SEM 0304 User manual

MAN-001 Rev. 4 | Created 3-10-2020 | ECN-00519

This manual covers all Model 0304 and Model 0305 congurations

For service, parts, and customer support, contact us:

SECURITY ENGINEERED MACHINERY

5 Walkup Drive | Westborough, MA 01581

508-366-1488 | [email protected]

www.semshred.com

SEM Model 0304 & 0305

Operation and Maintenance Manual

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 1

Contents

Disclaimers.............................................................................................................. 2

Safety ..................................................................................................................... 3

About Your Shredder - 0304................................................................................... 4

Overview and Intended Use...................................................................................4

Shredder Conguration ..................................................................................................4

About Your Shredder - 0305................................................................................... 5

Overview and Intended Use...................................................................................5

Shredder Conguration..........................................................................................5

Acceptable Media – HDD Combo Chute...............................................................6

Acceptable Media – SSD Combo Chute................................................................6

Unacceptable Media ..............................................................................................6

Unpacking and Installation .................................................................................... 7

Uncrating ................................................................................................................7

General Installation ............................................................................................... 8

Conveyor Shroud Installation ................................................................................. 9

Assembling Dust Cover .......................................................................................... 9

Electrical .............................................................................................................. 11

Installation ............................................................................................................11

Voltage Specications...........................................................................................12

Operation ............................................................................................................ 13

Standard and CE Control Scheme - 0304/0305 ...................................................13

Pre-Start Up..........................................................................................................13

Start Up Procedure and Operation ..................................................................... 14

Shut-Down Procedure ..........................................................................................15

Maintenance ......................................................................................................... 16

Maintenance Tools and PPE ................................................................................. 16

Maintenance Schedule ......................................................................................... 16

Air Filtration System ............................................................................................18

Current Relay Adjustment ....................................................................................21

Cutting Head Adjustment ...................................................................................22

Maintenance Diagrams ......................................................................................... 23

General Layout - 0305 ..........................................................................................23

General Layout - 0304 ..........................................................................................24

Drive System.........................................................................................................25

Extra Options and Spare Parts............................................................................. 26

Model 0305 & 0304 Operation and Maintenance Manual

2 SEM | www.semshred.com

Disclaimers

Every care has been taken by the staff of SEM in compilation of the data contained in

all training and informational materials (“collateral”) and in verication of its accuracy

when published; however, the content of this collateral is subject to change without

notice due to factors outside the control of SEM and this collateral should therefore

be used as a guide only. The products referred to in these publications are continually

improved through further research and development, which may lead to the alteration

of information contained in this collateral. SEM does not accept any responsibility

whatsoever for misrepresentation by any person of the information contained in

this collateral and expressly disclaims any and all liability and responsibility to any

person, whether a reader/viewer of this collateral or not, with respect to claims,

losses, damage, or any other matter, either direct or consequential, arising out of or in

relation to the use and reliance upon any information contained or products referred

to in this collateral. SEM does not warrant that the equipment will work properly in

all environments and applications, and makes no warranty or representation, either

implied or expressed, with respect to the performance, throughput, or maintenance

requirements of the machine. Performance, throughput, and maintenance requirements

vary depending on screen size, feed rate, and media type as well as operational

procedures. Information in this collateral is subject to change without notice and does

not represent a commitment on the part of SEM. SEM assumes no responsibility for any

inaccuracies that may be contained in this collateral or any omissions that may have

occurred. SEM makes no commitment to update or keep current the information in this

collateral and reserves the right to make improvements to this collateral and/or to the

products described therein at any time without notice.

Proprietary Information: This document contains proprietary and condential

information of SEM, and shall not be used, disclosed or reproduced, in whole or in

part, for any purpose, without the prior written consent of SEM. Title in and to this

document and all information contained herein remains at all times in SEM. This

information is exempted from disclosure under FOIA, as amended.

The combo SSD chute and SSD units intended for the destruction of solid state

media only. Attempting to shred rotational drives in the SSD chute could cause

catastrophic damage to the unit and will void warranty.

