SENKO SG-60 User manual

Solid fuel

COOKERS

SG-60, SG-75 and SG-90

SN-EN-9/16

SENKO cookers SG –

Instruction manual

1

Dear client, thank you for choosing a SENKO cooker!

This product was designed and manufactured to its minutest

details in order to fulfill your every need for functionality and

safety.

This

Instruction manual

will teach you to operate your cooker

properly, so please read the manual carefully before using the

cooker.

Senko management

Symbols used in this

INSTRUCTION MANUAL:

ATTENTION WARNING

SAFETY ADVICE AND RECOMMENDATIONS

SENKO cookers SG –

Instruction manual

2

CONTENTS

1. GENERAL ……………………………………………………………………..4

1.1. FUEL ……………………………………………………………………….6

1.2. FEEDING …………………………………………………………………...6

1.3. CHIMNEY ………………………………………………………………….7

1.3.1. CHIMNEY CAP ………………………………………………………..7

1.3.2. CHIMNEY FUNCTION ………………………………………………….8

1.4. INSULATION ……………………………………………………………..10

2. WARNINGS AND SAFETY …………………………………………………10

3. TECHNICAL FEATURES ……………………………………………………11

4. INSTALLATION ……………………………………………………………..14

4.1. POSITIONING …………………………………………………………….14

4.2. CHIMNEY PREPARATION AND CONTROL ……………………………….16

4.3. CONNECTING TO CHIMNEY ……………………………………………...16

4.4. FRESH AIR VENTS ………………………………………………………..20

4.5. OVEN THERMOMETER …………………………………………………..22

4.6. INSTALLATION TESTING …………………………………………………22

5. HANDLING THE PRODUCT ……………………………………………….23

5.1. DIRECTING THE FLUE GAS ……………………………………………….23

5.2. AIR ADJUSTMENT AND REGULATION …………………………………...24

5.3. FIREBOX GRATE …………………………………………………………25

5.4. FIRING ……………………………………………………………………26

5.4.1. PROCEDURE ………………………………………………………..26

5.4.2. OPTIMUM USE VALUES ……………………………………………...26

5.4.3. ADDING FUEL ………………………………………………………27

5.4.4. FEEDING IN TRANSITION PERIOD …………………………………….28

5.5. OVEN DOOR ……………………………………………………………..28

5.6. FUEL BOX ………………………………………………………………..29

5.7. HEIGHT ADJUSTMENT …………………………………………………...30

SENKO cookers SG –

Instruction manual

3

6. CLEANING …………………………………………………………………..30

6.1. CLEANING THE FLUE GAS CHANNEL …………………………………….31

6.1.1. COOKERS SG-75 and SG-90 …………………………………………..31

6.1.2. COOKER SG-60 ……………………………………………………..32

7. MAINTENANCE …………………………………………………………….33

7.1. OLD COOKER DISPOSAL ………………………………………………...33

7.2. SPARE PARTS …………………………………………………………….33

8. MALFUNCTIONS / CAUSES / SOLUTIONS ……………………………...34

9. TECHNICAL SUPPORT …………………………………………………….35

10. TECHNICAL DATA …………………………………………………………36

11. TERMS OF WARRANTY …………………………………………………...37

WARRANTY ……………………………………………………………………...38

INSTALLATION REPORT ……………………………………………………….39

CE MARKING …………………………………………………………………….40

SENKO cookers SG –

Instruction manual

4

1. GENERAL

Classical solid fuel cookers

E 2560 SG-60

E 2375 L SG-75

E 2375 D SG-75

E 2390 L SG-90

E 2390 D SG-90

are models from the SENKO cookers palette which can accommodate your

needs in the best possible way. Therefore, we ask you to CAREFULLY READ

THESE INSTRUCTIONS, which will help you to achieve the best possible

results already during the initial use.

The manufacturer is not responsible for any consequences (people or

animal injuries or property damages) resulting from failure to comply with

this

Manual.

The cooker is hot during operation and the use of protective

heat insulated gloves is compulsory during handling. Children and infirm

individuals are not allowed to handle the cooker.

The external appearance of the cooker is shown on the first page of this

Manual. Cooker principal parts are made of stainless steel plates and

castings of quality grey cast. The cookers are produced with flue gas

connection point on the left or the right side. When ordering the cooker

or the spare parts, it is necessary to state its full designation, for

example: cooker E 2375 D SG-75; which means that the flue gas connection

is on the right side, if the cooker is observed frontally.

The cookers are manufactured in accordance with the EN 12815

standard and comply with all the requirements set by this standard.

These SENKO cookers are intended for cooking, baking and space

heating!

