GS1 3 THEORY

3 Theory

3.1 Volumetric Water Content

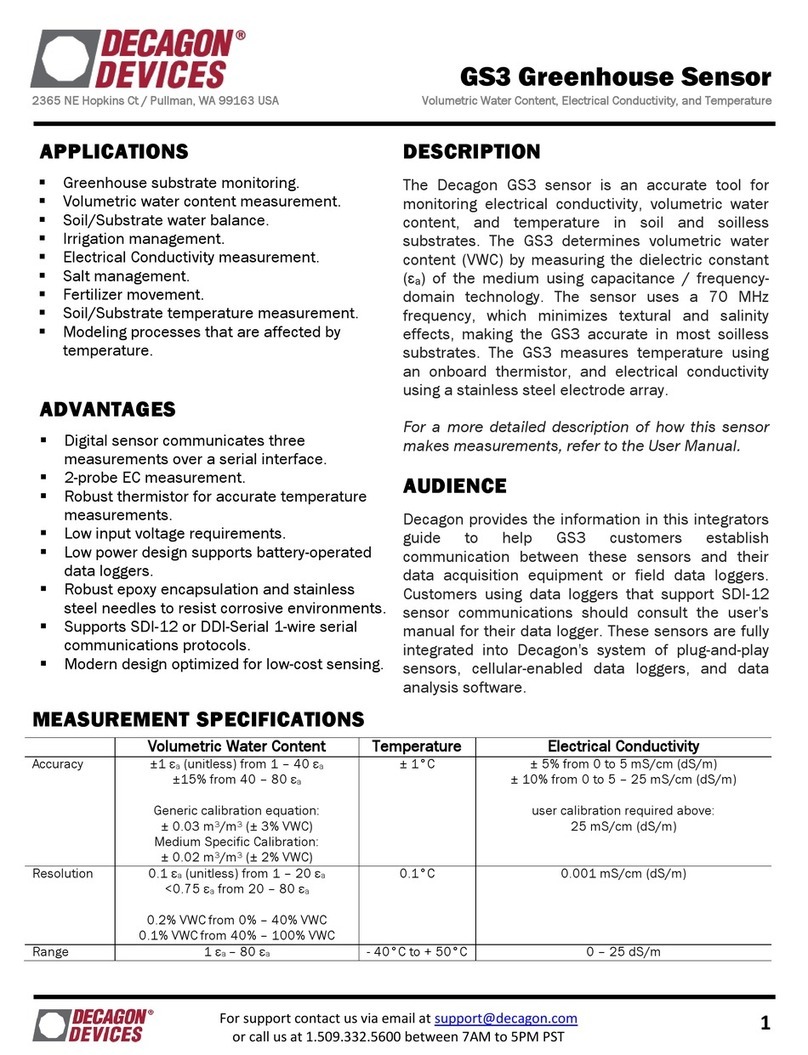

The GS1 sensor uses an electromagnetic field to measure the dielec-

tric permittivity of the surrounding medium. The sensor supplies a

70 MHz oscillating wave to the sensor prongs that charges according

to the dielectric of the material. The stored charge is proportional

to substrate dielectric and substrate volumetric water content. The

GS1 measures the charge and outputs a raw value that strongly cor-

relates to VWC. Decagon has a few helpful reminders to consider

before using your sensor.

•If you are installing sensors in a lightning prone area with

a grounded data logger, please see our Application Note at

www.decagon.com/lightning.

•Decagon advises that you test the sensors with your data log-

ging device and software before going to the field.

Before you select a site for installation, remember that the soil next

to the sensor surface has the strongest influence on its readings. It

is important to avoid air gaps or extremely compact soil around the

sensor, which can skew readings. Do not install the GS1 next to

large metal objects, which can attenuate the sensor electromagnetic

field and distort output readings.

Because the sensors have gaps between their prongs, it is also impor-

tant to consider the size of the media where you insert the sensor. It

is possible to get sticks, bark, roots or other material stuck between

the sensor prongs, which will adversely affect readings. Finally, be

careful when inserting the sensors into dense soil, as the prongs can

bend if you apply excessive force when pushing them into the soil.

3.2 Procedure

Excavate a hole or trench a few centimeters deeper than the sensor

installation depth. At the installation depth, shave off some soil from

the vertical soil face to expos undisturbed soil. Insert the sensor into

5