Senix Ultrasonic Sensor User manual

Jameco Part number 151482

Ultrasonic Sensor

with RS-232 Output

User's Guide

Jameco Part Number 151482

Senix Corporation, 52 Maple St., Bristol, VT 05443

© 1998 by Senix Corporation

Jameco Part number 151482

Product

Overview

The 151482 product is an ultrasonic sensor designed to

measure the distance between its transducer and a user

target. The distance is measured without contacting the

target object, and is accomplished by sending an

ultrasonic "pulse" and measuring the time for the pulse

"echo" to return from the target object. The measured

time is related to the speed of sound of the pulse. After

the distance (time) is measured, the sensor transmits the

distance as binary data on the RS-232 output. Each count

of the binary data represents a distance of .013536 inches

at nominal speed of sound. The sensor provides data up

to a maximum range of 10 feet.

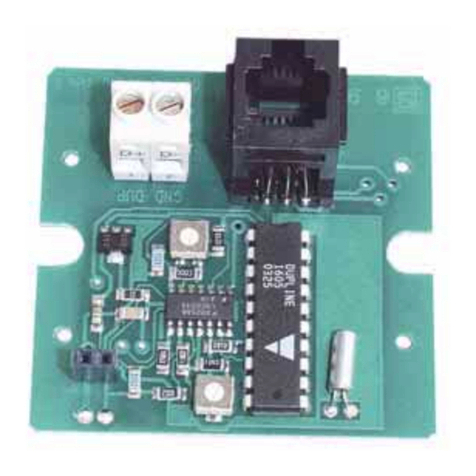

The 151482 consists of a circuit board, ultrasonic

transducer, transducer connecting cable, 3.5" DOS

compatible floppy diskette, computer connecting cable

and this user manual.

Revision History

Initial product release April 1, 1998

Warranty

Senix, Inc. will repair or replace, at our option, any part

found by us to be defective in material or workmanship if

the product is received by Senix, freight prepaid, within

one year from the date of original shipment to buyer.

Disclaimer and Release. The warranties, obligations and

liabilities of Senix and the remedies of buyer set forth

above are exclusive and in substitution for, and buyer

hereby waives, releases and renounces all other

warranties, obligations and liabilities of Senix and all

other rights, claim, and remedies of buyer against Senix,

expressed or implied, arising by law or otherwise,

including but not limited to: (A) Any implied warranty or

merchantability or fitness; (B) Any implied warranty

arising from course of

performance, course of dealing or usage of trade; (C)

Any obligation, liability, right, claim or remedy in tort,

whether or not arising from the negligence of Senix

(whether active, passive or imputed); and (D) Any

obligation, liability, right, claim or remedy for loss or

damage to any product.

Exclusion of Consequential and Other Damages. Senix

shall have no obligation or liability, whether arising in

contract (including warranty), tort (including active,

passive or imputed negligence) or otherwise, for loss of

use, revenue or profit with respect to any non

conformance or defect in any product delivered under

this agreement, or for any other direct, incidental or

consequential damages.

Governing Law. The terms and conditions of this

agreement shall be governed by the domestic law of the

State of Vermont, U.S.A.

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 2

Jameco Part number 151482

TABLE OF CONTENTS

PRODUCT OVERVIEW...................................................................................................... 2

Revision History................................................................................................................................................... 2

Warranty............................................................................................................................................................... 2

ULTRASONICS OVERVIEW............................................................................................. 4

Introduction........................................................................................................................................................... 4

Advantages............................................................................................................................................................ 4

Typical Applications............................................................................................................................................. 4

GETTING STARTED........................................................................................................... 5

Unpacking............................................................................................................................................................. 5

Specifications........................................................................................................................................................ 5

Mounting............................................................................................................................................................... 5

Beam Pattern......................................................................................................................................................... 6

Orientation............................................................................................................................................................ 6

Connections .......................................................................................................................................................... 6

OPERATION.......................................................................................................................... 7

Starting the sensor................................................................................................................................................. 7

Distance Calculation............................................................................................................................................. 7

Software................................................................................................................................................................ 7

Performance.......................................................................................................................................................... 8

Precautions............................................................................................................................................................ 8

Adjustments.......................................................................................................................................................... 8

IN CASE OF DIFFICULTY................................................................................................. 9

Basic Checkout..................................................................................................................................................... 9

Common Problems ............................................................................................................................................... 9

Repairs and Returns.............................................................................................................................................. 9

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 3

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

Ultrasonics

Overview

Introduction

Ultrasonic sensors measure the distance or presence of a

target object by sensing a sound wave, above the range of

hearing, at the object and then measuring the time for the

sound echo to return. Knowing the speed of sound, the

sensor can determine the distance of the object from the

transducer element.

(1) Ultrasonic pulse transmitted from sensor

(2) Ultrasonic echo returns from target

Advantages

Non-contact

Measures through the air without touching the

target object, at relatively large distances.

Object Ranging

Object distance is measured rather than just the

presence or proximity.

Distance Proportional Output

The sensor's outputs are proportional or related to

the measured target range.

High Resolution

Precise discrimination of target position.

Unaffected by Target's Optical Characteristics

The sensor's operation is not sensitive to ambient

light levels, the target color, or target's optical

transparency or reflectivity.

Sensitive

Detects large and small objects.

Typical Applications

and many more...

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 4

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

Getting

Started

Unpacking

Check that you received the following items:

•Circuit board

•Ultrasonic transducer with connecting cable

•RS-232 Computer Cable

•3.5" DOS compatible floppy diskette

•This manual

Specifications

Circuit Board

Power Input 8-24 VDC @ 40 ma.

Range 6 inches to 10 feet

Output RS-232, Transmit only

Output Format 9600 baud, 8 data bits, 1 stop

bit, no parity

Output Protocol 3 character burst:

#1:55H (sync character)

#2: LSB count data

#3: MSB count data

Resolution 0.013536 inches/count at

room temperature

Temperature 0 to +70 C (32 to 160 F)

Humidity 5-95%, non-condensing

Measurement Period 50 mSec (20 Hz update)

Interface connections Terminal Block

Transducer connection 2-pin Molex

Weight 1.6 oz.

Size 2.85L x 1.85W x 1.25H

Transducer

Type Electrostatic Ultrasonic

Frequency 50 kHz

Beam Shape Conical

Beam Angle 15 degrees total @ 3db down

Temperature -30 to +70 C (-20 to +160 F)

Board Connection Blade terminals

Size 1.69" diameter x 0.5" deep

Weight 0.3 oz.

Mounting

Ultrasonic transducer

The transducer mounts in a 1.54" diameter circular hole

cut into any sheet material. The transducer can be glued

using a resilient compound such as GE Silicone Sealant.

Grounding

If the sheet material is metal, surface contact to

the transducer will connect the surface to the

sensor's ground (PWR-). This is allowable as

long as it doesn't conflict with other wiring.

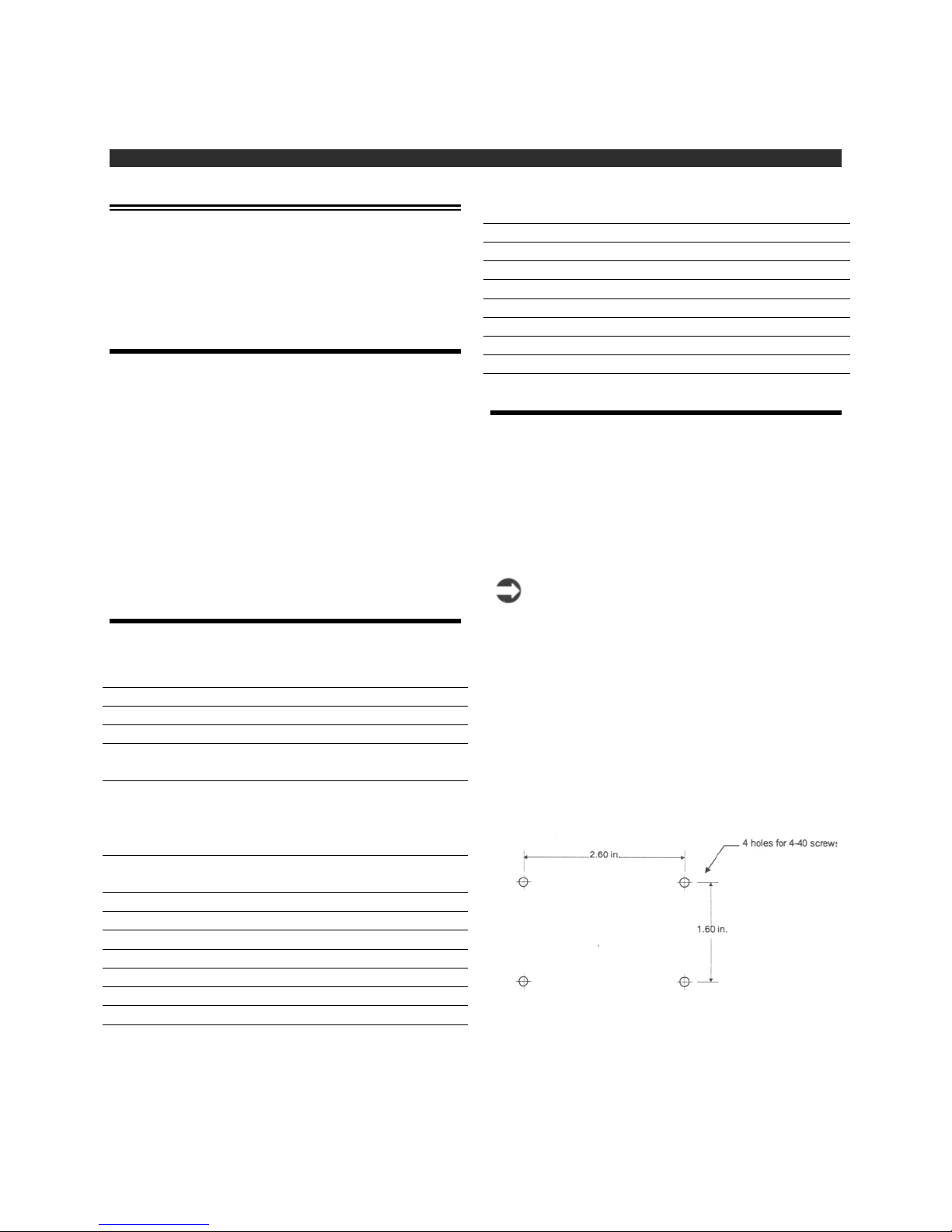

Circuit board

The circuit board mounts on 4 standoffs using 4-40

screws in the following hole pattern:

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 5

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

Beam Pattern

The beam pattern is conical with a total angle of about 15

degrees. The cone starts at the face of the sensor at about

1.5 inches in diameter and grows from there as shown in

the diagram below. The beam pattern is approximate and

represents the boundary where the return echoes are 3db

down.

Orientation

The transducer orientation should be perpendicular to the

target object for best results. The sensor will loose the

target if the ultrasound energy is reflected away from the

transducer rather than back to it. Curved or spherical

objects make good targets. Make sure other unintended

targets are not visible to the sensor.

Connections

Ultrasonic transducer

The ultrasonic transducer is provided with a cable

attached. Connect the transducer cable (2-pin brown

female Molex connector) into the mating Transducer

Connector on the circuit board.

The two BLADE terminals press onto mating terminals

on the transducer. The shield end (ground) should be

attached to the terminal of the transducer's outer shell,

placing the outer shell at ground potential.

Power Input

Connect a +8 to 24 volts DC power supply via the DC +

and GND terminals of the Terminal block Connecting the

power backward will not damage the board. As soon as

you apply power, the Power

Indicator will light and the transducer will begin clicking

repetitively.

RS-232 Data Output

The system provides an RS-232 serial data output on the

TX terminal of the terminal block as shown in the above

drawing. There is no serial data input. The output is

connected as follows to an RS-232 device input:

Sensor Terminal Input Device RS-232 Cable

TX RS-232 In RED

Gnd Ground GREEN

The RS-232 cable included with the sensor connects the

sensor to a standard personal computer serial port

(COM1 or COM2). One end of the cable is a 9-pin

female (DB9F) connector that mates with a standard PC

9-pin COM port connector. The other cable end has 2

tinned wires that connect to the sensor terminal block

listed above in the Sensor Terminal column.

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 6

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

Operation

Starting the sensor

Following installation and connection according to the

preceding sections, the sensor starts running as soon as

the DC power is applied.

When the sensor is running the Power Indicator should

be ON and a repetitive clicking heard from the

transducer.

Distance Calculation

The sensor's measured distance is represented by the data

transmitted on the TX terminal of the terminal block. The

data is contained in 3-characters burst with the following

definition:

#1:55H (sync character)

#2:LSByte of count data

#3:MSByte of count data

Bytes 2 and 3 combined are combined into a single

16-bit word representing a distance proportional value as

shown below:

The distance can be calculated from the 16-bit data value

as follows: Inches = Value * 0.013536

The maximum count value is about 8865, representing a

distance of 10 feet (120 inches). Targets closer than 6

inches will generally return values down to about 5.2

inches. If the sensor does not detect a target within 10

feet, the sensor transmits a zero value.

Software

A QuickBasic example program is provided on the

included floppy disk that will read the sensor data output

and display the measured distance on a personal

computer screen. The following files are provided on the

diskette:

JAMECO1.EXE -- DOS executable program

JAMECO1.BAS -- QuickBasic source code for

JAMECO1.EXE showing how the programming and

display of sensor data are accomplished.

