Sensia JISKOOT InSpec Sampler User manual

1

1

JISKOOT™ MEASUREMENT SYSTEMS

InSpec Sampler Controller

Application Operation Manual

Software Version 5.10 - Volume 1

Manual No. H128, Rev. 1

MEASUREMENT

2

REVISION HISTORY

ISSUER

APPROVER

DATE

1st Issue ______________________________

JMc

SFW

NOV-30-2020

InSpec Sampler Controller

3

Table of Contents

SECTION 1: INTRODUCTION..............................................................................................................................11

1.1 INTENDEDUSE...................................................................................................................................11

1.2 IDENTIFYING THE PARTS OFTHE INSPECFRONT DISPLAY .........................................................11

1.2.1 FRONT PANEL ...................................................................................................................11

1.3 BASIC OPERATION OF THE INSTRUMENT (START, STOP, RESET, MANUAL)..............................14

SECTION 2: COMMON SOFTWARE FEATURES...............................................................................................15

2.1 MAIN FEATURES ................................................................................................................................15

2.2 INSPEC SECURITY.............................................................................................................................15

2.2.1 COMMON SECURITY MENU ITEMS.................................................................................15

2.3 NAVIGATINGTHE INSPEC DISPLAY .................................................................................................17

2.3.1 BASIC SCREEN LAYOUT ..................................................................................................17

2.4 DATA ENTRY.......................................................................................................................................18

2.4.1 NUMERIC ENTRY...............................................................................................................18

2.4.2 ALPHANUMERIC ENTRY...................................................................................................19

2.4.3 PASSWORD ENTRY ..........................................................................................................19

2.4.4 QUESTIONS & DECISIONS...............................................................................................19

2.4.5 SELECT/ASSIGN KEY........................................................................................................19

2.5 REGISTERS.........................................................................................................................................20

2.5.1 REGISTER MODE OPTIONS .............................................................................................20

2.6 DISPLAY SETUP .................................................................................................................................22

2.6.1 SCROLL SETUP.................................................................................................................22

2.6.2 DISPLAY ITEMS .................................................................................................................22

2.6.3 DISPLAY DEC.....................................................................................................................22

2.6.4 ENGINEERING DISPLAY...................................................................................................22

2.6.5 BAR GRAPH 1 ....................................................................................................................23

2.6.6 BAR GRAPH 2 ....................................................................................................................23

2.7 THE ALARMS MENU ...........................................................................................................................24

2.7.1 Set Display Text ..................................................................................................................25

2.7.2 Set Source Register ............................................................................................................25

2.7.3 Set Active Register..............................................................................................................25

2.7.4 Invert Active?.......................................................................................................................25

2.7.5 Minimum Value....................................................................................................................25

2.7.6 Maximum Register...............................................................................................................25

2.7.7 Invert Rslt?..........................................................................................................................25

2.7.8 Hysteresis (%).....................................................................................................................25

2.7.9 Set phases ..........................................................................................................................25

2.7.10 Alarm Delay.........................................................................................................................25

2.7.11 Send to output.....................................................................................................................25

2.7.12 Alarm Type..........................................................................................................................25

2.7.13 Email notification .................................................................................................................26

2.7.14 Inhibit Trim...........................................................................................................................26

2.8 SECURITY...........................................................................................................................................26

2.9 THE SYSTEMS MENU.........................................................................................................................26

2.9.1 InSpec ID.............................................................................................................................26

2.9.2 Set date/time.......................................................................................................................26

2.9.3 Email Setup.........................................................................................................................27

2.9.4 Serial ports,.........................................................................................................................28

2.9.5 MODBUS TCP SLAVE........................................................................................................30

2.9.6 MODBUS TCP MASTER.....................................................................................................30

2.9.7 IP SETTINGS......................................................................................................................30

2.9.8 USER COMMANDS............................................................................................................31

2.9.9 IO.........................................................................................................................................32

2.10 RECORDS AND LOGS ........................................................................................................................35

InSpec Sampler Controller

4

2.10.1 GENERATE REPORT.........................................................................................................35

2.10.2 PRINT..................................................................................................................................35

2.10.3 DELETE BATCHES.............................................................................................................36

2.10.4 EMAIL..................................................................................................................................36

2.10.5 LOG SETUP........................................................................................................................38

2.11 SOFTWARE DESCRIPTION................................................................................................................38

2.11.1 OPERATING SYSTEM........................................................................................................38

2.11.2 FILES ..................................................................................................................................38

SECTION 3: DATA COMMUNICATIONS.............................................................................................................39

3.1 WHAT IS IT?.........................................................................................................................................39

3.2 ONEBIT AT ATIME, OR AWHOLE BYTE?.........................................................................................39

3.3 PARALLEL TRANSMISSION...............................................................................................................39

3.4 SERIAL TRANSMISSION ....................................................................................................................39

3.5 SIMPLEX, HALF DUPLEX OR FULL DUPLEX?...................................................................................39

3.6 SIMPLEX..............................................................................................................................................39

3.7 HALF DUPLEX.....................................................................................................................................39

3.8 FULL DUPLEX .....................................................................................................................................39

3.9 THE RIGHT CONNECTION .................................................................................................................40

3.10 RS232..................................................................................................................................................40

3.11 RS422..................................................................................................................................................41

3.12 RS485..................................................................................................................................................41

3.13 LINE TERMINATION AND FAIL-SAFE ...........................................................................................................41

SECTION 4: IP SETTINGS...................................................................................................................................42

4.1 IP SETTINGS...........................................................................................................................................42

4.1.1 What is an IP Address?.......................................................................................................42

4.1.2 What do IP addresses look like?.........................................................................................42

4.1.3 Configure DHCP..................................................................................................................43

4.1.4 IP Address...........................................................................................................................43

4.1.5 Subnet mask .......................................................................................................................43

4.1.6 Default gateway...................................................................................................................44

4.1.7 Primary DNS .......................................................................................................................44

4.1.8 Secondary DNS...................................................................................................................44

4.1.9 SMTP URL Address............................................................................................................45

4.1.10 Print URL Address...............................................................................................................45

4.1.11 NTP URL Address...............................................................................................................45

4.1.12 View MAC Address..............................................................................................................45

4.2 NTP SETUP (NETWORK TIME PROTOCOL SETUP)......................................................................................45

4.3 RESOLVING IP ADDRESSES......................................................................................................................45

