Sensata Nanoprecise 6VW User manual

Copyright © 2022 Sensata Technologies, Inc. Page 1

|MACHINE HEALTH MONITORING (MHM) 6VW SENSOR

OPERATION MANUAL

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 2

Copyright © 2022 by Sensata Technologies

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or

translated into any language in any form by any means without the written permission of Sensata

Technologies.

Disclaimer

This manual is provided for informational purposes. SENSATA TECHNOLOGIES MAKES NO

WARRANTY OF ANY KIND CONCERNING THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Sensata Technologies shall not be liable for errors, omissions, or inconsistencies that may be

contained herein or for incidental or consequential damages in connection with the furnishing,

performance, or use of this material. Information in this document is subject to change and does

not represent a commitment on the part of Sensata Technologies. The information in this

operation manual is not all-inclusive and cannot cover all unique situations.

Where to Get Product Support

Sensata provides several ways to reach your Product Support team to get the answers you need

when you need them:

Americas

1 855 SENSATA (736 7282)

EMEA

Spain: +34 930 016 218

Germany: +49 391 2881460

To search for additional documentation or tools, visit sensata.com/iq

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 3

Contents

1GENERAL INFORMATION 6

1.1 Scope 6

1.2 Safety Messages 6

1.3 Considerations 6

1.3.1 General 6

1.3.2 Configuration 7

1.3.3 Installation 7

1.3.4 Battery 8

1.3.5 Environmental 8

1.4 Return of Materials 8

2INTRODUCTION 10

2.1 Overview of Machine Health Monitoring (MHM) 10

2.2 What is Predictive Maintenance (PdM)? 10

2.3 Predictive Maintenance (PdM) Process 11

3PLANNING 12

3.1 Planning for Installation and Commissioning 12

3.1.1 Understanding Your Environment 12

3.1.2 Site Surveys 12

3.1.3 Assessing the Machine Asset 13

3.1.4 Determining the number of sensors needed 13

3.1.5 Cellular/Wi-Fi connection strength 13

3.1.6 Identifying Plant Hierarchy 15

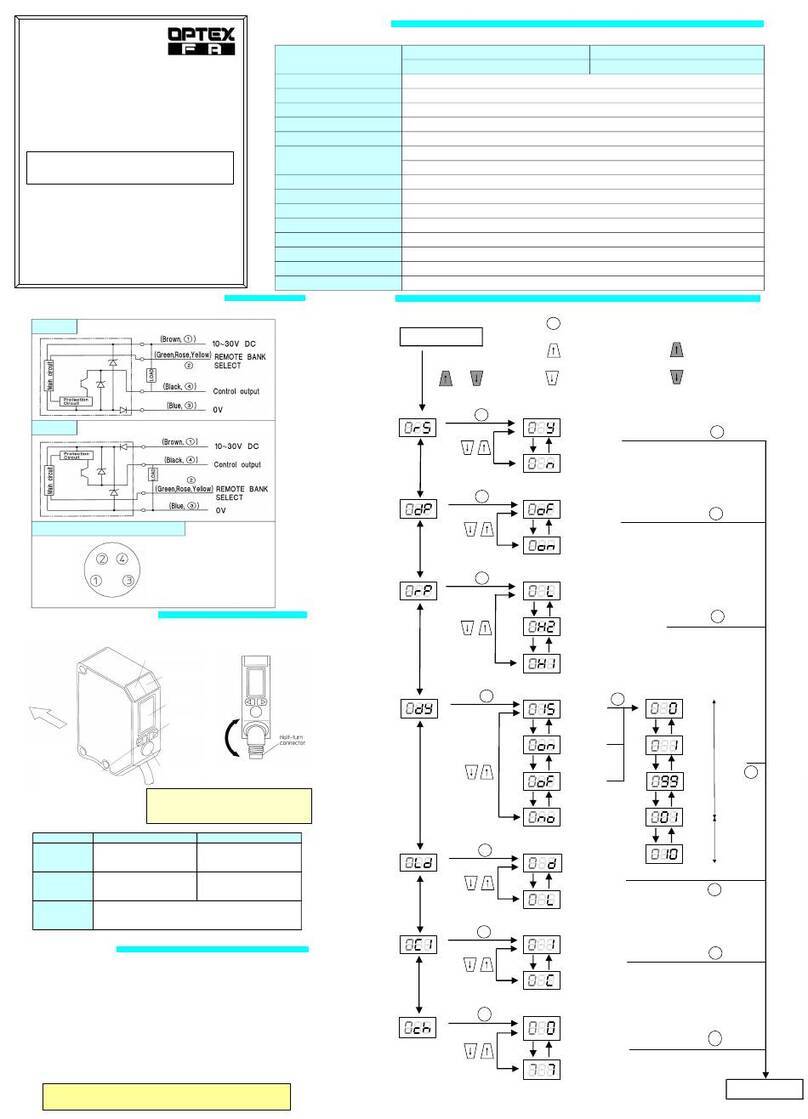

4CONFIGURATION 16

4.1 Sensata DIY App 16

4.1.1 Finding the DIY App and User Credentials 16

4.1.2 Sensata DIY User Tasks and Overview 16

4.1.3 Understanding Asset Layouts 17

5INSTALLATION & COMMISSIONING 18

5.1 Device Handling 18

5.2 Sensor Mounting Types 18

5.2.1 Sensor Stud Mount Installation Method (Permanent Installation) 19

5.2.2 Sensor Magnet + Adhesive Installation Method (Permanent Installation) 20

5.2.3 Sensor Magnet Only Installation Method (Temporary Method) 21

5.2.4 Fin Installation Method 21

5.3 RPM Sensor Installation 22

5.3.1 Needed for Installation 22

5.3.2 Low-Speed RPM Installation Safety Considerations 23

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 4

5.3.3 Choosing the right location to install the sensor and the magnet: 23

5.3.4 Sensor Orientation 24

5.4 Powering the 6VW Sensor 24

5.5 6VW Sensor Connection Status to the Cellular Network 24

6CELLULAR AND Wi-FI CONNECTION 26

6.1 Connecting Sensors via Blinkup 26

6.1.1 Blink Up Using Wi-Fi 26

6.1.2 SIM Card Instructions for Cellular Operation 27

7SENSOR BATTERY REPLACEMENT 29

