Senix TL4QL-L1 User manual

15 IN. 46cc CULTIVATOR

Operator’s manual

Model: TL4QL-L1

For customer support, please call 1-800-261-3981 or send email to:

SAVE THIS MANUAL FOR FUTURE REFERENCE.

TM

2www.senixtools.com

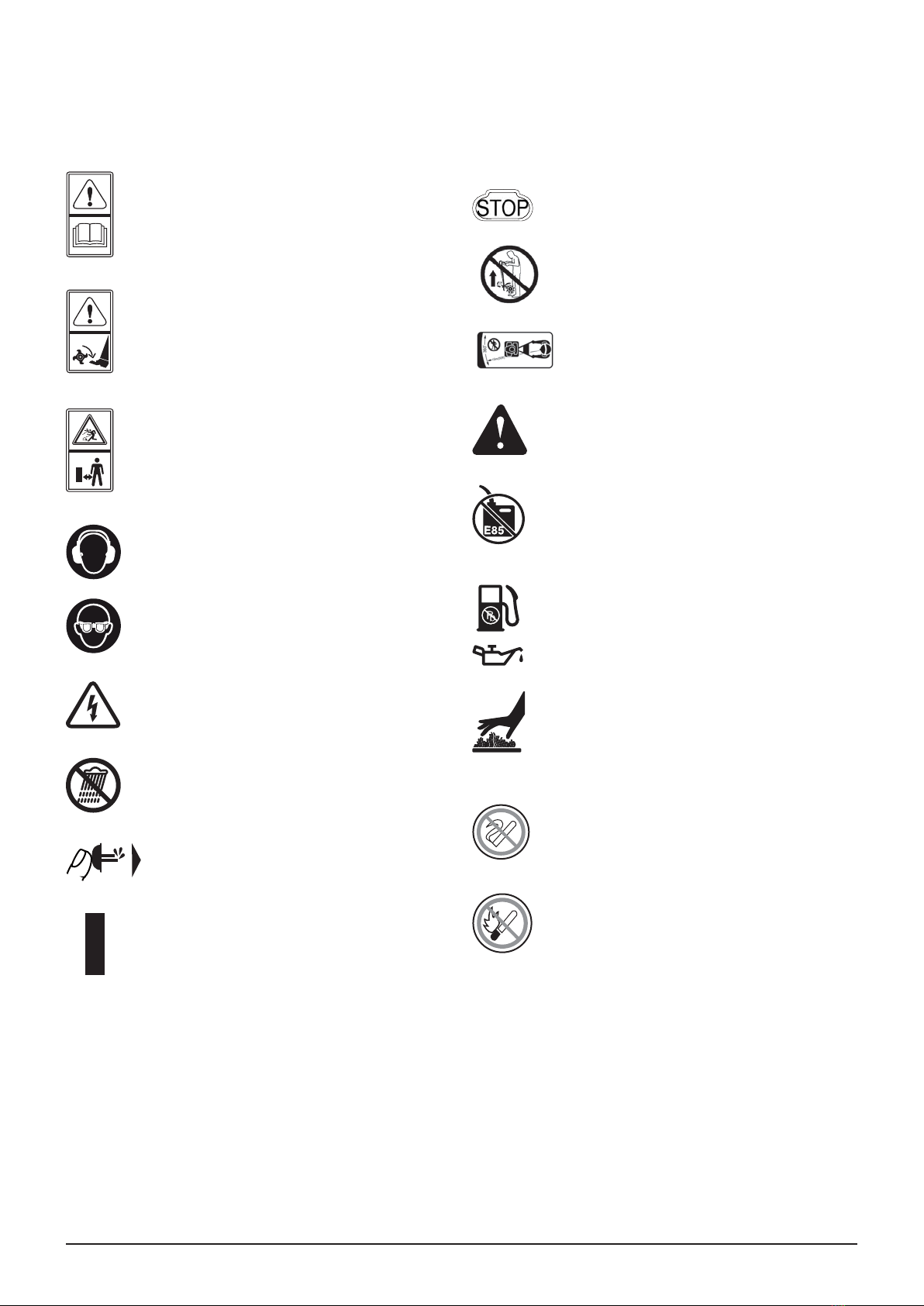

• SAFETY & INTERNATIONAL SYMBOLS •

This operator’s manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator’s manual for complete safety, assembly, operating and maintenance and repair information.

DO NOT USE E85 OR E15 FUEL IN THIS

UNIT. It has been proven that fuel contai-

ning greater than 10% ethanol will likely

damage this engine and void the warranty.

Always use clean, fresh unleaded fuel.

Refer to operator’s manual for the proper

type of oil.

Hot surface. Do not touch a hot muffler or

cylinder. You may get burned. These parts

get extremely hot from operation. They

remain hot for a short time after the unit is

turned off.

Do not smoke in the work area, around the

product and in the vicinity of flammable

materials!

No open flames in the work area around

the product.

Indicates danger, warning or caution. Pre-

cautions that involve your safety.

Avoid power lines, use in dry conditions.

Do not expose to rain.

Wear ear protection.

Wear eye protection.

Push primer bulb, fully and slowly, 10

times.

ON / START / RUN

OFF or STOP

Keep hands and feet away from sharp rot-

ating parts – danger of injury! When clea-

ning, repairing, or inspecting, make certain

the working tool and all moving parts have

stopped.

Carry unit with carry handle.

Keep bystanders a minimum of 15m (50ft.)

away while operating unit.

Caution/ Warning.

WARNING-To reduce the risk of injury, user

must read instruction manual.

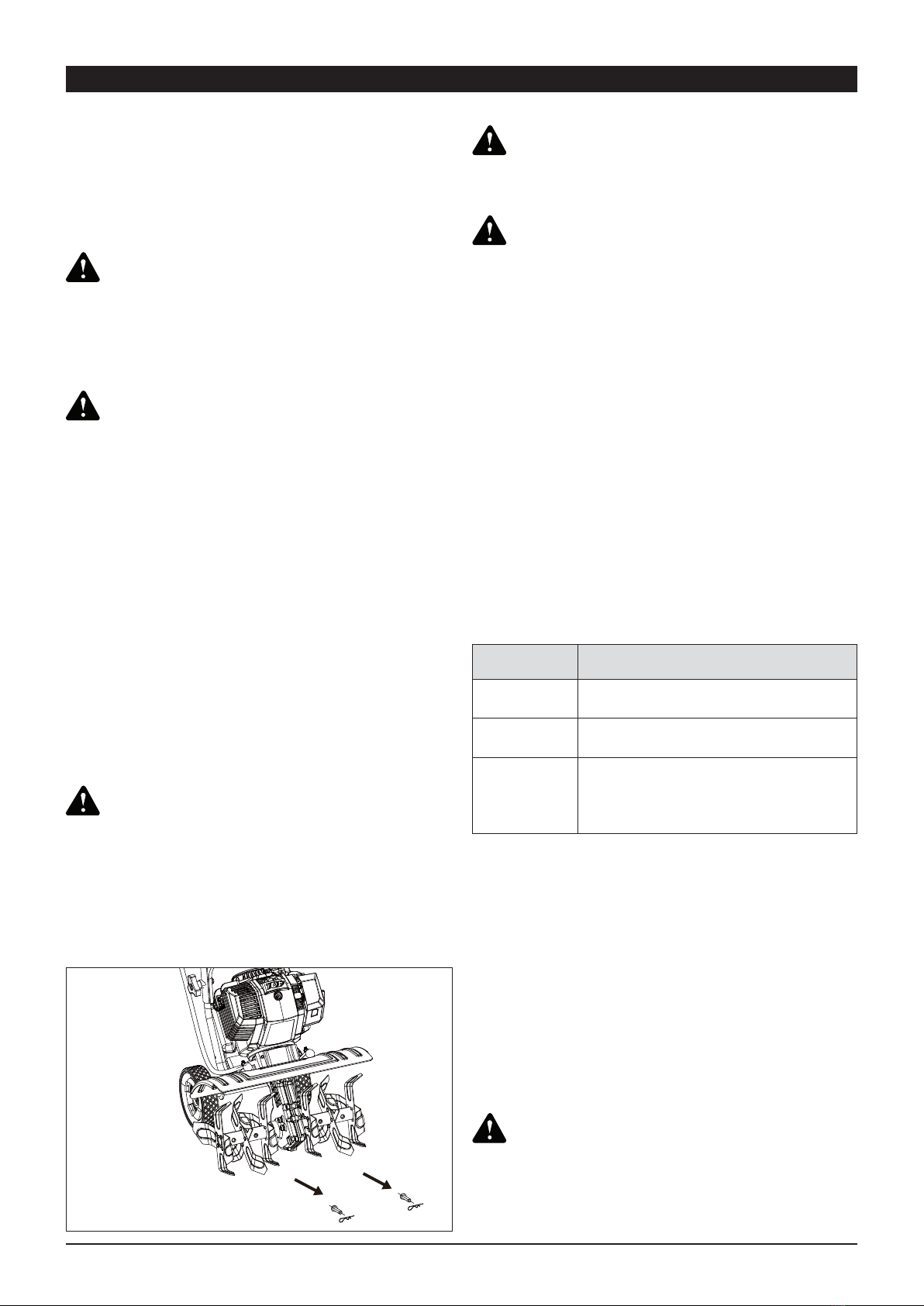

Risk of flying objects or debris.

