Toro Dingo 22445 User manual

Operator’s Manual

English (CE)

Form No. 3324-220 Rev A

Tiller

DingoAttachment

Model No. 22445—200000001 & Up

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196 All Rights Reserved

2

Printed in the USA

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Decals 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stability Ratings 4. . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tips for Tilling 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 5. . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 5. . . . . . . . . . . . . . . . . . .

Adjusting Tiller Drive Chain Tension 5. . . . . . . . .

Tiller Tine Replacement 6. . . . . . . . . . . . . . . . . . .

Storage 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

We want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number on a plate located on the product.

For your convenience, write the product model and serial

numbers in the space below.

Model No:

Serial No.

The warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury, even death. DANGER,

WARNING and CAUTION are signal words used to

identify the level of hazard. However, regardless of the

hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended precautions

are not followed.

WARNING signals a hazard that may cause serious injury

or death if the recommended precautions are not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed.

Two other words are also used to highlight information.

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

Safety

Improper use or maintenance by the operator or owner can

result in injury. To reduce the potential for injury, comply

with these safety instructions and those in the traction unit

operator’s manual. Always pay attention to the safety alert

symbol, which means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure to

comply with the instruction may result in personal injury

or death.

DANGER

POTENTIAL HAZARD

•Contact with rotating tines may cause injury.

WHAT CAN HAPPEN

•Rotating tines can cut hands, feet or other body

parts.

HOW TO AVOID THE HAZARD

•Keep away from the rotating tines while

operating the tiller.

•Keep your hands, feet, and any other part of

your body or clothing away from rotating

parts.

•Before adjusting, cleaning, repairing and

inspecting the tiller, lower the tiller and loader

arms to the ground and stop the engine.

Remove the key.

3

WARNING

POTENTIAL HAZARD

•There may be buried power, gas, and/or

telephone lines in the area needing tilling.

WHAT CAN HAPPEN

•Shock or explosion may occur.

HOW TO AVOID THE HAZARD

•Have the property or area to be tilled marked

for buried lines.

WARNING

POTENTIAL HAZARD

•Tines can throw dirt, debris, and small rocks.

WHAT CAN HAPPEN

•The operator or bystander could be injured by

flying debris.

HOW TO AVOID THE HAZARD

•Run the tiller so that debris is thrown away

from the traction unit.

•Keep all bystanders away from the work area.

WARNING

POTENTIAL HAZARD

•When the engine is off, attachments in the

raised position can gradually lower.

WHAT CAN HAPPEN

•Someone nearby may be pinned or injured by

the attachment as it lowers.

HOW TO AVOID THE HAZARD

•Always lower the loader arms before you shut

off the traction unit.

Safety Decals

# 93–7321

2

1

3

# 100–4708

4

5

Figure 1

1. Cuttinghazard–foot

2. Cutting hazard–hand

3. Keep away from moving

parts

4. Trown object hazard

5. Keep bystanders away

Specifications

Overall width 44.0

in. (112 cm)

Overall length 20.0 in. (51 cm)

Overall height 26.0 in. (66 cm)

Tilling width 40.0

in. (102 cm)

Tine diameter 19.0 in. (48 cm)

Tine speed (max) 245 rpm @ 3600 engine rpm (flow divider @ 9 o’clock position)

Tine speed (recommended) 225 rpm @ 3600 engine rpm (flow divider @ 10 o’clock position)

Tine thickness .25 in. (0.63 cm)

4

Tine width 2.5 in. (6.4 cm)

Number of tines 36

Shaft diameter 1.50 in. (3.8 cm)

Drive Chain ANSI 60 reduction ratio 1.8:1

Hydraulic motor displacement 6.20 cu. in. (102 cc)

Weight 363 lb. (165 kg)

Stability Ratings

To determine the degree of slope you can traverse with the

tiller installed on a traction unit, find the stability rating

for the hill position you want to travel in the table below,

then find the degree of slope for the same rating and hill

position in the Stability Data section of the traction unit

operator’s manual.

Orientation Stability Rating

Front Uphill C

Rear Uphill C

Side Uphill B

Note: The tiller is rated for use without the counterweight.

