Sensia True-Cut R Series User manual

Manual No. 20165019, Rev. A

Clif Mock

True-Cut R-Series

Sample Receptacles

User Manual

Table of Contents

General Description...................................................................................................1

Installation and Operation..........................................................................................2

Maintenance ..............................................................................................................3

Trouble Shooting........................................................................................................4

Pressure Venting....................................................................................................4

Plugging.................................................................................................................4

© 2004 NuFlo Technologies, Inc. All information contained in this publication is

confidential and proprietary property of NuFlo Technologies, Inc. Any reproduction

or use of these instructions, drawings, or photographs without the express written

permission of an officer of NuFlo Technologies, Inc. is forbidden.

All Rights Reserved.

Printed in the United States of America.

Manual No. 20165019, Rev. A

July 2004

July 2004 1 M20-3 Mixing System

General Description

The R-Series receptacle provides for the safe, convenient storage and transportation of

samples collected from the customer's pipeline. When an R-Series receptacle is used in

combination with the Clif Mock M20-3 Mixing System, a sample can be collected,

transported to a testing laboratory, and mixed in the same receptacle. The 304 stainless steel

(316 optional) tank assembly, which is rated for 100-psi maximum pressure, inserts directly

into the M20-3 Mixing System and serves as a mixing reservoir. The ability to collect,

transport, and mix a sample in one reservoir eliminates water loss and helps to prevent light

ends during transfers.

In addition to allowing direct hook-up to the sample probe, the R-Series receptacle is equipped with a

carrying handle for transporting the contents to a laboratory for analysis. The R-Series receptacle is