Be aware of that there is a risk of flying ob-

jects and/or debris when using the machine

keep bystanders away.

3www.senixtools.com

Table of Contents

WARNING:

Always wear the appropriate Personal

Protective Equipment (PPE) when

operating this machine.

DANGER:

Signals an EXTREME hazard. Failure

to obey a safety DANGER symbol WILL

result in serious injury or death to

yourself or to others.

WARNING:

Crude oil, gasoline, diesel fuel and

other petroleum products can expose

you to chemicals including toluene

and benzene, which are known to the

State of California to cause cancer

and birth defects or other reproductive

harm. These exposures can occur

in and around oil fields, refineries,

chemical plants, transport and storage

operations such as pipelines, marine

terminals, tank trucks and other

facilities and equipment. For more

information go to: www.P65Warnings.

ca.gov/petroleum.

WARNING:

Signals a SERIOUS hazard. Failure to

obey a safety WARNING symbol CAN

result in serious injury to yourself or to

others.

SAFETY INFORMATION

CAUTION:

Signals a MODERATE hazard. Failure

to obey a safety CAUTION symbol MAY

result in property damage or injury to

yourself or to others.

NOTE: Advises you of information or

instructions vital to the operation or

maintenance of the equipment.

WARNING:

This product contains a chemical

known to the state of California to

cause cancer, birth defects or other

reproductive harm.

WARNING:

ENGINE EXHAUST, SOME OF ITS

CONSTITUENTS AND CERTAIN

FINISHED COMPONENTS CONTAIN

OR EMIT CHEMICALS KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE

CANCER AND BIRTH DEFECTS OR

OTHER REPRODUCTIVE HARM. WASH

HANDS AFTER HANDLING.

Read the operator’s manual and follow

all warnings and safety instructions.

Failure to do so can result in

serious injury to the operator and/or

bystanders.

SAFETY INFORMATION...................................................................3

WARRANTY......................................................................................8

KNOW YOUR UNIT...........................................................................9

SPECIFICATIONS*.........................................................................10

ASSEMBLY......................................................................................11

OPERATION....................................................................................13

MAINTENANCE..............................................................................16

TROUBLESHOOTING....................................................................20

PARTS.............................................................................................21

EC DECLARATION OF CONFORMITY...........................................23

4www.senixtools.com

INTENDED USE

This engine gasoline powered cultivator

is intended for loosening and working

up the soil in a garden and for tilling

coarse soil for mixing in fertilizer,

peat and compost in domestic areas.

This product may not be used to till

extremely dry or wet soil.

This product is intended for private

domestic use only, not for any

commercial trade use. It must not be

used for any purposes other than those

described.

GENERAL SAFETY RULES

• Read, understand, and follow all

instructions on the machine and in the

manual(s). Be thoroughly familiar with

the controls and the proper use of the

machine before starting.

• Use this equipment for its intended

purpose only.

• Familiarize yourself with all of the

safety and operating decals on

this equipment and on any of its

attachments or accessories.

• Do not put hands or feet near or under

rotating parts.

• Only allow responsible individuals

who are familiar with the instructions

to operate the machine. Do not allow

children to operate this machine.

Do not allow adults to operate the

machine without proper instruction.

Thoroughly inspect the area where the

machine is to be used and remove all

foreign objects. Your equipment can

propel small objects at high speed

causing injury or property damage.

Stay away from breakable objects,

such as house windows, automobiles,

greenhouses, etc.

• Wear appropriate clothing such as a

long-sleeved shirt or jacket. Also wear

long trousers or slacks. Do not wear

shorts. Never wear sandals, sneakers

or open shoes, and never operate the

machine with bare feet.

• Do not wear loose clothing or jewelry.

They can get caught in moving parts.

Always keep hands, feet, hair and

loose clothing away from any moving

parts on engine and machine.

• Always wear safety goggles or safety

glasses with side shields when

operating the machine to protect your

eyes from foreign objects which can

be thrown from the unit. Always wear

a protective hearing device.

• Always wear work gloves and sturdy

footwear. Wear footwear that will

improve footing on slippery surfaces.

Leather work shoes or short boots

work well for most people. These will

protect the operator’s ankles and

shins from small sticks, splinters, and

other debris.

• It is advisable to wear protective

headgear to prevent the possibility of

being struck by small flying particles,

or being struck by low hanging

branches, twigs, or other objects

which may be unnoticed by the

operator.

• Do not operate the machine without

proper guards or other safety

protective devices in place.

• See manufacturer’s instructions for

proper operation and installation of

accessories. Only use accessories

approved by the manufacturer.

• Operate only in daylight or good

artificial light.

• Do not operate product when fatigued

or under the influence of alcohol,

drugs or other medication which can

cause drowsiness or affect your ability

to operate this machine safely.

• Never operate machine in wet grass.

Always be sure of your footing; keep

a firm hold on the handle and walk;

never run.

• Watch for traffic when operating

cultivator near, or when crossing

roads.

• If the equipment should start to

5www.senixtools.com

vibrate abnormally, stop the engine

(motor) and press and hold the On/

Off switch in the off position till the

engine stops. The switch will return to

the on position automatically.

• Check immediately for cause.

Vibration is generally a warning of

trouble. If the noise or vibrations

of the machine increase, stop

immediately and perform an

inspection.

• Never leave the machine unattended

when the engine is running. Press

and hold the On/Off switch in the off

position till the engine stops. The

switch will return to the on position

automatically. The OFF switch

will come back to the ON position

automatically.

• Regularly inspect the machine. Make

sure parts are not bent, damaged or

loose.

• Temperature of muffler and nearby

areas may exceed 150° F (65° C).

Allow muffler and engine areas to

cool before touching. Never pick up or

carry the machine while the engine is

running.

• Prolonged exposure to noise and

vibration from gasoline engine-

powered equipment should be

avoided. Take intermittent breaks and/

or wear ear protection from engine

noise as well as heavy work gloves to

reduce vibration in the hands.

• Keep all screws, nuts and bolts tight.

• Do not transport the machine from

one place to another with the engine

running.

• When moving the packaged machine,

always do so with a partner.

• Check local regulations for age

restrictions on use of this machine.

PRODUCT-SPECIFIC SAFETY RULES

• Do not cultivate above underground

utilities, including water lines, gas

lines, electric cables, or pipes. Do not

operate the machine on terrain/soil

with large rocks and foreign objects

which can damage the equipment.

• After striking a foreign object, stop

the engine. Press and hold the On/

Off switch in the off position till the

engine stops. The switch will return to

the on position automatically. Inspect

the machine for damage. If damaged,

repair before starting and operating

the machine.

• The tines of the cultivator should not

rotate when the engine is idling. If

it does rotate when engine is idling,

contact us at 1-800-261-3981.

• If an object becomes lodged in

the tines, press and hold the On/

Off switch in the off position till the

engine stops. The switch will return to

the on position automatically. Allow to

cool before attempting to remove the

foreign object.

• The clutch will transfer maximum

power after about two hours of normal

operation. During this break-in period

clutch slippage may occur. The clutch

should be kept free of oil or other

moisture for efficient operation.

ENGINE SAFETY PRECAUTIONS

If your product comes with a separate

engine manual, be sure to read

and follow all safety and warning

precautions outlined there, in addition

to any in this manual.

Preventing Carbon Monoxide Poisoning

• Always start and run engine outdoors.

Do not start or run engine in an

enclosed area, even if doors or

windows are open.

• Never try to ventilate engine exhaust

indoors. Carbon monoxide can reach

dangerous levels very quickly.

• Never run engine outdoors where

exhaust fumes may be pulled into a

building.

• Never run engine outdoors in a poorly

ventilated area where the exhaust

6www.senixtools.com

fumes may be trapped and not easily

taken away. (Examples include: in

a large hole or areas where hills

surround your working area.)

• Never run engine in an enclosed or

partially enclosed area. (Examples

include: buildings that are enclosed

on one or more sides, under tents, car

ports or basements.)

• Always run the engine with the

exhaust and muffler pointed in the

direction away from the operator.

• Never point the exhaust muffler

towards anyone. People should

always be many feet away from

the operation of the engine and its

attachments.

• Do not change the engine governor

settings or over-speed the engine.

Gasoline Fires and Handling Fuel Safely

• Use extra care in handling gasoline

and other fuels. They are flammable

and vapors are explosive.

• When storing extra fuel be sure that

it is in an appropriate container and

away from any fire hazards.

• Prevent fire and explosion caused

by static electric discharge. Use only

nonmetal, portable fuel containers

approved by the Underwriter’s

Laboratory (U.L.) or the American

Society for Testing & Materials

(ASTM).

• Always fill fuel tank outside in a well

ventilated area. Never fill your fuel

tank with fuel indoors. (Examples

include: basement, garage, barn,

shed, house, porch, etc.) Never fill

tank near appliances with pilot lights,

heaters, or other ignition sources.