If you use the counterweight with the tiller, the traction

unit will be less stable in the front and side uphill

positions.

WARNING

POTENTIAL HAZARD

•Exceeding the maximum slope can cause the

traction unit to tip.

WHAT CAN HAPPEN

•If the traction unit tips, you or bystanders could

be crushed.

HOW TO AVOID THE HAZARD

•Do not drive the the traction unit on a slope

steeper that the maximum slope.

Operation

IMPORTANT: Lift and move the attachment using the

traction unit.

Refer to your traction unit Operator’s Manual for more

information on installing and removing the tiller from

your traction unit.

Tips for Tilling

•Clean the area of trash, branches, and rocks before

tilling to prevent equipment damage.

•Always begin tilling with the slowest ground speed

possible. Increase speed if conditions permit.

•Always use full throttle (maximum engine speed).

•Till in long, straight passes. Do not make turns while

the tiller is in the ground, as equipment damage may

result.

•Avoid excessive tilling of the soil, as finely tilled soil

will not absorb moisture easily and puddles of water or

run-off may occur.

•When tilling hard packed, very dry, or virgin soil, raise

the tiller so only the very top of the soil is penetrated.

On succeeding passes the depth may be lowered.

•Run the tiller so that the dirt is thrown away from you.

•If a rock or other obstruction gets into the tiller tines,

reverse the rotation direction to dislodge it.

5

Maintenance

Service Interval Chart

Service Operation Each

Use 5

Hours 25

Hours Storage

Service Notes

Shaft bearing–lubricate X X

Chain tension–adjust and lubricate initial X

Tines–check X Replace as required

Tine bolts–check and tighten XReplace as required

Chipped surfaces–paint X

CAUTION

POTENTIAL HAZARD

•If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

•Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

•Remove the key from the ignition switch before you do any maintenance.

Greasing and Lubrication

Service Interval/Specification

Grease the 2 tiller shaft fittings every 25 operating hours.

Grease immediately after every washing.

Grease Type: General-purpose grease.

How to Grease

1. Lower the loader arms and stop the engine. Remove

the key.

2. Clean the grease fittings with a rag.

3. Scrape any paint off the front of the fittings.

4. Connect a grease gun to each fitting.

5. Pump grease into the fittings until grease begins to

ooze out of the bearings.

6. Wipe up any excess grease.

Lubricating Tiller Drive Chain

Lubricate tiller drive chain after the initial 5 hours of

operation and every 25 operating hours thereafter.

Lubricant Type: Commercial chain lube.

1. Lower the loader arms and stop the engine. Remove

the key.