SENKO cookers SG –

Instruction manual

5

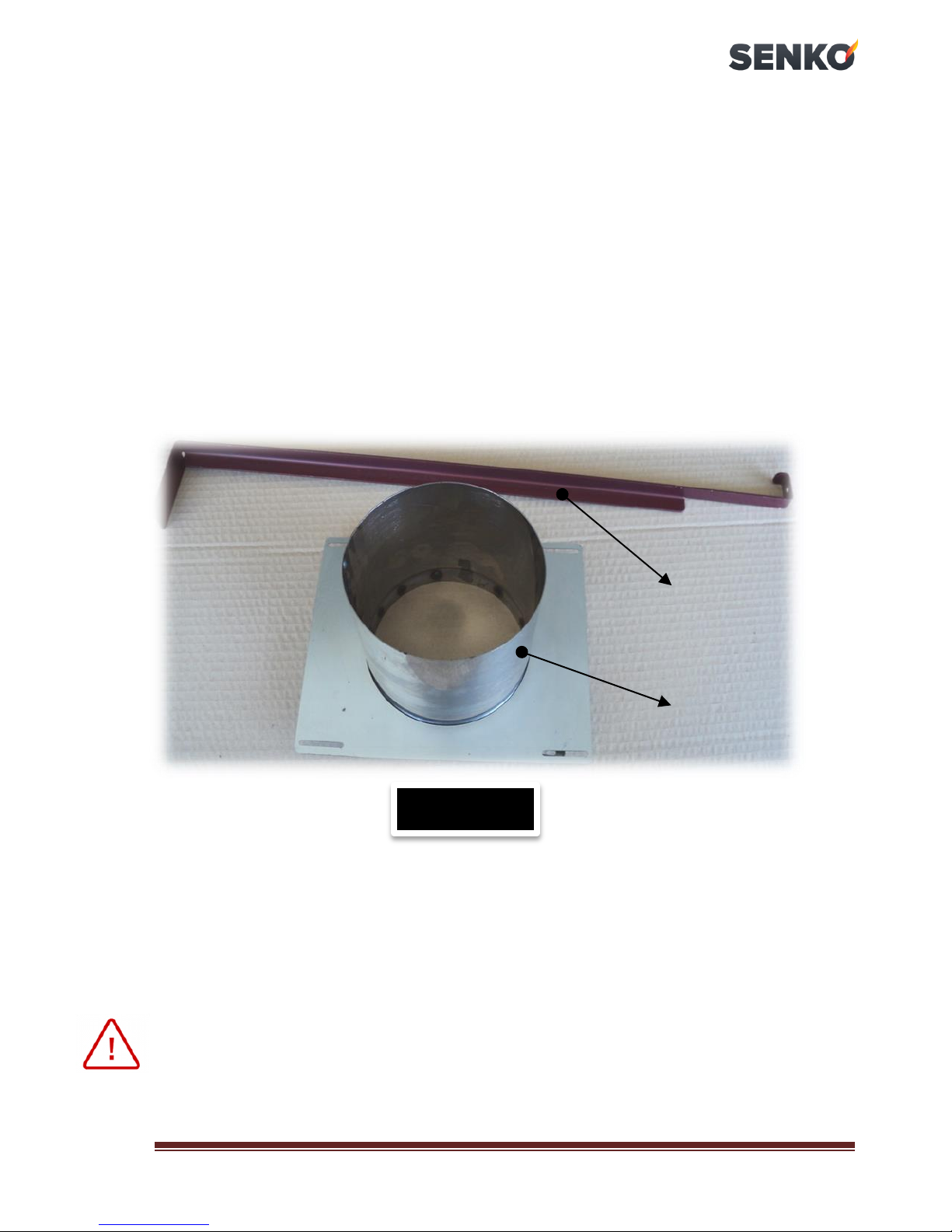

Figure 1

23

22

The cooker is packaged in a EURO pallet. During transport, the cooker

must be properly fastened in order to prevent tumbling or damages. The

standard delivered cooker set consists from:

cooker,

instruction manual,

chimney terminal extension (22),

cooker cleaning tool (23).

CAUTION! The cooker weighs between 130 and 200 kg. Extra caution

is necessary when unloading, transferring, moving and installing the

cooker in order to avoid physical injury.

SENKO cookers SG –

Instruction manual

6

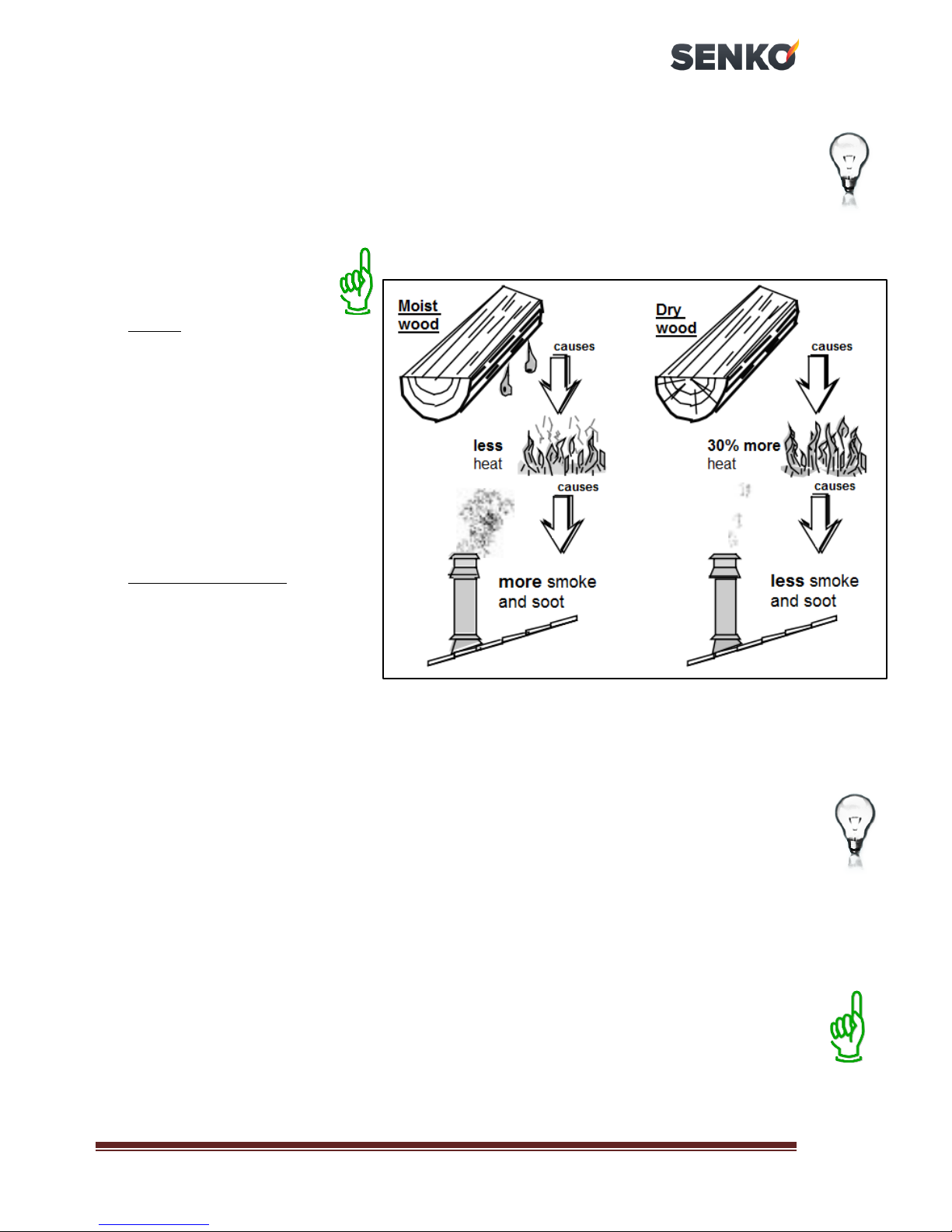

1.1. FUEL

The use of moist and low-calorie wood is not recommended. The wood

moisture must be lesser than 17%. The energy content of moist wood is

low, at approx. 2,3 kWh/kg and it greatly pollutes the door glass, as well as

the chimney and the cooker.