4.3.1 EMAIL –DEFAULT SMTP PORT = 25 ...............................................................................45

4.3.2 NETWORK PRINTER –DEFAULT PORT = 515................................................................46

4.3.3 NTP TIME –DEFAULT PORT = 123 (UDP/IP PROTOCOL)..............................................46

4.3.4 MODBUS TCP –DEFAULT NETWORK PORT = 502........................................................46

SECTION 5: SD CARD FILE SYSTEM ................................................................................................................47

5.1 SYSTEM DIRECTORY ...............................................................................................................................47

5.1.1 MODLOG.CSV....................................................................................................................47

5.1.2 REGLOG.CSV.....................................................................................................................47

5.1.3 REBOOTLOG.CSV .............................................................................................................47

5.1.4 SECLOG.CSV.....................................................................................................................47

5.1.5 USERS.BIN.........................................................................................................................47

5.2 BACKUP DIRECTORY ...............................................................................................................................47

5.3 TEMP DIRECTORY ...................................................................................................................................47

5.3.1 CSDATA..............................................................................................................................48

5.3.2 IMAGES ..............................................................................................................................48

5.3.3 SYSTEM..............................................................................................................................48

5.4 BATCH DIRECTORY .................................................................................................................................48

InSpec Sampler Controller

5

5.4.1 LOG.TXT.............................................................................................................................49

5.4.2 LOG.CSV ............................................................................................................................49

5.4.3 AL_PH.CSV.........................................................................................................................49

5.4.4 REPORT.TXT......................................................................................................................50

5.4.5 REPORT.HTM.....................................................................................................................50

SECTION 6: FTP FILE SYSTEM ACCESS..........................................................................................................51

SECTION 7: INSITU PROGRAMMING ................................................................................................................52

7.1 PROGRAMMING FROM THE BOOTLOADER ...................................................................................................52

7.1.1 Automatic Software Update via the bootloader. ..................................................................52

7.1.2 Manual Software Update Via The Bootloader. ....................................................................53

7.2 UPGRADING EXISTING SOFTWARE VIA TESTCARD ......................................................................................54

7.3 UPGRADING –THE UPGRADE DATA FOLDER. ..............................................................................................55

7.4 UPGRADING THE BOOTLOADER SOFTWARE VIA THE APPLICATION ...............................................................56

SECTION 8: SD CARD SYSTEM FILES..............................................................................................................58

SECTION 9: MODBUS INFORMATION...............................................................................................................61

9.1 GENERAL ...............................................................................................................................................61

9.2 INVALID ADDRESSES ................................................................................................................................61

9.3 MODBUS SERIAL SET-UP.......................................................................................................................61

9.4 ETHERNET MODBUSTCP SETUP ..............................................................................................................61

9.5 NODE NUMBER .......................................................................................................................................61

9.6 MODE ....................................................................................................................................................61

9.6.1 ASCII...................................................................................................................................62

9.6.2 RTU.....................................................................................................................................62

9.6.3 TCP.....................................................................................................................................62

9.7 WORD ORDER ........................................................................................................................................62

9.8 FUNCTIONS SUPPORTED..........................................................................................................................62

9.9 MODBUS ADDRESSES..............................................................................................................................63

9.10 COMMS DATA REGISTERS........................................................................................................................63

9.11 RTU DELAY (SERIAL ONLY)......................................................................................................................63

9.12 STRING SIZE ...........................................................................................................................................63

9.13 FLOAT SIZE.............................................................................................................................................63

9.14 START OFFSET........................................................................................................................................63

9.15 MODBUS SLAVE ......................................................................................................................................64

9.16 MODBUS MASTER ...................................................................................................................................64

9.16.1 General................................................................................................................................64

9.16.2 Queries Blocks ....................................................................................................................64

9.16.3 Modbus poll delay (serial only)............................................................................................64

9.16.4 Modbus retries.....................................................................................................................64

SECTION 10: USER COMMANDS.......................................................................................................................65

10.1 INTRODUCTION........................................................................................................................................65

10.2 COMMAND TYPES ....................................................................................................................................65

SECTION 11: USER CONFIGURABLE LOGIC (UCL) ........................................................................................67

11.1 HOW DOES UCL RUN? ............................................................................................................................67

11.2 HOW TO WRITE A UCL PROGRAM..............................................................................................................67

11.3 HOW TO USE BUILD -PART 1 ....................................................................................................................67

11.4 HOW TO EXECUTE A UCL PROGRAM..........................................................................................................67

11.5 WHAT MAKES UP A UCL PROGRAM? .........................................................................................................68

11.6 TYPES AND TYPE CASTING.......................................................................................................................69

11.6.1 Integer Type........................................................................................................................69

11.6.2 Floating Point Type..............................................................................................................69

11.6.3 Boolean Type ......................................................................................................................69

11.6.4 Register Names...................................................................................................................69

11.6.5 Casting................................................................................................................................69

11.7 ARITHMETIC OPERATORS (+, -, *, /, %)......................................................................................................70

InSpec Sampler Controller

6

11.8 BOOLEAN LOGICAL OPERATORS (&&, ||, ^^, !)............................................................................................70

11.9 BOOLEAN COMPARISON OPERATORS (==, !=, >, <, >=, <=)........................................................................70

11.10 BIT-WISE OPERATORS (&, |, ^)..................................................................................................................71

11.11 SHIFT OPERATORS (>>, <<) ....................................................................................................................71

11.12 POINTER ARITHMETIC OPERATORS ...........................................................................................................71

11.13 COMPLEX MATH OPERATORS (LOG, LN, POW, SIN, COS, TAN, ASIN, ACOS, ATAN)............................71

11.13.1 LOG EXAMPLE...................................................................................................................71

11.13.2 LN EXAMPLE......................................................................................................................71

11.13.3 POW EXAMPLE..................................................................................................................72

11.13.4 SIN EXAMPLE ....................................................................................................................72

11.13.5 COS EXAMPLE...................................................................................................................72

11.13.6 TAN EXAMPLE ...................................................................................................................72

11.13.7 ASIN EXAMPLE..................................................................................................................72

11.13.8 ACOS EXAMPLE ................................................................................................................72

11.13.9 ATAN EXAMPLE.................................................................................................................72

11.13.10 RAND EXAMPLE ................................................................................................................72

11.14 OPERATORS DECISION MAKING (? :).........................................................................................................72

11.15 OPERATOR PRIORITY AND PARENTHESISING ..............................................................................................73