If the fuel has to be drained, this

should be done outdoors. The drained

fuel should be stored in a container

specifically designed for fuel storage

or it should be disposed of carefully.

• Never remove the fuel cap or add fuel

with the engine running. Stop engine

and allow to cool before filling.

• Never drain fuel from engine in an

enclosed area.

• Always wipe up excess (spilled) fuel

from engine before starting.

• Clean up spilled fuel immediately. If

fuel is spilled, do not start the engine

but move product and fuel container

from area. Clean up spilled fuel and

allow to evaporate and dry after

wiping and before starting.

• Allow fuel fumes/vapors to escape

from the area before starting engine.

• Test the fuel cap for proper installation

before starting and using engine.

• Always run the engine with fuel cap

properly installed on the engine.

• Never smoke while refilling engine fuel

tank.

• Do not store engine with fuel in fuel

tank indoors. Fuel and fuel vapors are

highly explosive.

• Never siphon fuel by mouth to drain

fuel tank.

• Always have an adult fill the fuel tank

and never allow children to fill the fuel

tank.

• Never allow an adult or anyone under

the influence of drugs or alcohol to fill

the fuel tank.

• When storing gasoline or equipment

with fuel in the tank, store away from

furnaces, stoves, water heaters or

other appliances that have a pilot light

or other ignition source because they

can ignite gasoline vapors.

WARNING:

ENGINES GIVE OFF CARBON

MONOXIDE, AN ODORLESS,

COLORLESS, POISONOUS GAS.

CARBON MONOXIDE MAY BE

PRESENT EVEN IF YOU DO NOT

SMELL OR SEE ANY ENGINE EXHAUST.

BREATHING CARBON MONOXIDE

CAN CAUSE NAUSEA, FAINTING OR

DEATH, IN ADDITION TO DROWSINESS,

DIZZINESS AND CONFUSION.IF

7www.senixtools.com

YOU EXPERIENCE ANY OF THESE

SYMPTOMS, SEEK FRESH AIR AND

MEDICAL ATTENTION IMMEDIATELY.

BURNS AND FIRES

The muffler, muffler guard and other

parts of the engine become extremely

hot during the operation of the engine.

These parts remain extremely hot after

the engine has stopped.

Prevention of Burns and Fires

• Never remove the muffler guard from

the engine.

• Never touch the muffler guard

because it is extremely hot and will

cause severe burns.

• Never touch parts of the engine that

become hot after operation.

• Always keep materials and debris

away from muffler guard and other hot

parts of the engine to avoid fires.

CHILDREN AND BYSTANDERS

Tragic accidents can occur if the

operator is not alert to the presence

of children and/or bystanders. Never

assume that others will remain where

you last saw them.

• Keep the area of operation clear of all

persons, especially small children and

pets. Keep children under the watchful

care of a responsible adult.

• Be alert and turn machine off if

children enter the area.

• Before and while moving backwards,

look behind and down for small

children.

• Never allow children to operate the

machine.

• Use extra care when approaching

blind corners, shrubs, trees, or other

objects that may obscure vision.

WARNING:

HOT GASES ARE A NORMAL BY-

PRODUCT OF A FUNCTIONING

INTERNAL COMBUSTION ENGINE.

FOLLOW ALL SAFETY INSTRUCTIONS

TO PREVENT BURNS AND FIRES.

SERVICE

• Always stop the engine whenever you

leave the equipment, before cleaning,

repairing or inspecting the unit.

Engine should be turned off and cool.

Never make adjustments or repairs

with the engine (motor) running.

• Always wear eye protection when you

make adjustments or repairs.

• Keep all nuts and bolts tight and keep

equipment in good condition.

• Never tamper with safety devices.

Check their proper operation regularly.

• When servicing or repairing the

machine, do not tip the machine over

or up unless specifically instructed

to do so in this manual. Service and

repair procedures can be done with

the machine in an upright position.

Some procedures will be easier if the

machine is lifted on a raised platform

or working surface.

• To reduce fire hazard, keep machine

free of grass, leaves or other debris

build-up. Clean up oil or fuel spillage.

Allow machine to cool before storing.

• Stop and inspect the equipment if you

strike an object. Repair, if necessary,

before restarting.

• Clean and replace safety and

instruction decals as necessary.

• Inspect machine before storage. When

not in use, press and hold the On/

Off switch in the off position till the

engine stops. The switch will return

to the on position automatically. And

store indoors in a dry place locked or

otherwise inaccessible to children.

• Use only original equipment parts for

the manufacturer including all nuts

and bolts.

SAVE THESE INSTRUCTIONS

8www.senixtools.com

LIMITED THREE-YEAR WARRANTY

3 year limited warranty on Senix 15 in. 46cc Cultivator.

FOR THREE YEARS from the original date of retail purchase this Cultivator is warranted against defects in

materials and workmanship period. Defective product will receive free repair.*

This warranty does not cover normal wear of parts and components such as, line or blades nor does this warranty

cover product transportation cost for warranty or service.

Warranty is subject to the following conditions

• Warranty applies to the original purchaser at retail and is not transferrable.

7KHWRROKDVQRWEHHQPLVXVHGDEXVHGQHJOHFWHGDOWHUHGPRGL¿HGRUUHSDLUHGE\DQ\RQHRWKHUWKDQDQ

authorized service center.

• Only genuine OEM accessories have been used with or on this product.

• The tool has been subjected to normal wear and tear.

• The tool has not been used for trade or professional purposes.

• The tool has not been used for rental purposes.

• This warranty only covers defects arising under normal usage and does not cover any malfunction, failure or

defect resulting from misuse, abuse (including overloading the product) accidents, neglect or lack of proper

installation and improper maintenance or storage.

To locate your nearest Senix service provider call toll free at 800-261-3981 or email us at [email protected].

Additional Limitations

$Q\LPSOLHGZDUUDQW\JUDQWHGXQGHUVWDWHODZLQFOXGLQJZDUUDQWLHVRIPHUFKDQWDELOLW\RU¿WQHVVIRUDSDUWLFXODU

purpose, are limited to two years from the date of purchase. The manufacturer is not responsible for direct, indirect,

incidental or consequential damages. Some states and provinces do not allow limitations on how long an implied

warranty lasts and/or do not allow the exclusion or limitation of incidental damages, so the above limitations and

H[FOXVLRQVPD\QRWDSSO\WR\RX7KLVZDUUDQW\JLYHV\RXVSHFL¿FOHJDOULJKWVDQG\RXPD\DOVRKDYHRWKHUULJKWV

which vary from state to state or province to province.

YAT USA declines any responsibility in regard to civil liability arising from abusive use or not in conformity with

proper use and maintenance of the machine as described in the operator’s manual.

YAT USA is not responsible for direct, indirect, incidental or consequential damages. After the purchase, the

manufacturer operator’s manual.

YAT USA is not responsible for direct, indirect, incidental or consequential damages. After the purchase, the

manufacturer recommends proper maintenance of the machine and to read the operator’s manual before using the

machine.

*Original purchase receipt may be required for proof of purchase.

For customer service contact us toll free at 1-800-261-3981 or Senixtools.com.