Use only recommended

fuel:

wood: common beech,

common hornbeam, oak,

black locust

air dried for a minimum

of 2 years

relative humidity 15-17%,

energy content at approx.

4,2 kWh/kg

wood briquettes: energy

content at approx. 4,4

kWh/kg

1.2. FEEDING

manually when necessary

we recommend the logs to be of 50 x 50 mm vertical cut, up to 2/3 of

the firebox length

use smaller logs for a more intensive fire, and more massive logs to

maintain fire

the minimum distance between the logs must be 1 cm, the same

distance of 1 cm applies for the briquettes

to maintain constant oven temperature, add smaller quantities of fuel

occasionally approx. 0,5 kg

it is necessary to use protective heat insulated gloves when adding

fuel to the firebox

protective heat insulated gloves must also be used when opening and

closing the oven and firebox door and removing the tray from the oven

and ash box.

SENKO cookers SG –

Instruction manual

7

1.3. CHIMNEY

The cooker is connected to the chimney via 120 mm diameter sliding

rosette. It is necessary to execute the connection of the rosette and the

chimney tightly and impermeably. If the cooker is separated from the

chimney opening (not recommended) the connection is made via standard

120 mm diameter smoke venting pipe –see

chapter 4.3

.

We also advise to equip the chimney with solid material and possible

condensation products collection chamber and to install the chamber in

question beneath the smoke channel inlet, in a manner which allows easy

access and inspection via impermeable door.

IMPORTANT

BEFORE connecting to the chimney it is necessary always to make a

calculation (according to EN 13384 and all other standards for the

chimney dimensioning)!

The chimney has a very important function of the smoke exhaust at

solid fuel heating devices and therefore MUST BE well and properly

dimensioned!

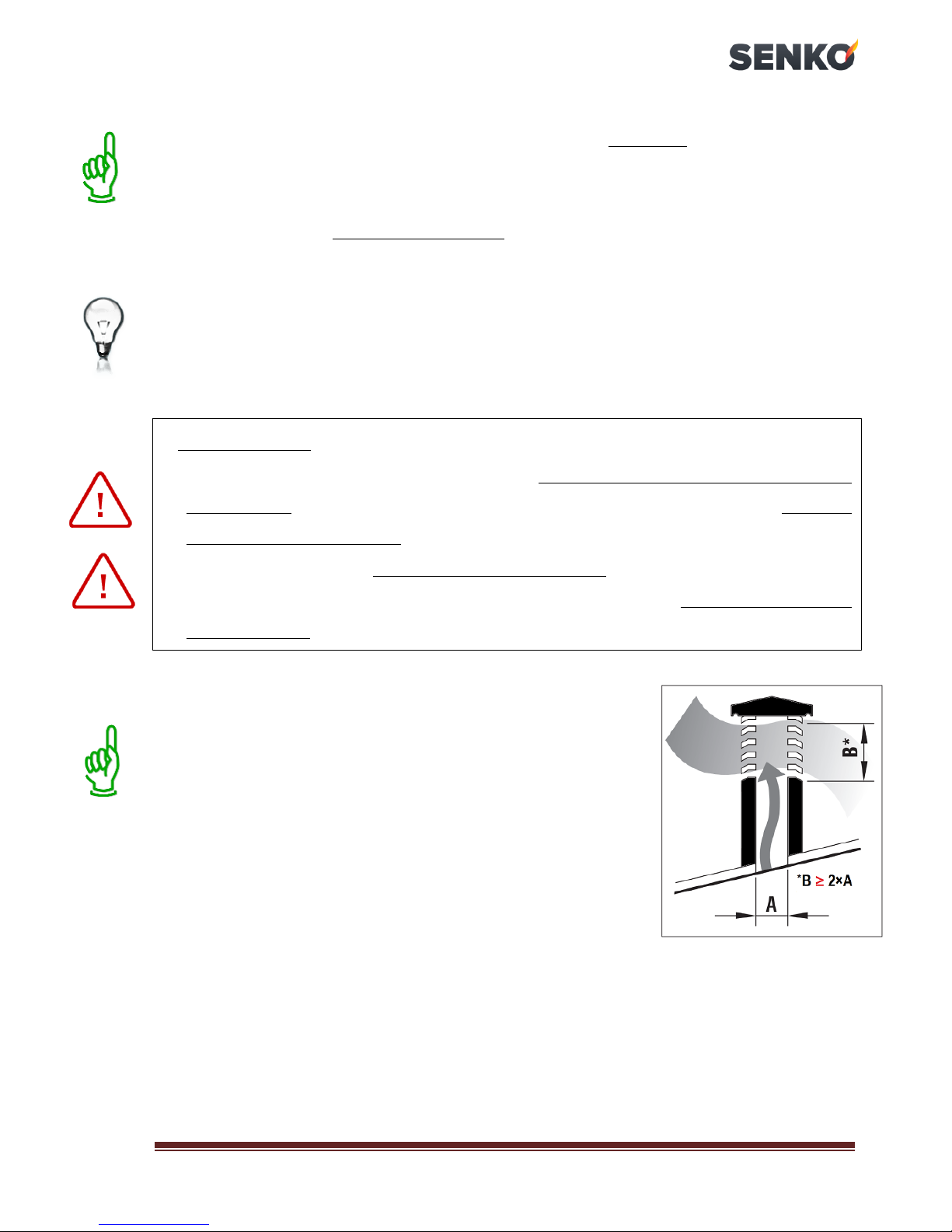

1.3.1. CHIMNEY CAP

Chimney cap must fulfill the following prerequisites:

identical internal diameter to that of the

chimney,

operational exit cross-section no less than the

double inner diameter of the chimney –see B ≥

2×A in the Figure beside,

constructed to prevent rain, snow, leaves and

other foreign bodies from entering the

chimney,

constructed to enable expulsion of combustion products in case of

wind from any direction and incline,

installed to enable proper dispersion and dilution of combustion

products outside the reflux zone (backflow) because the counter

pressure occurs here. Therefore, it is necessary to adhere to limitations

listed in

Figure 2

,

mechanical appliances for flue gases suction are not allowed.