11.16 OPERATORS:CONDITIONAL JUMP LOOP LABELS (IF$LABEL, $LABEL:).....................................................73

SECTION 12: FLOW WEIGHTED AVERAGING..................................................................................................76

SECTION 13: PID BLOCKS.................................................................................................................................77

SECTION 14: STORING CONFIGURATION BACKUPS.....................................................................................78

SECTION 15: RESTORING CONFIGURATION BACKUPS................................................................................79

SECTION 16: SYSTEM START UP MENU..........................................................................................................80

16.1 EXIT.....................................................................................................................................................80

16.2 TOGGLE WDOG..................................................................................................................................80

16.3 ENABLE DEBUG..................................................................................................................................80

16.4 DEFAULT UK.......................................................................................................................................80

16.5 DEFAULT US.......................................................................................................................................80

16.6 DEFAULT MODBUS ............................................................................................................................80

16.7 CLEAR MODBUS ADDRS....................................................................................................................80

16.8 DEFAULT FILES..................................................................................................................................80

16.9 WIPE INSTRUMENT............................................................................................................................80

16.10 FORMAT SD CARD .............................................................................................................................81

16.11 STARTUP CTRL ..................................................................................................................................81

16.12 CLEAR REG CHECK ...........................................................................................................................81

16.13 REGISTER EDITOR.............................................................................................................................81

16.14 SYSTEM BACKUP...............................................................................................................................81

16.15 SYSTEM RESTORE ............................................................................................................................81

SECTION 17: WEB (HTTP) INTERFACE.............................................................................................................82

SECTION 18: SVG SCHEMATIC - WEB INTERFACE ........................................................................................83

SECTION 19: REMOTE IO MODULE ..................................................................................................................87

19.1 FIELD CONNECTIONS........................................................................................................................87

19.2 CONNECT WITHWEB INTERFACE....................................................................................................87

19.3 REMOTE ADCDEVICE .......................................................................................................................88

19.4 REMOTE DAC DEVICE .......................................................................................................................89

19.5 REMOTE DIGITAL DEVICE.................................................................................................................90

19.6 REMOTE PULSE DEVICE ...................................................................................................................90

SECTION 20: REMOTE IO WEB PAGE...............................................................................................................92

SECTION 21: SAFETY INFORMATION...............................................................................................................93

SECTION 22: INSTALLATION DETAILS.............................................................................................................94

22.1 GENERAL............................................................................................................................................94

22.2 LOCATION...........................................................................................................................................94

22.3 MOUNTING..........................................................................................................................................94

InSpec Sampler Controller

7

SECTION 23: MAKING CONNECTIONS.............................................................................................................95

23.1 FIELD AND POWER CONNECTIONS (REAR).................................................................................................95

23.2 INPUT POWER....................................................................................................................................95

23.2.1 EARTHING REQUIREMENTS............................................................................................95

23.3 SHIELDED (SCREENED) CABLES .....................................................................................................96

SECTION 24: FIELD CONNECTIONS .................................................................................................................97

24.1 CABLE SCREENS &DRAIN WIRES....................................................................................................97

24.2 PLUG NO’S 1,2,3&4..........................................................................................................................97

24.2.1 RELAY OUTPUTS (4 OFF).................................................................................................97

24.3 PLUG NO. 5..........................................................................................................................................98

24.3.1 RS422 & RS485 TERMINOLOGY.......................................................................................98

24.3.2 RS422 & RS485 TERMINATION ........................................................................................99

24.3.3 RS422 & RS485 CONNECTIONS.......................................................................................99

24.4 PLUG NO. 6..........................................................................................................................................99

24.4.1 24V DC POWER (1 OFF)..................................................................................................100

24.4.2 DUAL FUNCTION DIGITAL INPUTS/OUTPUTS (4 OFF).................................................100

24.4.3 VOLTAGE OR CURRENT PULSE INPUTS (2 OFF) ........................................................100

24.4.4 4-20mA ANALOGUE OUTPUT (2 off)...............................................................................101

24.4.5 4-20mA ANALOGUE INPUT (3 off)...................................................................................101

SECTION 25: INSTRUMENT SPECIFICATIONS...............................................................................................102

25.1 GENERAL SPECIFICATIONS............................................................................................................102

25.2 INSULATION CO-ORDINATION........................................................................................................103

25.2.1 AC POWER INLET CREEPAGE/CLEARANCE................................................................103

25.2.2 RELAY OUTPUTS CREEPAGE/CLEARANCE.................................................................103

25.3 COMPLIANCE TO INTERNATIONAL STANDARDS..........................................................................103

SECTION 26: INSTRUMENT BREAKDOWN.....................................................................................................104

26.1 DISASSEMBLY..................................................................................................................................104

26.2 REASSEMBLY...................................................................................................................................104

SECTION 27: PRINTED CIRCUIT BOARDS .....................................................................................................105

27.1 FITTING &REMOVAL........................................................................................................................105

27.1.1 MAIN CASE/EXTRUSION.................................................................................................105

27.1.2 FRONT PANEL .................................................................................................................105

27.2 PRINTED CIRCUIT BOARD CONFIGURATION................................................................................106

27.2.1 PCB HANDLING PRECAUTIONS.....................................................................................106

27.2.2 PCB IDENTIFICATION & DESCRIPTION.........................................................................106

27.3 F3174 CONFIGURATION ..................................................................................................................107

27.3.1 BATTERY REPLACEMENT..............................................................................................107

27.4 F3175 CONFIGURATION ..................................................................................................................108

27.4.1 SWITCH SETTINGS FOR ‘SW1’.......................................................................................108

27.4.2 TRIGGER THRESHOLD ADJUSTMENT..........................................................................108

27.5 F3176 CONFIGURATION ..................................................................................................................109

27.5.1 DISPLAY CONTRAST ADJUSTMENT..............................................................................109

SECTION 28: FREQUENTLY ASKED QUESTIONS .........................................................................................111

28.1 BATTERY STORAGE LIFE................................................................................................................111

28.2 DATA RETENTION TIME...................................................................................................................111

28.3 LCD BACKLIGHT LIFE EXPECTANCY..............................................................................................111

SECTION 29: MAINTENANCE / ENTRETIEN ...................................................................................................112

29.1 HEALTH AND SAFETY PRECAUTIONS /PRECAUTION SANTE ET SECURITE.............................112

InSpec Sampler Controller

8

29.2 CLEANING THE INSPEC...................................................................................................................112

