Sensata Magnum Energy ME-PAE Series User manual

© 2017 Sensata Technologies

Service Instructions: 64-1003 Rev A 1

Control Board Removal and Replacement

1.0 Description

These instructions provide information on removing the

control board in a ME, RD, MS or MS-PAE Series inverter/

charger and replacing with a new control board.

• Part numbers: TCB-MEXXXX, TCB-RDXXXX,

TCB-MSXXXX or TCB-MSXXXXPAE

Note: This document is part of a series of Service Instructions

to help qualified personnel replace components that have

failed or have been damaged.

2.0 Installation Preparation

Before removing or replacing the control board, read this

entire document and follow all instructions.

2.1 Safety Precautions

Follow all electrical safety precautions and the ESD

prevention guidelines below, and in the Electrical Safety

Precautions and Electrostatic Discharge Prevention:

Service Instructions: 64-1000.

Warning: Hazardous voltages are present within

the inverter when power is applied. Do not remove

the inverter’s top cover without first turning off

and disconnecting all AC and DC power to the

inverter. Always replace the top cover before

reconnecting power.

Warning: The capacitors inside the inverter

store electric energy even after all AC and DC

power is removed. After disconnecting all AC

and DC power to the inverter, wait 5 minutes for

the energy in the capacitors to dissipate before

working on the unit.

Caution: Observe all ESD safety precautions

when working with the control and FET boards,

and within the inverter. Failure to follow ESD

safety precautions could result in damage to

internal components and the inverter.

2.2 Included Materials

Before dismantling the inverter, inspect the new control

board to ensure there is no obvious physical damage. Look

at the Model ID label on the new control board (see Figure

1 or 2, Item A)*and verify that the model number on this

label corresponds to the model number of the inverter that

is being repaired. Contact Sensata if any item appears to

be damaged, missing or incorrect.

*- The Model ID label for each inverter/charger may

appear anywhere on top of the board’s RJ connectors.

Note: All removed items must be returned if repair is for

warranty consideration. Save the packing material and

shipping container to use when returning the removed items.

2.3 Required Tools and Equipment

Before disassembling the inverter, ensure you have the

following tools and equipment to remove and replace the

control board:

• T15 Torx head screwdriver (≥6” shaft required)

– for #6-32 screws

MS/MS-PAE Series Inverter/Chargers also require:

• T25 Torx head screwdriver – for #10-32 screws

• 7/16” socket, socket wrench and ≥6” extension

– for ¼-20 bolts

• Torque wrench (130 in-lbs torque required)

– for ¼-20 bolts with 7/16” head

• Pliers (≥1” jaw opening required)

Figure 1, ME or RD Series Control Board

3 7/8"

ME/RD Series - Model ID Label

A

Figure 2, MS/MS-PAE Series Control Board

MS/MS-PAE Series - Model ID Label

A

Ensure there is a blue current

transducer on back (i.e., a LEM)

4 5/8"

5"(MS-PAE)

(MS)

www.SensataPower.com

a product

brand of:

2© 2018 Sensata Technologies

Control Board Removal and Replacement

3.0 Removing & Replacing ME/RD Series

Control Boards

This section provides information on removing and

replacing the control board in a ME or RD Series inverter.

If you are replacing a control board in a MS or MS-PAE

Series inverter, proceed to Section 4.0.

3.1 Removing ME/RD Series Control Boards

1. Remove the inverter’s top cover and review the

internal components as described in the Top Cover

Removal and Replacement with Internal Component

Identification, Service Instructions: 64-1001.

2. Locate the ME/RD Series control board in the

inverter (Figure 6, Item A), and then remove the

two #6-32 screws securing it to the inverter base.

See Figure 3, Item B.

2. Insert the new control board into the bottom 16-

pin connector located on the FET board. Ensure the

connector pins are aligned correctly before pushing in.

3. Replace the two #6-32 screws (T15 head) to

secure the new control board to the FET board.

See Figure 3, Item B.

4. The new control board is now installed, review all the

connections a final time and ensure they are correct.

5. If there are no other internal components to replace,

reinstall the top cover as described in the Top Cover

Removal and Replacement with Internal Component

Identification, Service Instructions: 64-1001.