2. Remove the chain drive cover (Fig, 2).

3. Apply a commercial chain lube onto the chain spans.

4. Install the chain drive cover.

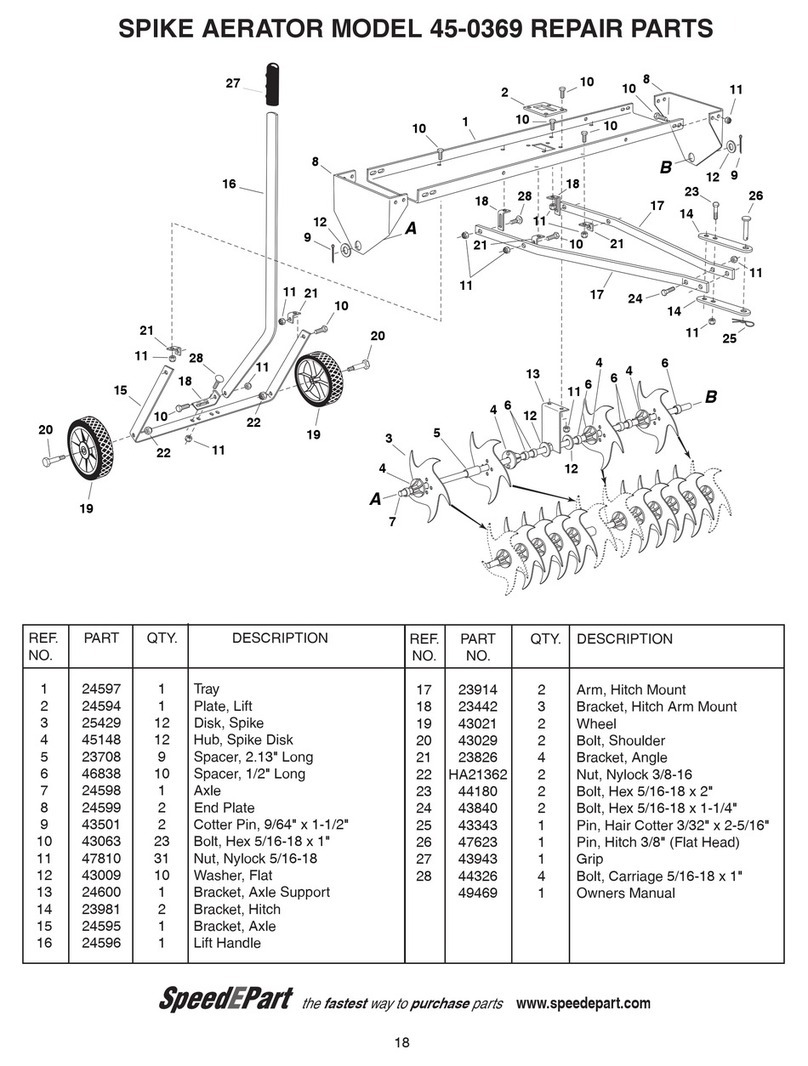

Adjusting Tiller Drive Chain

Tension

Adjust the tiller drive chain after the initial 5 hours of

operation and every 25 operating hours thereafter. There

should be 1/2 to 3/4 in. (1 to 2 cm) slack in the chain,

measured mid-way between the sprockets.

1. Lower the loader arms and stop the engine. Remove

the key.

2. Remove the chain drive cover (Fig, 2).

3. Loosen the 2 hydraulic motor, mount plate bolts

(Fig, 2).

4. Using the adjuster bolt, move the hydraulic motor

upward to tighten the chain (Fig, 2).

6

m–4372

2

1

23

Figure 2

1. Chain drive cover

2. Hydraulic motor, mount

plate bolt

3. Adjuster bolt

5. After proper chain tension is attained, tighten the

adjuster bolt and hydraulic motor mount plate bolts

(Fig, 2).

Note: When proper adjustment can no longer be attained

from the adjuster bolt or repeated chain failures occur,

replace chain.

6. Install the chain drive cover.

Tiller Tine Replacement

Check and replace tines when they become worn or dull.

Worn or dull tines will degrade the performance of the

tiller.

Tines should be installed as illustrated in Figure 3 with 2

left hand tines and 2 right hand tines on each hub.

m–4414

2

1

2

1

Figure 3

1. Left hand tine 2. Right hand tine

The cutting edges of the tines should face toward the rear

of the tiller.

Torque the tine mounting bolts to 63 to 77 ft.-lb. (85 to

104 N⋅m).

Storage

1. Before long term storage wash the tiller with mild

detergent and water to remove dirt and grime.

2. Check the condition of the drive chain. Adjust and

lubricate the chain.

3. Grease all fittings.

4. Check and tighten all bolts, nuts, and screws. Repair or

replace any part or tines that are damaged or worn.

5. Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Service Dealer.

6. Store the tiller in a clean, dry garage or storage area.

Cover the tiller to protect it and keep it clean.

7

Troubleshooting

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Tiller does not operate. 1. Hydraulic coupler not

completely connected 1. Check and tighten all couplers.

2. Defective hydraulic coupler 2. Check couplers and replace

any that are defective.

3. An obstruction in a hydraulic

hose 3. Find and remove the

obstruction.

4. Auxiliary valve on the traction

unit is not opening. 4. Repair the valve.

5. An obstruction in the tiller

(e.g., rock or root) 5. Find and remove the

obstruction.

6. Broken drive chain 6. Repair or replace the chain.

7. Loose drive chain 7. Adjust the chain tension.

8. Defective hydraulic valve 8. Replace or repair the defective

valve.

9. Defective drive motor 9. Replace or repair the drive

motor.

Table of contents

Other Toro Tiller manuals