SEM 7050P User manual

Pleasereadthismanualcarefully.It willanswerallyourquestions

regardinginstallation,operationandtrouble-shooting.

IMPORTANT:

Be sure to adhere to all safety suggestions listed

Order on-line GSA Customers www.fedshred.com

Commercial Customers www.semshred.com

THE WORLD LEADER IN DOCUMENT AND SENSITIVE WASTE DESTRUCTION

SOLUTIONS

WaJ.. j r, . SECURITYSHREDDERS.DISINTEGRATORS. WASTE

~~~~~I CONTAINERS. DEGAUSSERS

5 Walkup Drive . Westboro.MA01581

https://www.supplychimp.com

READ

READ CAREFULLY

CAREFULLY BEFORE

BEFORE USING

USING

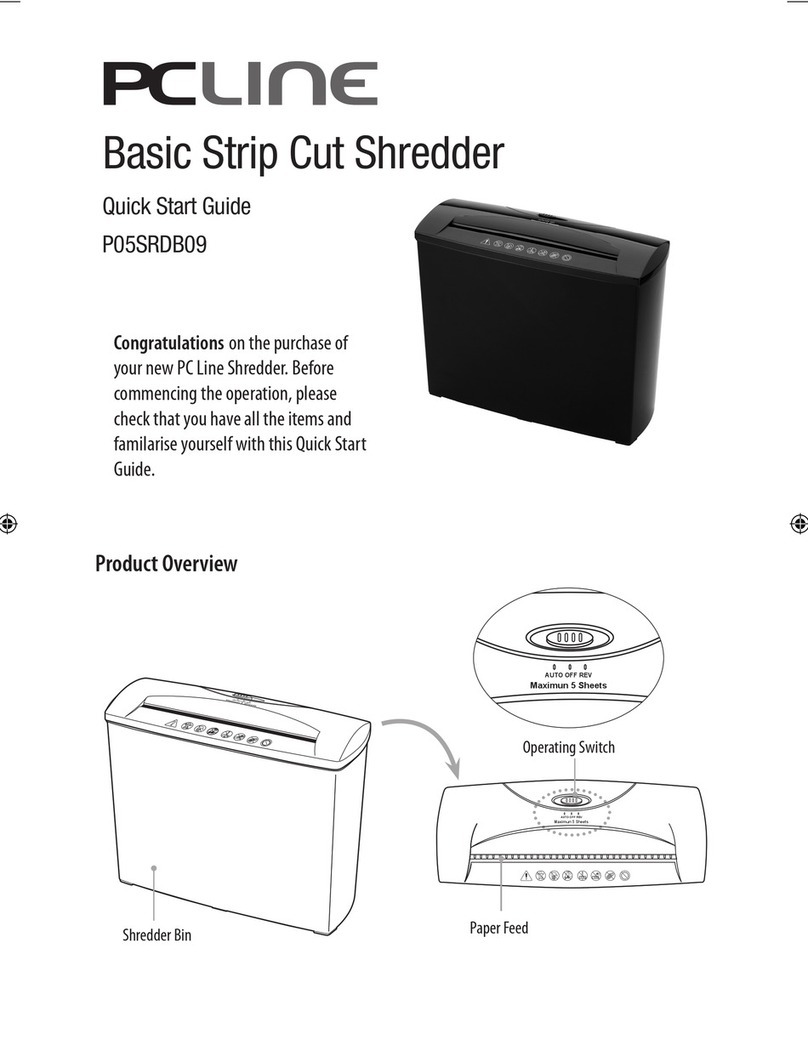

These

These Paper

Paper Shredders

Shredders are

are designed

designed for

for the

the in-office

in-office destruction

destruction of

of

paper

paper documents

documents to

to

an

an unidentified

unidentified waste.

waste. Proper

Proper care

care and

and use

use of

of

your

your shredder

shredder will

will insure

insure many

many years

years of

of

trouble

trouble free

free operation.

operation.

Content. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Content

..•••....................................

Page

General

General . . . . . . . .

........

3

3

Safety Instructions & Application

....................................

3

3

Safetylnstructions&Application

Installation

Installation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................................

3-4

3-4

Transportatio

Transportation n.. .. . . . . . . . . . . . . .. .. . . . . . .