4.0 Removing & Replacing MS/MS-PAE

Series Control Boards

4.1 Removing the MS/MS-PAE Series Control

Board

1. Remove the inverter’s top cover and review the

inverter’s internal components as described in the

Top Cover Removal and Replacement with Internal

Component Identification, Service Instructions:

64-1001.

2. Locate the MS/MS-PAE Series control board (Figure

7, Item A) in the inverter. Verify that it has a blue

DC current transducer (referred to hereafter as the

“LEM”) on the back. See Figure 7, Item C.

Note: The MS Series inverter was made with two types

of control boards; the earlier “non-LEM” type and the

current “LEM” type. This document provides instructions

only on replacing the LEM type control board. If repairing

a MS Series inverter that does not have a LEM type

control board, contact Sensata for assistance.

3. Locate and remove the two #6-32 screws (T15 head)

securing the control board. See Figure 3, Item B.

4. Firmly pull up on the control board by its top edge (or

upper corners) to remove it from the bottom 16-pin

connector on the FET board. The current sense wire

(Figure 7, Item B) will still be attached through the

LEM on the back.

5. Look on the front of the control board and pull on

the 16-pin ribbon connector to remove. See Figure 3,

Item A.

6. Move the control board aside to provide access to the

¼-20 bolt (7/16” head) screwed into the negative FET

busbar—see Figure 7, Item F. Remove this ¼-20 bolt,

and at the same time use a pair of pliers to hold the

negative FET busbar in place. This will prevent the

busbar from twisting while this bolt is being removed.

See Figure 4.

Note: Record how this hardware is removed, it will need

to be reconnected in the same way.

7. After removing the bolt, pull the loose side of the

current sense wire (Figure 7, Item B) out of the LEM.

8. The control board is now removed. Using ESD

precautions, place this control board aside until it can

be placed in an antistatic bag to be returned with any

other replaced components.

