking during program-

ming.

Led “OUT”: status light of the output.

PARAMETER PROGRAMMING

Programming is easily accessed by holding

the “SET” button down for more than 7

seconds; the first parameter is displayed

while the status light Led “SET” remains

blinking during the programming period.

Other parameters are accessed with the

“UP” and “DOWN” button. With the “SET”

button, the actual setting of each parame-

ter is displayed. To change a parameter

setting, push the “SET” plus the “UP” (or

“DOWN”). The system will automatically re-

turn to its normal operating mode a few

seconds after the programming procedure

is completed or interrupted.

DESCRIPTION OF PARAMETERS

diF: diFferential.

The switching differential (hysteresis) can

be set with positive value (make on rise) or

with negative value (make on fall).

LSE: Lower SEt.

This is the lower limit below which the user

cannot change the setpoint; normally set at

the lowest value recommended for the

sensor.

HSE: Higher SEt.

Similar to “LSE”, however setting an upper

limit for the setpoint.

Att: Alarm temperature type (“HAL” and

“LAL”).

Ab = absolute;

re = relative.

HAL: Higher ALarm.

Maximum temperature alarm. Maximum

temperature value – when exceeded the

information is sent to the Televis system.

LAL: Lower ALarm.

Minimum temperature alarm. When the

temperature reaches a lower value the in-

formation is sent to the Televis system.

Set to a negative value when parameter

“Att = re”.

AFd: Alarm (Fan) differential.

PAO: Power-on Alarm Override.

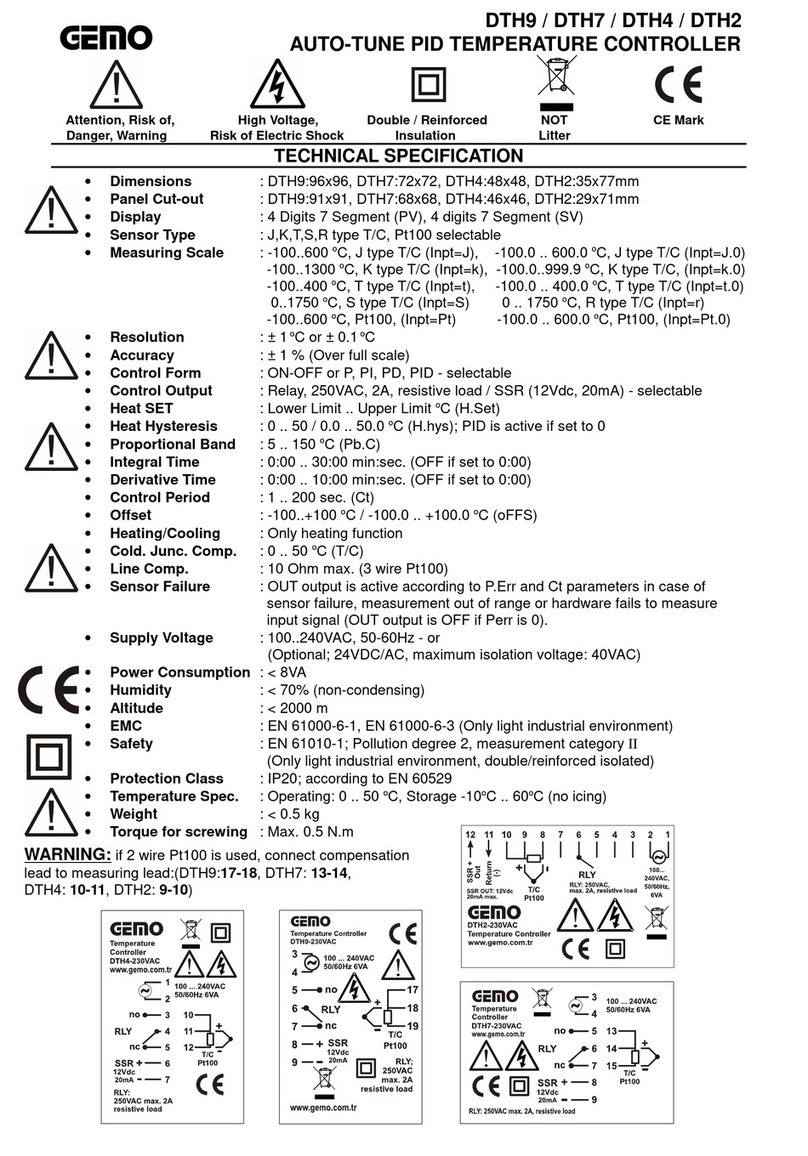

HOW IT IS MADE

• Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm

(2.637")

• Mounting: flush panel mount with

mounting bracket

• Protection: the instrument front-

panel is waterproof IP65; an op-

tional snap-on cover can be

supplied to provide additional pro-

tection of the rear terminal block

• Connections: screw terminal block

(2.5 mm2; one wire each terminal

only, in compliance with VDE

norms)

• Output: one (1) SPDT relay 8(3)A

250VA

• Auxiliary output: 12 VC/60 mA (for

transducer power supply, e.g. hu-

midity sensor, pressure transducer,

etc.)