SENKO cookers SG –

Instruction manual

8

1.3.2. CHIMNEY FUNCTION

Among all the meteorological and geographical factors that influence

the chimney function (rain, fog, snow, insolation period, etc.) the wind is

most certainly the crucial one. Apart from the pressure caused by the

temperature difference between the flue gases and the outer chimney air,

there is another type of pressure –wind dynamic pressure.

Roof

slope

Distance between the

roof ridge and the

chimney

Minimum chimney height

(measured from the roof

surface)

A

, m

H

min, m

15°

< 1,85

0,5 m above the roof ridge

> 1,85

1 m from the roof

30°

< 1,5

0,5 m above the roof ridge

> 1,5

1,3 m from the roof

45°

< 1,3

0,5 m above the roof ridge

> 1,3

2 m from the roof

60°

< 1,2

0,5 m above the roof ridge

> 1,2

2,6 m from the roof

Figure 2

FLAT ROOF

PITCHED ROOF

Z=REFLUX ZONE

SENKO cookers SG –

Instruction manual

9

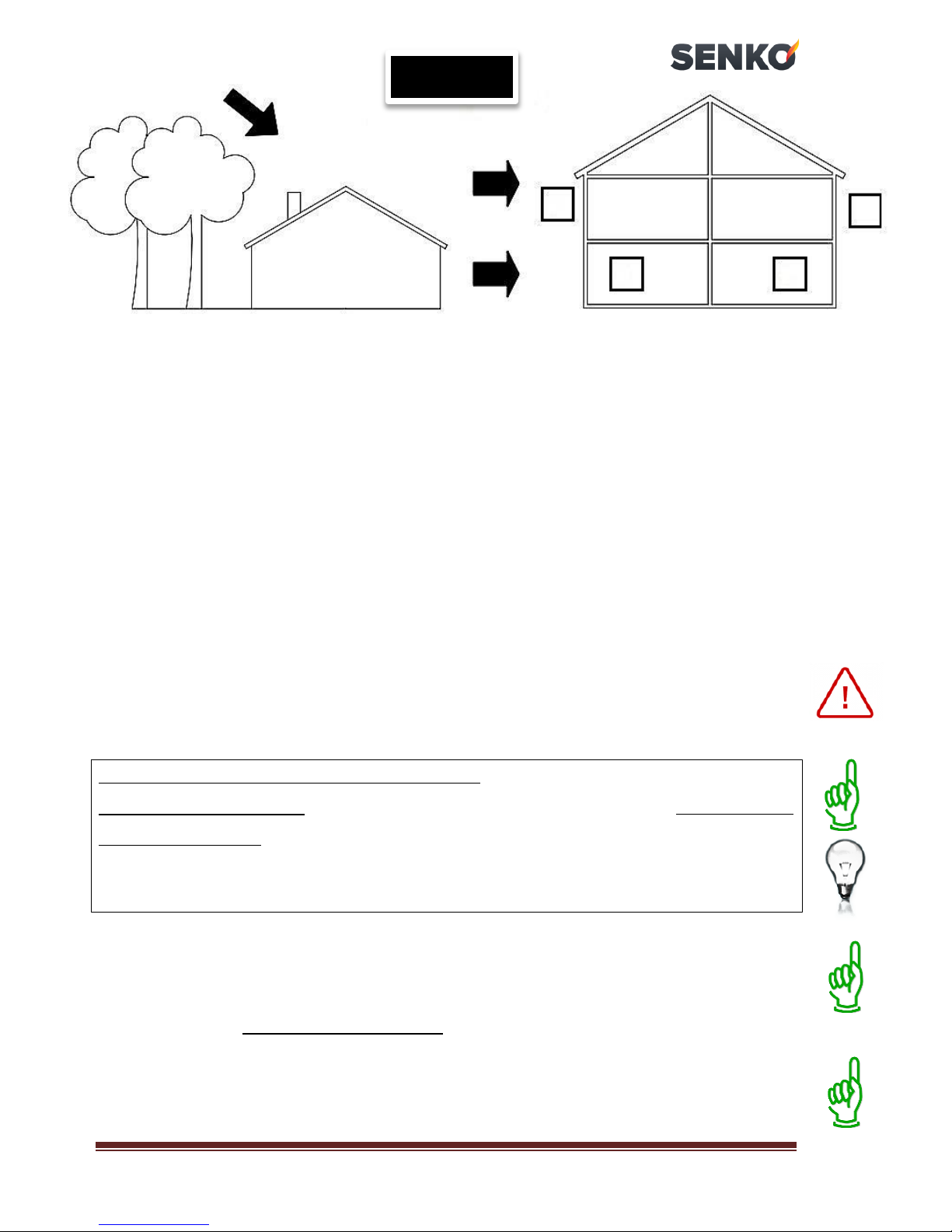

Ascending wind ALWAYS has the effect of increasing the pressure,

i.e., underpressure (flue draught), provided the chimney is properly

installed. Descending wind ALWAYS has the effect of decreasing the

draught overpressure occurs. Apart from wind direction and velocity,

chimney position in relation to the house roof and surrounding area is also

important (

Figure 3

).

The wind also influences the chimney function indirectly by creating

areas of high (overpressure) and low (underpressure) pressure, both inside

and outside the residential area (

Figure 4

).

Pressure that facilitates chimney function can occur in rooms directly

exposed to the wind (B), but it can also adversely affect the chimney

through external pressure if the chimney is situated on the side exposed to

wind (A). Contrary to that, underpressure can occur in lee rooms (C),

adversely affecting functions of the chimney situated on the opposite side

(D) from the wind direction.

Figure 3

wind

Unfavorable

position

Favorable

position

Horizontal wind 8 m/s

underpressure of

30 Pa

Descending wind under

45

angle and 8 m/s

overpressure of 17 Pa

High (positive)

pressure zone

OVERPRESSURE

Low (negative)

pressure zone

UNDERPRESSURE

Flue

gases

from the

cooker

SENKO cookers SG –

Instruction manual

10

1.4. INSULATION

Cooker is to the outer surfaces isolated with chamotte plates 20 mm

thick. The sides are chamber derived and cooled with the natural air

circulation. The depth of the chamber is 25 mm. Other parts of the cooker

interior are lined with chamotte brick, 40 mm thick.