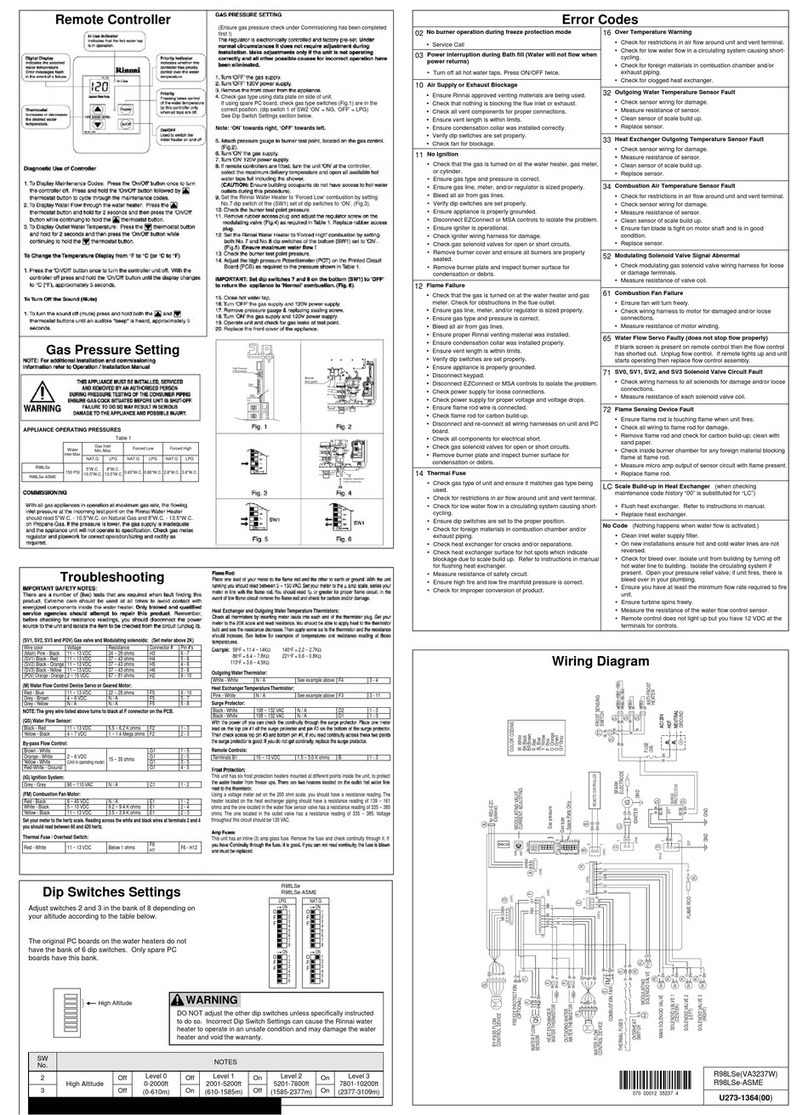

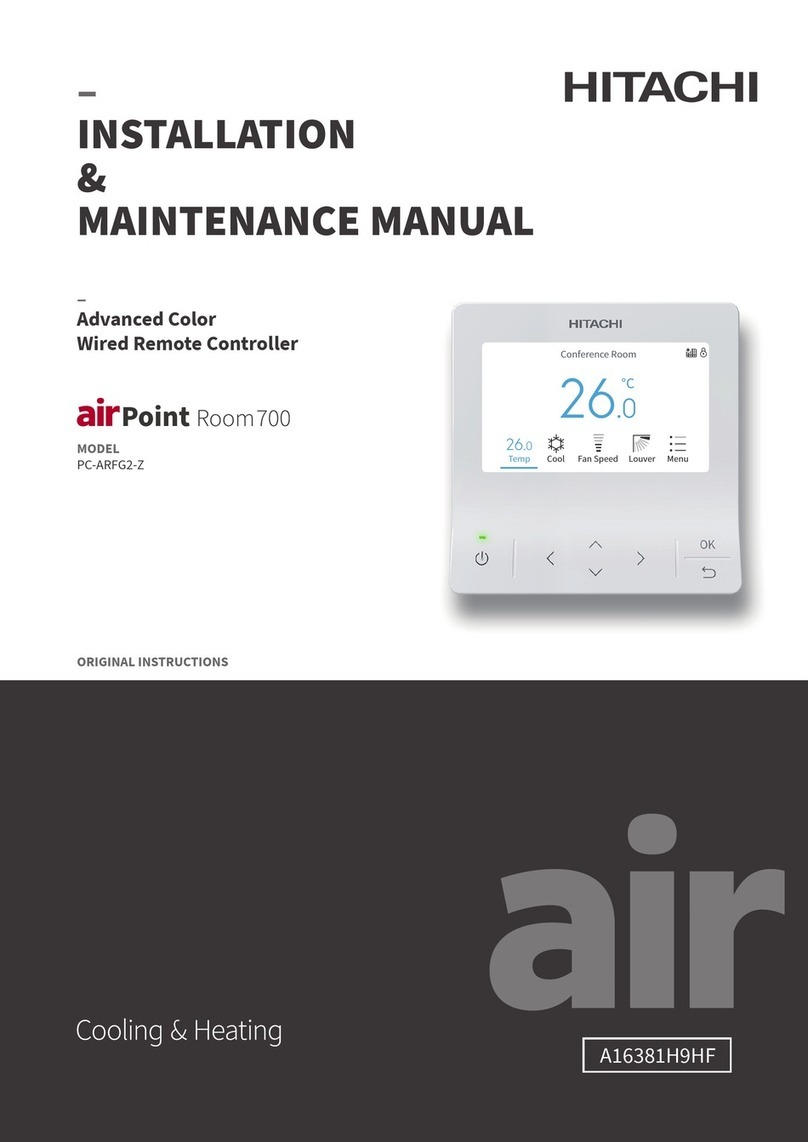

Figure 3, Top View of the Control Board

3. Grasp the control board by its top edge

(or upper corners) and firmly pull up to remove it from

the bottom 16-pin FET board connector.

4. Locate and pull off the 16-pin ribbon connector. See

Figure 3, Item A.

5. The control board is now removed. Using ESD

precautions, place it component-side up on a

grounded, static-free surface until it can be placed

in an antistatic bag to be returned with any other

replaced components.

3.2 Replacing ME/RD Series Control Boards

Note: If the FET board also needs to be replaced, follow the

information described in either the Small FET Board Removal

and Replacement, Service Instructions: 64-1004; or the Large

FET Board Removal and Replacement, Service Instructions:

64-1005; depending on your particular FET board—before

replacing the control board.