YAT USA, Inc. 6441 Hendry Rd. Suite A Charlotte, NC. 28269

WARRANTY

9www.senixtools.com

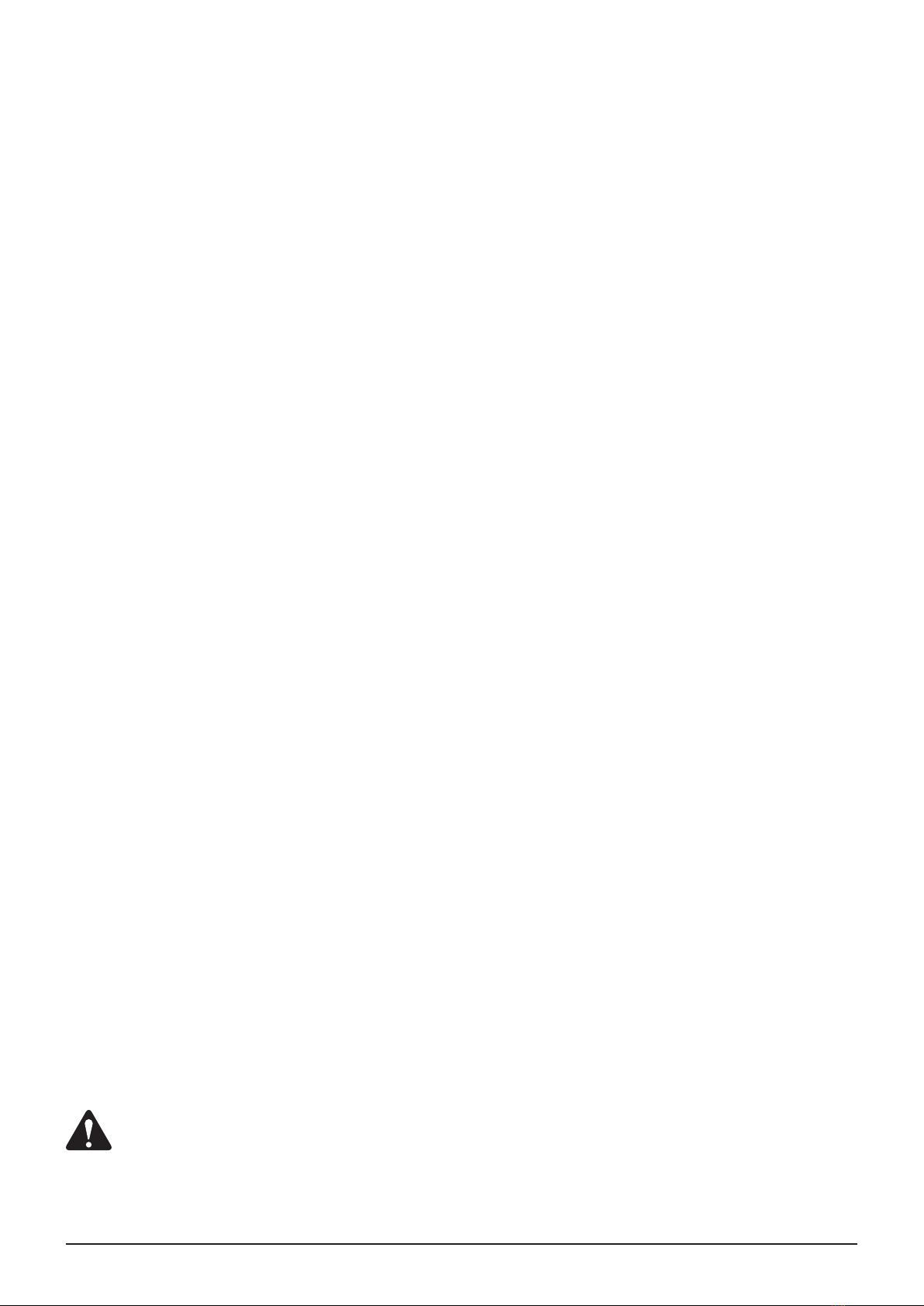

KNOW YOUR UNIT

Model: TL4QL-L1

As a cultivator:

Loosening and working up the soil in a garden and for tilling coarse soil for mixing in fertilizer, peat and compost in

domestic areas.

A Throttle lever K Tines

B Handle grip ( left and right ) L Wheel

C On/off switch M Lower handle bar

D Cable N Choke button

E Cable clip O $LU¿OWHUNQRE

F Knob P Fuel cap

G Starter grip and rope Q Middle handle bar

H Primer bulb R Upper handle bar

I Guard S 2LO¿OOSOXJ

J Gearbox

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

10 www.senixtools.com

Model TL4QL-L1

Engine displacement 46 cc

Max. engine power 1400 W

Blade speed 250 RPM

Blade cutting width 15.7 in. (400 mm)

Blade cutting depth 7.84 in. (200 mm Max.)

Fuel tank capacity 28.16 oz. (800 ml)

Oil tank capacity 3.37 oz. (100 ml)

Weight approx. 25.4 lbs. (11.5 Kg)

SPECIFICATIONS*

11www.senixtools.com

This product requires assembly. Carefully remove the

product and any accessories from the box. Make sure

that all items listed in the packing list are included. In-

spect the product carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the product.

WARNING:

The equipment and packaging material are not toys.

Do not let children play with plastic bags, foils, or small

parts. These items can be swallowed and pose a suffo-

cation risk!

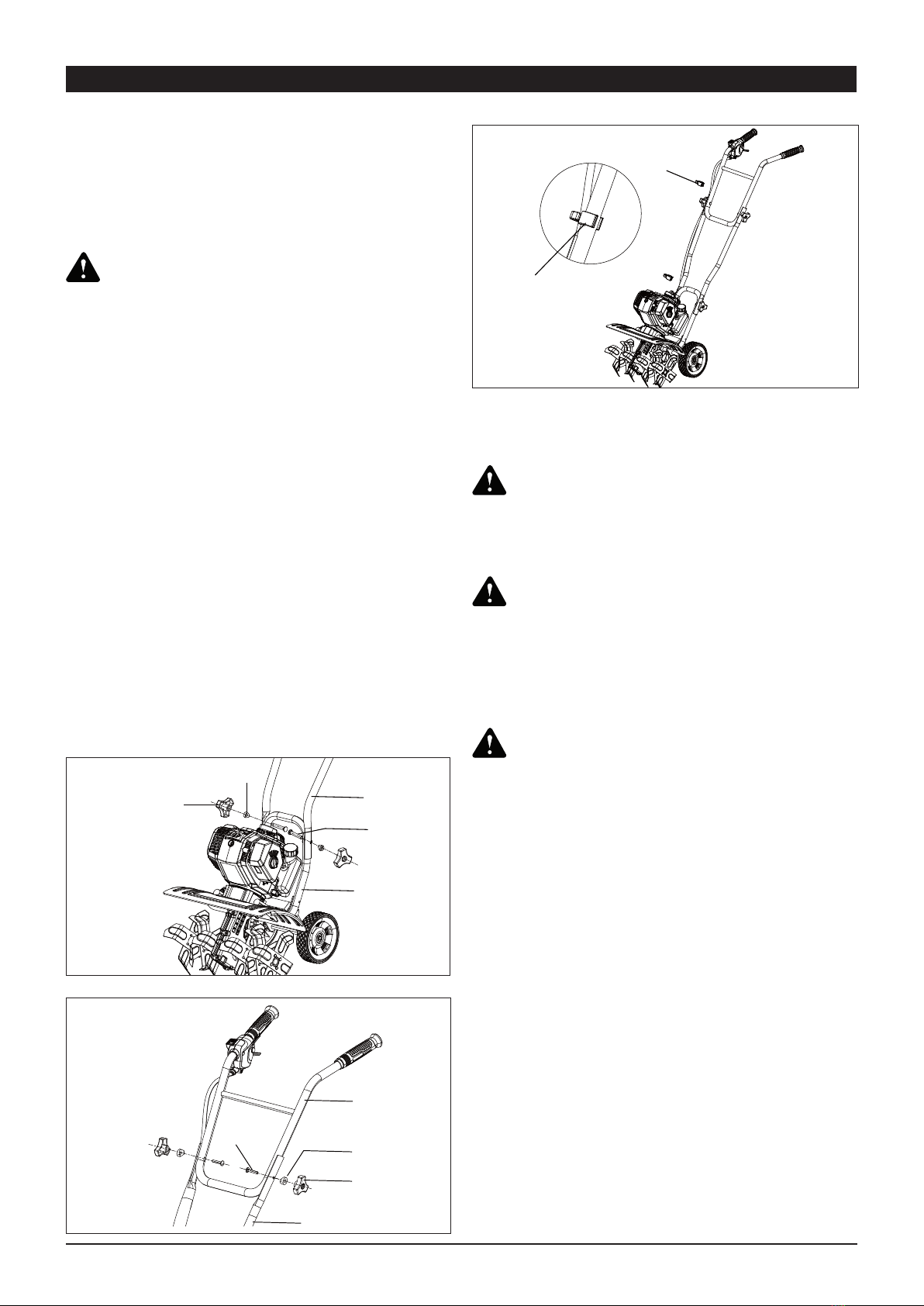

INSTALLING THE HANDLE BAR

The product must be fully assembled before operation!

Do not use a product that is only partly assembled or

assembled with damaged parts.

Follow the assembly instructions step-by-step and use

the pictures provided as a visual guide to easily assem-

ble the product!

Never start the engine before it is completely assem-

bled!

1. Set up the cultivator on flat and firm ground to ensure

safe and sturdy operating.

2. Align the holes in the middle handle bar (BB) with the

holes in the lower handle bar (M) and secure the con-

nection with the bolts (AA), knobs (DD), and gaskets

(CC) (Fig. 1).

3. Align the holes in the upper handle bar (R) with the

holes in the middle handle bar (BB) and secure the

connection with the bolts (AA), knobs (DD), and gas-

kets (CC) (Fig. 2).

BB

CC

DD

AA

M

Fig. 1

R

BB

DD

CC

AA

Fig. 2

ASSEMBLY

4. Secure the cables with the cable clips (EE) (Fig. 3).

EE

EE

Fig. 3

ADDING OIL: INITIAL USE

CAUTION:

Attempting to start the engine before it has been pro-

perly filled with lubricant will result in equipment failure

not covered by the warranty.

WARNING:

Overfilling the crankcase may cause serious issues.

Check the oil level before each use. The importance

of maintaining the proper oil level cannot be overemp-

hasized. Change the oil according to the Maintenance

Schedule.

CAUTION:

Do not overfill. Overfilling the crankcase may cause ex-

cessive smoke, oil loss, and engine damage.

NOTE: Oil must be added before starting the unit.

NOTE: This unit comes with a 3.37 fluid oz. (100 ml

SAE 10W-30) container of oil.