• Inputs (depending on model):

PTC / Pt100 / current (4…20 mA;

Ri = 41 Ω) for EWPC 902/T/S;

EWHS 28/31 for EWPC 902/R/S

and EWPA 007/030 for EWPC

902/P/S

• Serial connection: RS-485 serial

port for connection to the Televis

system

• Televis system compatibility: soft-

ware release 2.3.2 or greater

• Resolution: 1 °C (°F) or 0.1 °C (°F).

The right-most digit can also be

set to read-out in 0 or 5 only, or in

all 10 digits

• Accuracy: better than 0.5% of full

scale

• Power supply: 12…24 VA/C

WHAT IT IS

The EWPC 902/S is a series of mi-

croprocessor based and fully pro-

grammable process controllers for

single setpoint applications.

The instrument is equipped with a

RS-485 port for the purpose of con-

necting it into a Televis system.

Three different versions of this con-

troller are available: EWPC 902/T/S

for Temperature, EWPC 902/R/S for

Relative humidity and EWPC

902/P/S for Pressure control.

EWPC 902/S

temperature controller with Televis output

tAo: temperature Alarm override.

cPP: compressor Probe Protection.

Select compressor relay status in case of

room probe defect.

oF = compressor OFF in case of probe de-

fect;

on = compressor ON in case of probe de-

fect;

dc = NOT AVAILABLE.

ctP: compressor type Protection.

Select the type of (short-cycle) protection

best suited for the compressor; the actual

delay time is programmed with the next

parameter.

nP = no Protection;

don = delay on start; delay applies when

relay is energized;

doF = delay at switching oFf. Delay after

stop, i.e. time between stop and subse-

quent start;

dbi = delay between two successive starts.

Limits the number of start-ups per hour.

cdP: compressor delay Protection.

The time delay - in minutes - applicable to

the previous parameter “ctP”.

odo: output delay (at) on.

Time delay - in minutes - applied to activa-

tion of the relays after start-up.

CAL: CALibration.

Temperature read-out offset to allow for a

fixed adjustment up or down due to probe

location, if desired.

dEA: dEvice Address.

To select the (address) label of the device in

relation to the supervisory system.

FAA: FAmily Address.

To select the (family) label of the device in

relation to the supervisory system.

ndt: number display type.

Visualization number of display.

in = entire;

dE = decimal;

hF = half.

Lci: Lower current input.

For EWPC 902/R/S, EWPC 902/P/S and

EWPC 902/T/S with current input only.

Read-out corresponding to 4 mA input sig-

nal (factory set at 20 %R.H for EWPC

902/R/S).

Hci: Higher current input.

For EWPC 902/R/S, EWPC 902/P/S and

EWPC 902/T/S with current input only.

Read-out corresponding to 20 mA input

signal (factory set at 100 %R.H for EWPC

902/R/S).

PAS: PASsword.

Permits to set the password value.

0 = no password required to enter para-

meter programming;

1…15 = admitted values for the password.

rEL: rELease firmware.

Code of device version.

Hdc: Hardware code.

Read-only parameter indicating the hard-

ware code of the device.

tAb: tAble of parameters.

This shows the configuration of the para-

meters as set in the factory; can not be

modified (for factory identification and di-

agnostic purposes only).