1. Remove the new control board from its antistatic

bag, and then reconnect the 16–pin ribbon cable

connector. Before pushing in the connector,

ensure it is seated with the red stripe on the

ribbon cable facing toward the rear of the inverter

(Figure 3, Item A) and the connector pins are aligned

correctly.

Two #6-32 screws (T15 head)

B

16-pin Ribbon Connector

(note red stripe toward rear of unit)

A

© 2018 Sensata Technologies 3

Control Board Removal and Replacement

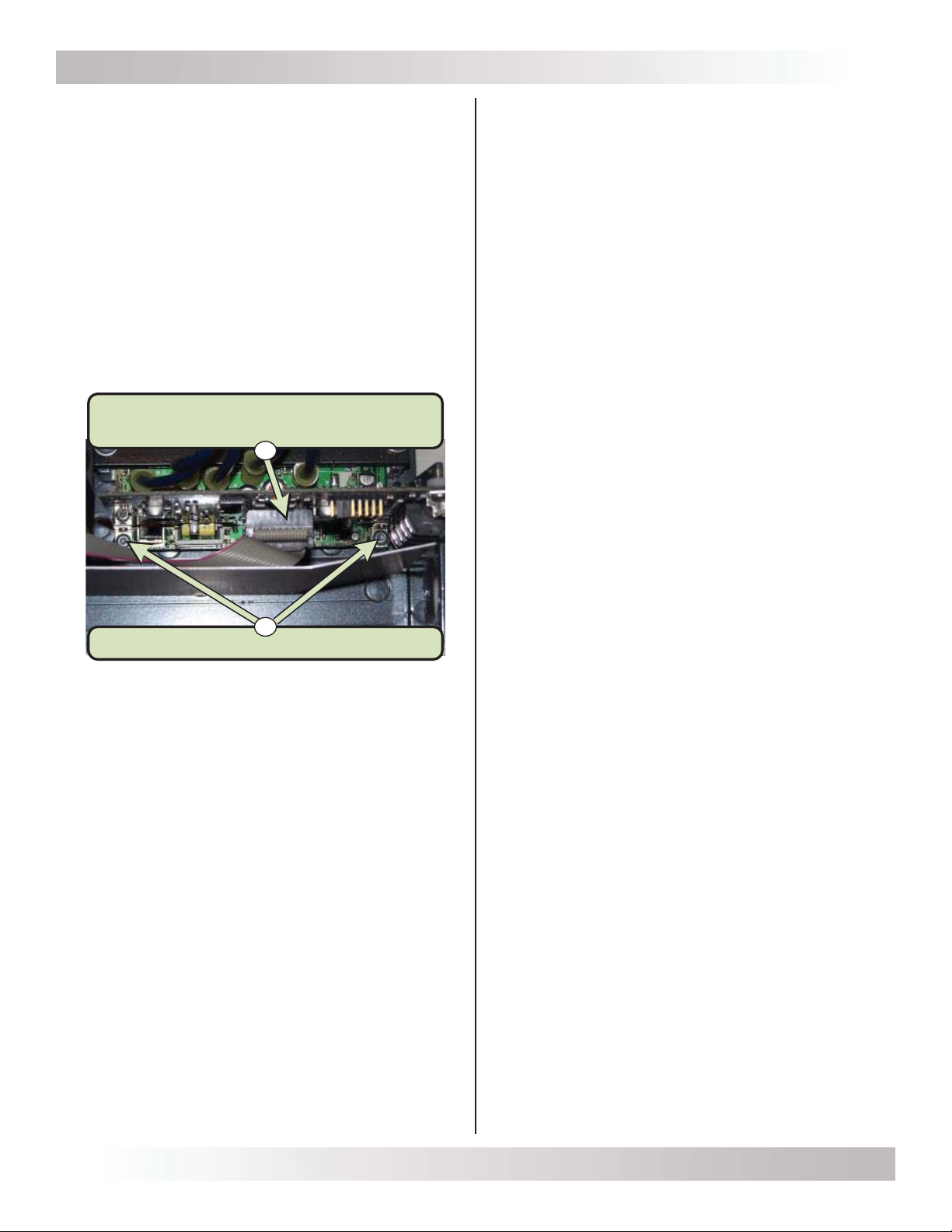

Figure 4, Preventing Busbar from Twisting

4.2 Replacing MS/MS-PAE Series Control Boards

Note: If the FET board also needs to be replaced, follow

the information described in the Large FET Board Removal

and Replacement, Service Instructions: 64-1005—before

replacing the MS/MS-PAE Series control board.