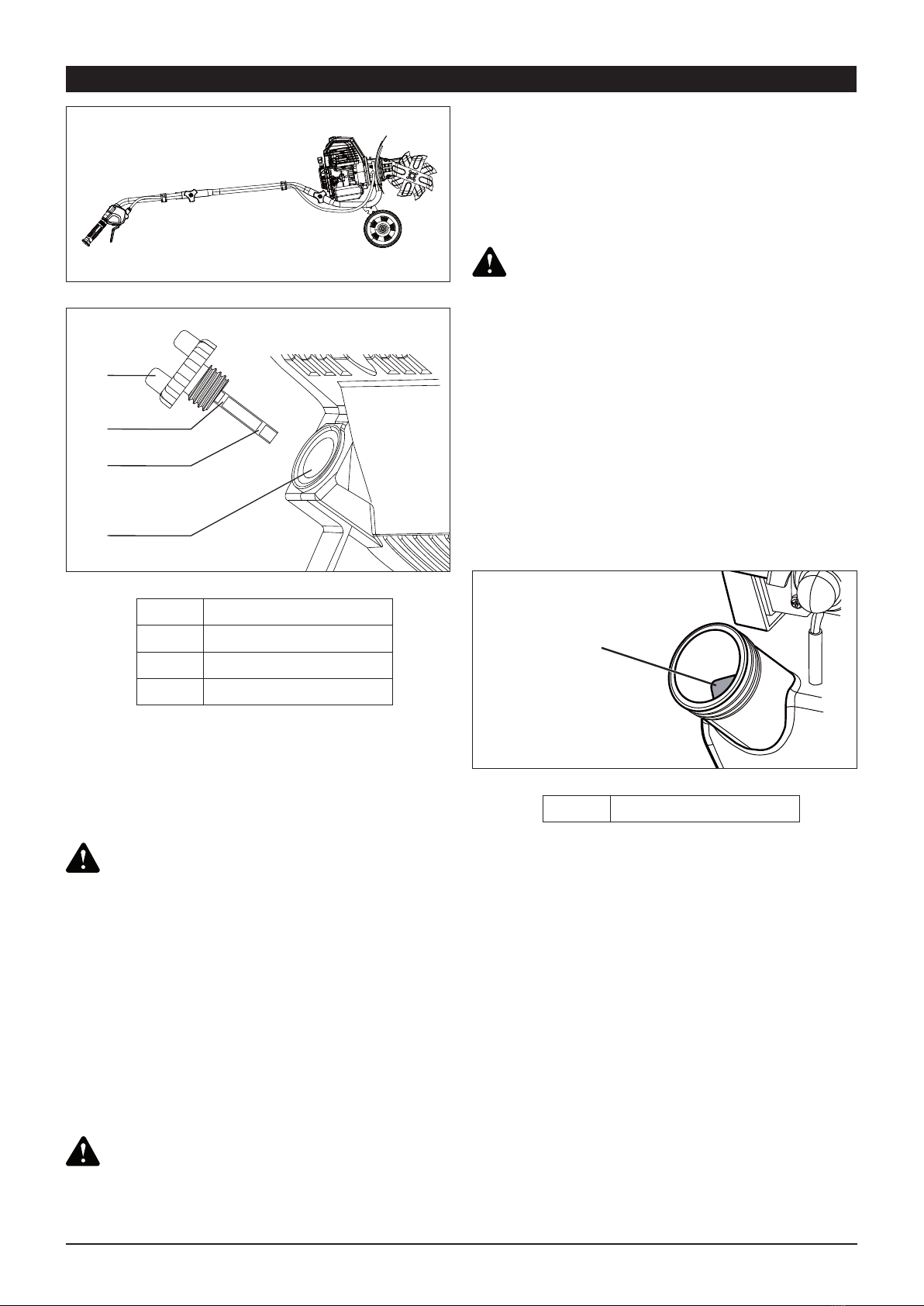

1. Set the unit on a flat, level surface horizontally as

shown below (Fig. 4).

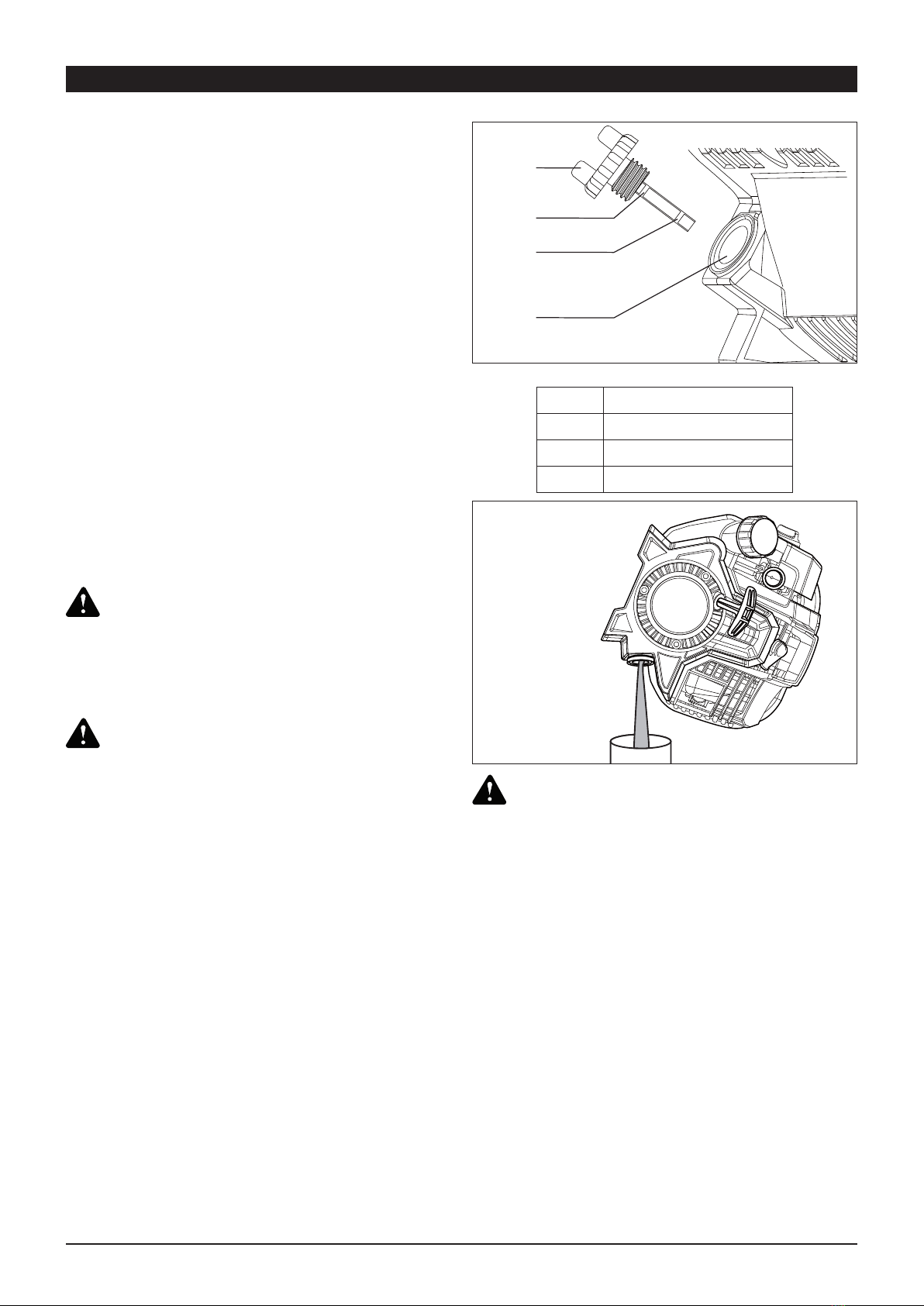

2. Unscrew the oil fill plug (Fig. 5).

3. Pour the 3.37 fluid oz. (100 ml) oil into the oil fill hole.

DO NOT overfill.

4. Insert the dipstick into the fill spout but do NOT screw

in. Remove dipstick and check the oil level.

5. When oil level is full, the oil will be between the up-

per limit and lower limit on the dipstick. If oil level is

below the lower limit, add oil until the fluid level rises

between the upper limit and lower limit on the dipstick

(Fig. 5).

NOTICE: Never add oil to the fuel tank. This unit has a

four-cycle engine. DO NOT mix oil with gasoline.

6. Wipe up any oil that may have spilled.

7. Reinstall the oil fill plug (Fig. 5).

12 www.senixtools.com

ASSEMBLY

Fig. 4

4

1

2

3

Fig. 5

12LO¿OOSOXJ'LSVWLFN

2 Upper limit

3 Lower limit

42LO¿OOKROH

USING THE RIGHT OIL

Use a high-qualitySAE 10W-30 weight oil. DO NOT use

dirty oil. Failure to use clean oil of the correct type can

cause premature engine wear and failure.

FUELING THE UNIT

WARNING:

Gasoline is extremely flammable. Ignited vapors may

explode. Always stop the engine and allow it to cool

before filling the fuel tank. Do not smoke while filling the

tank. Keep sparks and open flames at a distance from

the area.

Remove the fuel cap slowly to avoid injury from fuel

spray. Never operate the unit without the fuel cap secu-

rely in place.

Add fuel in a clean, well-ventilated outdoor area. Wipe

up any spilled fuel immediately. Avoid creating a source

of ignition for spilled fuel. Do not start the engine until

fuel vapors dissipate.