SECTION 30: TROUBLESHOOTING.................................................................................................................113

30.1 SOLVING COMMON PROBLEMS.....................................................................................................113

30.1.1 POWER & BATTERY PROBLEMS...................................................................................113

30.1.2 DISPLAY PROBLEMS ......................................................................................................113

30.1.3 SERIAL PROBLEMS.........................................................................................................113

SECTION 31: SUPPORT....................................................................................................................................115

31.1 CONTACT INFORMATION................................................................................................................115

31.2 RECOMMENDED SPARES...............................................................................................................115

31.2.1 First 10 Years Operation ...................................................................................................115

31.2.2 10+ Years Operation.........................................................................................................115

31.3 REPACKAGINGFOR SHIPMENT .....................................................................................................115

SECTION 32: DEFINITION OF TERMS & SYMBOLS.......................................................................................116

32.1 ABBREVIATIONS &ACRONYMS......................................................................................................116

32.2 SYMBOLS /SYMBOLES....................................................................................................................118

APPENDIX A: INSPEC CONTROLLER PANEL CUT-OUT DETAIL.................................................................120

APPENDIX B: INSTALLATION SEQUENCE (SAFE AREA UNIT) ...................................................................121

APPENDIX C: REMOTE I/O (RIO) CONFIGURATION......................................................................................124

APPENDIX D: PUBLISHER NOTES..................................................................................................................126

*Mark of Sensia

InSpec Sampler Controller

9

GENERAL

WARNING!

This instrument is designed for connection to hazardous electric voltages.

Ignoring this warning can result in severe personal injury or mechanical damage.

To avoid the risk of electric shock and fire, the safety instructions of this manual must be

observed and the guidelines followed.

The specifications must not be exceeded, and the unit must only be applied as described

in the following.

Prior to the installation and commissioning of the unit, this manual must be examined

carefully.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

HAZARDOUS

VOLTAGE

CAUTION!

WARNING!

Until the instrument is fixed, do not connect hazardous voltages to the instrument.

The following operations should only be carried out on a disconnected module and under

ESD-safe conditions: -

Dismantlement of the instrument for setting of dipswitches and jumpers.

General mounting, connection and disconnection of wires.

Troubleshooting the module.

REPAIR OF THE INSTRUMENT MUST ONLY BE DONE BY JISKOOT.

INSTALLATION

WARNING!

Installation may only be carried out by electrically skilled and instructed personnel in

accordance with national legislation, including the relevant standards.

All technical data on the instrument is to be observed.

Changes to the design and modifications to the equipment are not permitted.

The equipment shall only be operated as intended and only in undamaged and perfect

condition.

Sufficient segregation must exist between different cables and wires carrying different

types of signal or power and all other circuits.

All wires must be terminated, complete with crimping lugs. Unused cores should be

terminated to the earth bus bar.

InSpec Sampler Controller

10

GENERAL

ATTENTION!

Cet instrument est conçu pour la connexion à des tensions électriques dangereuses.

Ignorer cet avertissement peut entraîner des blessures graves ou des dommages

mécaniques.

Pour éviter tout risque de choc électrique et d'incendie, les consignes de sécurité de

ce manuel doivent être observées, et les orientations suivies.

Les spécifications ne doivent pas être dépassées, et l'unité ne doit être appliquée que

comme décrit dans le texte suivant.

Avant la mise en service et l'installation de l'unité, ce manuel doit être examiné avec

soin.

Si l'équipement est utilisé d'une manière non spécifiée par le fabricant, la protection

assurée par l'équipement peut être altérée.

TENSION

DANGEREUSE

ATTENTION!

ATTENTION!

Ne pas connecter des tensions dangereuses à l'instrument avant que celui-ci ne soit fixé.

Les opérations suivantes doivent être effectuées avec le module débranché et dans des

conditions DES:-

Démantèlement de l'instrument pour régler les dipswitches et cavaliers.

Montage, connexion et déconnexion des fils.

Dépannage du module.

LA REPARATION DE L’APPAREIL DOIT UNIQUEMENT ETRE EFFECTUEE PAR

JISKOOT.

INSTALLATION

ATTENTION!

L’installation ne peut être effectuée que par du personnel électricien qualifié,

conformément à la législation nationale, y compris les normes pertinentes.

On doit observer toutes les données techniques sur l'instrument.

Les changements au niveau de la conception ou de l'équipement ne sont pas autorisés.

L'équipement doit être utilisé comme prévu et uniquement s’il est dans un état intact et

parfait.

Une séparation suffisante doit exister entre les différents câbles et les fils transportant

différents types de signaux ou de puissance et tous les autres circuits.

Tous les fils doivent être terminés, avec pattes de sertissage. Les noyaux non-utilisés

doivent être terminés au jeu de barres de la terre.

InSpec Sampler Controller SECTION 1: INTRODUCTION

11

SECTION 1: INTRODUCTION

1.1 INTENDED USE

The Jiskoot InSpec is used for Sampling, Blending or Wildstream control applications as

determined by the application software installed within it.

The controller is not intended to be used as a standalone piece of equipment and must be built-

in to the end product and mounted in the vertical plane.