..........................

.

. . . ...

...

4 4

Pre-assembly

Pre-assembly.. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .5

.5

Power

Power Supply.

Supply.

.

.

5

5

Direction. .

.

.....

. . . . .5

5

Checking

Checking Rotating

Rotating Direction . .

. .

. .

.

Operating

Operating....... .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........

.

. .

.

..................................

5-7

5-7

Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .

......................

'

....

7-8

7-8

Accessories .

Accessories.

..

. .8

8

TechnicalTechnical DataData

................

. . . . . . . . . . . . . . . . . . . ..

.

...................

8

8

Recommended

Recommended Spare

Spare Parts

Parts

...................................

. .

...

.

8

8

Using

Using and

and Ordering

Ordering Spare

Spare Parts

Parts. . . .. . .. . .. . .

.............

.

. .

.9

9

Service.Customer

Customer Service . . . . . .

.

.........

......

.

. . . . .. . . . .9

9

https://www.supplychimp.com

M RTANT FET PROC

DU

Your

Yournew

newpaper

papershredder

shredderincorporates

incorporates powerful,

powerful, heavy

heavyduty

dutycutting

cutting mechanisms.

mechanisms.

followedSerious

Seriousand

and permanent

permanentinjury

injury

may

may

result

result

if

if

proper

properprecautions

precautions are

are not

not followed.

~uipment1.

1.

This

This equipmentshould

should never

neverbe

be operated

operated by

by children

children or

or

individuals

individuals

untrained

untrained in

in or

or

incapable

incapable of

of

understanding

understanding the

the safety

safety precautions!

precautions!

2.

2. Do

Do not

not reach

reach into

into the

the feed

feed o~ning

o~ning

for

for any

any reason!

reason! Never

Never insert

insert fingers,

fingers,

hands,

hands, other

other extrematies

extrematies or

or

objects

objects not

not meant

meant to

to be

be shredded

shredded into

into the

the

feed

feed openings!

openings!

3.

3.

Do

Do not

not operate

operate or

or

come

come in

in close

close proximity

proximity to

to this

this equipment

equipment wearing

wearing long

long

hair,

hair, necktie,

necktie, loose

loose clothing

clothing or

or

jewelry,

jewelry, wnich

wnich may

may activate

activate a

a photoelectric

photoelectric

on/off

on/off switch

switch and/or

and/or be

be puned

puned Into

Into the

the machine!

machine!

4.

4.

Maintenance

Maintenance or

or

repair

repair of

of

this

this equipment

equipment should

should be

be performed

performed only

only by

by

trained,

trained, authorized

authorized service

service personnel.

personnel.

removirt95.

5.

Always

Always disconnect

disconnect electric

electric power

power (unplug)

(unplug) before

before removirl9 or

or opening

opening

the

the cover

cover or

or

other

other panel

panel giving

giving access

access to

to internal

internal mechanisms.

mechanisms.

https://www.supplychimp.com

I

This

This instruction

instruction manual

manual helps

helps you

you learn

learn the

the safe

safe and

and comfortable

comfortable operation

operation with

with this

this machine.

machine. Before

Before

working

working with

with the

the machine

machine please

please read

read these

these instructions

instructions carefully

carefully and

and consider

consider the

the safety

safety regulations.

regulations.

DANGER!

DANGER! Non-compliance

Non-compliance with

with the

the instructions

instructions may

may endanger

endanger persons.

persons.

WARNING!

WARNING!

Non-compliance

Non-compliance with

with the

the instructions

instructions may

may cause

cause damage

damage to

to the

the machine.

machine.

The

The operating

operating instructions

instructions must

must always

always be

be available

available for

for the

the operator.