WARNING:

Gasoline and its vapors are highly flammable and ex-

plosive. To prevent serious injury and property damage,

handle it with care. Keep away from ignition sources

and open flames, handle outdoors only.

Pour fuel outdoors where there are no sparks or flames.

Slowly remove the fuel cap after stopping the engine.

Do not smoke while fueling. Wipe spilled fuel from the

unit. Move at least 3 m (10 ft) away from the fueling

source before starting the engine.

WARNING:

Always wear heavy, long pants, boots, gloves, and a

long-sleeve shirt. Do not wear loose clothing, jewelry,

short pants, sandals, or go barefoot. Secure hair so it is

above shoulder level.

1. Position the unit with the fuel cap facing up.

2. Slowly remove the fuel cap.

3. Place the fuel container spout into the fuel tank fill

hole and fill the tank. Stop adding fuel when you see

that the level reaches the base of the tank spout

(Fig. 6).

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 3 m (10 ft) from the fuel contai-

ner and the fueling site before starting the engine.

1

Fig. 6

1 Base of the tank spout

13www.senixtools.com

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a se-

cond is sufficient to inflict serious injury.

WARNING:

Always wear eye protection along with hearing protecti-

on. Failure to do so could result in objects being thrown

into your eyes and other possible serious injuries.

WARNING:

Do not use any attachments or accessories not recom-

mended by the manufacturer of this product. The use

of attachments or accessories not recommended can

result in serious injury

WARNING:

Operation of this equipment could create sparks that

can start fires around dry vegetation. A spark arrestor

may be required. The operator should contact local fire

agencies for laws or regulations relating to fire preven-

tion requirements.

USING THE RIGHT FUEL

The use of old fuel is the most common cause of per-

formance problems. Use only fresh, clean unleaded

gasoline less than 30 days old.

NOTICE: This unit has a four-cycle engine. DO NOT

mix oil with gasoline.

Definition of Blended Fuels

Today’s fuels are often a blend of gasoline and oxyge-

nates such as ethanol, methanol or MTBE (ether). Alco-

hol-blended fuel absorbs water. As little as 1% water in

the fuel can make fuel and oil separate, forming acids

when stored. ALWAYS use fresh fuel (less than 30 days

old) with less than 10% ethanol. Dispose of old fuel ac-

cording to federal, state and local regulations.

Using Blended Fuels

If using a blended fuel:

Always use fresh unleaded gasoline.

Use the fuel additive STA-BILL®or an equivalent.

WARNING:

DO NOT USE E85 OR E15 FUEL IN THIS UNIT. It

has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the

warranty.

WARNING:

Operate this unit only in a well-ventilated outdoor area.

Carbon monoxide exhaust fumes can be lethal in a con-

fined area

USING THE RIGHT OIL TYPE

Using the proper type and weight of oil in the crankcase

is extremely important.

Check the oil before each use and change the oil regu-

larly. Failure to use the correct oil, or using dirty oil, can

cause premature engine wear and failure.

Use a high-quality SAE 10W-30 weight oil ofAPI (Ame-

rican Petroleum Institute) service class SF, SG, SH.

WARNING:

Avoid accidentally starting the unit. To avoid serious in-

jury, the operator and the unit must be in a stable posi-

tion when pulling the starter rope.

WARNING:

Do not operate the unit inside a closed environment,

such as a room or building; breathing carbon monoxide

from exhaust fumes can kill.

WARNING:

Inspect unit before each use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in pla-

ce and secure. Replace cutting attachment parts that

are cracked, chipped, or damaged in any way. Make

sure the cutting attachment is properly installed and

securely fastened. Make sure the cutting attachment

shield is properly attached and in the position recom-

mended by the manufacturer.

CAUTION:

Clear the area to be tilled before each use. Remove

all objects such as rocks, broken glass, nails, wire, or

string which can be thrown or become entangled in the

cutting attachment. Clear the area of children, bystan-

ders, and pets outside a 50 ft (15 m) radius: there is still

a risk of injury from thrown objects outside the 50 ft (15

m) zone. Bystanders should be encouraged to wear eye

protection.

If you are approached, stop the engine and cutting

attachment. In the case of bladed units, there is the

added risk of injury to bystanders from being struck with

the moving blade.

WARNING:

In some countries regulations define at what time of the

day and on what special days products are allowed to

be used and what restrictions apply! Ask your commu-

nity for detailed information and observe the regulations

in order to preserve a peaceful neighborhood and avoid

committing administrative offences.

WHEEL ADJUSTMENT

WARNING:

Always wear safety glasses, ear protection and work

gloves during operation. Avoid wearing loose clothing

and accessories.

OPERATION

14 www.senixtools.com

The wheels can be adjusted to two positions.

1. Pull on the wheel and move it to required position,

let go of the wheel and make sure it locks in position

(Fig. 7).

WARNING:

The wheels can be adjusted in two different positions.

Always ensure the wheels are securely locked! Do not

attempt to use the product with the wheels in any other

position or unlocked!

1

2

Fig. 7

1 Working

2 Transport

STARTING INSTRUCTIONS

1. When oil level is full, the oil will be between the up-

per limit and lower limit on the dipstick. If oil level is

below the lower limit, add oil until the fluid level rises

between the upper limit and lower limit on the dips-

tick. Reinstall the oil fill plug. (Fig. 5)

2. Fill the fuel tank. Stop adding the fuel when you see

that the level reaches the base of the tank spout.

3. Slowly press and release the primer bulb 10 times

(Fig. 8).

4. Push the choke button in until it clicks (Fig. 9).

NOTE: The choke automatically disengages when the

throttle lever is squeezed.

5. Pull the starter rope with a controlled and steady mo-

tion five times until engine starts or attempts to start

(Fig. 10).

6. Squeeze the throttle lever to release the choke but-

ton (Fig. 11).

IF.. the unit fails to start. Squeeze the throttle control,

and pull the starter rope until the engine starts.

IF THE ENGINE IS HOT... begin the starting procedure

with step 5.

STOPPING INSTRUCTIONS

1. Release the throttle lever and allow the engine to

idle.

2. Press and hold the On/Off switch in the Off (O) posi-

tion until the engine comes to a complete stop

OPERATION

(Fig. 12). Make sure the cutting attachment has stop-

ped before the unit is set down.

NOTE: This OFF switch will come back to the ON posi-

tion automatically.

Fig. 8

Fig. 9

Fig. 10

Fig. 11

15www.senixtools.com

OPERATION

Fig. 12

HOLDING THE UNIT

• Stand in the operating position (hold the machine in

front of your body). Stand up straight. Do not bend

over.

• Keep feet apart and firmly planted.

• Hold the handle with two hands. Keep the arms

straight.

• Do not over-reach; Keep all parts of your body away

from the rotating cutting attachment and hot surfaces.

WARNING:

Do not operate the machine with a damaged or excessi-

vely worn cutting device.

CLEARING JAMS

If the blades get jammed by a wire or other obstruction

and cannot move, follow these important safety rules:

• NEVER reach for, or try to remove, jammed material

while the engine is running.

• ALWAYS switch the unit off and wait for blades to stop

before clearing a jam.

• ALWAYS inspect the blades after clearing a jam to

make sure all jammed material has been cleared, and

to make sure blades are not damaged.

16 www.senixtools.com

MAINTENANCE

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

NOTICE: Users are not allowed to set the carburetor or

ignition. If further assistance is required, take the unit to

a qualified service dealer.

WARNING:

To avoid serious injury, always stop the engine and

allow it to cool before cleaning or maintaining the unit.

Never perform cleaning or maintenance while the unit is

running. Disconnect the spark plug wire to prevent the

unit from starting accidentally.

WARNING:

Wear protective clothing and observe all safety instruc-

tions to prevent serious injury.

CLEANING

Use a small brush to clean the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and sol-

vents such as kerosene, can damage plastic. Wipe off

any moisture with a soft cloth.

Correct and regular cleaning is not only important for

the safe use of this product, but also extends its life

span.

LUBRICATION

For a long lifespan, make sure that the cutting blades

are cleaned and lubricated at regular intervals in order

to ensure the best possible performance. Routinely ap-

ply a thin film of lubricating oil.

REPLACING THE BLADES

WARNING:

To avoid serious injury, always stop the engine and

allow it to cool before replacing the blades.

To replace the blades, take off the pin.

Take off the broken blades and replace the new blades

according to the original position (Fig. 13).

Re-insert the pin to secure the blades.

Fig. 13

MAINTENANCE SCHEDULE

WARNING:

When the engine idles, user should check the cutting

attachment stops while turning routinely.

WARNING:

To prevent any danger or defects, user should check

and maintain every part of the machine before use and

after dropping or other impacts.

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require

special tools or skills. If you are unsure about these pro-

cedures, take the unit to a qualified service dealer.

NOTE: Maintenance, replacement, or repair of the

emission control devices and system may be performed

by a qualified service dealer.

NOTE: Please read the California/EPA statement that

came with the unit for a complete listing of terms and

coverage for the emissions control devices, such as the

spark arrestor, muffler, carburetor, etc.