1.2 IDENTIFYING THE PARTS OF THE INSPEC FRONT DISPLAY

1.2.1 FRONT PANEL

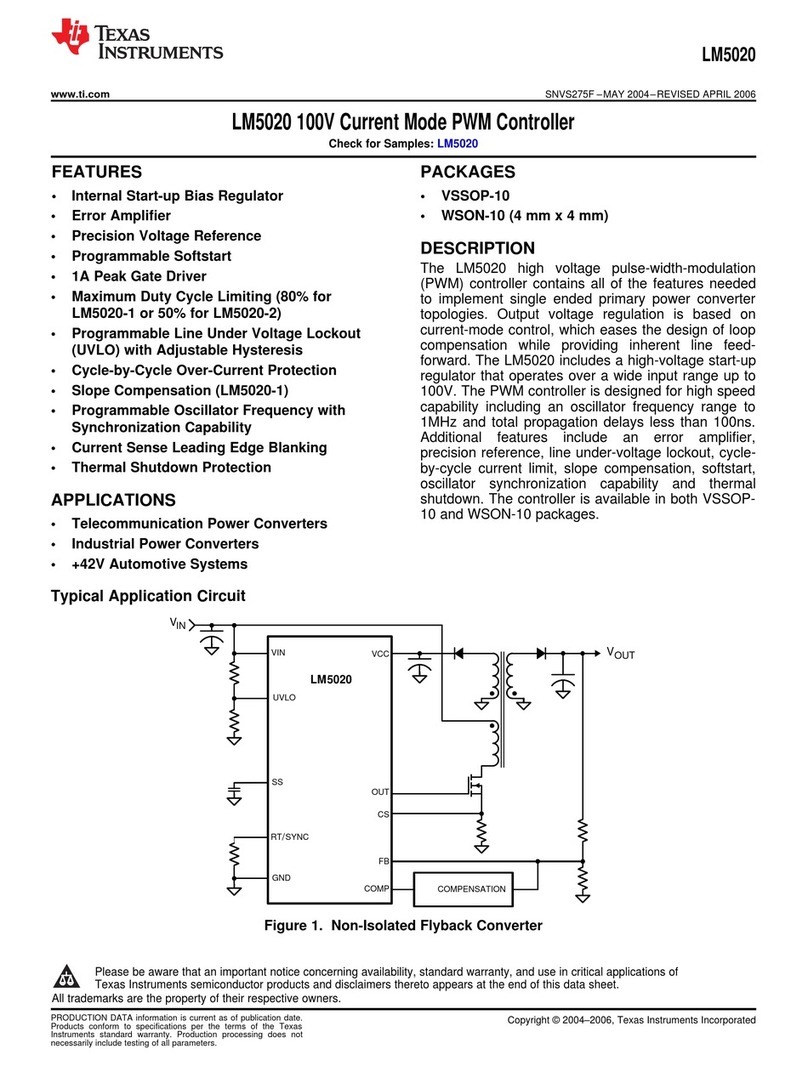

Figure 1 - InSpec Front View

SECTION 1: INTRODUCTION InSpec Sampler Controller

12

A brief description of the indicated front display items follows:

AThe Alarm RGB LED indicator.

BReceiver 2 Tri-Colour LED. The text ‘Receiver’ is specific to the InSpec Sampler Controller. If you

have purchased an InSpec Blender Controller this text will state ‘Stream 2’. In either case the

LED’s indicate which current sampling can/or blending stream is in use. In the case of the sampler,

you would always expect either Receiver 1 or Receiver 2 to be lit; whereas in the case of the

Blender both streams 1 and 2 will often be active at the same time. The given colour is dependent

on the application (Sampler or Blender) and will be explained in the application section of the

manual.

CBar Graph Indicator 2. This ten-barred array of LED’s represents the user-configured value for the

bar graph. A designated register value and associated min and max graph 2 registers

(F_GRAPH_MIN2/F_GRAPH_MAX2) are used to determine the output.

DMENU. There are five indented secondary button functions on the front display interface. This one

indicates that the ENTER button (see E that follows) also enables the user to enter/go into the

InSpec menu structure.

EENTER. Along with the directional cursor buttons, the ENTER button will be one of the most used

buttons of the instrument. This button allows you to confirm entered alphanumeric values, to

confirm control decisions and navigate into selected menu items.

FDELETE. This indented secondary button function is associated with the RESET button. When the

instrument is being configured the secondary key functions MODE, CANCEL and DELETE are

likely to be used far more than their primary button purpose of START, STOP and RESET. The

DELETE button allows users to cancel decisions and erase alphanumeric characters from an

entered value/text.

GRESET. This is the primary function of the button and will be used daily/regularly by operators of

the instrument to reset a batch/blend. Selecting this button when there is no batch/blend in process

will result in a message explaining that there is no batch to reset

HCURSOR BUTTONS. H points to the right cursor button. Let’s look at all of the cursors. The four

cursors are primarily used to navigate around the menu. Left and right step you through the

available options at any given sub-menu or decision and up and down take you into or out of the

current sub-menu. The cursor keys have alternative uses within specific menu functions. i.e., when

an engineer is in the register access screen, the right or left cursor will search through the registry

looking for a user specified search string. Within the same screen the up and down cursor buttons

travel through the registers numerically. During text entry, the cursor buttons are used to enter text

using the up and down buttons and to move through the string with the left and right buttons. On

the front panel, the left and right cursor buttons can be used to move between the 12 configurable

front display items. In the alarm display screen, the down cursor acts as an acknowledgement

button to ‘ACK’ all active alarms. (See I below).

IACK - Acknowledgement. The indented ACK button forms the secondary function of the Down

cursor button. ACK is used to acknowledge all unacknowledged alarms in the alarm display screen

in a two-step process. Pressing this cursor once will take you straight into the display alarms menu

option (browsed via the ‘Alarms→Display Alarms’ option). Pressing it again will acknowledge all the

alarms in the display. This gives the operator the ability to examine new alarms before

acknowledging them.

JNumeric Entry Keypad. 1 thru 9, and ‘.’, 0 and -. These keys are used during configuration and

batch/blend setup to enter values/titles. When the menu is closed these twelve keypad buttons are

each associated with the 12 user configurable display items allow the user to jump quickly to a

particular item (See Display Section).

KCentre Cursor Button. This button doubles up as an alternative Enter key (See E above).

Engineers’ may find it more convenient to use during configuration when they are spending a lot of

time using the other directional cursors.

LSTOP. This is the primary function of the button and will be used daily/regularly by operators of the

instrument to stop a batch/blend. Selecting this button when there is no batch in process will result

in a message explaining that there is no batch to reset.

MCANCEL. This indented secondary button function is associated with the STOP button. The cancel

button can be used to step out of each sub-menu (repeatedly pressing cancel will close the menu

and bring you out to the front display) and can be used to cancel out of a control sequence. I.e.,

when starting a batch/blend the user will be prompted and taken through a series of questions that

the user can cancel out of using this button.

InSpec Sampler Controller SECTION 1: INTRODUCTION

13

NSTART. This is the primary function of the button and will be used daily/regularly by operators of

the instrument to start a batch/blend. If the instrument is currently running a warning message will

appear to tell them a process is currently running.

OMODE. This is the secondary function of the START button. It will only ever be used by an

engineer whilst configuring/changing the current controller’s parameters. The mode button is used

in the register access screen to bring up a list of function choices that can be performed on any

given register (Set Current, Description, Display, Search, View Modbus Address and Set Modbus

Address). It can also be optionally used when the engineer selects ‘Set Current’ on an integer or

long integer value to toggle between Decimal and Hexadecimal number entry mode.