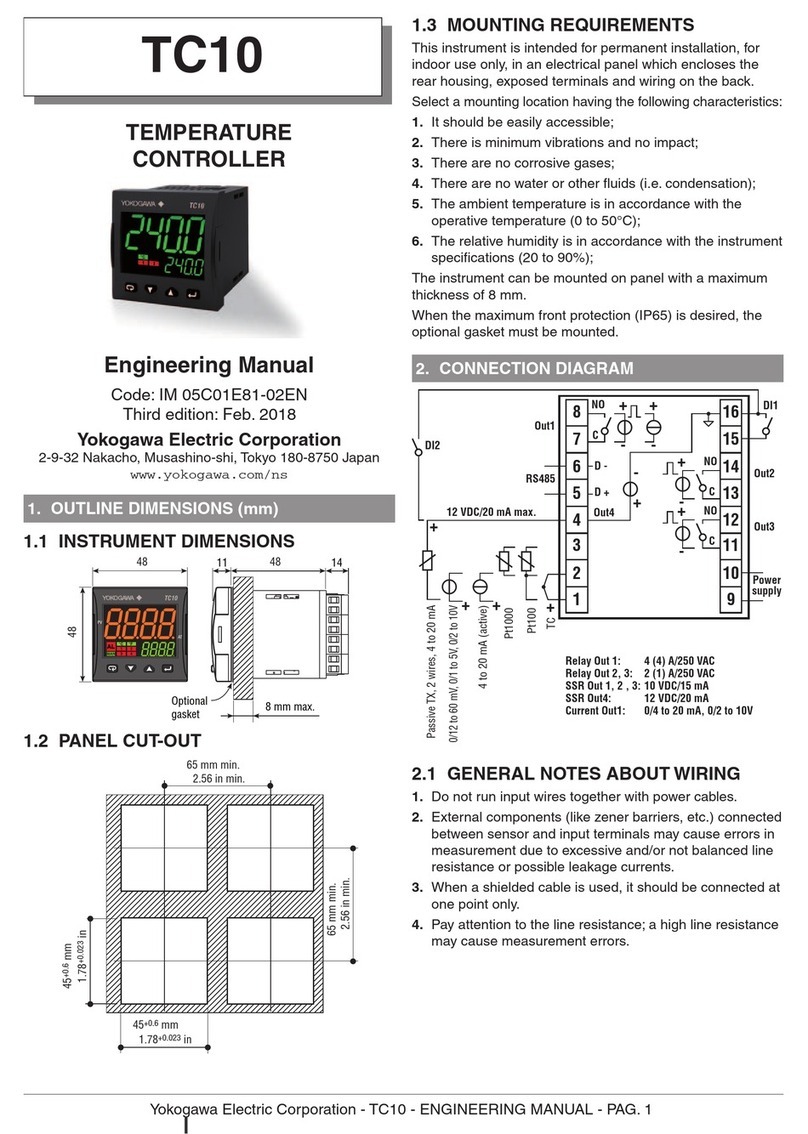

INSTALLATION

The instrument is designed for flush panel

mount. Prepare a 71x29 mm panel cut-

out; insert the instrument through the front

and fasten with the U-bracket supplied

with the unit. The ambient temperature

around the instrument should be kept be-

tween –5…65 °C (23…149 °F).

Do not install the instrument in moist

and/or dirty places or near heat sources; it

is suitable for operation in environments

with an ordinary pollution level.

Leave enough room for air circulation by

the cooling holes of the instrument.

ELECTRICAL WIRING

The instrument is equipped with a screw

terminal block suitable for max 2.5 mm2

wiring (one wire each terminal only, in com-

pliance with VDE norms). Make sure that

the low voltage power supply matches re-

quirements: 12…24 Va/c.

According to the type, the probe shall be

connected according to the electric dia-

gram on the instrument body.

In case of Eliwell pressure or humidity

probes connected to EWPC 902/R/S or to

EWPC 902/P/S, bear in mind that two-wire

probes (such as EWHS 28 or EWPA) are

directly supplied by the instrument, while

the 4-wire probe (EWHS 31) needs an ex-

ternal power supplier.

Temperature probes do not require polarity

insertion and can be easily by using com-

mon 2-lead wires (please note that long

probes involve a worse instrument perfor-

mance for EMC electromagnetic compati-

bility: utmost care shall be put in cabling).

Probe cables shall be kept separate from

line voltage and load wires for safety and

EMC reasons. The coordinated European

standards impose that power wires (and

generally, all parts subject to dangerous

voltage) shall be kept separate from very

low voltage with insulation and distances

suitable to ensure at least a double or rein-

forced insulation. EMC requirements sug-

gest/impose to put more care in such

separation by using insulating separate

raceways and proper cable fixing methods.

The relay output is voltage-free and inde-

pendent. Do not exceed the maximum al-

lowed power: 8(3)A 250Va. For heavier

loads, an external contactor with suitable

power shall be used.

ERROR ANNOUNCIATION

The instrument is provided with only one

error message “E1”, both in case of short-

ed sensor and in case of sensor break, or

sensor absence. The “E1” error message

also appears in the event of underrange of

the system temperature or in the event of

overrange of the system temperature.