2. WARNINGS AND SAFETY

When connecting the cooker to the chimney, adhere to national and

European norms and local regulations.

PROCEDURE IN CASE OF CHIMNEY FIRE

In case of chimney fire, close the openings for the air inlet and DON’T open

the firebox door. Extinguish the fire using appropriate fire extinguishers.

NEVER EXTINGUISH A FIRE WITH WATER! In case of fire also call the local

fire department. Comply with local regulations for fire protection!

Prior to use, verify with the local authorized chimney-sweeper whether

the cooker is properly connected to the chimney (the chimney-sweeper

must complete the installation report at the end of this

Manual

).

Special attention must be paid that there is enough air for combustion

being supplied to the room cooker is installed in.

Descending

wind

wind

A

B

C

D

Figure 4

A-B zones in overpressure

C-D zones in underpressure

SENKO cookers SG –

Instruction manual

11

3. TECHNICAL FEATURES

SENKO cookers SG are intended for cooking, baking and household

heating. They are equipped with an oven just like the traditional kitchen

cooker. Cookers are suitable for installation between other kitchen

appliances (with ensuring minimum safety distances –see

chapter 4.1.

)

without heating risks.

They are made of stainless steel plates and castings of quality grey

casts. The cooking plate (1) is made of 8 mm thick steel plate. Cooker

interior is lined with chamotte.

The fuel box (12) is on the frontal side, at the bottom, just above the

manual primary air regulator (10) and the ash box (11). Above them is a

firebox (6) with a grate (16) and the oven (7) with door and thermometer

(18).

Also, the cooker is on the front equipped with two handles, one serves

as a flue gas deflector (14) and is located on the side where is the chimney

connection point, while the other (15) serves as a lever for moving the

firebox grate (16) –

only at cookers SG-75 and SG-90

.

The following figure display the schematic of the cookers and their

accompanying parts.

SENKO cookers SG –

Instruction manual

12

9. Cleaning hatch lid

10. Primary air manual regulator

11. Ash box

12. Fuel box

13. Chimney connection point

14. Flue gas deflector

15. Handle for grate moving

16. Movable grate

17. Oven door glass

18. Oven thermometer

SCHEMATIC DISPLAY FOR COOKERS

SG-75

and

90

THE KEY:

1. Cooking plate

2. Frame

3. Cooker base with screws for

height adjustment

4. Cooker housing

5. Lower door

6. Firebox door

7. Oven with door

8. Oven door hinge

19. Door hinge bolt

20. Firebox door glass

21. Primary air inlet hatch

22. Chimney connection point

extension

23. Cooker cleaning tool

Figure 5a

LEFT COOKER

SG

- view from the side

RIGHT COOKER

SG

- view from the side

SENKO cookers SG –

Instruction manual

13

SCHEMATIC DISPLAY FOR COOKER

SG-60

Figure 5b

THE KEY:

1. Cooking plate

2. Frame

3. Cooker base with screws for height adjustment

4. Cooker housing

6. Firebox door

7. Oven with door

8. Oven door hinge

9. Cleaning hatch lid

10. Primary air manual regulator

11. Ash box

12. Fuel box

13. Chimney connection point

14. Flue gas deflector

16. Firebox grate

17. Oven door glass

18. Oven thermometer

19. Door hinge bolt

20. Firebox door glass

21. Primary air inlet hatch

22. Chimney connection point extension

23. Cooker cleaning tool

COOKER

SG-60

- rear end view

COOKER

SG-60

- view from the side

SENKO cookers SG –

Instruction manual

14

4. INSTALLATION

Once you have removed packaging from the cooker, it is necessary to

make a detailed inspection in order to determine any potential damages

that might have occurred during transport. Nay detected damages must

instantly be reported to the manufacturer.

In places of any connection points on the cooker (chimney, air inlet),

inspection hatches must be installed for system maintenance and

servicing purposes.