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 3

Safety

Read and understand instruction manual and be aware of all warning stickers.

Always follow proper PPE and lock out tag out procedures (LOTO).

Make sure that all guards and access panels are in place at all times, EXCEPT when the

power is locked off for maintenance work or cleaning.

Always know where emergency stop buttons are located.

Always know or have quick access to emergency phone numbers.

Always ensure that all maintenance and operating personnel read and understand this

manual, including those personnel working second or third shift.

Always have a standard break-in time for a new operator. A minimum of two hours is

suggested.

Always wear safety glasses when operating shredder.

Always lock-out power at the disconnect when shredder is not in use, when servicing

shredder, or when performing routine shredder maintenance. This includes cleaning.

Never operate this or any other machine while under the inuence of drugs, alcohol,

or medications.

Never wear loose tting clothing, ties, or jewelry while in the vicinity of this shredder.

Never allow long hair to be in the vicinity of the machine without use of a protective

hair net.

Never place any part of your body in or on any part of the machine while in operation.

Never allow other personnel within ten feet of this machine while in operation.

Never remove guards, perform maintenance, or clear jam up debris without rst

locking out power disconnect.

Never allow horse play around machine.

Never bypass or interfere with any safety limit switches or guards. They are safety

devices and serious injury can result if bypassed.

Never allow minors to operate the machine.

Model 0305 & 0304 Operation and Maintenance Manual

4 SEM | www.semshred.com

About Your Shredder

0304

For information about other cutting head congurations and features, such as wider

feed chutes, 11” X 2.5” (option to 19.25”W), contact SEM customer care.

The maintenance and operation information in this manual is also applicable to the

Model 0301 and 0302. Contact SEM Customer Care for electrical information or details

about these devices.

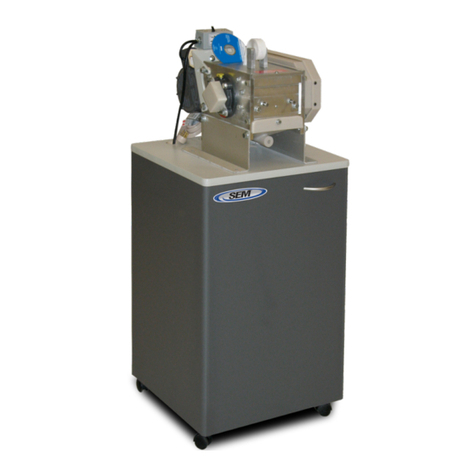

Overview and Intended Use

The SEM Model 0304 HDD/SSD Shredder employs a 20 horsepower motor to de

-

stroy up to 3,000 rotational or solid state hard drives or up to 3,500 e-media devices

(phones, RAM, etc.) per hour depending on the cutting head conguration chosen

at purchase. This unit is also capable of destroying enterprise drives at a rate of up

to 800 per hour, and up to 1,400 enterprise SSDs per hour. Solid state media can be

destroyed with a combo HDD chute but SEM recommends using the combo SSD chute

for higher security destruction.

Size and Weight:

When fully assembled, the SEM Model 0304 is approximately 67”

(170.18cm) tall by 65” (165.1cm) wide and 114” (289.56cm) deep. It weighs approxi

-

mately 4,700 lbs (2,100 kg).

Note:

The images shown in this manual may appear slightly different due to the age

of your machine and the features ordered with it. All functionality and locations re

-

main the same or very similar to your machine. Contact SEM customer service with any

questions. Some iimages may show optional features that must be ordered at time of

purchase.

Shredder Conguration

The SEM Model 0304 is designed to shred standard rotational hard drives, solid state

drives, tapes and various electronic media depending on the cutting head congura

-

tion chosen at the time of purchase. Hard drive shreds at 1.5” or 0.75” shred widths.

This can also shred SSDs but not to secure particle sizes.

HDD/SSD combo units have two cutting heads allowing destruction of both types of

media. HDD can be shredded to 38mm/1.5”, while SSD can be shredded to 0.375”.