Run the program as follows:

1. Insert the floppy disk into the computer. The

program can be run from floppy, or the 2 files listed

above can be copied to a subdirectory on the

computer's hard drive and run from there.

2. Connect and power the sensor as described

previously in Getting Started.

3. Run the program by typing JAMECO1 at the DOS

prompt. This runs the executable file. The program

can also be run as a DOS task under Windows 3.1

or Windows 95.

4. The program will first display "Which COM port is

the sensor connected to (1/2)?" Type the number 1

or 2 depending upon which port you are using, then

press the <Enter> key.

5. The program now displays distance. A zero value is

displayed if no target is detected within 10 feet. The

data is updated every 50 mSec. To exit the

program, hit any key.

Refer to the source code file JAMECO1.BAS to

understand how to read sensor data and calculate the

distance.

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 7

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

Performance

Update Rate

The sensor measures distance repetitively at an interval

of approximately 50 milliseconds. This is the interval

between the "clicks" heard from the transducer. After

each measurement, the 3 characters of data are

transmitted on the RS-232 output.

Target Considerations

The target must reflect the ultrasound energy back to the

sensor. Sensor performance will be affected by the

strength of the "echo". Flat surfaces are best when

perpendicular to the beam direction. Curved surfaces are

generally good targets because a portion of the energy is

generally reflected directly back to the sensor.

Low-density materials including some foams, cloth and

powders may exhibit reduced detection range, or can

absorb or be transparent to ultrasound. In many cases

these materials are easily detected, so testing a material

sample is recommended. Increasing the sensor's gain

using the sensitivity adjustment may be required.

Temperature Effects

The most significant factor that affects measurement

accuracy is temperature. At room temperature, a change

of 10 degrees will result in approximately 1% change in

the speed of sound and therefore the same change in the

distance output. This model sensor does not compensate

for temperature affects.

Precautions

•Keep unintended targets from transducer's field

of view. Keep the beam pattern in mind.

•Keep transducer away from ultrasonic noise

sources, such as pressurized air nozzles

Adjustments

Sensitivity

This adjusts the electronic sensitivity to the strength of

the ultrasonic echo being returned from the target object.

Very small or sound absorbing targets may not send a

very strong echo and therefore may require increased

sensitivity for stable detection. The sensitivity

potentiometer is located next to the terminal block on the

solder side of the circuit board. The unit is shipped at

mid range and in general it does not require adjustment.

Sensitivity can be increased by rotating the potentiometer

clockwise and decreased by counterclockwise rotation.

Full rotation of the pot is 180 degrees.

Ultrasonic Tuning Adjustments

The ultrasonic tuning adjustments consist of a

transformer T1 (silver case) and inductor L1. These

generally do not require adjustment unless the cable

length to the transducer is lengthened.

To adjust these components:

1. Put an oscilloscope probe on test point TP1 and

set the scope to trigger on the transmitted pulse.

This test point is a hole in the PCB that is

labeled on the component side of the board.

2. Using delayed sweep, monitor a target echo

signal and adjust T1 for maximum amplitude.

3. Using the same signal as in step 2, adjust L1 for

maximum amplitude.

Transducer Cable Length

As the cable length is increased, sensitivity will

decrease. A practical cable maximum length is

20 feet, and longer cables should be shielded in

electrically noisy areas.

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 8

Jameco Part number 151482

151482 - Ultrasonic Sensor User's Guide

In Case of

Difficulty

Basic Checkout

With DC power applied to the sensor the Power Indicator

should be ON and a clicking sound should be heard from

the ultrasonic transducer.

If the Power Indicator is not ON check the power

connections. The board will not be damaged by a reverse

polarity connection.

If the Power Indicator is ON but the sensor is not

clicking, check the cable connections between the circuit

board and ultrasonic transducer. Look for broken or

shorted wires or loose connectors.

Common Problems

Output stuck at short distance value

1. An object is near the front of the sensor that is

being detected, possibly associated with the

mounting arrangement.

2. The sensor is "self-detecting" its own transmit

signal. Reduce the sensitivity by turning the

Sensitivity adjustment counterclockwise.

3. No target is being detected. Place a target in

front of the transducer at a known distance and

test for a reasonable voltage value.

Repairs and Returns

If you need to discuss a problem or return a unit please

call the following number for technical support:

Jameco Electronics

(415)592-8097 (voice)

(415)592-2503

Senix Corporation, 52 Maple St., Bristol, VT 05443

Page 9

Table of contents

Other Senix Accessories manuals