Sensata Dimensions ADI-24J11 User manual

1

LED Signal Battery Backup System

Installation, Operation and Maintenance Manual

ADI-24J11

Form: 121984D

August 2008

2

Table of Contents

Section Description Page

1.0 Safety Instructions …………………………………………………….. 3

1.1 Warning Symbols ……………………………………………………………………….. 3

1.2 Battery backup System Precautions ……………………………………………… 3

1.3 Battery Precaution ……………………………………………………………………… 3

2.0 Specifications ……………………………………………………………. 4

3.0 System Physical Description …………………………..…………….. 5

3.1 BBS Physical Description ……………………………………………………………… 5

3.2 CMBPS-30ATR 511016-2 (Enclosed case) ……………………………………… 7

3.3 CMBPS-30ATR 511016-1 (Open back panel) …………………………………. 7

4.0 Installation ……………………………………………………………….. 8

4.1 BBS Components ……………………………………………………………….………. 8

4.2 Recommended Useful Tools for Installation …………………………………… 8

4.3 Mounting the BBS ………………………………………………………………………. 9

4.4 Wiring the BBS …………………………………………………………………………… 13

4.5 Dry-Relay Contact Wiring ……………………………………………………………. 15

5.0 Adjustments ……………………………………………………………… 17

5.1 Remaining Battery Capacity Adjustment ……………………………………….. 17

6.0 Communications ………………………………………………………… 19

6.1 Connecting the RS232 Port ………………………………………………………….. 19

6.2 Terminal Setup …………………………………………………………………………… 19

6.3 Using the BBS Communication Interface ………………………………………. 22

7.0 Theory of Operation ……………………………………………………. 24

7.1 System Description …………………………………………………………………….. 24

7.2 Startup Procedure ………………………………………………………………………. 27

8.0 Maintenance & Troubleshooting ….………………………………… 28

8.1 Preventive Maintenance ………………………………………………………………. 28

8.2 Trouble Analysis …………………………………………………………………………. 29

9.0 Parts List ………………………………………………………………….. 32

10.0 Electrical Interconnection ……………………………………………. 33

11.0 Limited Warranty ……………………………………………………….. 34

3

1 Safety Instructions

Important: Read this manual before installation, it contains important safety,

installation, and operating instructions. Save this manual and keep it in a safe place.

1.1 Warning and Danger Symbols:

To reduce the risk of electrical shock and to ensure the safe operation of your

Dimensions power inverter, the following symbols are used throughout the manual.

ATTENTION:

Important operating instructions.

Follow them closely.

DANGER:

Risk of personal harm and/or

electrocution exists in this area.

Use extreme caution.

1.2 Battery Backup System (BBS) Precautions:

•BBS produce hazardous voltages. To avoid risk of harm or fire, the unit must be

properly installed.

•There are no user serviceable parts inside, do not remove the cover.

•The BBS should not be mounted in a location that may be exposed to rain or spray.

•The BBS should not be installed in a zero clearance enclosure.

•Damage to the BBS will occur if correct polarity is not observed when installing the

DC input cables.

•Damage to the BBS will occur if an external AC power source is applied to the

inverter’s AC hardwire output.

•The BBS contains a circuit breaker and capacitor that may produce a spark. Do not

mount in a confined battery or gas compartment.

•Make sure the BBS is turned OFF during installation.

1.3 Battery Precautions:

•Working in the vicinity of lead-acid batteries is dangerous. There is a risk of acid

exposure.

•Batteries generate explosive gases during operation.

•There is risk of high current discharge from shorting a battery that can cause fire

and explosion. Use insulated tools during installation.

•Remove all rings, watches, jewelry or other conductive items before working near

the batteries.

•Inspect the batteries once a year for cracks, leaks or swelling.

•Dispose of the batteries according to local regulations. Do not incinerate batteries;

risk of explosion exists.