FREQUENCY MAINTENANCE REQUIRED

Every 10 hours ЬClean the air filter.

Refer to Maintaining the Air Filter.

Every 20 hours ЬChange the oil. Refer to Changing the Oil.

• Replace the oil after the first 5 hours.

Every 30 hours

ЬHave the rocker arm clearance checked by a

qualified service dealer.

• Check the spark plug condition and gap.

Refer to Maintaining the Spark Plug.

NOTE: If the engine frequently work under dusty or

other severe circumstances, increase the cleaning fre-

quency.

REMARKS

• The maintenance interval is only a recommendation

for machines in ordinary operating condition.

• If there are any abnormal signs from the machine,

please do the proper inspection and maintenance im-

mediately.

• All other repairs or maintenance should be done by a

qualified service center

CHECKING THE OIL LEVEL

WARNING:

Check the oil level before each use. The importance of

maintaining the proper oil level cannot be overempha-

sized.

17www.senixtools.com

MAINTENANCE

Inspecting the Oil Level

1. Stop the engine and allow it to cool.

2. Set the unit on a flat, level surface horizontally.

NOTE: Failure to keep the engine level may result in a

faulty oil level reading.

3. Remove dipstick and check oil level. When oil level is

full, the oil will be between the upper limit and lower

limit on the dipstick (Fig. 14). If the oil level is too

low, add oil. Refer to Adding Oil.

Adding Oil

1. Set the unit on a flat, level surface horizontally.

2. Clean the area around the oil fill plug (Fig. 14) to pre-

vent debris from entering the oil fill hole.

3. Unscrew the oil fill plug.

4. Insert the dipstick into the fill spout but do NOT screw

in. Remove the dipstick and check the oil level. Add

oil until the fluid level rises between the upper limit

and lower limit on the dipstick (Fig. 14).

NOTE: If the oil level is too high, tip the unit and drain

the excess oil into an appropriate container.

5. Wipe up any oil that may have spilled.

6. Reinstall the oil fill plug.

WARNING:

DO NOT overfill the oil level. Overfilling will result in too

much oil in the engine crankcase, and may cause smo-

ke or fumes that can injure the user.

CHANGING THE OIL

WARNING:

Old engine oil is considered special waste and has to

be disposed according to your local environment pro-

tection regulation. Do not pour the oil into a garbage

can, sewer, soil etc.

Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities.

1. Clean the area around the oil fill plug (Fig. 14) to pre-

vent debris from entering the oil fill hole.

2. Unscrew the oil fill plug.

3. Tip the unit vertically to pour the oil out of the oil fill

hole and into a container (Fig. 15). Allow ample time

for complete drainage.

NOTE: Dispose of the old oil according to federal, state

and local regulations.

4. Wipe up any oil that may have spilled.

5. Set the unit on a flat, level surface horizontally.

6. Pour 3.37 oz. (100 ml SAE 10W-30) of SAE 30 oil

into the oil fill hole. When oil level is full, the oil will

be between the upper limit and lower limit on dipstick

(Fig. 14). If the oil level is too low, add oil. Refer to

Adding Oil.

7. Wipe up any oil that may have spilled.

8. Reinstall the oil fill plug.

4

1

2

3

Fig. 14

1 Oil fill plug/Dipstick

2 Upper limit

3 Lower limit

4 Oil fill hole

Fig. 15

WARNING:

DO NOT overfill the oil level. Overfilling will result in too

much oil in the engine crankcase, and may cause smo-

ke or fumes that can injure the user.

MAINTAINING THE AIR FILTER

Failure to maintain the air filter can result in poor perfor-

mance or can cause permanent damage to the engine.

Engine failure due to improper air filter maintenance is

not covered by the product warranty.

Cleaning the Air Filter

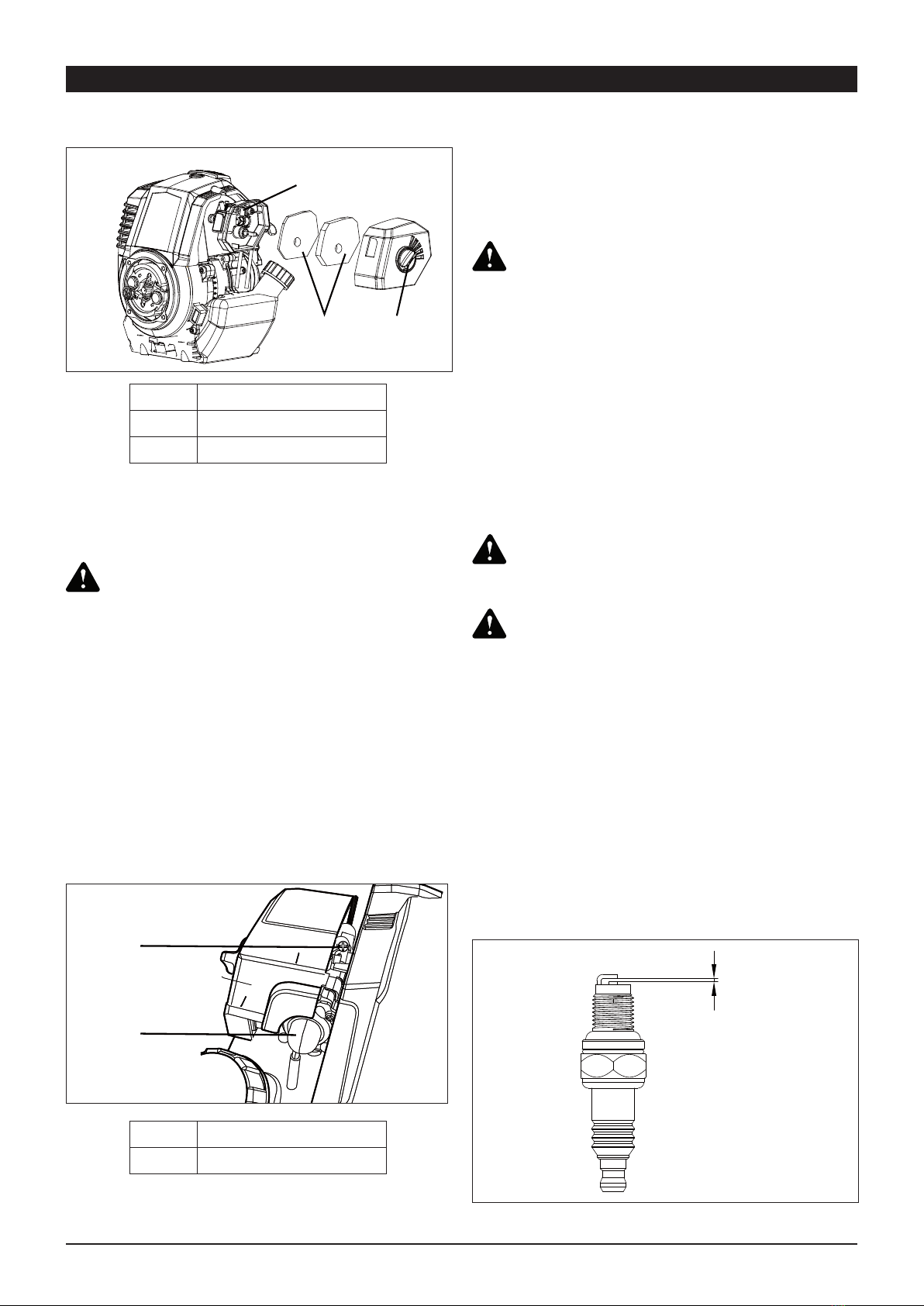

1. Unscrew the air filter knob completely. Remove the

air filter cover from the air filter housing (Fig. 16).

2. Remove the air filter from the air filter housing.

3. Wash the air filter in detergent and water. Rinse the

air filter thoroughly and allow it to dry.

4. Reinstall the air filter in the air filter housing (Fig. 16).

NOTICE: Operating the unit without the air filter and air

filter cover will VOID the warranty.

5. Insert the tab on the air filter cover into the hole in the

air filter housing. Push the air filter cover back onto

18 www.senixtools.com

the air filter housing. Tighten the air filter knob to se-

cure the air filter cover (Fig. 16)

1

23

Fig. 16

1 Air filter housing

2 Air filter

3 Air filter knob

NOTICE: Do not overtighten as this may strip the air

filter knob.

ADJUSTING THE IDLE SPEED

WARNING:

The cutting blades will move when adjusting the idle

speed. Wear all protective clothing and keep all bys-

tanders, children, and pets at least 50 ft. away. Make

adjustments with the unit supported by hand so that

the cutting blades does not contact the ground or any

object.

Keep all parts of your body away from the cutting bla-

des and muffler. Failure to follow these instructions

could result in serious injury.

If the engine will not idle properly:

1. Start the engine. Refer to STARTING INSTRUC-

TIONS.

2. Release the throttle control and let the engine idle.

1

2

Fig. 17

1 Idle speed screw

2 Primer bulb

• If the engine stops, increase the idle speed. Use a

small screwdriver to turn the idle speed screw clock-

wise, 1/8 of a turn at a time, until the engine idles

smoothly (Fig. 17).