operator.

is capableThe

The machine

machine is capable of

of

shredding

shredding loose

loose and

and crumpled

crumpled paper

paper as

as well

well as

as cartons

cartons with

with staples.

staples.

Due

Due to

to material

material separation

separation we

we recommend

recommend to

to avoid

avoid shredding

shredding plastic

plastic foils

foils at

at the

the same

same time.

time.

DANGER!

DANGER!

Only

Only Qualified

Qualified persons

persons are

are allowed

allowed to

to operate

operate the

the machine

machine

No

No operation

operation by

by

children

children

DANGER!

DANGER!

Do

Do

not

not shred

shred any

any strapping

strapping materials

materials or

or

fluids

fluids which

which can

can loop,

loop, splinter,

splinter, chemically

chemically

react

react or

or

explode.

explode.

WARNING!

WARNING!

Feeding

Feeding large

large steel

steel components,

components, rigid

rigid materials,

materials, screws

screws or

or

nails

nails will

will damage

damage the

the shredding

shredding

mechanism.

mechanism.

The

The machine

machine is

is mounted

mounted on

on castors

castors and

and easy

easyto

to move.

move. The

The machine

machine must

must be

be installed

installed on

on a

a firm,

firm,

level,

level, dry

dryfloor.

floor.

. The machine must not be used outside.

DANGER!

DANGER! • The machine must not be used outside.

. Do not use in the of flammable or gases.

• Do not use in the vicinity

vicinity

of

flammable liquids

liquids

or

gases.

. not use in wet environments.

• Do

Do

not use in wet environments.

. Protect the power cable from extreme and

• Protect the power cable from extreme heat,

heat, oil,

oil, and sharp

sharp edges.

edges.

WARNING!. assignment

WARNING!·

Do

Do

not

notcover

coverthe

the ventilation

ventilation slits.

slits. Follow

Followthe

the space

space aSSignment plan

plan carefully.

carefully.

.Consider the floor 2630lbs

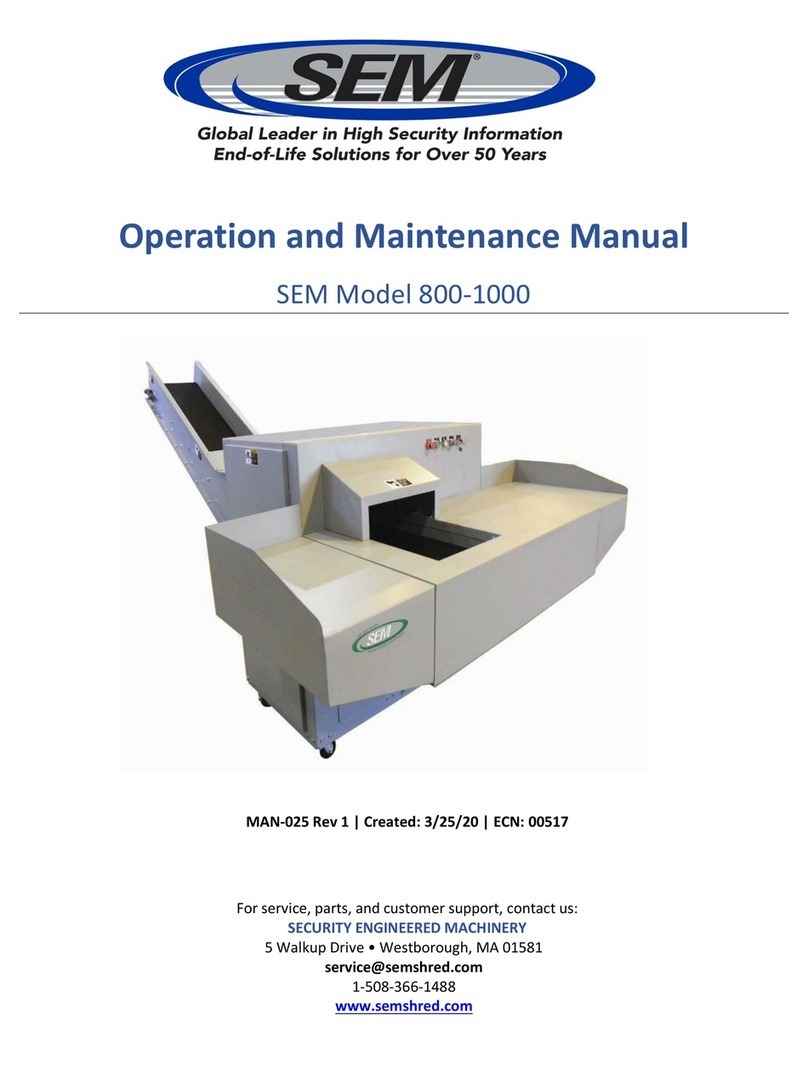

• Consider the floorLoading.