8OPERATION 30

8.1 Sensata IQ Overview 30

8.1.1 Main Page 33

8.1.2 Equipment Main Page 34

8.2 Vibration 34

8.2.1 Vibration RMS 34

8.2.2 Vibration Overall RMS 34

8.2.3 Vibration Peak 35

8.2.4 Vibration Kurtosis 35

8.2.5 Vibration Amplitude (Fault Characterization) 35

8.2.6 Vibration Spectrum 36

8.2.7 Vibration Waveform 36

8.2.8 Vibration Frequency Spectrum Waterfall 37

8.3 Acoustic Emission (Sound) 37

8.3.1 AE RMS 37

8.3.2 AE Frequency Spectrum 37

8.3.3 AE Frequency Spectrum Waterfall 37

8.3.4 AE Time Waveform 38

8.4 Magnetic Flux 38

8.4.1 Flux RMS 38

8.4.2 Flux Frequency Spectrum 38

8.4.3 Flux Time Waveform 38

8.5 Temperature 38

8.6 Humidity 38

8.7 Speed 38

8.8 Upload Speed 39

8.9 Battery 39

8.10 NanoAI Alarm & Adaptive Fault Amplitude Threshold 39

8.11 Sensata IQ Dashboard Terminologies 39

8.12 Health Score & RUL Calculation 42

Notification on Health Status Summary & RUL 43

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 5

8.12.1 Algorithm for Self-Adaptive Fault Stage 4 Threshold 44

8.12.2 Notification Details with Different Health Status 44

8.12.3 RUL presentation 45

8.12.4 Notification by NanoAI Alarm 45

8.12.5 Notification by Email Alarm 46

8.13 Sensor Operational Status Notification 47

8.14 Notification on Real-Time Anomaly Detection by Edge Computing 48

8.14.1 Anomaly Detection by Temperature on Edge 50

9TROUBLESHOOTING 51

9.1 Hardware Overview 51

9.1.1 Hardware Troubleshooting 51

9.1.2 Check the Battery 52

9.1.3 Check for damage 53

9.1.4 Verify IR sensor position 53

9.1.5 Ensure eSIM switch 53

9.2 Cellular Connectivity 54

9.2.1 A Board LED Blink Pattern 54

9.2.2 Waiting for Modem 54

9.2.3 Waiting for the SIM 54

9.2.4 Registering with a cell 54

9.2.5 Cell Registration is Denied 54

9.2.6 Connecting via PPP (Point to Point Protocol). 54

9.2.7 Checking PPP connection. 55

9.2.8 B-Board LED Blinking pattern 55

10 SPECIFICATIONS AND REFERENCE DATA 56

10.1 Functional Specifications 56

10.2 Physical Specifications 57

10.3 Performance Specifications 59

11 PRODUCT CERTIFICATIONS 60

11.1 Wireless Certifications 60

11.2 Certifications 61

12 PRODUCT DECLARATIONS 63

12.1 UKCA Mark 63

12.2 CE Mark 63

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 6

1 GENERAL INFORMATION

1.1 Scope

This document provides support information for the proper installation, commissioning, and

operation of the Sensata Machine Health Monitoring sensors and the use of the corresponding

Sensata IQ software and applications. It also includes the usage and installation of accessories

provided along with the sensors, which may include SIM (Subscriber Identity Module) cards,

mechanical mounting options, and other useful tools.

1.2 Safety Messages

Instructions in this operation manual may require review and special precautions to ensure the

safety of the personnel performing the operations.

The Sensata 6VW sensor complies with Part 15 of the FCC (Federal Communications Commission)

Rules. Operation is subject to the following conditions:

•This device may not cause harmful interference, this device must accept any interference

received, including interference that may cause undesired operation.