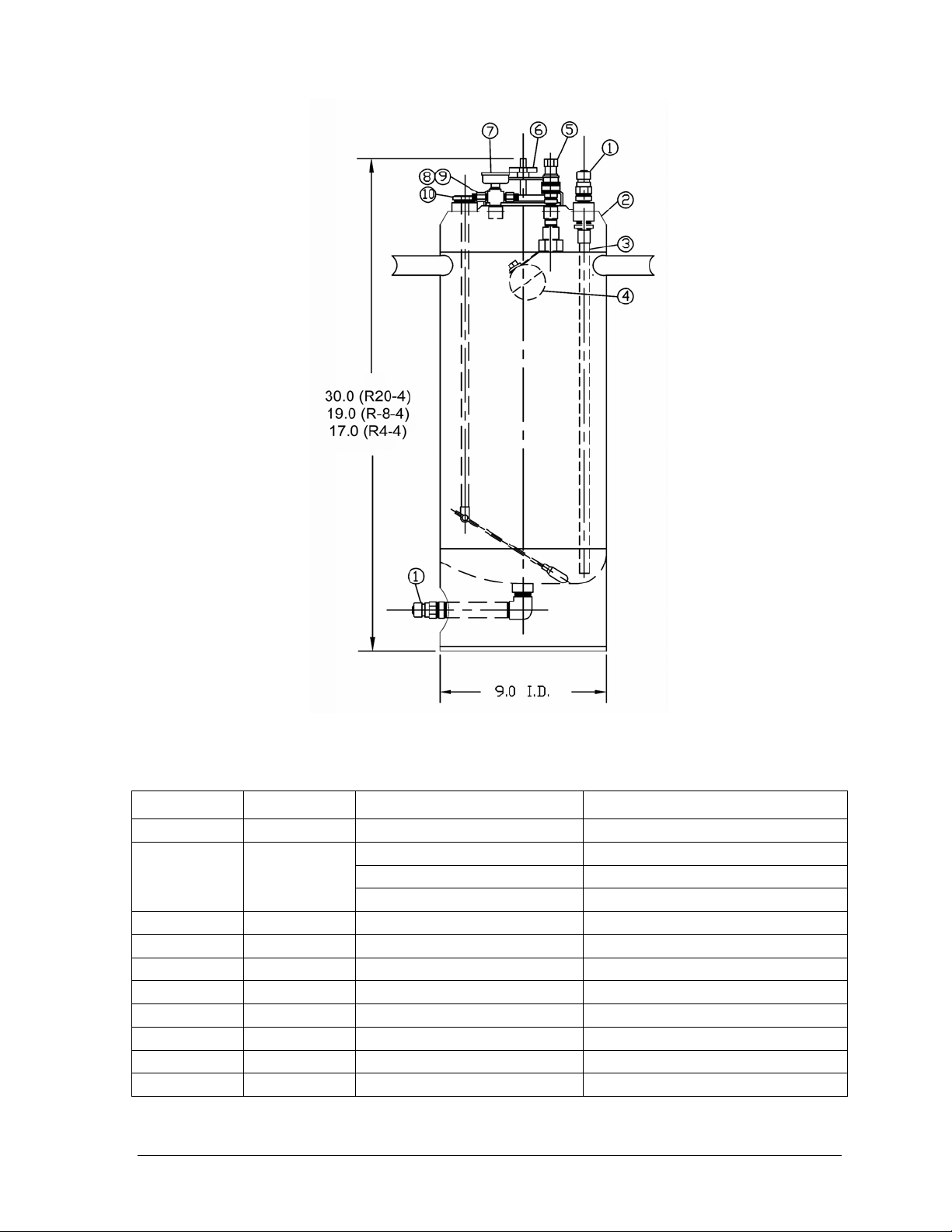

avaialble in three sizes (Figure 1):

•R4-4 (1-gallon capacity)

•R8-4 (2-gallon capacity)

•R20-4 (5-gallon capacity)

Figure 1—R-Series portable receptacles (from left): R20-4 (5 gallons), R8-4 (2 gallons),

and R4-4 (1 gallon).

M20-3 Mixing System 2 July 2004

Components of the R-Series receptacles include:

•a 316 stainless steel pressure-relief valve fixed at 5 psi

•a 316 stainless steel vacuum relief valve fixed at 1 psi

•a 316 stainless steel ¼-in. MNPT ×¼-in. MNPT manual vent valve

•a sample inlet ½-in. FQD nozzle

•a 0-to-60 back MTD 1/8-in. NPT pressure gauge

•a high level shut-off assembly to prevent overfilling

•a ¾-in. FQD nozzle (mixing discharge)

•a ¾-in. FQD nozzle (suction)

Installation and Operation

Use the following procedure to collect and transport a sample from the field to a laboratory.

1. Connect the sample fill line from the sample probe to the ½-in. sample inlet connection at

the top of the receptacle via a shut-off valve (supplied by customer).