1. Remove the new control board from its antistatic bag

and place the loose side of the current sense wire

(Figure 7, Item B) back through the LEM.

2. Reconnect the 16–pin ribbon cable connector to the

front of the new control board. Before pushing it in,

ensure it is connected with the red stripe on the ribbon

cable facing toward the rear of the inverter (refer to

Figure 3, Item A for reference) and the connector pins

are aligned correctly.

3. Insert the new control board into the bottom 16-pin

FET board connector. Ensure the connector pins are

aligned correctly before pushing in.

4. Reconnect the negative bus cable and the current

sense wire (running through the LEM) to the negative

FET busbar using the ¼-20 bolt. This connection must

be torqued to 130 in.-lbs. Use a pair of pliers to hold

the negative FET busbar in place while this bolt is

being tightened to prevent the busbar from twisting

or breaking. See Figure 4 for reference.

Caution: Ensure the ¼-20 bolt is reconnected

in the same way as it was removed, and is

correctly torqued. This connection carries very

high DC current, and an improper connection

will affect the performance of the inverter and

may cause damage. See Figure 5 for reference.

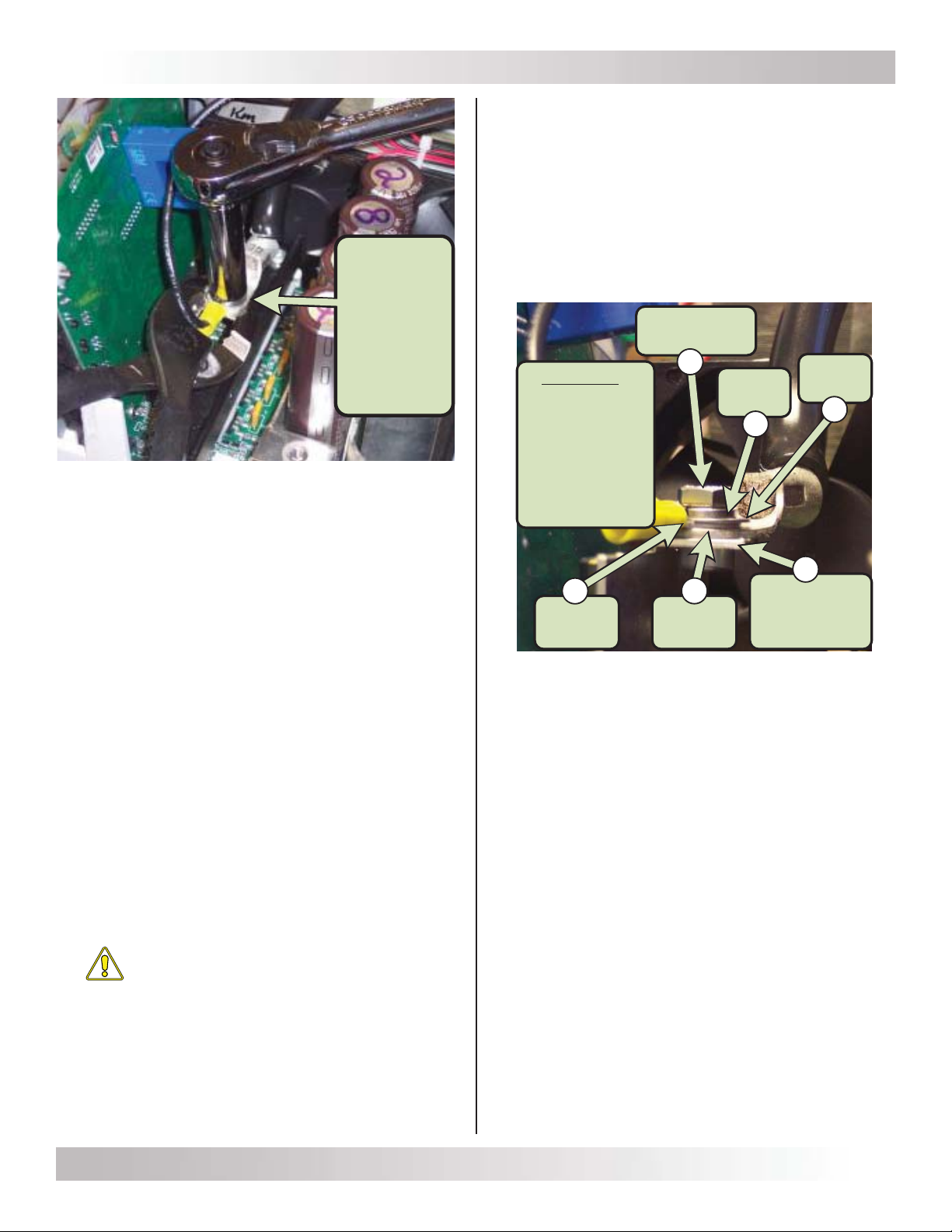

Figure 5, Connections to Busbar

5. Secure the new control board into the bottom 16-pin

FET board connector by screwing in the two #6-32

screws (T15 head) to the FET board. See Figure 3,

Item B.

6. The new control board is now installed. Review all the

connections a final time to ensure they are correct.

7. If there are no other internal components to replace,

reinstall the top cover as described in the Top Cover

Removal and Replacement with Internal Component

Identification, Service Instructions: 64-1001.

Use pliers to

hold the

busbar

while

removing or

replacing

the

¼-20 bolt Sequence

1. ¼-20 bolt

2. Lock washer

3. Flat washer

4. Sense wire

5. Bus cable

6. Busbar

(captive nut)

¼-20 bolt

(7/16" head)

Busbar

(with captive

nut)