•This device must be installed to ensure a minimum separation of 20 cm (about 7.87 in)

from all persons.

Review the following safety messages before performing an operation preceded by the warning

symbol:

WARNING

Possible danger!

Non-compliance may result in death or serious injury.

Possibilité de danger!

Le non-respect peut entraîner la mort ou des blessures graves.

Explosions could result in death or serious injury:

•Before connecting the sensor in an explosive environment, make sure the instruments

are installed in accordance with applicable field wiring practices.

•Verify that the operating environment of the Sensata 6VW sensor is consistent with the

appropriate hazardous locations' certifications.

1.3 Considerations

1.3.1 General

The Sensata 6VW sensor has different sensing capabilities in the same device. These include

triaxial vibration, acoustic emission, temperature, magnetic flux, and speed detection. The

sensors gather data by converting the physical world into data that is transmitted through Wi-Fi

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 7

or cellular networks to the cloud where it is processed, and machine learning algorithms are used

to calculate actionable insights. The display of raw data and insights are sent to a unique URL

known as Sensata IQ. See the following figure to understand the high-level architecture.

1.3.2 Configuration

The sensor can be configured before or after installation, but it is highly recommended that you

configure the sensor before installation using supporting Sensata tools. By fully configuring

before installation, you can save time at the destination and simplify the entire installation and

commissioning process.

Ensure the sensors are installed per applicable field installation practices. Please see the

following sections on installing the sensors for more information.

The 6VW sensors are powered whenever the battery is installed, the isolating paper tab removed,

and the slide switch is in the on position.

1.3.3 Installation

When choosing an installation location and position, provide ample access to the sensor.

The sensor has multiple mounting locations possible. The normal mounting position for a

horizontal asset is in a vertical orientation, perpendicular to the shaft and on the bearing case.

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 8

Horizontal mounting is also an option. For more information, see section 5 Installation&

Commissioning.

1.3.4 Battery

The Sensata 6VW sensor uses a battery assembly that includes a Lithium Thionyl Chloride D sizes

battery with a supercapacitor. Off-the-shelf Lithium Thionyl Chloride D batteries are not

recommended. The supercapacitor is an important part of the system and ensures additional

storage capacity when an inrush of current is required to support the modem.

The battery comes with the device, but it is not electrically connected when the device is shipped.

You need to connect the battery by grasping the paper by gently pulling the isolating paper tab

out. You may then turn the device on by using the slide switch.

1.3.5 Environmental

The monitor operates within specifications for ambient temperatures between

–10°C and +85°C (14°F and 185°F).