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 5

About Your Shredder

0305

For information about other cutting head congurations and features, such as wider

feed chutes or .375 SSD shred widths contact SEM customer care.

The maintenance and operation information in this manual is also applicable to the

Model 0301 and 0302. Contact SEM Customer Care for electrical information or details

about these devices.

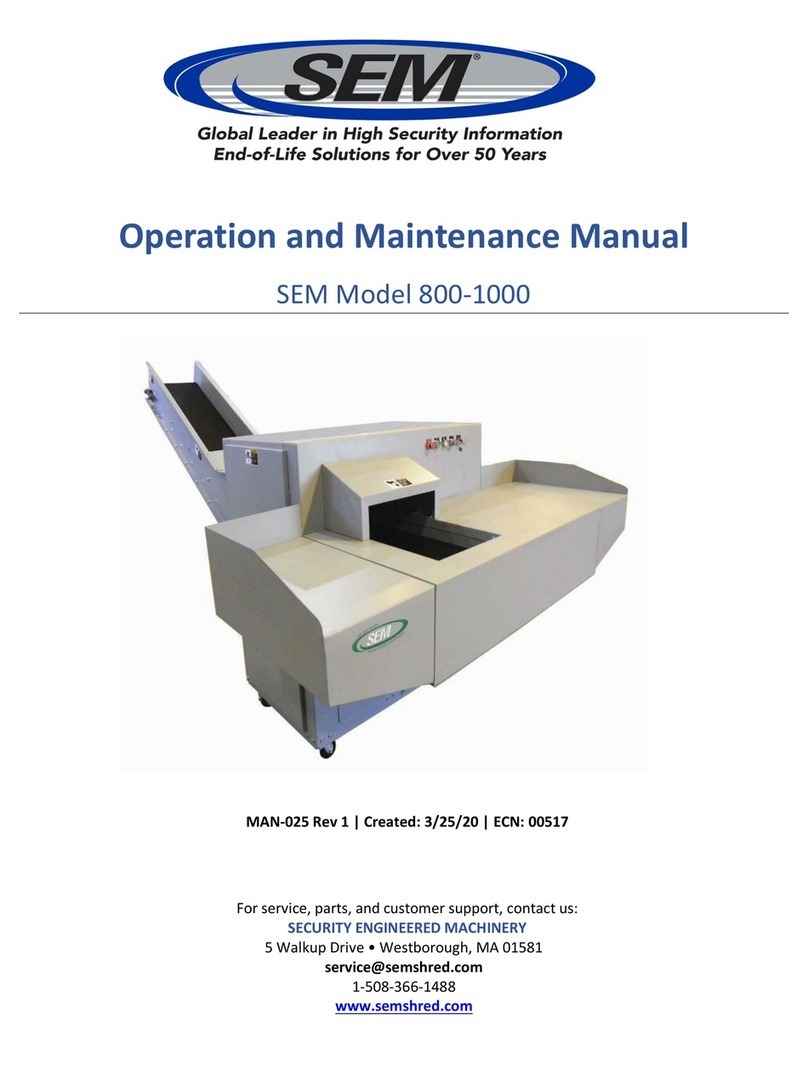

Overview and Intended Use

The SEM Model 0305 HDD/SSD Shredder employs a 10 horsepower motor to de-

stroy up to 3,000 rotational or solid state hard drives or up to 3,500 e-media devices

(phones, RAM, etc.) per hour depending on the cutting head conguration chosen

at purchase. This unit is also capable of destroying enterprise drives at a rate of up

to 800 per hour, and up to 1,200 enterprise SSDs per hour. Solid state media can be

destroyed with a combo HDD chute but SEM recommends using the combo SSD chute

for higher security destruction.

Size and Weight: When fully assembled, the SEM Model 0305 is approximately 66”

(167.64 cm) tall by 58” (147.32 cm) wide and 89” (226.06 cm) deep. It weighs approxi-

mately 2,800 pounds (1270 kg).

Note: The images shown in this manual may appear slightly different due to the age

of your machine and the features ordered with it. All functionality and locations re-

main the same or very similar to your machine. Contact SEM customer service with any

questions. Some images may show optional features that must be ordered at time of

purchase.