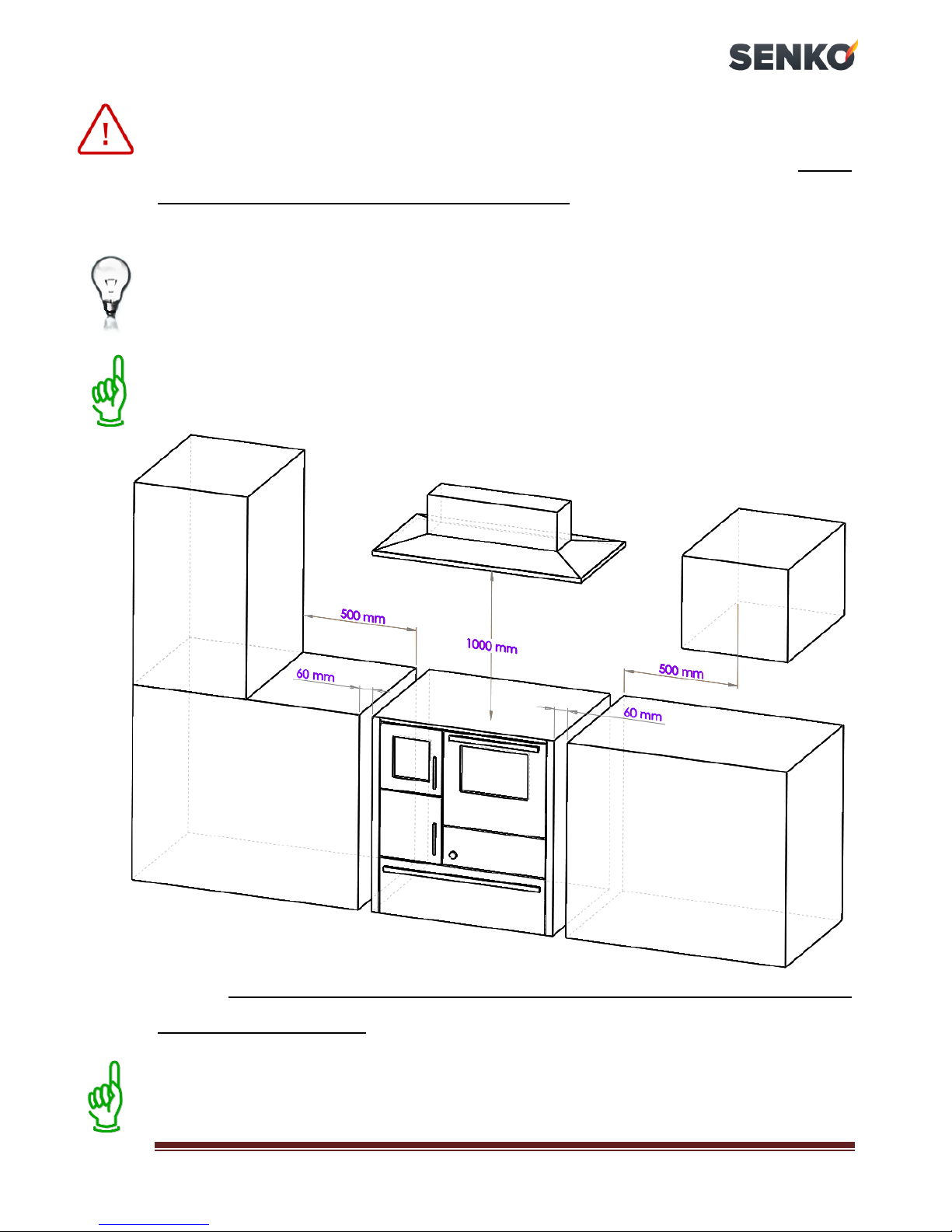

4.1. POSITIONING

A spirit level must be used to place the cooker in a horizontal

position with no incline. It is necessary to ensure the minimum distance of

the cooker from any flammable objects; such as wood, chipboard, cork

and similar. If the materials are easily combustible such as PVC,

polyurethane and similar, the necessary safety distances need to be

doubled.

The minimum distance from any flammable surfaces above is 1000 mm

and in front of the cooker is 800 mm, and 200 mm in all other directions.

When mounting the cooker on the floor made from easily combustible

material (wooden floors), the cooker must be mounted on an insulating

non-combustible surface.

A cooker should not be placed in rooms where there are gas stoves

or cookers, and in the bathroom, in buildings intended as laundries or

A

200 mm from the rear wall

B

200 mm from the side wall

C

800 mm from the front side

D

500 mm floor protection

E

300 mm (measured from the

maximum angle of firebox door

opening)

F

Floor protection

G

Radiation area

SENKO

cooker

SENKO cookers SG –

Instruction manual

15

similar. The same applies for rooms or flats with air circulation or hot air

circulation with ventilation systems (air condition, extractor or kitchen

hoods), EXCEPT if such ventilation systems have safety mechanisms, which

sustain the air pressure above 4 Pa in a room, where the cooker is mounted

or in rooms which are in direct contact with exterior air.

It is recommended to place the cooker as close as possible to the

chimney hole, i.e. next to the chimney hole itself in order to avoid using

an additional smoke uptake pipe (

Figure 6a

)!

If you want to set the cooker between the kitchen units, it is necessary

to ensure the minimum distances shown in the figure below.

The distance between the cooker and kitchen element is intended for

air circulation (cooling) –see the Figure above.

Here also you should take care on how to ensure access to a cooker for

maintenance and servicing.