Please verify that the operating environment of the sensor is consistent with the appropriate

hazardous location certifications.

1.4 Return of Materials

You may need to ship the device to Sensata Technologies for return or replacement in case of

warranty issues. Before shipping, contact Sensata Product Support to obtain a Return Materials

Authorization (RMA) number and receive additional instructions.

Sensata Product Support contact information:

Americas

1 855 SENSATA (736 7282)

EMEA

Spain: +34 930 016 218

Germany: +49 391 2881460

Web: https://www.sensata.com/contact-us

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 9

______________________________________________________________________________

Note

If the 6VW sensor has been exposed to hazardous substances, a Material Safety Data Sheet

(MSDS) must be included with the returned materials. An MSDS is required to be available to

people exposed to specific hazardous substances.

Shipping considerations for wireless products (Lithium Batteries)

•The 6VW sensor was shipped to you with the battery inside but with an isolated paper

tab. Remove the tab to connect the battery for proper operation.

•Primary lithium batteries are regulated in transportation by the U.S. Department of

Transportation and are also covered by IATA (International Air Transport Association),

ICAO (International Civil Aviation Organization), and ADR (European Ground

Transportation of Dangerous Goods).

•It is the responsibility of the shipper to ensure compliance with these or any other local

requirements. Please consult current regulations and requirements before shipping.

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 10

2 INTRODUCTION

2.1 Overview of Machine Health Monitoring (MHM)

Organizations around the world are seeking ways to maximize the performance of their machine

assets. These organizations are negatively impacted by machine asset downtime, which on

average occurs hundreds of times per year and can cost millions in lost production.

A machine health monitoring solution enables a connection to your current rotational equipment

and provides critical insights that allow you to reduce unplanned downtime, optimize

maintenance strategies and reduce labor expense.

The first step is to use machine health monitoring to address unplanned downtime in machine

assets. This happens at the ground level: on the factory floor where various machine

configurations make up production lines.

Until recently, the most advanced way to prevent unplanned downtime in manufacturing was to

create and use predictive models that track machine data —such as vibration, oil analysis, and

thermography —to predict when machine malfunctions would occur. However, most facilities

do not monitor these machines continuously and in other senses only sporadically. In many

plants, companies assign people resources and create route-based repair initiatives to maintain

machines. Or perhaps they utilize outside contractors to regularly conduct preventive

maintenance readings and assessments. Both approaches incur costs that increase maintenance

budgets. So, to lessen the impact on both the people resources and budget impact, leading

organizations are turning to Predictive Maintenance (PdM) strategies.

2.2 What is Predictive Maintenance (PdM)?

Predictive maintenance (PdM) techniques are designed to help users determine the condition of

machine assets and to provide insights into when maintenance should be performed. The

predictive approach promises significant cost savings over route-based maintenance because

tasks are performed only when needed. It can be regarded as condition-based maintenance

carried out as suggested by insights into the machine asset.

The value of predictive maintenance (PdM) is to allow convenient scheduling of maintenance and

to prevent unplanned downtime. Companies that implement such strategies typically see a fast

return on investment and significant maintenance expenses.

Predictive maintenance differs from preventive maintenance because it relies on the actual

condition of machine assets, rather than average or expected life statistics, to predict when

maintenance will be required. Machine Learning approaches are implemented for the definition

of the actual condition of the machine asset and for forecasting its longevity.

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 11

2.3 Predictive Maintenance (PdM) Process

It is Sensata’s primary goal to help your company facilitate a successful Predictive Maintenance

(PdM) implementation. As such, Sensata has identified the critical path shown in the graphic

below. The Sensata PdM solution incorporates leading-edge sensing technology (the 6VW

sensors) and software (Sensata IQ). The buildout of your PdM project will utilize both and you

will engage with each. In the following manual sections, each section header will contain the

highlighted topic in which you will be working. This will be noted by a change in the font color.

Plan

Project Configure

Sensors Install

Sensors Connect

Sensors Operation

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 12

3PLANNING

3.1 Planning for Installation and Commissioning

The most important function ensuring the success of your application is planning. Planning helps

us decide how best to use our resources (people, time, money, information, equipment).