4

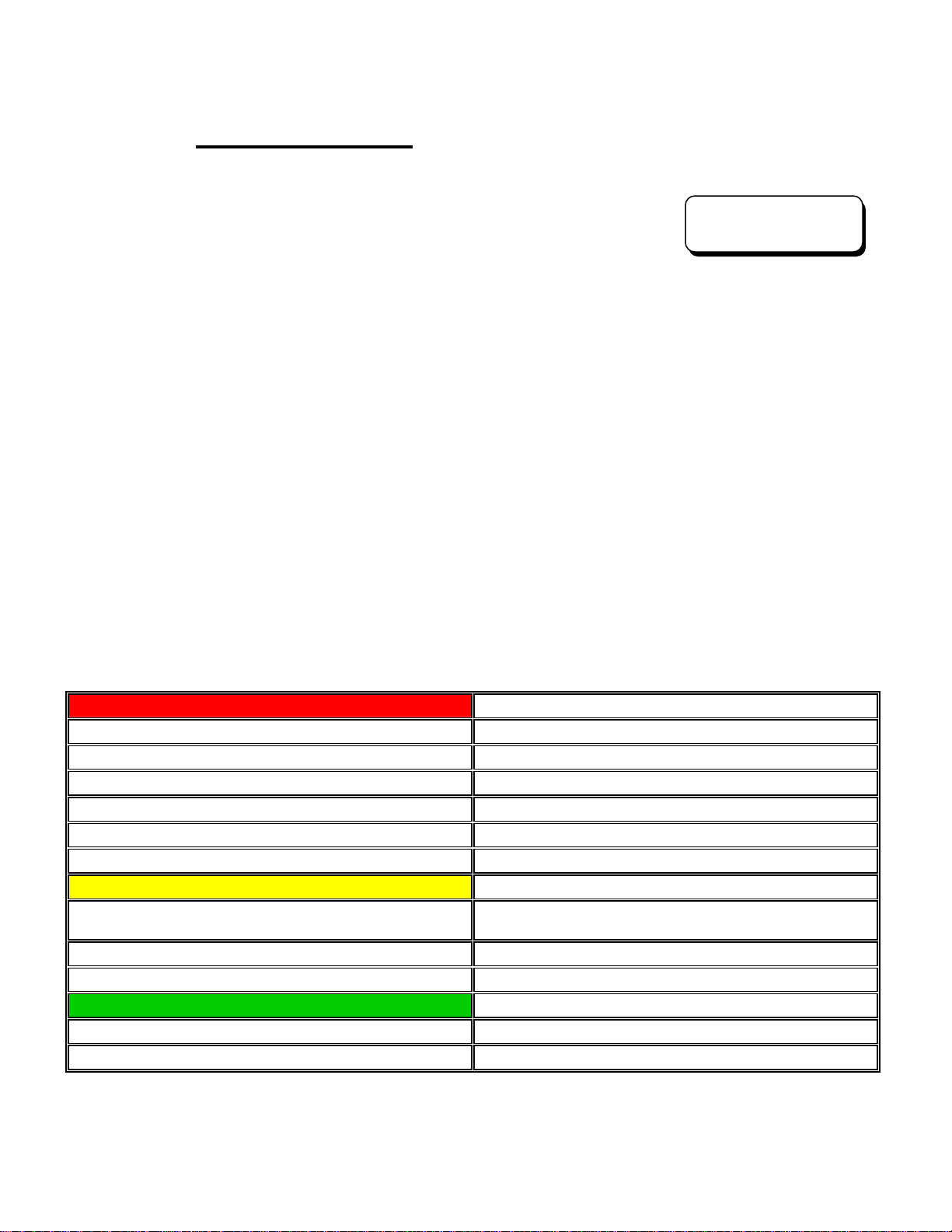

2 Specifications

Other Design Features:

•Thermally-controlled cooling fan

•Automatic utility line power bypass when utility line volta

g

e is

outside the range of 100 to 130 VAC ± 2 VAC

•Automatic inverter mode dropout when utility line power has

been restored above 105 VAC ± 2 VAC for more than 30

seconds

•Li

g

htnin

g

sur

g

e protection compliant with IEEE 587/ANSI

C.62.41

•Completely connectorized system

•LED for Inverter Power, Low Battery, High Temp, & Overload

•LED for Battery Charger On & Full plus Check Batteries

•LED Battery Voltage Indicator & Voltage Test Points

•LED for Relay A (On Batt), Relay B (Low Batt), and Relay C (2

hour Time)

•Two terminal blocks provide access to BBS Form C dry relay

contacts

•Low Batt voltage threshold (Relay B) is adjustable

•Inverter Run Time Meter w/reset

•Inverter Event Counter Meter w/reset

Unit Protection:

•Automatic electronic short circuit/overload

protection

•Automatic over temperature shutdown

•Input and Output circuit breakers

Battery Protection:

•Automatic low battery shutdown at 21 VDC

•In-line battery cable fuse

•Remote temperature sense cable

•

T

emperature compensated battery char

g

in

g

system - shuts off over 50°C (122°F)

Communication:

•RS232 Communication port provides local

pro

g

rammin

g

, system alarms and download o

f

event buffer via windows based PC.

BBS MODEL NUMBER: ADI-24J11 LED Status light and wiring connectors at front

Output Power (Watts Continuous) 1,100 @ 25°C (77°F), 700 @ 74°C (165°F)

Output Current (Amps AC) Up to 9

Peak Output (Amps AC) 37

Input Current (Amps DC) Up to 55

Weight (Lbs.) 41

Dimensions (WxDxH) (inches) 12½ x 13 x 8

BATTERY CHARGER Built-in

Output Voltage (Volts DC) Regulated and temperature compensated end of charge

at 27.6

Output Current (Amps DC) Up to 13

Input Current (Amps AC) Up to 7

TRANSFER RELAY Built-in

Current Rating (Amps AC) 15

Transfer Time (milliseconds) 40 typical

Output Voltage: 120 VAC regulated (110 to 125VAC)

Output Frequency: 60 Hz ± 0.05%

Output Waveform: Pure sine wave, less than 3% THD

Input Voltage: (VDC) 21 to 28

Operating Temperature: -37° to 74° C (-35° to 165° F)

Efficiency: Up to 85%

•Usage: All NEMA traffic equipment within the inverter’s power rating.