Shredder Conguration

The SEM Model 0305 is designed to shred standard rotational hard drives, solid

state drives, tapes and various electronic media depending on the cutting head

conguration chosen at the time of purchase. Hard drive shreds at 1.5”shred widths.

This can also shred SSDs but not to secure particle sizes.

HDD/SSD combo units have two cutting heads allowing destruction of both types of

media. HDD can be shredded to 1.5”, while SSD can be shredded to 0.375”.

Model 0305 & 0304 Operation and Maintenance Manual

6 SEM | www.semshred.com

Acceptable Media

HDD Combo Chute

The following media is acceptable to be destroyed with combo HDD chute:

• Rotational Hard Drive

• Enterprise Hard Drive

• Tapes

SSD Combo Chute

The following media is acceptable to be destroyed with an combo SSD chute:

• Solid State Drives

• Enterprise SSDs

Do not shred rotational hard drives using the combo SSD chute as damage to the

machine may occur and your warranty will be voided.

Unacceptable Media

The following materials should never be destroyed used a SEM Model 0305 shredder.

• Batteries

• Capacitators

• LCDs

Batteries and capacitors should never be destroyed using this machine. Both can be

found inside of cell phones, tablets, etc. They must be removed from all devices before

shredding. Destruction of batteries could lead to safety hazards and cause damage to

the machine. All batteries must be removed from cell phones, PDAs, tablets, etc. prior

to destruction.

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 7

Unpacking and Installation

Your new SEM shredder has been secured to a pallet for shipping. Please inspect

equipment immediately for shipping damage.

• Note any damage to the packaging or unit on the bill of lading and contact SEM

customer service.

• Retain packaging for 90 days.

• Using a lift truck with a minimum capacity of 4,000 lbs. Remove the machine from

the carrier and transport to operation site. Remove pallet and discard responsibly

after 90 days.

• SEM shredders are equipped with swivel casters for ease of handling.

• Inspect the machine for any damages prior to installation and operation. Check the

oil level and check for any oil leaks.

• After inspection, make certain that all guards and safety devices are installed

properly.

• If purchased, make sure to install the conveyor shroud and gaylord dust cover

before operation.

• Consumables are also included within shipments.

Uncrating

• Fork lift with 4,000 or 6,000 lb. capacity, see above.

• Pry bar

• Strap cutters

• Hammer, drill

• #2 Phillips, T20, T25 Bits, 9/16”socket wrench

Unpacking:

• Remove front and top of crate with drill and appropriate bits marked with

spraypaint. Cut straps holding the unit with strap cutters.

• Remove bolts holding brackets at the base of the unit in the front and back.

Remove boards in front and on top of the unit.

• Remove the unit from the pallet and bring as close to installation point as possible

with fork lift truck.

Model 0305 & 0304 Operation and Maintenance Manual

8 SEM | www.semshred.com

General Installation

This machine may be installed in an ofce or warehouse setting within six feet of an

appropriate electrical receptacle.

Note: The unit’s weight is mostly on the left side. Use care when moving and stay clear

if it begins to tip.

Note: It is recommended to move the unit as close to the installation area as possible

using a fork lift, particularly if it requires traversing uneven surfaces.

Storage: If unit requires storage, it can be stored in its shipping crate or unpackaged. If

unpackaged, ensure that all caster locks are engaged.

To transport, unlock all caster locks and then push on a at surface. Do not push this

unit on inclined or declined surfaces as control of the unit may be lost and damage to

the machine or injury to personnel may occur.

Install the output conveyor if not

installed. Requires metal shears,

one 1-1/8” open wrench or

adjustable wrench, 9/16” socket

wrench, and 1/2” wrench.

• With the assistance of an

overhead crane or a forklift, the

conveyor can be hoisted into

position. Use a sling to lift the

conveyor assembly into place,

then, using the bolts supplied

at rear of machine, attach

conveyor and tighten bolts.