3.1.1 Understanding Your Environment

When considering the installation of sensors at your sites or plants, there are several inputs

required that make sensor installation and commissioning easier. For instance, understanding

the safety conditions, operational environments, asset information, network strength at the

potential application point are critical to obtaining the best result. As such it is important to

gather and document for later use, what may be input to the Sensata commissioning tools.

3.1.2 Site Surveys

Site surveys are an important part of a proper application. In specific, the review of the cellular

or Wi-Fi network can speed your results to data and insights from the Sensata solution (6VW and

Sensata IQ software). The site cellular or Wi-Fi networks available may be either strong or weak.

Knowing the strength of your networks will aid in the sensor’s ability to transmit data to the

cloud. Weak networks can cause the sensor to operate sporadically or not at all and thereby limit

the machine asset insights. So, to ensure the performance of the solution, Sensata utilizes some

tactics to support a successful installation. Your assigned Field Application Engineer (FAE) can

provide the details. As a reference point, the following flow chart describes the high-level

process.

By sending a sensor to your site and by directing the sensors to the specific application points,

Sensata personnel can identify the sensor’s ability to send data to the cloud for processing.

Therefore, it is highly recommended that a site survey be conducted before the installation of

OTA Firmware

update to a

sensor

Delivery of asset

to site

Sensor moved to

application point

and powered on

Site Lead and

FAE

collaboration -

data gathered

Repeat as many

times as

necessary

Make

recommendatio

ns and conduct

next steps.

Plan Configure Install Connect Operation

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 13

the 6VW sensors. If Sensata FAEs (Field Application Engineer) identify weak Wi-Fi or cellular

networks for the sensor, additional recommendations will be provided that if implemented will

ensure strong connectivity between the 6VW sensor and the cloud.

3.1.3 Assessing the Machine Asset

One of the most important steps in planning for the commissioning of the machine asset is to

ensure that the proper data is gathered. Examples of essential information would be such things

as (but not limited to):

•Variable or constant speed

•RPM

•Bearing type and bearing number

•Electrical line frequency

•Running time

•Asset temperature

Each asset type is unique and therefore may require you to gather specific types of information

as inputs to the Sensata tools (namely the Sensata DIY App). The results and insights

communicated by Sensata IQ are related to the type and quality of machine asset inputs

information entered. If any information is unavailable, it is recommended that you contact the

equipment manufacturer or system integrator.

3.1.4 Determining the number of sensors needed

Frequently asked of Sensata from prospective users is, “How do I know how many sensors I need

to monitor my machine asset?” The general rule is that each rotating machine asset has 2 or

more bearings. Ideally, it is best to have one sensor used with each bearing. However, there are

machine assets where there may be some near each other. In these situations, we recommend

that you work closely with your Sensata FAE to determine the number of sensors required.

3.1.5 Cellular/Wi-Fi connection strength

The 6VW can connect to either LTE-M or Wi-Fi networks. As a default the sensors will be

configured at the time of production for LTE-M connectivity. If you require a Wi-Fi connection,

please review the balance of this section, and then proceed to section 6.2 Connecting Sensors via

Blinkup.

To ensure the sensor will connect version sensor should have following minimum connectivity to

assure proper data upload. Your Sensata FAE (See Product Support contact information on page

2) can assist with the determination of the network strength for each sensing location.

•LTE-M

RSRP: > -110 dBm

RSRQ: > -12 dBm

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 14

Below an RSRP of -110 dBm (-111, -112, -113 dBm…) and -12dBm (-13, -14, -15 dBm…), a cellular

signal booster that boosts the LTE-M network will be required for the 6VW sensor to operate

properly.

•GSM/2G

RSSI: > -105 dBm

If the RSSI (Received Signal Strength Indicator) of the 2G signal is below -105dBm (-106, -107, -

108 dBm…), a cellular signal booster that boosts the 2G network will be required for the 6VW

sensor to operate properly.

•Wi-Fi

RSSI: > -75 dBm

Upload speed: > 300 kbps

The 6VW sensor should have following minimum connectivity to assure proper data upload. If

the RSSI of the Wi-Fi signal is below -75 dBm (-78, -79, -80 dBm…), additional steps will need to

be taken to ensure connectivity.