Loading. Weight

Weightapproximately

approximately 2630lbs(1200kg).

(1200kg).

https://www.supplychimp.com

ATTENTION! Do not raise the machine higher than necessary to avoid tipping.

Transportis only possible from the back and with built-intransport safety device (4) and (5).

Make sure the lifting truck is centered under the machine.

~, ~~ 1,.

~ (5)

'""tI'" -".

https://www.supplychimp.com

PRE-ASSEMBLY

.Open the door

. Removethetransportsafetydevice(4)and(5)andkeepfor later

transportuse

.Mountthe supportingscrews(6)

.Screwdownthesupportingscrewsuntilthe rearrollsarerelieved.

Mountthe waste bin . Mount the shackle (9)

. Change both plastic bag

(as described under changing

the waste bag)

. Push the waste bin into the

machine

. Close the door

POWER SUPPLY FOR 208V OR 220V=70AMPS MINIMUM SERVICE

The name plate is located at the rear of the machine.

. Data stated on the rating plate must correspond to the values of the power supply unit.

. Voltage "V' . Frequency "Hz" . Power Consumption"A"

Connect the supplied power cord, using a ground.

CHECKING ROTATING DIRECTION

Operate the machine for a short time as described under "Operation"

. The material is transported into the machine by the conveyor belt. b,

,.

./

When the machine works in the opposite direction

As the machine is wired according to the lEG standardized rotary

field, when changing the rotary direction we recommend that this

is performed by an experienced specialist. The rotary direction

may be changed by exchanging the "L1" and "L2" connections in

the plug.

DANGER! Incorrect exchange of the connections may endanger the operator.

In doubt, this work should be performed by an electrical specialist.

OPERATING

The machine will only run when door is closed!

DANGER! The machine may only be operated by persons who have read and understood

the operating instructions.

DANGER! Keep hands away from running shredding mechanism!

Theshredding mechanism maycauseserious injury!

https://www.supplychimp.com

OPERATING ELEMENTS

(1) Start

(2) Stopandpilotlightfor dooropen

(3) Reverseandthe lampwastebinfull

(4) KeySwitch

(5) Standby

(6) Mainswitch(canalsobe usedasemergencyoff button)

(7) Pilotlighttemperatureindicator

(8) Emergencyoff

STARTING THE MACHINE

Do not shred any material which may loop or splinter. Material, which does not

go through the cutting head can only be pushed in with the pusher (9). In case

of danger, press emergency off button (8).

. Turn main switch (6) into position "I"

. Emergency button (8) must be unlocked (turn to th right)

. Turn on the key switch (4) turn to the right then the standby (5) illuminates

. Press and release the black button (1) Conveyor belt is running

. Feed the paper over the total width of the conveyor belt

In case the quantity of material inserted is increased the machine automatically changes to a more

powerful and slower function. if this performance is still not sufficientthe machine starts to reverse

shortly and afterwards runs again forward. The machine switches between both speed levels until

all the material inserted is fully destroyed.

ATTENTION! If possible let the machine work at its normal speed. ~

Shred continuous paper only in stacks .~. , j'

Stoppingthe Machine

. Press the red key (2) or press the emergency OFF button (8).

Keep hands away from running shredding mechanism!

. Yellow pilot light (7) appears /1 I

Temperatureof the motor is too high

Decreasethe material on the conveyor belt to make the machine work in normal speed.