TECHNICAL DATA

Housing: black ABS plastic, autoestin-

guish.

Dimensions: front 74x32 mm

(2.913x1.260"), depth 67 mm (2.637").

Parameter

diF

LSE

HSE

Att

HAL

LAL

AFd

PAO

tAo

cPP

ctP

cdP

odo

CAL

dEA

FAA

ndt

Lci*

Hci*

PAS

rEL

Hdc

tAb

* only for EWPC 902/R/S, EWPC 902/P/S and EWPC 902/T/S with current input

2EWPC 902/S 7/2000 ing

DEFAULT SETTINGS - STANDARD MODELS

Description

diFferential

Lower SEt

Higher SEt

Alarm temperature type

Higher ALarm

Lower ALarm

Alarm (Fan) differential

Power-on Alarm Override

temperature Alarm override

compressor Probe Protection

compressor type Protection

compressor delay Protection

output delay (at) on

CALibration

dEvice Address

FAmily Address

number display type

Lower current input

Higher current input

PASsword

rELease firmware

Hardware code

tAble of parameters

Range

–12…12

–999…999

–999…999

Ab / re

–999…999

–999…999

1…50

0…10

0…250

oF / on / dc

nP/don / doF /dbi

0…15

0…99

–12…12

0…14

0…14

in / dE / hF

–999…999

–999…999

0 / 1…15

/

/

/

Default

–1

–80

600

Ab

0

0

1

10

0

oF

nP

0

0

0

0

0

in

20

100

0

/

/

/

Unit

°C / °F

°C / °F

°C / °F

flag

°C / °F

°C / °F

°C / °F

hours

minutes

flag

flag

minutes

minutes

°C / °F

number

number

flag

°C / °F

°C / °F

flag

/

/

/

3EWPC 902/S 7/2000 ing

Mounting: flush panel mount with mount-

ing bracket.

Protection: the instrument frontpanel is

waterproof IP65; an optional snap-on cov-

er can be supplied to provide additional

protection of the rear terminal block.

Connections: screw terminal block

(2.5 mm2; one wire each terminal only, in

compliance with VDE norms).

Display: 12.5 mm LED (0.50").

Push buttons: located on front panel.

Data storage: non-volatile EEPROM

memory.

Operating temperature: –5…65 °C;

(23…149 °F).

Storage temperature: –30…75 °C;

(–22…167 °F).

Output: one (1) SPDT relay 8(3)A 250Va.

Auxiliary output: 12 Vc/60 mA (for trans-

ducer power supply, e.g. humidity sensor,

pressure transducer, etc.).

Inputs (depending on model): PTC / Pt100

/ current (4…20 mA; Ri = 41 Ω) for EWPC

902/T/S; EWHS 28/31 for EWPC 902/R/S

and EWPA 007/030 for EWPC 902/P/S.

NOTE: the four-wires EWHS 31 need the

external voltage.

Serial connection: RS-485 serial port for

connection to the Televis system.

Televis system compatibility: software

release 2.3.2 or greater.

Resolution: 1 °C (°F) or 0.1 °C (°F). The

right-most digit can also be set to read-out

in 0 or 5 only, or in all 10 digits.

Accuracy: better than 0.5% of full scale.

Power supply: 12…24 Va/c.

DISCLAIMER

This manual and its contents remain the

sole property of Invensys Climate Controls

s.p.a., and shall not be reproduced or dis-

tributed without authorization. Although

great care has been exercised in the

preparation of this document, Invensys

Climate Controls s.p.a., its employees or

its vendors, cannot accept any liability

whatsoever connected with its use.

Invensys Climate Controls s.p.a. reserves

the right to make any changes or improve-

ments without prior notice.

EWHS 28 input

4…20 mA

input

12 Vdc out

blue

brown

EWPC 902/S

6 7 8 9

POWER SUPPLY

510

7 8

PTC Pt100

load

7 8 7 8

7 8

1 2 3

+–

RS-485

EWPA 007

EWPA 030

brown

white

7 8

CONNECTIONS

Invensys Climate Controls s.p.a.

via dell'Industria, 15

Zona Industriale Paludi

32010 Pieve d'Alpago (BL)

ITALY

Telephone +39 0437 986111

Facsimile +39 0437 986066

Email [email protected]

Internet http:/www.climate-eu.invensys.com

7/2000 ing

cod. 9FT40075

This manual suits for next models

3

Other Eliwell Temperature Controllers manuals