P Bar Graph Indicator 1. This ten-barred array of LED’s represents the user-configured value for the

bar graph. A designated register value and associated min and max graph 1 registers

(F_GRAPH_MIN1/F_GRAPH_MAX1) are used to determine the output.

QThe 20x2 LCD front display screen.

RReceiver 1 Tri-Colour LED. The text ‘Receiver’ is specific to the InSpec Sampler Controller. If you

have purchased an InSpec Blender Controller this text will state ‘Stream 1’. In either case the

LED’s indicate which current sampling can/or blending stream is in use. In the case of the sampler,

you would always expect either Receiver 1 or Receiver 2 to be lit; whereas in the case of the

Blender both streams 1 and 2 will often be active at the same time. The given colour is dependent

on the application (Sampler or Blender) and will be explained in the application section of the

manual.

SStatus RGB LED. This lamp is used to indicate what the current status of the controller is. Both the

sampler and the blender have recognised status conditions indicating the current operating

condition of the controller. The given colour is dependent on the application (Sampler or Blender)

and will be explained in the application section of the manual.

TThe up cursor button is primarily used to scroll through the given character set to look for a

required alphanumeric character during data entry and to scroll through the register list. It can also

be used from the front display to turn ‘scrolling’ on and off. Scrolling is described in the display

section.

SECTION 1: INTRODUCTION InSpec Sampler Controller

14

1.3 BASIC OPERATION OF THE INSTRUMENT (START, STOP,

RESET, MANUAL)

The Start, Stop and Reset buttons act in their primary function when the menu is closed and

showing the front display. This allows a batch or blend to be started, stopped or reset quickly from the

front panel. Within the menu they take on their secondary functions of Mode, Cancel and Delete –where

appropriate. The self-explanatory functions of the start, stop and reset buttons are duplicated within the

menu. Selecting the very first ‘Control’ item of the menu (as shown above) will result in the user being

taken down into the control menu where, amongst other commands, the ‘Start’, Stop’ and ‘Reset’

commands are duplicated.

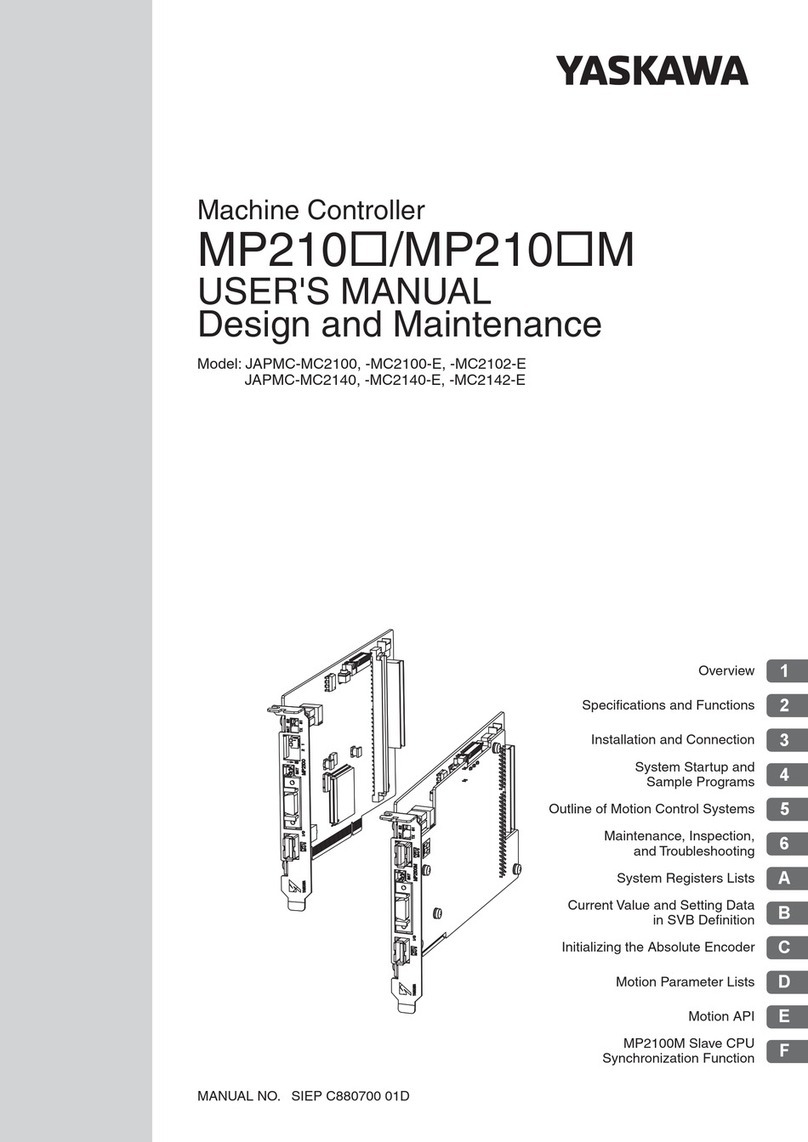

Figure 2 - Control Menu

Within the menu, the operator can also select the ‘Manual’ item to change specific batch

parameters. These available parameters depend on the given application.

The following table briefly summarises the five primary / secondary key buttons

PRIMARY

KEY NAME

SECONDARY

KEY NAME

FUNCTION IN MAIN

DISPLAY

FUNCTION IN MENU

START

MODE

To start the application

Bring up register options

and toggle between

integer and hex entry

modes.

STOP

CANCEL

To stop the application

Cancel out of a menu or

entry mode.

RESET

DELETE

To reset the application

Delete entered

alphanumeric characters

or cancel out of a decision.

ENTER

MENU

Enter the menu from the

front display

Enter menu / select menu

item / confirm values /

confirm control decisions

DOWN

CURSOR

ACK

Acknowledge all active /

unacknowledged alarms

Go down / enter menu

items / scroll down through

alphanumeric characters.

UP

CURSOR

Toggle between scrolling

and non-scrolling on main

display and alarms

Go up / exit menu items /

scroll up through

alphanumeric characters.

InSpec Sampler Controller SECTION 2: COMMON SOFTWARE FEATURES

15

SECTION 2: COMMON SOFTWARE FEATURES

The Jiskoot InSpec is used for Sampling, Blending and Wildstream control applications. As such, many

of the fundamental operating principles are the same regardless of the installed software. This manual will cover

the common features of your controller and an additional manual section will cover the application specific

software that is currently installed on your unit.