______________________________________________________________________________

Note

Sensors support only 2.4GHz Wi-Fi network bandwidth. The 6VW sensor can determine what

type of security is required, be it WEP, WPA, or WPA2. It supports all these security mechanisms.

The 6VW IS NOT compatible with enterprise-level Wi-Fi authentication, 802.1x, which requires

logging in with a username and password.

The 6VW sensor uses the following ports which should be open for outgoing connection.

______________________________________________________________________________

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 15

3.1.6 Identifying Plant Hierarchy

An important part of planning is to consider the needs of the

organization as you create and implement the machine asset

structure. By utilizing the machine asset organizational structure

and/or implementing the structures proposed by Sensata, you can

ensure that all users will follow and understand the format. There

are two structures represented in the Sensata DIY app: Classic Layout

and Machine Layout. The Classic Layout structure has been most

requested of Sensata and therefore is the default, but the Machine

Layout adds a layer of information, which some companies find

helpful. Your decision on this topic is important as the choice of

Classic or Machine Layout only occurs in the Sensata DIY app with the

first sensor deployment. After that, the choice will be fixed in the

layout that you first chose.

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 16

4 CONFIGURATION

4.1 Sensata DIY App

The Sensata DIY app is a tool that is used to support sensor configuration to the machine asset.

The DIY app guides the user through the asset management and sensor management

assignments and readies the sensor for installation on the machine asset.

4.1.1 Finding the DIY App and User Credentials

You can find the Sensata IQ DIY app on the Apple App Store for iOS devices or Google Play for

Android devices. Search for “Sensata IQ DIY” with the platform search tools. Install and open the

app. Or you can scan the following QR codes to the respective locations.

iOS App Store

Google Play Store

After Sensata IQ DIY installation, you will need user credentials (username and password) to

continue. There are two ways to get these credentials if you have not already received them, 1)

through your Sensata FAE (See Product Support contact information on page 2) by providing your

full name and email address, or 2) by scanning the QR code on the label on the inside of the box

and by clicking on “Get Credentials”. The adjacent figure provides an overview of the sensor

configuration process.

4.1.2 Sensata IQ DIY User Tasks and Overview

The Sensata IQ DIY App is a powerful, yet simple tool to support remote configuration of the 6VW

sensors. With the information gathered about your machine assets, you can quickly navigate

through the DIY app and prepare yourself for the physical installation of the devices. Below is an

overview of some of the steps required to conduct configuration.

Plan Configure Install Connect Operation

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 17

______________________________________________________________________________

Note: If this is your first time through the DIY App, at the home screen please activate the guide

to better understand the functions available to you.

4.1.3 Understanding Asset Layouts

In the Sensata DIY App, there are 2 layouts available –classic or machine layout. On your first

engagement with the DIY App, you will be allowed to select your preferred method for defining

the hierarchy. Many companies choose the classic layout and therefore this is the default, but

you may elect to use the machine layout to provide another layer of information. Either will work

well, but please note that your first selection will lock the layout for all future entries.

1) Use credentials to

log in

2) Use Asset

Management to

create Plant,

Equipment, and

Components

3) Configure the

sensor by answering

questions about the

asset.

4) Scan sensor QR

code and assign

sensors to

components

5) Repeat as many

times as necessary

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 18

5 INSTALLATION &

COMMISSIONING

WARNING

Possible danger!

Non-compliance may result in death or serious injury.

Possibilité de danger!

Le non-respect peut entraîner la mort ou des blessures graves.

Sensata recommends that the person(s) installing the Machine Health Monitoring solution be

someone who has a recognized degree, certificate, or professional standing, or demonstration of

related abilities by extensive knowledge, training, and experience.

5.1 Device Handling

Before beginning the installation process:

Verify the connectivity and strength of the cellular or Wi-Fi network to ensure that the

sensor will operate at the machine asset location before turning on the device. For

support with connectivity, please contact your local FAE (See Product Support contact

information on page 2).

CAUTION

Do not drop, hammer, or impact the device housing before, during, or after

installation.

Ne laissez pas tomber, ne martelez pas et ne heurtez pas le boîtier de

l'appareil avant, pendant ou après l'installation.