• Install conveyor belt around

drive pulley (under cutting

head) and pull belt along belly

pan and top plate. A second

person may be necessary to bring both ends together. When both ends are put

together, take extra care to align the lacing. When aligned properly, put connecting

pin (supplied) through the lacing. Clip off any excess pin which may be hanging out.

• Tighten belt snug. Belt must be tight enough so that it cannot be stopped by a

hand.

Remove

hardware

from end of

conveyor.

Reinstall bolts

where they

were removed

(both sides).

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 9

Conveyor Shroud Installation

Install conveyor shroud if not installed. It is recommended that two people do

this and requires 1/2” wrench, 1/2” socket, and 1-1/8” wrench. This section only

applies to units purchased with the optional conveyor shroud.

• Remove hardware from the end of the conveyor.

Loosen the nut holding the conveyor’s bearing covers and remove the covers.

• Have second person hold the shroud in place at the end of the conveyor and install

the bolts into the holes from which they were removed.

• Ensure conveyor shroud side covers are on the outside.

• Tighten bolts and reinstall conveyor bearing covers.

• With the assistance of an overhead crane or a forklift, the conveyor can be hoisted

into position. Use a sling to lift the conveyor assembly into place, then, using the six

bolts supplied at rear of machine, attach conveyor and tighten bolts.

• Install conveyor belt around drive pulley (under cutting head) and pull belt along

belly pan and top plate. A second person may be necessary to bring both ends

together. When both ends are put together, take extra care to align the lacing.

When aligned properly, put connecting pin (supplied) through the lacing. Clip off

any excess pin which may be hanging out.

Assembling Dust Cover

This section only applies to units purchased with the optional dust cover.

• Open the box (not included) and unfold.

• Fold open the walls inside the base.

• May help to place a piece of wood inside to hold the shape. (Fig. 1)

• Staple or otherwise secure the walls to the base.

• Slide the opening in the middle of the cover around the conveyor shroud and

tighten the cord. (Fig. 2)

• Slide the rest of the cover over the box. (Fig. 3)

• Guide the belt through the loops and tighten snugly. (Fig. 4, 5)

Model 0305 & 0304 Operation and Maintenance Manual

10 SEM | www.semshred.com

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 11

Electrical

Installation

NOTE: All electrical MUST be completed by a licensed electrician.

• Be sure to follow proper “Lock Out Tag Out” (LOTO) procedures.

• A schematic can be found in both the electrical panel and debris drawer. Available

in PDF on request.

• All units work on 3-phase AC power.

• All electrical installation must be done by a qualied electrician. Follow all national

and local electrical codes and ordinances.

• All internal wiring has been factory installed and tested prior to shipping. Electrical

installation consists of providing adequate machine power only.

• Check building service to ensure correct voltage is available and that the electrical

current requirements can be met.

• Ensure area is clear. Turn the key switch on and turn E-STOP clockwise, ensuring it’s

not engaged. Check for proper motor rotation. The conveyor belt should run away

from the operator if the forward button is pressed. Motor rotation is dependent on

how customer’s electrical panel is wired. If rotation is wrong, a licensed electrician

can correct it.

• Electrical installation is complete. Replace all guards and safety devices.

• Notes: SEM recommends a less than 3% voltage drop on the receptacle/disconnect

for optimal performance while under load.

• Run a few drives and adjust current relay as needed. See section 4.6 for information

regarding adjusting current relay. Recommend using a licensed electrician.

Model 0305 & 0304 Operation and Maintenance Manual

12 SEM | www.semshred.com

Voltage Specications

0305

Voltage /

Frequency

Full Load Amps (FLA)

[FLA with Air System]

Recommended

Disconnect

Apparent Power

(Line to Line) kVA

208V/60Hz 31 [36] 50 Amp 11.2 [13]

230V/60Hz 28 [33] 50 Amp 11.2 [13.1]

380V/50Hz 18.1 [20.4] 30 Amp 11.9 [13.4]

400-415V/50Hz 18 [20.3] 30 Amp 12.7 [14.3]

460V/60Hz 14 [16.1] 30 Amp 11.2 [12.8]