•Warranty: Two year parts and factory labor with Advance Replacement Program

ADI-24J11

5

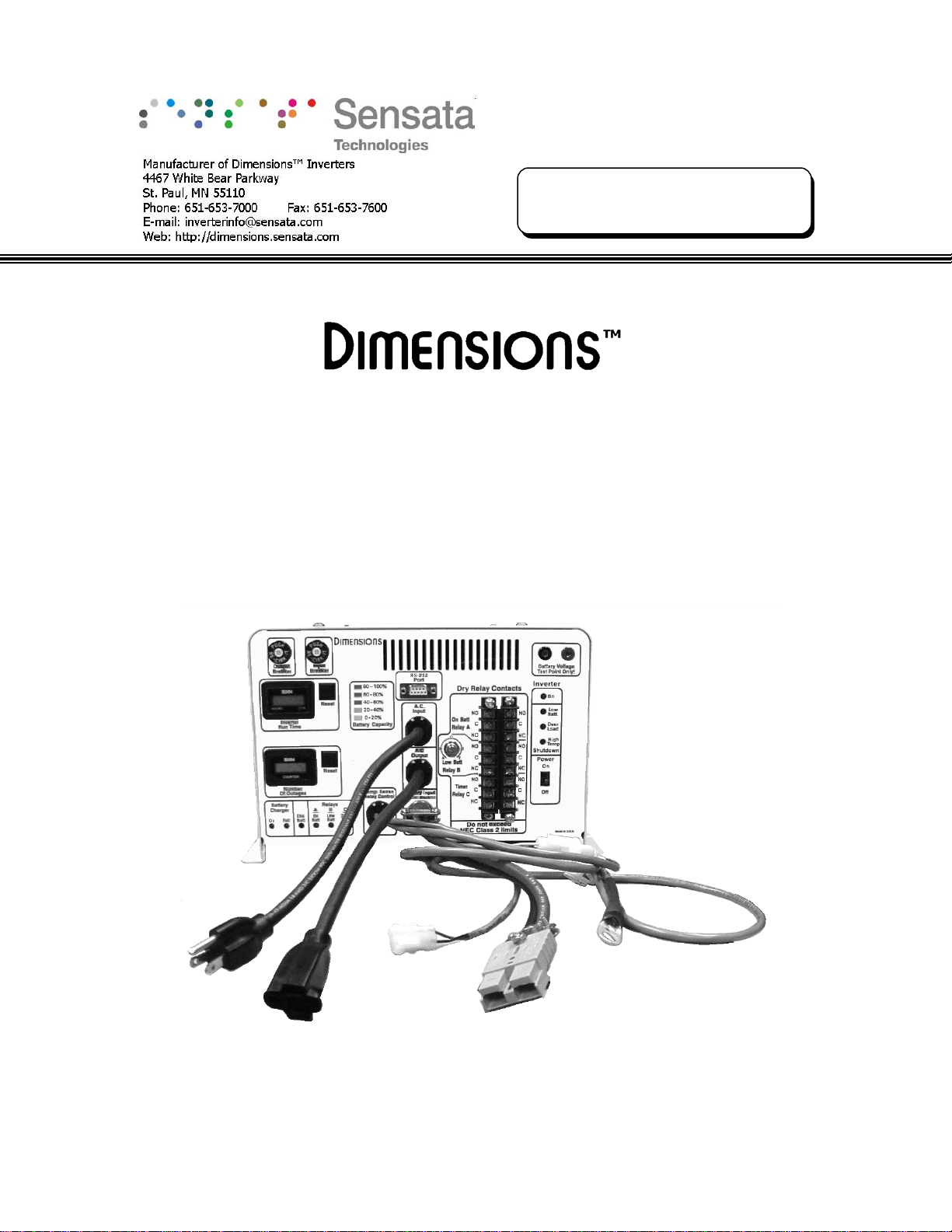

System Physical Description Section 3

3.1 BBS Physical Description

FIGURE 1: BBS Module model ADI-24J11 physical description front and rear view

17

1

15

2

3

2324252627

14

13

4

5

6

910 1211

7 8

16

18

19

20

21

22

Table of contents

Other Sensata Power Supply manuals

Popular Power Supply manuals by other brands

Videx

Videx 520MR Installation instruction

Poppstar

Poppstar 1008821 Instructions for use

TDK-Lambda

TDK-Lambda LZS-A1000-3 Installation, operation and maintenance manual

TDK-Lambda

TDK-Lambda 500A instruction manual

Calira

Calira EVS 17/07-DS/IU operating instructions

Monacor

Monacor PS-12CCD instruction manual