2. Start the drive motor on the sample probe.

3. After the sample is taken, stop the drive motor on the sample probe.

4. Close the shut-off valve.

5. Uncouple the fill line from the receptacle and cover the inlet with a dust cover.

6. Transport the receptacle to the laboratory.

7. Empty the sample from the receptacle via the ¾-in. FQD connection at the base of the

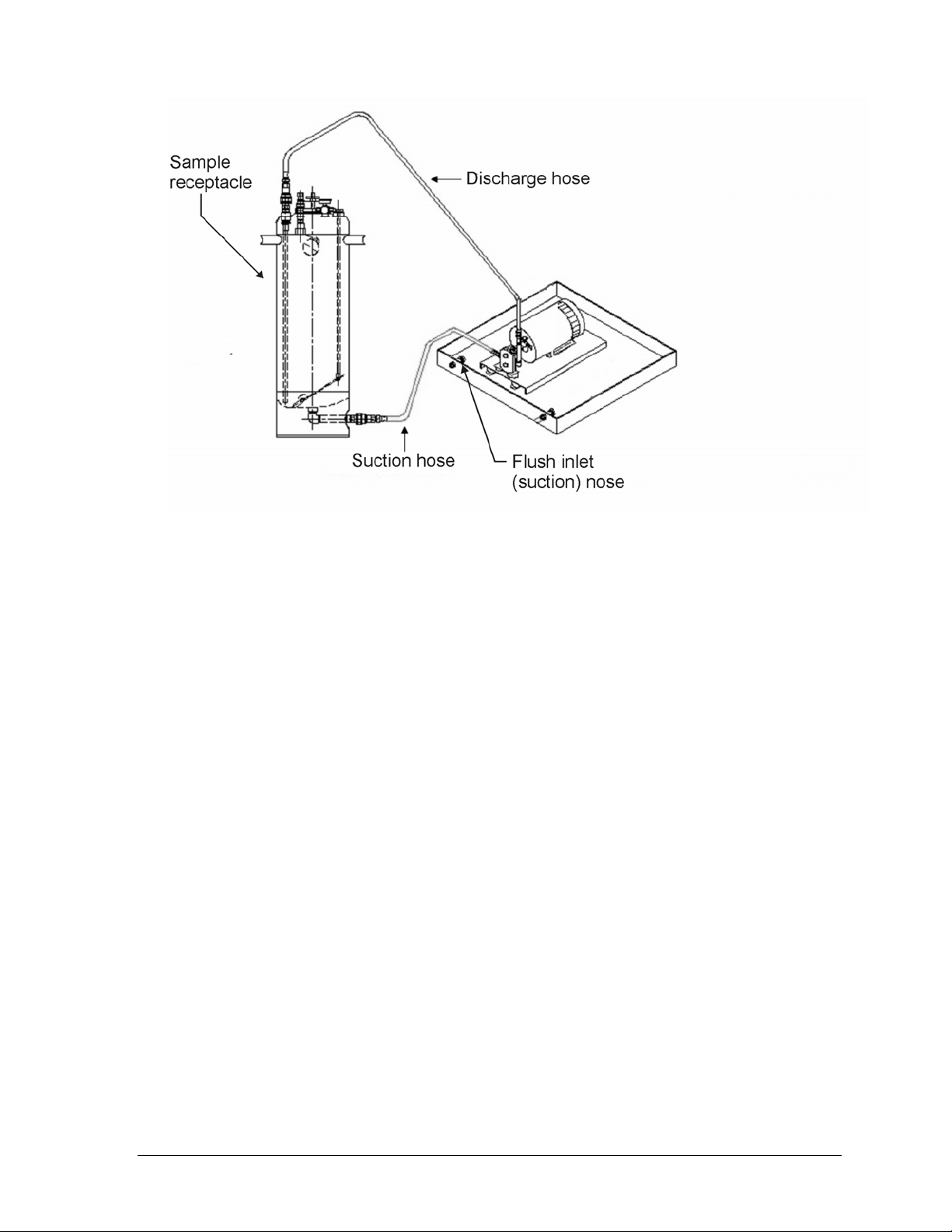

receptacle, or connect the receptacle to the M20-3 mixing system (Figure 2). Detailed

instructions for mixing a sample are provided in the M20-3 Mixing System manual.

July 2004 3 M20-3 Mixing System

Figure 2—Hose connections for mixing a sample inside the receptacle with the M20-3

mixing system

Maintenance

Perform the following maintenance after each use of the R-Series receptacle.

1. After all the sampled liquid is withdrawn from the receptacle, clean the receptacle tank,

the inlet, and the discharge with a solvent to prevent contamination of subsequent

samples.

2. After the sample has been drained from the receptacle, inject the cleaning solvent through

the fill line to clean the line, the sample inlet, and the high level shut-off.

3. Remove the lid from the receptacle. Taking care not to damage the high level shut-off

assembly, wash the inside of the receptacle with the solvent. Flush the solvent through

the 3/4-in. FQD connection at the base of the receptacle.