. Yellow pilot light (7) lights up

temperature is too high wait approximately 10 to 20 minutes until motor cools down.

STOPPING THE MACHINE

For short breaks

. Press and release the red button (2) Conveyor belt stops

For longer breaks

. Turn main switch (6) to position "0" - the entire machine shuts down

. Turn the key switch (4) and remove the key - now the machine is

secured from unauthorized use.

CHANGING THE WASTE BAG

Ifthe lampwaste bag full lights up you should emptythewastebag.

. Open the door (9)

. Pull out the waste bin from the machine

https://www.supplychimp.com

If one of both bags is full

. Turn the handle (10) to empty waste bag

. Turn the waste bin and push it into the machine with the

full plastic bag in front

. Close the door (9)

If both bags are full

. Remove the metal cover (11)

. Remove the round belt from the waste bag frame (12)

. Remove waste bags for storage on a pallet.

. Tie the bags (for sealing parts and binding wires see accessories) ~ ~

. Place a new bag into the bag frame and fold it down approx.

12"to 15"to the outside. Tighten the bag with the plastic band :\

. Fasten the bag with the round belt

. Attach the metal cover (11)

. Close the door 9 ~~

. Check the function of the door switch. Start the machine.

If the door is open the machine has to stop immediately ~~-- -(it

NOTE: Waste collection bags SEM part number 64258190 50/Box ~ :-lA-

OILING THE SHREDDING MECHANISM nl'\"

I

If the sheet capacityreduces or after bag is full we recommend that

you oil the shredding mechanism

. Move the lever (13) of the oil pump once

. After this lubrication please let the machine run several times

backwards and forwards alternately

. If the tank (14) is empty refill oil.

Type of oil: SEM Shred Oil #6470IL (4 Gallon case)

DANGER! Disconnectfrom the mains before starting any service work or before removingthe

cover. (5) (i)

MALFUNCTION: Standby (5) is not lighting up

CAUSE: The door is open

Main switch is OFF

The Emergency button is pressed

Key switch is not plugged in

On-site fuse

Machine is overloaded-the motor protection switch is re-activated after 10 minutes

MALFUNCTION: Motor makes a buzzing noise and the machine shows no performance

CAUSE: One phase is missing

REMEDY: Check if all three phases are suppliedwith electric power (voltage)by an electrician

https://www.supplychimp.com

MALFUNCTION: Machinedooris difficultto open

CAUSE: Guidingbarofthe lowercuttingheadcoveris dirty

REMEDY: Cleanandgreasetheguidingbar

MALFUNCTION: Machine switches off during normal operation

CAUSE: Bag full control light will light - Shred bag is full

REMEDY: Change waste bag

OR

CAUSE: Yellow pilotlight(7) lightsup.temperatureof the motoristoo high

REMEDY: Wait approximately 10 to 20 minutes until machine cools down

Plastic bags 3501 (50 pieces) 0000 413

Pusher 9000 593

For closing the plastic bags: Locking device 0000 591

Binding Wire (1000 pieces) 9000 597

IMPORTANT: Onlyusemanufacturerrecommendedaccessories

ShredCapacity:

ShredSize:

Speed:

Horsepower:

Dimensions:

Weight:

Power:

7050P

up to 500 Sheets

5/16" x 3-1/8"

45 FPM

12-3/4HP (Dual drive 2 speed)

67-1/2"H x 40-3/4"W x 85-1/2"D

2500 Ibs.

208V/230V 3 phase

Replacement Plastic Waste Bags #190 Part Number 6425B190 SO/Box

Shredder Lubricating Oil4 gallon case Part Number 64701L

https://www.supplychimp.com

. use SEMsparepart

• Only

Only use original

original SEM spare part replacements

replacements

. We their and functional

• We guarantee

guarantee their quality

quality and functional reliability

reliability

. claimson parts servicemustbe bySEM's

• Warranty

Warranty claims on parts and/or

and/or service must be approved

approved by SEM's

Customer

Customer Service

Service Manager

Manager

HINTS

HINTS

FOR

FOR

ORDERING

ORDERING

SPARE

SPARE

PARTS

PARTS

The

The spare

spare parts

parts shown

shown on

on the

the following

following pages

pages have

have part

part numbers.