2.1 MAIN FEATURES

•Simple user-friendly Web and front panel interface.

•Configurable 'hot-keys' to display key parameters or alarms.

•Standard configurations can be saved and loaded.

•Quick release panel mounting latches and wiring connectors.

2.2 INSPEC SECURITY

Different InSpec menu options are available depending on the logged in user’s current level of security.

A defined user has one of two levels of security access –they will have either operator access or engineer

access. The available configuration and display menus associated with each level of access can be viewed in the

application manual.

By default, a defaulted InSpec controller has 3 defined users. These are:

Jiskoot - The highest level of user access and is reserved for Jiskoot engineering staff only and cannot

be edited or removed.

Operator level access allows minimal access to the menu interface. This access level allows a user to

start batches, change manual batch parameters, view alarms, print batch reports and select files for email etc.

Note that for all levels of security password entry, the character entered for the password will each appear as an

asterisk (*). Upon acceptance, the InSpec will switch into operator level and the menu will change accordingly.

Available options will decrease if you log out from engineer level down to operator level. When the operator mode

is selected from the engineer level, it returns the sampler to the operator security level without prompting for a

password.

IMPORTANT: The default password for the Operator user is 789. For security purposes, you will need to

change this password to prevent undesirable access to the system. Should you ever default the

instrument, the password will revert to the default of 789.

Engineer level allows full access to the menu interface and allows a user to fully operate and configure

the InSpec.

IMPORTANT: The default password for the Engineer user is 456. For security purposes, you will need to

change this password to prevent undesirable access to the system. Should you ever default the

instrument, the password will revert to the default of 789.

2.2.1 COMMON SECURITY MENU ITEMS

LOGIN USER

This option is always available regardless who is currently logged in. If no-one is logged in this

will be the only available option under the security menu. On selecting this item, you will be presented

with a choice of defined usernames. On selecting the desired user, you will then be presented with the

password prompt. On entering a successful password, you will then be logged into the InSpec with the

associated level of security access.

ENTERING A PASSWORD

If the password is entered from the front panel numeric keypad then each number will appear

as the asterisk (*) character. As the numeric keypad is not accessible for the Ex InSpec, you must use

the cursors to enter text as explained below.

Selecting either the up or down key to scroll through and display the numeric characters.

Selecting either the right or the left key will result in moving back/forward one character. When you

move between characters, the previously selected character immediately changes to an asterisk ‘*’. If no

keys are pressed for a second, then the currently selected numeric character on display will also change

to an asterisk. This feature allows passwords to be entered using only the cursor keys.

SECTION 2: COMMON SOFTWARE FEATURES InSpec Sampler Controller

16

LOGOUT

This simply logs out the current user. The only option available then will be the LOGIN USER

option described previously above.

WHO AM I?

This allows quick identification of who is currently logged into the system. It may be useful for

various reasons, e.g., if an unattended InSpec is still logged in you can see who previously logged in.

SECURITY TIMEOUT

Only users logged in with engineer level access can set the security timeout value. If you have

adequate access and select this option, you will be asked whether you want to enable a timeout value

for both an operator and an engineer. If you select yes for either, you will then be prompted to enter the

timeout value in minutes. When this timeout value occurs, the user will be logged out and the only option

then available will be LOGIN USER as described previously above. A user must now log back in to

initiate a batch or make any changes.

The timeout facility is very useful when users with engineering access are configuring the

system. They can then lengthen the timeout period to prevent repeated user logins. For day to day

operation of the InSpec we advise enabling the timeout facility.

ADD USER

Only users logged in with engineer level access can add new users to the InSpec security

system. The process of adding a user involves entering the username, password, level of access

(Operator or Engineer), and their user ID (Note: A user ID can be used to group users together for

notification purposes. E.g., UCL script files can be written to setup email addresses for notification

depending on which user id is currently logged in etc).

The username must be unique. If the user already exists, the process of adding the new user

will be automatically cancelled.

Note: As the numeric keypad is not accessible for the InSpec-Ex, you must use the

cursors to enter text via scrolling through the character sets using the cursor keys. For this

reason, we strongly advise only using numerical passwords on an InSpec-Ex to avoid spending

a long time scrolling through the entire character set looking for specific characters.

Note: Blank passwords are also acceptable. If for whatever reason this is acceptable

within your system. We would naturally suggest you add passwords to enable security.

EDIT USER

All users logged in to the InSpec can access this edit option. Users with engineer access can

edit\delete other engineer accounts but operators can only edit their own account. Operators cannot

change engineer accounts or any other operator’s account. The edit user menu interface allows for the

password, security access level and user id to be changed.

SECURITY TIMEOUT

This item allows a user with Engineer access to enable/disable the menu timeout facility and to

specify the length of the timeout in minutes. This is very useful when users with engineering access are

configuring the system. They can then lengthen the timeout period to work around having to keep log

back in every couple of minutes. For day to day operation of the InSpec we advise enabling the timeout

facility. When the menu time out occurs, it reverts back to the logged out mode. A user must now log

back in to initiate a batch or make any changes.

InSpec Sampler Controller SECTION 2: COMMON SOFTWARE FEATURES

17

2.3 NAVIGATING THE INSPEC DISPLAY

2.3.1 BASIC SCREEN LAYOUT

The InSpec display consists of a 20x2 LCD display. The display operates within several

modes. We will look at each of these briefly. The most common screen that an operator will see during

day-to-day use is the front display screen. This is the default screen shown during operation.

Figure 3 - InSpec Front Display Screen

The above front display shows the current value in the F_FLOW register, the associated flow

units and the current status of the controller is indicated as ‘Waiting’ by ‘WTG’ to the bottom left of the

display. Each application has a set of specific three letter abbreviations for each status condition of the

controller. These abbreviations will be listed and explained in the specific ‘status’ section of your

Sampler / Blender application manual.

In normal display mode, the front display shows one register value and its associated

configurable display title. This is ‘FLOW’ in the above example. There is also a configurable scrolling

feature and, at a user defined time period (in seconds), the screen will scroll through a series of up to

twenty-four defined register values. The scrolling mode can be turned on or off from the front display by

pressing the up cursor button. Items that appear in the scroll list are chosen and set up via the

‘Display→Display Setup→Scroll Setup’ menu item. To enter the menu press either the enter button,

the centre cursor button or the down button. You will see the following display.