SENKO cookers SG –

Instruction manual

16

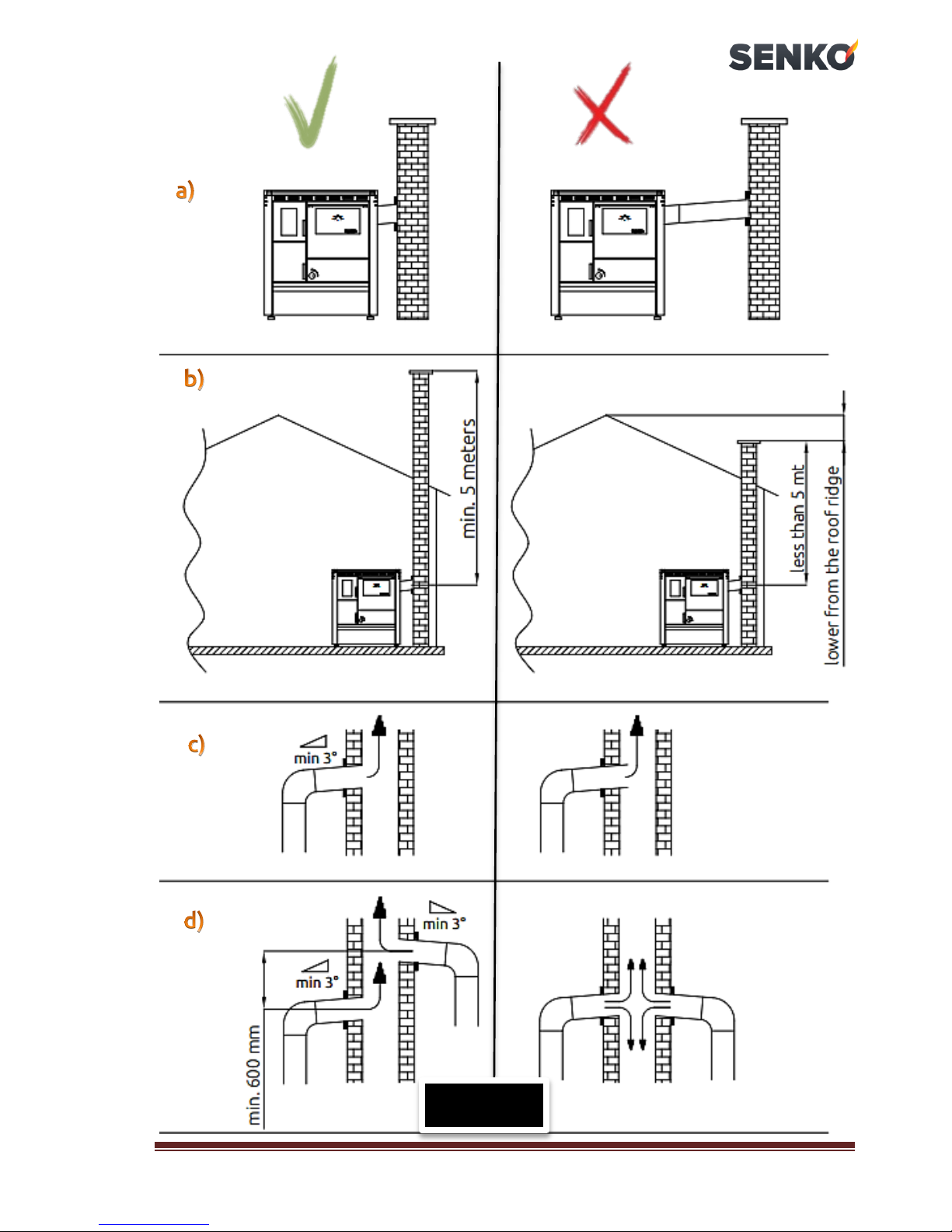

4.2. CHIMNEY PREPARATION AND CONTROL

Prior to cooker mounting, it is necessary to check the chimney –the

diameter, height, possible clogging or damages. The chimney must be

certified by an authorized local chimney-sweeper. The effective chimney

height must be at least 5 meters from the point of flue gases outlet

(

Figure 6b

).

Flue draught must be within parameters 12 ± 2 Pa.

The chimney must be at least 0,5 meters above the roof ridge (see

Figure 2

). The minimum distance between the two connections on the

same chimney must be 60 cm (

Figure 6d

).

Chimney diameter is chosen according to information provided by the

chimney manufacturer –e.g., for flue draught of 12 Pa, the diameter is

usually 130 mm.

The chimney must be smooth on the inside, well insulated and well

fastened. All cleaning hatches must be well fastened. All gaskets must be

regularly inspected and replaced when necessary.

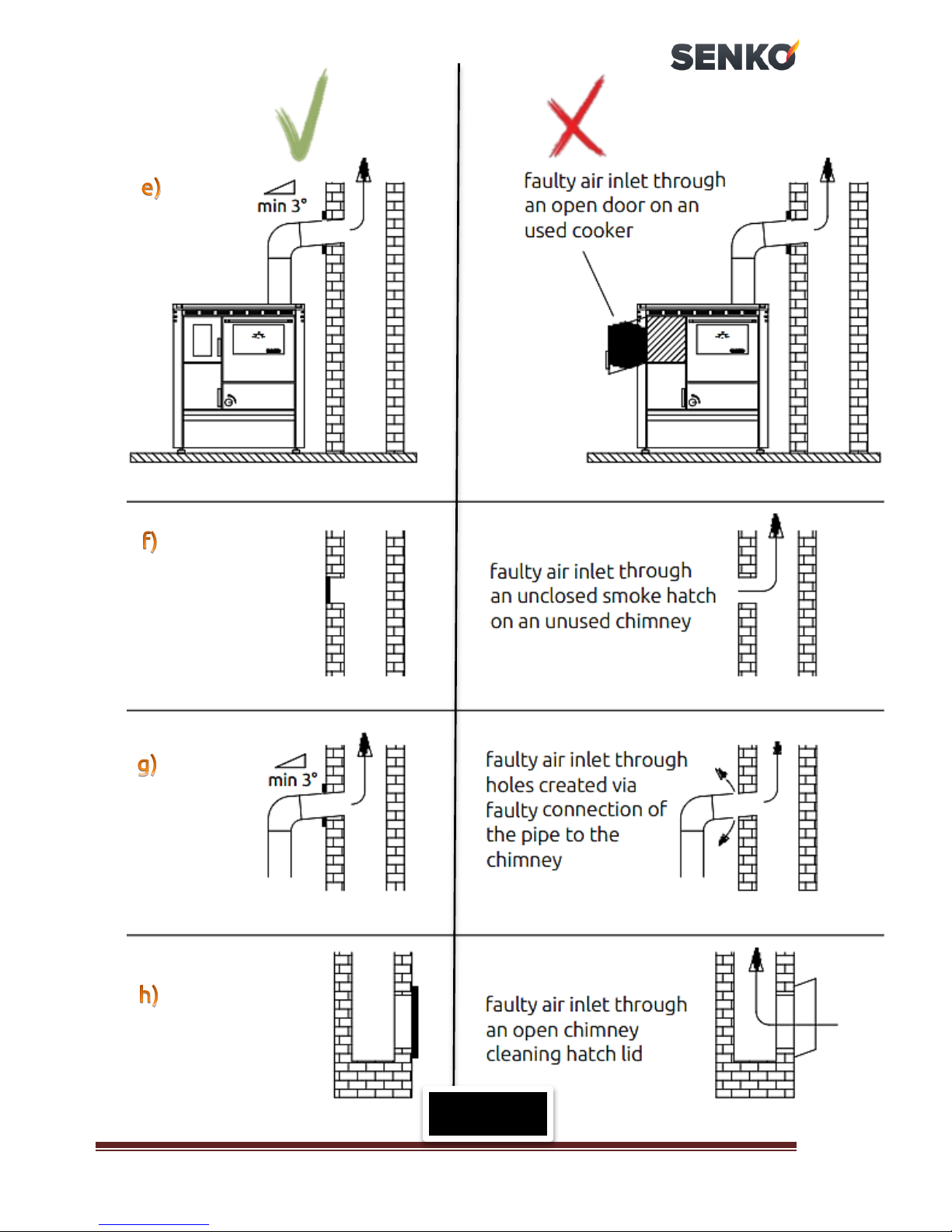

4.3. CONNECTING TO CHIMNEY

When connecting the cooker to the chimney it is necessary to adhere to

local, national and European regulations (norms) –DIN 4705.

It is necessary to ensure that the connection between the cooker and

the chimney is executed tightly and impermeably. Smoke outlet pipe

must have a suitable incline (minimum 3°) in cases where the cooker is

removed from the chimney opening.

Smoke outlet pipe must not penetrate into the chimney clear

opening (

Figure 6c

).

Differences between the proper and improper connection of the cooker

to the chimney are displayed in the following figure.