numbers. This

This spare

spare parts

parts list

list shows

shows the

the

following

following information

information with

with respect

respect to

to the

the spare

spare parts

parts to

to be

be ordered.

ordered.

.PartNo. . .

• Part No. • Dimensions

Dimensions • Quantity

Quantity

. . Item No.

• Designation

Designation • Item No.

In

In order

order to

to avoid

avoid errors

errors and

and the

the delivery

delivery of

of

wrong

wrong parts,

parts, each

each parts

parts order

order should

should contain

contain the

the

following

following information.

information.

. Machine No. . Machine

• Machine No. (See

(See nameplate)

nameplate) • Machine Type

Type

. Part No. and of desired spare

• Part No. and designation

designation

of

desired spare parts

parts

. of desired spare

• Quantity

Quantity

of

desired spare parts

parts

. Desired mode of

• Desired mode

of

shipment

shipment (e.g.

(e.g. post,

post, freight,

freight, express)

express)

. Full & contact person &

• Full billing

billing & shipping

shipping addresses,

addresses, including

including contact person & telephone

telephone

OPTIONAL

OPTIONAL

ITEMS

ITEMS

AVAILABLE

AVAILABLE

Replacement

Replacement Plastic

Plastic Waste

Waste Bags

Bags Part

Part No.

No. 639SB140

639SB140

Shredder

Shredder Lubricating

Lubricating Oil,

Oil, Case

Case of

of

8

8 pints,

pints, Part

Part No.

No. 64901L8

64901L8

Shredder

Shredder Lubricating

Lubricating Oil,

Oil, Case

Case of

of

16

16 pints,Part

pints,Part No.

No. 64901L

64901L16

16

To

To

order

order spare

spare parts

parts or

or

optional

optional items

items you

you may

may contact

contact the

the Authorized

Authorized Service

Service Rep.

Rep. for

foryour

your area,

area, or

or

SEM's

SEM's Customer

CustomerService

Service Dept.

Dept. directly

directly at

at the

the following

following address:

address:

Security

Security Engineered

Engineered Machinery

Machinery

P.

P.

O.

O. Box

Box 1045

1045

Westboro,

Westboro, MA

MA01581

01581

Tel:

Tel:

800-225-9293

800-225-9293

Fax:

Fax: 508-366-6814

508-366-6814

Website:

Website: Commercial

Commercial www.semshred.com

www.semshred.com

Government

Governmentwww.fedshred.com

www.fedshred.com

Email:

Email: [email protected]

https://www.supplychimp.com

'utomatic Oiler

Disinteg rators/l ndustrial

Shredders

Recycling Collection

Containers and

Specialty Waste

Receptacles

For detailed products information including all

application and specifications contact

Customer Service at 1-800-225-9293

or via the web

Government 'W'W"W.fedshred.com or

Commercial 'W'W"W.semshred.com

THE WORLD LEADER IN DOCUMENT AND SENSITIVE WASTE DESTRUCTION

SOLUTIONS

W8.I_ir,a SHREDDERS. DISINTEGRATORS. SECURITY WASTE

~I~11J CONTAINERS. DEGAUSSERS

5 Walkup Drive. Westboro. MA01581

https://www.supplychimp.com

Other manuals for 7050P

1

Table of contents

Other SEM Paper Shredder manuals

SEM

SEM 800-1000 Series User manual

SEM

SEM 2226 Series User manual

SEM

SEM 1012/5 User manual

SEM

SEM 1201CC Quick start guide

SEM

SEM 344 Series Quick start guide

SEM

SEM 4140CLK Assembly instructions

SEM

SEM 1125P Quick start guide

SEM

SEM 0300 User manual

SEM

SEM 126C/2 Quick start guide

SEM

SEM 3130P Quick start guide