CAUTION

When installing the device in hazardous locations, ensure that the device is

grounded to the machine case.

Lors de l'installation de l'appareil dans des zones dangereuses, assurez-vous

que l'appareil est mis à la terre sur le boîtier de la machine.

CAUTION

If the equipment is used in a manner not specified by the manufacturer or

contrary to the instructions in this operation manual, the protection

provided by the equipment may be impaired.

Si l'équipement est utilisé d'une manière non spécifiée par le fabricant ou

contraire aux instructions de ce manuel, la protection fournie par

l'équipement peut être altérée.

5.2 Sensor Mounting Types

Different machine asset types require different mounting locations. For any asset type not shown

here, please contact Sensata to recommend mounting locations. In the adjacent image, the most

common mounting locations for this type of device are identified.

______________________________________________________________________________

Plan Configure Install Connect Operation

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 19

Note: It is advisable to place a sensor at every location there is a bearing to adequately cover the

assets' potential failure points. Example: On an electric motor, there is a drive end (DE) bearing

and a Non-Drive End (NDE) bearing.

______________________________________________________________________________

There are several possible mounting methods for the device including stud mount, magnet

mounting, or magnet and adhesive mount. The preferred method is to stud mount the device to

the machine asset as it provides the best mechanical coupling approach, which subsequently

improves the frequency response characteristic of the 6VW sensor. A second approach is to

utilize the magnet and adhesive mount which allows for device mounting in just minutes.

WARNING

Possible product damage!

Do not exceed the specified torque when tightening a stud-mounted

device. Overtightening the device will damage the sensing element and

void the manufacturer’s warranty.

Détérioration possible du produit!

Ne pas dépasser le couple spécifié lors du serrage d'un dispositif monté sur

goujon. Un serrage excessif de l'appareil endommagera l'élément de

détection et annulera la garantie du fabricant.

5.2.1 Sensor Stud Mount Installation Method (Permanent Installation)

1. Thoroughly clean the mounting surface. It should be clean and free of any residue, paint,

or other objects.

2. Prepare the flat surface using a spot face tool and drill pilot hole for tapping

______________________________________________________________________________

Note: The spot face tool attaches to a standard electric drill and provides a machined surface

that is at least 1.1 times greater than the diameter of the sensor. The spot face tool also drills a

pilot hole that can then be tapped for a stud-mounted sensor. (“Sensor mounting/attachment

tools and supplies”)

3. Tap for desired threading (1/4'' –28 UNF or M8)

4. Install sensor using the stud or adapter stud (Sensata part #6VW3-01 or 6VW3-09). Both

are available in the sensor packaging.

|6VW SENSOR

OPERATION MANUAL

Copyright © 2022 Sensata Technologies, Inc. Page 20

______________________________________________________________________________

Note: The use of Thread locker Red is recommended to secure the sensor to the stud or

adapter stud.

WARNING

-Possible danger!

Non-compliance may result in death or serious injury. The recommended

magnets have a pull force of 45 lb. and are extraordinarily strong. Handle

with care when working with multiple units or near metal structures.

Possibilité de danger!

Le non-respect peut entraîner la mort ou des blessures graves. Les aimants

recommandés ont une force de traction de 45 lb et sont très puissants.

Manipulez avec précaution lorsque vous travaillez avec plusieurs unités ou

à proximité de structures métalliques.

5.2.2 Sensor Magnet + Adhesive Installation Method (Permanent Installation)

1. Ensure the mounting surface is clean and free from any residue or paint to ensure the

bonding of the adhesive.

2. A smooth, flat mounting surface is desirable and can be achieved by milling or grinding at

the mounting point.

3. Place a small portion of epoxy on the underside of the mounting base (magnet)

4. Firmly press down the housing and magnet to the mounting area to force the adhesive

out from under the mounting base (magnet).

5. Hold the sensor housing onto the surface for at least 60 seconds until the adhesive can

support the weight of the sensor, ensuring the housing does not move or slide on the

adhesive.

6. Allow full cure of the adhesive per the directions of the manufacturer.

Other manuals for Nanoprecise 6VW

3

Table of contents

Other Sensata Accessories manuals