0304

Voltage /

Frequency

Full Load Amps (FLA)

[FLA with Air System]

Recommended

Disconnect

Apparent

Power (Line

to Line) kVA

208V/60Hz 52.4 [55.8] 75 Amp 11.2 [13]

230V/60Hz 48.4 [51.6] 75 Amp 11.2 [13.1]

460V/60Hz 24.2 [25.8] 50 Amp 11.9 [13.4]

380,400-415V/50Hz 27.5 [29.2] 50 Amp 12.7 [14.3]

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 13

Operation

Standard and CE Control Scheme

Depending on model, buttons may be in slightly different positions.

Emergency Stop: Immediately turns off power to the machine. Machine cannot turn

on until disengaged. Twist to disengage.

Shredder Forward: Starts the machine.

Shredder Reverse: Makes the cutters rotate backwards to unjam the machine or help

in cleaning waste from cutting head. Must be held down to run in reverse. Machine

must be stopped before reversing.

Key Switch: Turns power to the machine on or off.

Shredder Stop: Stops the machine. Press the stop button anytime to stop the

machine.

Hour Meter: Shows number of hours machine has operated.

Pre-Start Up

• Familiarize yourself with all controls and button locations.

• Ensure that all guards and covers are in place.

• A certied SEM service technician is available over the phone or on site for startup

instruction and training. Contact SEM customer service for details and have your

Model 0305 & 0304 Operation and Maintenance Manual

14 SEM | www.semshred.com

Start Up Procedure and Operation

PPE: SEM recommends wearing safety glasses, mask, and gloves while operating this

machine. However, each site should determine its own PPE.

Turn the KEY SWITCH on and disengage the E-STOP, then press the SHREDDER

FORWARD BUTTON. The cutters will begin to rotate towards each other and the

output conveyor will begin to run forward, away from the operator.

In Case of Emergency: The E-STOP button or turn the KEY SWITCH.

Feeding: Begin feeding material into the appropriate feed chute. Feed drives one at a

time.

Chute Blocker: If this unit is equipped with a chute blocker, be sure that it is covering

the correct chute. To change chutes, lift the knob and slide it towards the chute that is

not in use.

Reminder: DO NOT SHRED ROTATIONAL HARD DRIVES USING THE SSD CHUTE.

New Operators: New operators should be given a minimum 2-3 hour equipment

training time, beginning with a slow feed rate, approximately one drive every 10-15

seconds. The operator will soon be able to judge how quickly the shredder can be fed.

Debris Drawer Lock (Optional): The debris drawer is equipped with a lock and blue

key if CE or specied at purchase. Turn the key before opening the drawer. Do not

attempt to force the drawer open or open drawer while unit is running.

Important/Warning: The debris drawer is attached to keep excess material from col-

lecting on oor. Drawer must be emptied frequently (approx. every 100 drives) or dam-

age to the belt and unit may occur. Debris drawer should be emptied at the beginning

and end of each operator’s shift regardless of the number of drives shredded.

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 15

Clearing a Jam

• In the event of a jam, ensure that all personnel are clear of both the input chute and

the cutting head.

• Hold the SHREDDER REVERSE button for 5-7 seconds. This will cause the cutters

to run backwards for as long as the reverse button remains pressed.

• Release the reverse button. The machine will come to a stop. After the machine has

completely stopped, press the forward button and try to shred material.

• If machine jams again, reverse shredder, LOCK OUT POWER, and manually remove

the jammed material.

• Restart machine in the forward direction to resume operation.

Warning: NEVER hold the forward button as damage to the machine and the elec-

trical system may occur.

Shut-Down Procedure

• Allow input chute and output conveyor to clear all material before shutting down.

Wait approximately 30 seconds.

• Press the Shredder Stop button. Turn Key Switch to off position and activate

E-STOP.

• Turn off the disconnect switch.

Begin daily cleaning.

• See section 4.2 for maintenance schedule.