Bus

cable

Flat

washer

Lock

washer

Sense

wire

6

5

4

3

2

1

4© 2018 Sensata Technologies

Control Board Removal and Replacement

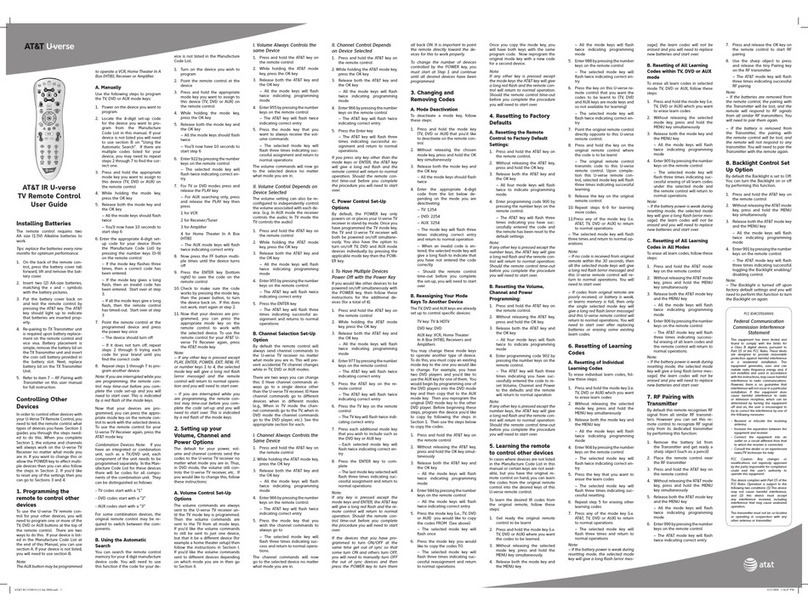

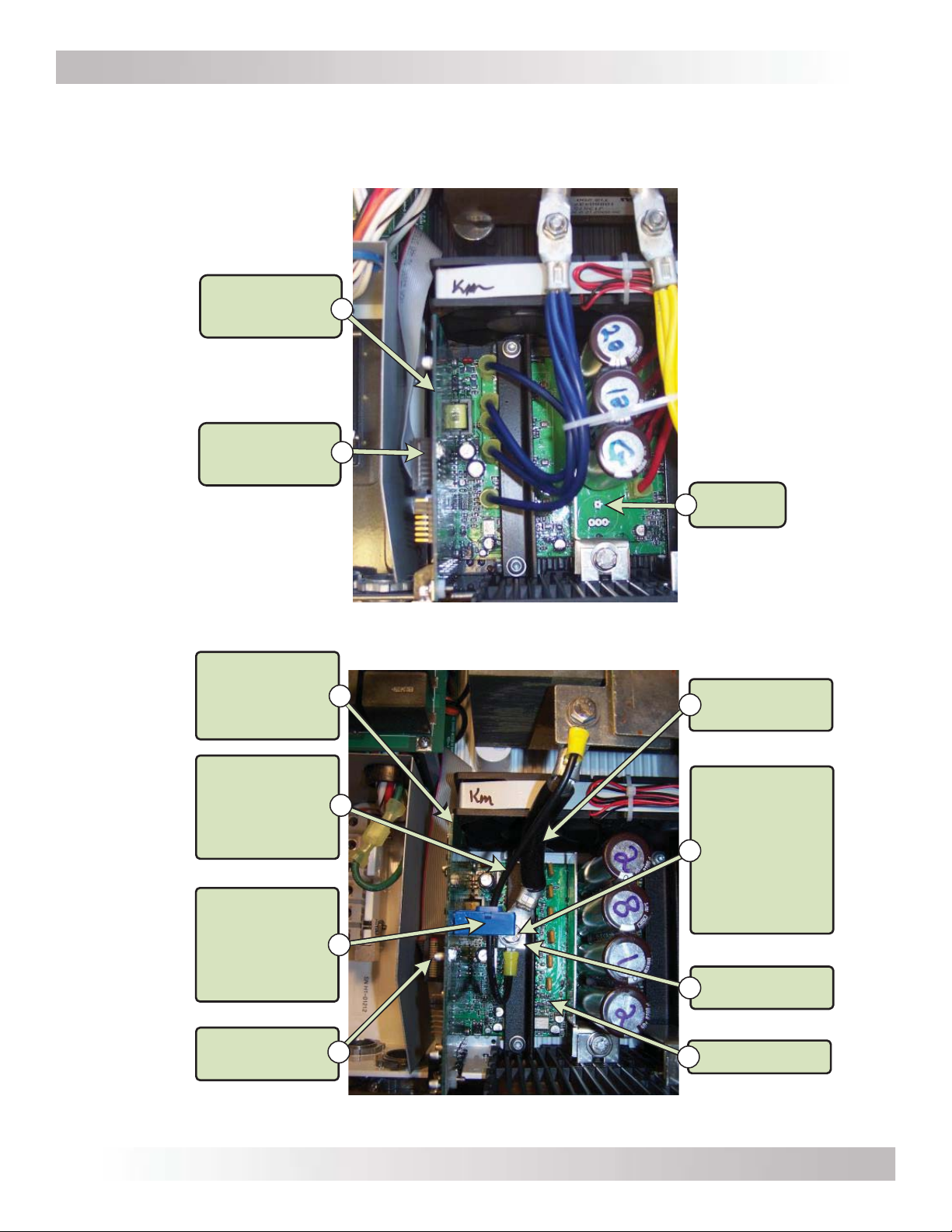

5.0 Identifying Components in the Control Board Compartment

Although Sensata offers multiple Magnum Energy inverter models—and uses a slightly different control board for each

model—the location of the control board for each inverter series is identical. Familiarize yourself with the components

involved in the removal and replacement of a control board.

Figure 6, ME/RD Series Control Board Compartment

16-pin Ribbon

Cable Connector B

ME/RD Series

Control Board A

FET Board

C

Figure 7, MS/MS-PAE Series Control Board Compartment

Negative

Bus Cable

Negative FET

Busbar

FET Board

¼-20 bolt

(7/16" head) –

holds Negative

Bus Cable and

Current Sense

Wire to

Negative FET

Busbar

G

E

H

16-pin Ribbon

Cable Connector

LEM - current

transducer

(connected to

MS/MS-PAE

control board)

Current

Sense Wire

(1 or 2 wires,

depending on

model)

MS/MS-PAE

Series

Control Board

(LEM type)

A

B

C

D

F

This manual suits for next models

2

Other Sensata Remote Control manuals