Figure 4 - Entering The Menu

On entering the menu, you will see the current depth of the menu listed in the top left hand side

of the menu display. In the above picture number ‘1’ indicates that you are in the first level of the menu.

The X/Y indicator to the right shows that in this level, under current security conditions, there are 4 items

in level ‘1’ of the menu and we are currently on item ‘1’. The arrow indicator to the bottom right of the

display shows that there are more options available to the right which can be accessed using the right

cursor button. A left arrow can also be displayed when there are options to the left of the current

position. Note: The X/Y number indicators will vary depending on which application you are

running and what your current level of security is.

SECTION 2: COMMON SOFTWARE FEATURES InSpec Sampler Controller

18

HINT: When you are at either end of a list of options you can use the left or the right button to

wrap back around the list. In the above example pressing the left cursor button will take you to option 4

of 4 at the other end of the list. This is very helpful when you enter a list of many options and you

already know that the item you wish to select is at the far end of the list. In this case, simply go

backwards instead of forwards to quickly select the required item.

Only an engineer can configure which values can be displayed on the front display. In the

above screen (figure 3) you would first have to navigate to the Security item (4/4) and login as an

Engineer.

The following display shows a menu at greater depth:

Figure 5 - Menu Depths

The top left hand part of the display indicates that this is level 4 of the menu and there are 5

items in this particular sub menu branch. Whenever you are in the menu, pressing either the cancel or

the up cursor button the same number of times as the depth (in this case 4) will bring you back right up

and out of the menu to the front display screen. If you press the cancel key again when you are on the

front display screen it will of course be interpreted as a ‘Stop’ command, however for a stop to occur the

enter key must then be pressed and pressing cancel again aborts the stop. Repeatedly cancelling will

always return you to the front display wherever you are in the menu. If you decide to cancel back out of

the menu whilst you are in the middle of a question or a series of questions, then you may also have to

confirm cancellation of the decision(s) you are in before you are able to cancel right up and out of the

whole menu.

2.4 DATA ENTRY

If the related prompts are enabled the operator will have to enter data at the beginning of a batch/blend.

Data is entered as follows.

2.4.1 NUMERIC ENTRY

There is no difference to the method of entry between numeric and alphanumeric characters.

The only difference is that the character symbols are not available in numeric entry mode.

Figure 6 - Numeric Data Entry

The above example of numeric data entry shows the cursor under the 5th position. Use of

either the up or down button at this location will result in the user scrolling through the available

numerical character set. Selecting the right cursor button will insert the character currently displayed and

the cursor will move along to the 6th position.

InSpec Sampler Controller SECTION 2: COMMON SOFTWARE FEATURES

19

Selecting the left and right cursor buttons within the existing value will result in the cursor

stepping backwards or forwards over existing characters. The up and down cursors can be used within

a value to change a specific digit. For example, you may wish to change the above value of 2000 to

2100. You could step back three positions using the left cursor button and press the up cursor button

once to move from 0 to 1, thus changing the entire value to 2100.

Selecting the delete key (primary function labelled RESET key) will delete the character

preceding the cursor and the cursor will move back one space. Many data entry points will result in the

last entered value being displayed the next time the question is repeated. Deleting every character and

again at the far left of the entered line will result in the original value being re-displayed. This is to help

operators recover a forgotten and accidentally scrambled pre-set. Complicated floating-point numbers

with extended decimal point notation will be hard to remember so this is a very useful escape option!

Selecting the ENTER key will complete the operation and the current value on display will be

written to the associated internal register.

2.4.2 ALPHANUMERIC ENTRY

The principle operations are as above. The only difference being that the available character

set is wider. Strings up to 48 characters can be entered. The screen itself is only 20 characters wide. If

you go beyond 20 characters, arrows →indicating that you are within a longer string are shown on

the top right of the entry screen.

2.4.3 PASSWORD ENTRY

The same data entry screen is used for entering passwords. The difference here is that each

number selected is displayed as an asterisk when you use the numeric keypad to hide the password.

However, the up/down buttons can also be used, and the real numeric values are briefly displayed

before timing out to an asterisk. This was put in for the Ex version where only the cursor keys are

available for data entry.

2.4.4 QUESTIONS & DECISIONS

Both an operator and an engineer will frequently encounter the need to make a decision. The

majority of these are confirmed using the YES/NO dialogue. Alternatively, there is also an ON/OFF

dialogue that behaves in the same manner.

Figure 7 - Examples of decision boxes

Decisions with more than two optional answers appear in list form and can be scrolled through

from left to right using the cursor buttons.

2.4.5 SELECT/ASSIGN KEY

The twelve circular entry keys ‘1’ thru ‘-’are used to represent each of the twelve available

screen display values. As such the following two dialog boxes are shown when you are being prompted

to select or assign a specific display value (1 thru 12). An example of the assign option is shown in the

display section further on.

SECTION 2: COMMON SOFTWARE FEATURES InSpec Sampler Controller

20

Figure 8 - Select & Assign Screens

2.5 REGISTERS

A register is a piece of memory that can be thought of as a location containing a single data item of a

certain type. The registers are stored in memory that is non-volatile so that when the unit is turned off the

contents of the registers remains intact. Registers are used by the system for storing information that must be

remembered, e.g. calibration constants, accumulated volumes, etc. Each register has a unique number and a

descriptive name. The name begins with a character plus an underscore. This prefix character identifies what sort

of register it is (see the types listed below). Some registers are given a default value but can be changed to suit

the particular application. Registers are split into six groups for storing different types of data.

Figure 9 - Register Display Screen

Each register is displayed with its associated number and value. In the above example, register 0 is

shown with its title F_VERSION and value 22.9999 above. The ‘F_’ preceding the name indicates that this is a

floating-point register. The prefixes for each type are:

•F_ →Floating Point Register

•I_ →Integer (Int16) Register

•L_ →Long (Int32) Register

•P_ →Pointer Register

•C_ →Char (Int8) Register

•S_ →String Register (20 characters long)

N: B: If you have previously entered a search pattern, pressing the left or the right cursor button in the

above (figure 6) register screen will invoke the previous search pattern. Otherwise, pressing the left or right

cursor button will bring up the search options as described in the register mode options section below.

2.5.1 REGISTER MODE OPTIONS

Six operations can be performed within the register display. Pressing the Mode (START) button

will bring up a list with the following options.

Set current, description, display, search, view mod add, set mod address.

Table of contents

Other Sensia Controllers manuals