Model 0305 & 0304 Operation and Maintenance Manual

16 SEM | www.semshred.com

Maintenance

Maintenance Tools and PPE

• Safety glasses and cut resistant gloves

• One 1-1/8” wrench or one adjustable wrench

• 7/16” and two 1/2” wrench or socket wrench

• Phillips head and athead screwdriver

• 1-1/8” crowfoot wrench

• Grease gun with standard tting

Maintenance Schedule

Daily:

• Empty debris drawer (every 100 drives and before and after every shift).

• Wipe down machine with cleaning solution.

• Rake waste in gaylord to prevent pyramiding.

Every 15-20 Hours:

• Open the conveyor rear access panel and clean debris from the cutters and inspect

air inlet. Remove any magnetic buildup over the air inlet.

• Grease main bearings, wear plates. There are eight grease ttings, four on each

side of conveyor. Add 4 pumps of grease into each tting. Warning: do not over-

pump.

• Apply light machine oil to cutters.

• Check belt tension. If slipping or loose, tighten.

• Replace prelter.

Every 30-40 Hours:

• Apply oil to conveyor drive chains.

• Check oil level of spur gears.

• Clean HEPA lter (see air ltration section).

• Replace prelter quarterly or as needed.

• Pliers

• WD-40

• Cleaning solution and rag

• Beam torque wrench 0-80in/lb

range

• Adapters- 1/4” to 3/8”. and

3/8” to 1/2”

Model 0305 & 0304 Operation and Maintenance Manual

SEM | www.semshred.com 17

Lube Schedule

Conveyor Belt Adjustment

Setting Tension

Tools Required: 1-1/8” wrench or adjustable wrench, beam torque wrench (0-80 in./

lb.), drive adapters, and 1-1/8” crowfoot wrench.

• Be sure to check belt tension every 20 hours. Belts stretch after break in period.

• Read all safety warnings before proceeding.

• De-energize the unit using proper LOTO procedures.

• Loosen bearing cover nut and remove bearing cover.

• Loosen jam nuts on each side of machine (see gure below). Leave 1/2” gap

between jam nut and adjustment bracket.

• Use beam torque wrench, adapters, and 1-1/8” crowfoot wrench to tighten

adjustment nuts to ensure torque range is between 40-50 in./lb.

• Ensure all personnel are clear and that no tools are on machine belt, or input chute.

ITEM FREQUENCY TYPE

Cutters Every 15-20 hours Light machine oil

Main bearings, Wear

Plates, Output Conveyor

Pulley Bearings

Every 15-20 hours Multi-purpose grease

(4 pumps per bearing)

Chain Every 30-40 hours Chain and cable lube

Jam Nut

Adjustment

top nut

Bearing Cover

Nut

Model 0305 & 0304 Operation and Maintenance Manual

18 SEM | www.semshred.com

• Turn machine on and run machine in forward for ve minutes.

• Stop machine and turn power off. Draw a mark on each adjustment nut with a

sharpie to track changes made in next step.

• Make all adjustments in small increments. By design, the conveyor belt should have

1/16” or less clearance between it and the side frames. Remove shroud if needed

to check the alignment position.

• Adjust alignment by tightening adjustment nut one quarter turn at a time on the

side of conveyor where the belt is rubbing the side frame. Tightening will move the

belt away from the nut being tightened.

• Fully tighten jam nuts up to plate.

• Replace bearing covers.

• Turn power on and run machine in forward for ve minutes.

If additional alignment is required, repeat the above steps.

Note: When the machine is run in reverse the belt may run slightly off center to the

either side. This is normal. The belt will stretch during the rst few days of operation.

This will affect alignment since the belt alignment relies in part on proper tensioning for

effective tracking.

Air Filtration System

The air ltration system (AFS) on this device is designed to help reduce possible odors

and possible contaminants from escaping into the atmosphere during the process of

hard drive destruction. The AFS is a low maintenance system that only requires periodic

inspection, lter cleaning, and lter changes. The frequency of the inspections is

dependent on usage.

HEPA Filter

Pre-Filter

This manual suits for next models

1

Table of contents

Other SEM Paper Shredder manuals