SENKO cookers SG –

Instruction manual

17

Differences between the proper and improper connection of the cooker to the chimney

Figure 6

SENKO cookers SG –

Instruction manual

18

Differences between the proper and improper connection of the cooker to the chimney

Figure 6

SENKO cookers SG –

Instruction manual

19

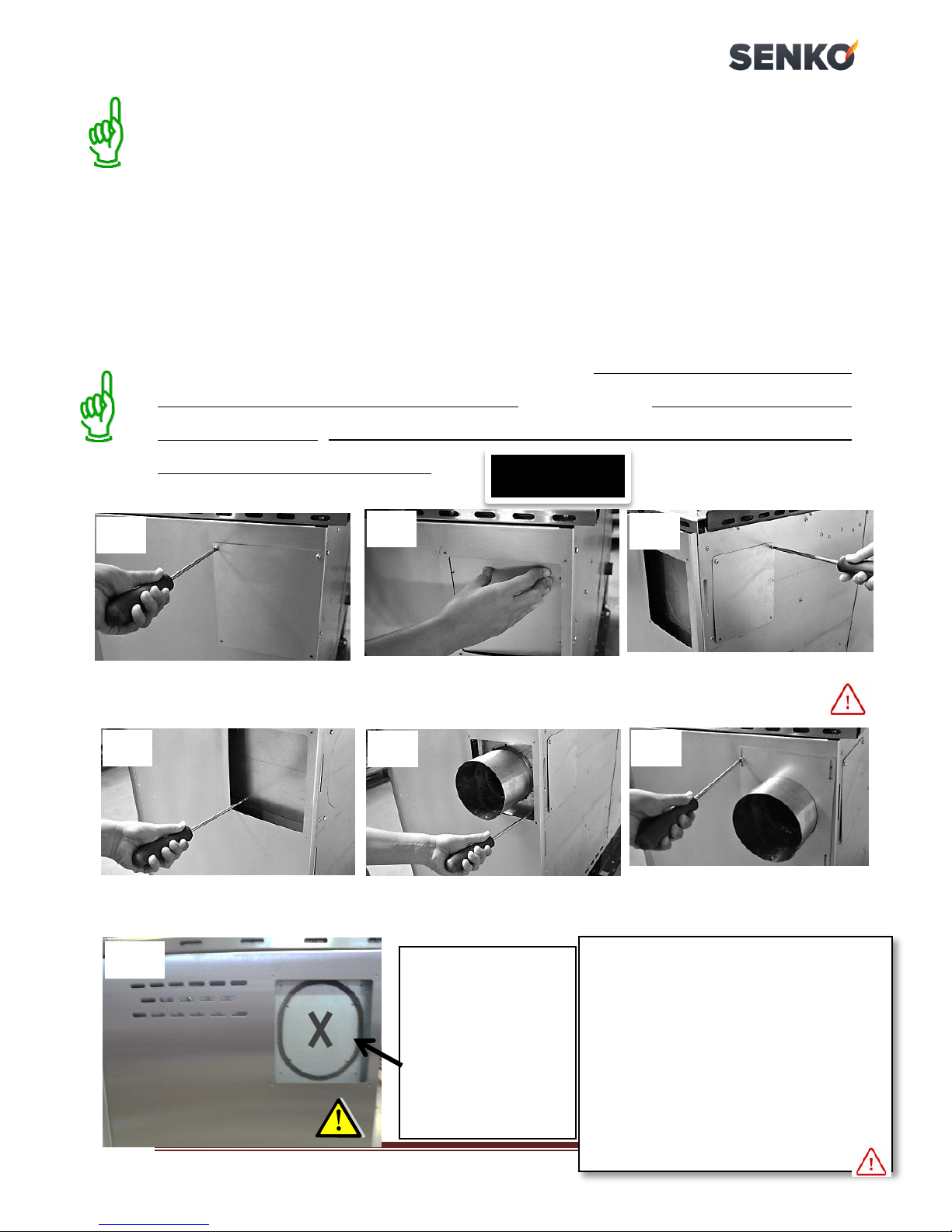

Figure 7

odvijačem skinite

zaštitni poklopac

Remove the external protective

lid with a screwdriver

Remove the sheet beneath the

lid by pressing onto the

weakest juncture

Install the sliding rosette by using

bolts previously used to attach

the inner protective lid

Install the external protective sheet

by using bolts previously used to

attach the external protective lid

Mount the protective lid onto

the remaining chimney

opening!

Remove the internal protective

lid with a screwdriver

When installing the sliding rosette on

the back of the cooker

it is necessary to:

remove the external protective lid with

a screwdriver,

by gently pressing remove the

following lid,

in place of the external lid attach the

sliding rosette with the same screws.

In doing so, you have remain the

external sheet metal of the rosette and

external lid (which are at the beginning

removed from the cooker), as excess.

Connect the cooker to the chimney using a sliding rosette, 120 mm in

diameter. Specially designed sliding rosette enables the adjustment of the

chimney opening in tolerance of 1,5 cm upwards, i.e. downwards.

In case it is necessary to connect the cooker to the chimney with

vertical uninsulated pipe, use the smoke outlet pipe, up to 125 cm

maximum length.

It is not allowed to reduce the prescribed pipe diameters!

If the cooker is further removed from the chimney opening, it is

connected via extension tube and an elbow. The extension smoke inlet

pipe must have an appropriate incline (see

Figure 6

)and must not exceed

100 cm in length. The connection of the chimney and the smoke inlet pipe

must be completely fastened!

1)

2)

3)

4)

5)

6)

Before installing

the sliding rosette,

it is obligatory to

stick the self-

adhesive strip

(provided with your

cooker) on the

inner sheet metal!

5)*

*on some models only

This manual suits for next models

7

Table of contents

Other SENKO Cooker manuals

Popular Cooker manuals by other brands

Falcon

Falcon Toledo TXT110DFSSEU Instructions for use and installation

Tricity Bendix

Tricity Bendix SPLASHBACK SB416 Operating & installation instructions

Commercial CHEF

Commercial CHEF CHC18MB user manual

Smeg

Smeg CX 60 manual

Currys

Currys ESSENTIALS CFTE60W17 instruction manual

Bertazzoni

Bertazzoni AMD6C61BX Installation, maintenance and use instructions