4. Dry the inside of the tank.

M20-3 Mixing System 4 July 2004

Trouble Shooting

Pressure Venting

If the high level shut-off has stopped the flow to the receptacle and the pressure gauge does

not return to "0" psi when the manual valve is opened, use extreme caution in opening the

lid. The valve may be plugged or the gauge may be defective, and the receptacle may still be

pressurized.

•If pressure escapes from the receptacle, the manual vent valve is faulty and must be

replaced.

•If there is no noticeable pressure escape, the pressure gauge is faulty and must be

replaced.

Plugging

If the sample from the pipeline is not accumulating in the receptacle, check the following

areas for possible plugging.

•Sample Probe. If there is no sample discharge when the fill line is removed from the

sample probe, remove the probe and clean it. Refer to the repair procedure for the

appropriate sample probe.

•Fill Line. If there is no sample discharge when the fill line is disconnected from the

quick disconnect coupling, remove the fill line from the sample probe. If there is

sample discharge at this point, the fill line is plugged; take steps to clean or replace it.

•Sample Inlet Nozzle. If there is no sample discharge when the quick disconnect

assembly is removed from the receptacle lid, disconnect the fill line from the

coupling. If there is sample discharge at this point, the sample inlet nozzle (quick

disconnect nose and/or coupling) is plugged; take steps to clean or replace it.

•High Level Shut-Off. Stop the drive motor on the sample probe and open the manual

vent valve to release pressure. Detach the ½ in. quick disconnect nose from the

receptacle lid and unscrew the lid from the tank. Reconnect the ½-in. quick

disconnect nose to the receptacle lid. Start the sample probe drive motor and watch for

sample discharge.

If the sample is not being discharged, remove the quick disconnect coupling, unscrew the

nose from the receptacle lid, and insert the nose back into the quick disconnect coupling. If

sample is discharged from the nose, disassemble the high level shut-off assembly and clean it.

July 2004 5 M20-3 Mixing System

BILL OF MATERIALS

ITEM QTY PART NO. DESCRIPTION

1 2 50142310075 ¾” Nose, QD

50142733002 R4-4 Tank, 304 SS

50142381872 R8-4 Tank, 304 SS

2 1

(select from

3 sizes) 50142381770 R20-4 Tank, 304SS

3 1 50142302204 Downcomer, Tube 1.2”, SS

4 1 50142311046 High Level Shut-off

5 1 50142310079 ½” Coupler, QD

6 Vacuum Lid

7 1 50142381040 Gauge, 0-60 psi, SS

8 1 50142200334 Pressure Relief Valve, 5 psi

9 1 50142303543 Vacuum Relief Valve, 1 psi

10 1 50142310029 Level Gauge

M20-3 Mixing System 6 July 2004

WARRANTY - LIMITATION OF LIABILITY: Seller warrants only title to the products,

software, supplies and materials and that, except as to software, the same are free from

defects in workmanship and materials for a period of one (1) year from the date of delivery.

Seller does not warranty that software is free from error or that software will run in an

uninterrupted fashion. Seller provides all software "as is". THERE ARE NO WARRANTIES,

EXPRESS OR IMPLIED, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE WHICH EXTEND BEYOND THOSE STATED IN THE

IMMEDIATELY PRECEDING SENTENCE. Seller's liability and Buyer's exclusive remedy in

any case of action (whether in contract, tort, breach of warranty or otherwise) arising out of

the sale or use of any products, software, supplies, or materials is expressly limited to the

replacement of such products, software, supplies, or materials on their return to Seller or, at

Seller's option, to the allowance to the customer of credit for the cost of such items. In no

event shall Seller be liable for special, incidental, indirect, punitive or consequential damages.

Seller does not warrant in any way products, software, supplies and materials not

manufactured by Seller, and such will be sold only with the warranties that are given by the

manufacturer thereof. Seller will pass only through to its purchaser of such items the

warranty granted to it by the manufacturer.

Table of contents