• If the cutting blades spin when the engine idles, redu-

ce the idle speed. Turn the idle speed screw counterc-

lockwise, 1/8 of a turn at a time, until the cutting head

stops moving.

WARNING:

The cutting attachment should never turn at idle. Turn

the idle speed screw counterclockwise to reduce the

idle RPM and stop the cutting attachment, or contact us

at 1-800-261-3981 for adjustment and discontinue use

until the repair is made. Serious injury could result from

the cutting attachment turning at idle.

MAINTAINING THE SPARK PLUG

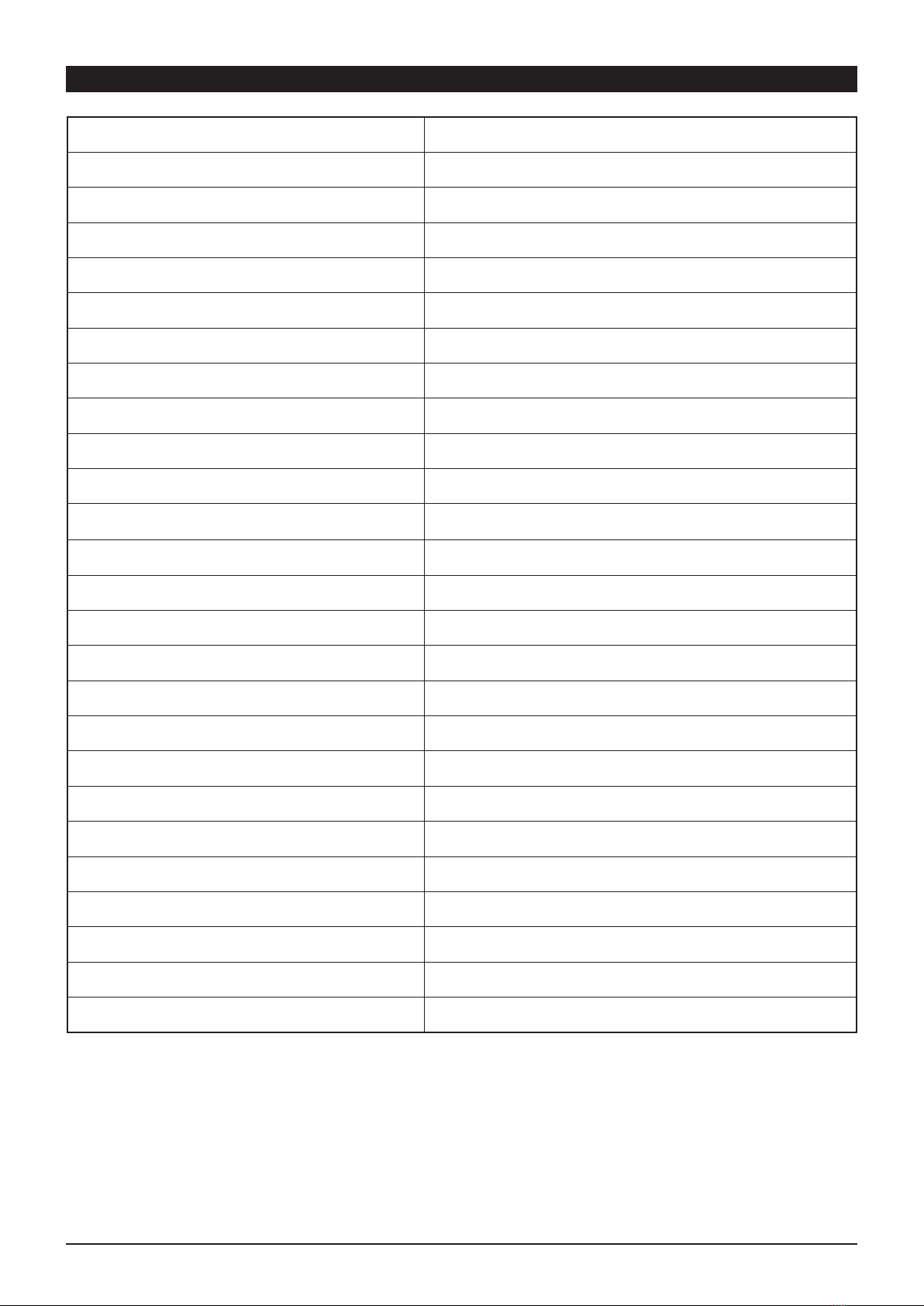

1. Stop the engine and allow it to cool. Grasp the spark

plug boot firmly and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug

from the cylinder head with a 5/8-inch socket, turning

counterclockwise.

CAUTION:

Do not remove the spark plug when the engine is hot.

CAUTION:

Do not sand blast, scrape or clean spark plug electro-

des. Grit in the engine could damage the cylinder.

3. Inspect the spark plug. If the spark plug is cracked,

fouled or dirty, replace it with replacement part refer

to PART or an equivalent spark plug.

4. Use a feeler gauge to set the air gap at

0.6 mm - 0.8 mm (0.025 in. - 0.031 in.) (Fig. 18).

5. Install the spark plug in the cylinder head. Tighten the

spark plug with a 5/8-inch socket, turning it clockwise

until snug.

NOTICE: If using a torque wrench, torque to 12 N•m.

Do not over tighten.

6. Reattach the spark plug boot.

1

Fig. 18

MAINTENANCE

19www.senixtools.com

10.60 mm - 0.80 mm

0.025 in. - 0.031 in.

STORAGE

ЬNever store a fueled unit where fumes may reach an

open flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or da-

mage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

• Store the unit after cleaning the cutting blade.

Short-term Storage (1-2 weeks)

Store the unit in a horizontal position.

Long-term Storage

1. Remove the fuel cap, tip the unit and drain the fuel

into an approved container. Reinstall the fuel cap.

2. Start the engine and allow it to run until it stalls. This

ensures that all fuel has been drained from the car-

buretor.

3. Allow the engine to cool. Remove the spark plug and

put 5 drops of any high quality motor oil into the cy-

linder. Pull the starter rope slowly to distribute the oil.

Reinstall the spark plug.

4. Thoroughly clean the unit and inspect it for any loose

or damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts or bolts.

5. Store the unit in a horizontal position.

Preparing the Unit for Use after Long-term Storage

1. Remove the spark plug. Tip the unit and drain all of

the oil from the cylinder into an approved container.

Reinstall the spark plug.

2. Change the oil. Refer to Changing the Oil.

NOTICE: Do not use fuel that has been stored for more

than 30 days. Dispose of old fuel and oil according to

federal, state and local regulations.

TRANSPORTATION

CAUTION:

Protect the product from any heavy impact or strong

vibrations which may occur during transportation in ve-

hicles.

Transport the unit in a horizontal position. If not possib-

le, transport the unit vertically with the engine at the top.

Secure the unit to prevent damage during transport.

Secure the unit to prevent it from slipping or falling over.

MAINTENANCE

20 www.senixtools.com

TROUBLESHOOTING

PROBLEM SOLUTION

THE ENGINE WILL NOT START.

The fuel tank is empty. Fill the fuel tank with fresh fuel.

The primer bulb was not pressed enough. Press the primer bulb 10 times.

The fuel is old (over 30 days). Drain the fuel tank and add fresh fuel.

The spark plug is fouled. Replace the spark plug.

THE ENGINE WILL NOT IDLE.

7KHDLU¿OWHULVGLUW\ &OHDQRUUHSODFHWKHDLU¿OWHU

The fuel is old (over 30 days). Drain the fuel tank and add fresh fuel.

Idle speed screw needs adjustment. Turn idle speed screw clockwise to increase idle speed.

THE ENGINE EMITS TOO MUCH SMOKE.

Too much oil in crankcase. 'UDLQHQJLQHRLODQGUH¿OOZLWKFRUUHFWDPRXQWRIHQJLQH

lubricant.

THE ENGINE WILL NOT ACCELERATE.

The fuel is old (over 30 days). Drain the fuel tank and add fresh fuel.

The cutting blades is bound with any objects. Stop the engine and clean the cutting blades.

7KHDLU¿OWHULVGLUW\ &OHDQRUUHSODFHWKHDLU¿OWHU

THE ENGINE LACKS POWER OR STALLS.

The fuel is old (over 30 days). Drain the fuel tank and add fresh fuel.

7KHDLU¿OWHULVGLUW\ &OHDQRUUHSODFHWKHDLU¿OWHU

The spark plug is fouled. Replace the spark plug.

UNSATISFACTORY CUTTING PERFORMANCE.

Cutting blade is dull/damaged. 5HSODFHRUFRQWDFWDTXDOL¿HGVHUYLFHGHDOHU

Cutting material exceeds capacity. Only cut material according to the capacity of the unit.

EXCESSIVE VIBRATION/NOISE OR EXHAUST.

Bolts/Nuts are loose. Tighten.

Gas/oil is incorrect. (PSW\XQXVHGIXHODQGRLO5H¿OOZLWKIUHVKIXHODQGRLO

,IIXUWKHUDVVLVWDQFHLVUHTXLUHGWDNHWKHXQLWWRDTXDOL¿HGVHUYLFHGHDOHU

Table of contents

Languages: