Sensor Therm Regulus RD User manual

PID Program Controller

Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

User Manual

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Content

2

Content

1General...............................................................................................................................................3

1.1 Information to this Manual.........................................................................................................3

1.2 CE Conformity...........................................................................................................................3

1.3 Limitation of Liability..................................................................................................................3

1.4 Terms of Warranty ....................................................................................................................3

1.5 Copyright...................................................................................................................................3

1.6 Explanation of Symbols ............................................................................................................4

1.7 Disposal ....................................................................................................................................4

1.8 Intended Use.............................................................................................................................4

1.9 Scope of Delivery......................................................................................................................4

2Safety..................................................................................................................................................5

2.1 General .....................................................................................................................................5

2.2 Electrical Connection................................................................................................................5

2.3 Use of a Pyrometer with Laser Targeting Light ........................................................................5

2.4 Secure start / Enable Front Panel Start....................................................................................5

2.5 Responsibility of the Operators.................................................................................................5

3Electrical Connection........................................................................................................................6

3.1 Pin Assignment.........................................................................................................................6

3.1.1 Thermocouple Types -K and -S...........................................................................................9

3.1.2 Digital Inputs ........................................................................................................................9

3.1.3 Digital Outputs ...................................................................................................................10

3.1.4 Analog Outputs..................................................................................................................11

4Commissioning ...............................................................................................................................11

4.1 Operation Modes ....................................................................................................................11

5SensorTools Software ....................................................................................................................12

5.1 Installation...............................................................................................................................12

1.1 Program Start..........................................................................................................................12

5.1.1 Connecting the Regulus ....................................................................................................12

5.2 General Settings .....................................................................................................................13

5.2.1 Select / Combine Measuring Devices................................................................................13

5.2.2 Pyrometer Alignment .........................................................................................................15

5.2.3 Device Configuration .........................................................................................................15

5.2.4 Start a Control Process in Manual Mode...........................................................................19

5.2.5 Create Program Sequences ..............................................................................................21

5.3 Starting a Program..................................................................................................................24

5.4 Graphical Display / Data Recording........................................................................................25

5.4.1 Data Playback....................................................................................................................27

5.5 Communication / Options........................................................................................................28

5.6 Spot Size Calculator ...............................................................................................................28

6Device Handling ..............................................................................................................................29

6.1 Menu Settings.........................................................................................................................30

6.1.1 Status Messages / Error Codes.........................................................................................32

7Technical Data.................................................................................................................................33

8Communication via Serial Interface / Interface Commands .......................................................34

Index.........................................................................................................................................................38

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

General

3

1 General

1.1 Information to this Manual

This manual enables the safe and efficient use with the device. The manual is part of the instrument and

has to be kept in a location where users of the controller always have access to.

Read this manual carefully before operating. For secure working all security notes and operation proce-

dures in this manual has to be followed.

Additionally the local accident prevention regulations and common safety regulations of the instruments’

operational area are valid.

The descriptions may differ from the current delivery status, since the pyrometer is continuously devel-

oped. Illustrations in this manual are for basic understanding and can differ from the actual construction.

1.2 CE Conformity

The product conforms to the following standards:

CE conformity: DIN EN 61326-1 (electromagnetic compatibility)

RoHS: 2011/65/EU

1.3 Limitation of Liability

All information and notes in this manual are made under consideration of valid standards and rules,

state of technology and our expert knowledge for many years.

The producer assume no liability for damages due to:

Non-observance of this manual

Usage out of intended use

Assignment of unskilled personnel

Unauthorized modifications

Technical modifications

Usage of spare parts not approved

The responsibilities of the delivery contract are valid as well as our general terms and conditions and

terms of delivery and the valid statutory rule at date of the conclusion of contract.

1.4 Terms of Warranty

A warranty period is 24 months from date of shipment form the Sensortherm facility. The seller will re-

pair or replace the device at its own discretion. Further claims of the buyer against the seller or its

agents are excluded, especially claims for damages that are not incurred in the delivery itself. This shall

not apply in cases of intent, gross negligence, or the absence of assured properties. Damage or misuse

of the product will be determined and void the warranty coverage. Repairs paid by the customer will in-

clude a 180 days warranty from date of shipment. Transportation costs are to be paid by the customer.

Any claims for damage caused by misuse, neglect or tampering with the sensor are excluded.

1.5 Copyright

This manual is protected by copyrights and are intended solely for internal purposes.

It is not permitted to transfer these instructions to third parties, duplication in any kind and form - includ-

ing excerpts - as well as recovery and / or notification of contents without written permission of the man-

ufacturer, except are internal purposes.

Contraventions are liable for damages. All other rights reserved.

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

General

4

1.6 Explanation of Symbols

The following symbols are used in this manual for restrictions, preventive measures and security notes.

Please pay attention to this symbols for safety reasons.

WARNING: This combination of symbol and signal word indicates a potentially dangerous

situation that can lead to death or serious injury if not avoided.

CAUTION: This combination of symbol and signal word indicates a potentially dangerous

situation that can result in minor or moderate injury if not avoided.

CAUTION, LASER RADIATION: This combination of laser radiation symbol and signal

word indicates the dangers of a laser targeting light.

NOTE: This combination of symbol and signal word indicates a potentially hazardous situa-

tion that can lead to property and environmental damage if not avoided.

INFO: This symbol indicates useful tips, recommendations and information for efficient and

trouble free operation.

1.7 Disposal

Dispose of the product properly when it is no longer usable: pyrometers include electrical and electronic

waste and have to be recycled or disposed environmentally friendly or to send to the manufacturer for

disposal.

1.8 Intended Use

The Regulus RD is a programmable PID temperature controller in table housing. It is optimized for use

with one or two Sensortherm pyrometers as temperature sensor. A second pyrometer can be used for a

second measurement point or to enlarge the overall temperature range when using 2 different ranges.

Types RDS and RDK are additionally equipped with a connection of a thermocouple probe type S or K

(Pt10Rh-Pt, temperature range 0-1750°C or NiCr-Ni, temperature range 0-1300°C), types RDSK, RDKK

or RDSS with 2 thermocouples. Selecting a pyrometer and a temperature probe with different tempera-

ture ranges enables e.g. operation of temperature recording with a pyrometer after temperature probe

recording. This enables a temperature control with a very long temperature range.

Operating the Regulus with a temperature sensor of other manufacturers is only possible via the analog

4-20 mA input.

1.9 Scope of Delivery

Regulus program controller in table housing

4 plug connectors for sensors and electrical connections, inputs/outputs and 2 for relays contacts, 1

USB cable

Software SensorTools

Info: Connection cables are not included in scope of delivery and have to be ordered separately.

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Safety

5

2 Safety

2.1 General

Any person who is tasked to carry out work with the device must have read and understood the operat-

ing instructions before beginning. Operation and maintenance of the system may only be performed by

trained personnel.

2.2 Electrical Connection

When connecting or when working on the mains voltage, the general safety guidelines are observed,

e.g. when connecting power transformers. Supply voltage can be lethal when touching. Improper instal-

lation can cause serious injury or physical damage. Only qualified personnel are allowed to work with

mains voltage.

2.3 Use of a Pyrometer with Laser Targeting Light

For easy alignment, the pyrometers may be equipped with a laser targeting light, laser class 2 (accord-

ing to IEC 60825-1-3-4) and has a sticker shown on the right. The laser emits a visible red light with a

maximum power of < 1 mW and a wavelength around 650 nm.

Safety precautions:

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, the eyes must be intentional-

ly closed and the head immediately moved out of the

beam.

2.4 Secure start / Enable Front Panel Start

In factory settings the device is set to secure start (“Enable front panel start”). This means the “controller

start” function of the Regulus can only be activated if an additional push button (must also be connect-

ed) is pressed. The function is helpful to prevent an accidentally controller start after changing a setting.

The button has to be connected to one of the digital inputs and activated via software menu (digital in-

puts). Deactivation is possible but not recommended (see 3.1 Pin Assignment).

2.5 Responsibility of the Operators

If the device is used in the commercial sector the operator is subject to the legal responsibilities for

workplace safety.

In addition to the safety instructions in this manual follow the regulations of safety, accident prevention

and environmental protection.

Laser

beam

direction

Laser warning label

on the device

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Electrical Connection

6

3 Electrical Connection

3.1 Pin Assignment

*)Note connector code: All connectors are coded (red plastic pins) to prevent accidentally inter-

change with other connectors.

Plug Connectors (Manufacturer Phönix Contact)

X1 to X4

Printed-circuit board connector type MC 1,5/12-STF-3,8 Ref.-No. 18 27 800

Cable housing type KGG-MC 1,5/12 Ref.-No. 18 34 440

X5 to X6

Printed-circuit board connector type MSTB 2,5/6-STF Ref.-No. 17 86 873

Cable housing type KGG-MSTB 2,5/6 Ref.-No. 18 03 905

Connectors X1 (Sensortherm pyrometer / external Sensor A) and

X2 (Sensortherm pyrometer / external Sensor B):

Pins

X1

Pins

X2

Function

Cable colors

Sensortherm

pyrometers

1

13

+24 V power supply for pyrometer / external sensor A or B

White

2

14

0 V power supply for pyrometer / external sensor A or B (GND1)

Brown

3

15

+I Analog input (4-20 mA) from sensor / pyrometer

Green

4

16

–I Analog input (4-20 mA) from sensor / pyrometer (GND1)

Yellow

5

17

Not connected

(Grey)

6

18

Not connected

(Pink)

7

19

Shield

Orange *)

8

20

Ground for digital interface RS232/RS485 to external sensor A

(GND1)

Red

9

21

TxD/D+/A for RS232/RS485 to external sensor A or B

Black

10

22

RxD/D-/B for RS232/RS485 to external sensor A or B

Violet

11

23

TxD/D+/A for RS232/RS485 to external sensor A or B

Grey-pink

12

24

RxD/D-/B for RS232/RS485 to external sensor A or B

Red-blue

*)Shield connection of a Sensortherm pyrometer: Only connect the pyrometer to system ground,

the orange shield cable is not connected to the Regulus to prevent ground loops and stray electric

currents.

X8: USB to PC

External sensor X1

External sensor X2

X7: RS232

X9: 24 V power supply

Ground

X10+11: Thermocou-

ple connectors

X5+6: Relays outputs

X3+4: Digital inputs /

control output

Pin 13...........24

Pins 1...........12

Pin 37...........48

Pin 25...........36

Pin 55....60

Pin 49....54

Connector codes *)

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Electrical Connection

7

Regulus

25

...

30

45

>10 kOhm

0 V

+24 V

Input A-F

Switch or push

button, see 3.1.2

Digital Inputs

0 V

+24 V

44 *)

31 *)

Regulus

34

35

36

Internal resistance

0–5 V

0–10 V

V

A

48

Galvanically isolated

from the power supply

0–20 mA

4–20 mA

Setpoint setting

via external

voltage 0–10 V

2 kΩ

Regulus

31

32

33

Internal resistance

40 kΩ

0 V

+10 V reference voltage

(only devices up to SN 1426)

Setpoint

setting via

potentiometer

Voltage

supply

from SN 1427:

+10 V externally

Connector X3 –Digital Inputs / External Setpoint Settings/ Control Output

Pin

Function

25

+ Digital input A

26

+ Digital input B

27

+ Digital input C

28

+ Digital input D

29

+ Digital input E

30

+ Digital input F

The inputs are activated with +24 V (can be taken from the power supply or connected externally).

*)Devices up to serial number 1426, these 24 V are available at pin 44

*)Devices up to serial number 1426, these 24 V are available at pin 31

When using an external voltage, 0 V (ground power supply, Pin 45) must be used as a reference

point.

44 *)

Up to SN 1426: 24 V (parallel to power supply connector X9) for digital inputs

31 *)

From SN 1427: 24 V (parallel to power supply connector X9) for digital inputs

NOTE to “enable front panel start”:

One digital input can be selected for the function “Enable front panel start” (see settings in 3.1.2

Digital Inputs and Software 5.4 Device configuration). This security function avoids the

accidentally start of the controller due to an additional push button which has to be pressed to-

gether with the “Start” button on the controller. A permanent connection of +24 V (pin 31 or 44)

to the desired output deactivates the function (on your own risk, not recommended).

31

Only devices up to SN 1426:

+10 V reference voltage output

32

0–10 V analog input for exter-

nal control of the reference

value with potentiometer *

33

Ground for 0–10 V analog input

for ext. control of the reference

value with potentiometer

(GND1)

Note: External setpoint setting with external voltage or potentiometer: In manual mode the refer-

ence value can be adjusted via external voltage 0–10 V.

For devices up to serial number 1426, this voltage can e.g. can be taken from the 10 V reference

voltage output (pin 31) and a 2 kOhm potentiometer (as a voltage divider to pins 31-33, the internal

resistance of the input is 40 kOhm).

From serial number 1427 this connection has 24 V for use with the digital inputs, therefore a 10 V

reference voltage must be provided externally.

34

0–20 mA or 4–20 mA

analog control output

35

0–5 V or 0–10 V

analog control output

36

Ground for pin 34 and Pin 35

(GND3)

Outputs selectable via software, see 5.4.

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Electrical Connection

8

Regulus

44

45

Output

Max. 100 mA

0 V

+24 V

100 kΩ

Min. 240 Ω

37

...

43

Regulus

46

47

48

Internal resistance

0–5 V

0–10 V

0–20 mA

4–20 mA

V

A

36

Galvanically isolated

from the power supply

Connector X4 –Digital Outputs / Actual Value Output

Pin

Function

37

+ Output A

38

+ Output B

39

+ Output C

40

+ Output D

41

+ Output E

42

+ Output F

43

+ Output G

44

+24 V power supply (connected parallel to power supply connector X9)

e.g for supply the Regulus when the power supply input should not be used.

45

Ground for power supply (is parallel to the power supply input X9) (GND1)

46

0–20 mA or 4–20 mA

analog actual value output

47

0–5 V or 0–10 V

analog actual value output

48

Ground for pin 46 and pin 47 (GND3)

Outputs selectable via software (see 5.4)

Connectors X5 + X6 –Relays Contacts

X5 and X6 are 4 relay changeover contacts (230 V, 6 A), switched from the outputs A-D.

Pin

Function

X5

49

Center of relays contact RC1

50

RC 1: Pins 49-50 closed at inactive output A

51

RC 1: ins 49-51 closed at active output A

52

Center of relays contact RC2

53

RC 2: Pins 52-53 closed at inactive output B

54

RC 2: Pins 52-54 closed at active output B

X6

55

Center of relays contact RC3

56

RC 3: Pins 55-56 closed at inactive output C

57

RC 3: Pi Pins 55-57 closed at active output C

58

Center of relays contact RC4

59

RC 4: Pins 58-59 closed at inactive output D

60

RC 4: Pins 58-60 closed at active output D

Connector X7 –PC Interface

Pin

Function

2

RS232 PC RxD / RS485 PC D-

3

RS232 PC TxD / RS485 PC D+

5

Ground for interface (GND2)

1

2

RC

49 50 51 52 53 54

3

4

RC

55 56 57 58 59 60

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Electrical Connection

9

3.1.1 Thermocouple Types -K and -S

Please consider the special characteristics of thermocouples if the device is equipped with correspond-

ing connectors. Thermocouple probes are sensitive against temperature variation. Using a Regulus and

a thermocouple with different device temperatures can induce a failure current that results in a tempera-

ture display different of the effective temperature.

Always ensure that temperatures of thermocouple and Regulus are the same to achieve a correct tem-

perature result. Wait a certain time after storage or transport the Regulus and a thermocouple in differ-

ent temperature environments before correct temperature measurement can be achieved. Depending

on the temperature deviations a wait time of 15 to 60 minutes is recommended.

Reduce interference: Induction systems

may cause interferences to the temperature

measured with a thermocouple. To reduce

this, the inductor and the heated object

must be connected to the earth terminal on

the back of the Regulus with a ground wire

of at least 4 mm².

3.1.2 Digital Inputs

The instrument is equipped with 6 digital inputs to operate the instrument

partially extern. Every input can be assigned to one of these functions (see

Software 5.4 Device configuration).

24 V has to be connected either with a push button or switch to an input to

activate its function (see under 3.1 Connector X3).

Start / Stop controller (push button):

Every trigger starts or stops the controller in turn.

Activate controller (switch):

Controller is active as long as input signal is active (24 V to the desired pin).

Emergency stop (switch):

Controller is active if 24 V is set. Without voltage input controller is deactivated, all outputs will be set

to 0 V or 0 mA (safe condition).

Reset error (push button):

Resets the controller in case of a device error. The controller tries to continue operation.

Program step trigger (push button):

In program mode the next program step can be selected.

Enable front panel start (push button):Front panel can only be done with additionally connected

and pressed push button (see 3.1 Pin Assignment Connector X3). The input for this function can

be selected. Stop function on front panel is always executable.

INFO:

Enable front panel start is a security setting to prevent an accidentally controller start.

Deactivation is possible but not recommended.

External program selection (switch), (only inputs A - E): allows the external selection of the manual

mode or a program. The inputs are binary coded, i.e.:

- With a digital input only a program or "Manual" can be activated. With 2 inputs are 3 programs

available, with 3 inputs 7 programs with 4 inputs and 15 programs with 5 inputs, all 26 programs

are available.

At all combinations not listed, "manual" is activated.

Selectable functions:

Induction system

Regulus

Thermocouple

Ground wire min. 4 mm²

Earth terminal

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Electrical Connection

10

Activated

program

Digital Input

(1 = input active)

Program

to activate

Digital Input

(1 = input active)

Activated

program

Digital Input

(1 = input active)

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

Manual

0

0

0

0

0

9

1

0

0

1

0

18

0

1

0

0

1

1

1

0

0

0

0

10

0

1

0

1

0

19

1

1

0

0

1

2

0

1

0

0

0

11

1

1

0

1

0

20

0

0

1

0

1

3

1

1

0

0

0

12

0

0

1

1

0

21

1

0

1

0

1

4

0

0

1

0

0

13

1

0

1

1

0

22

0

1

1

0

1

5

1

0

1

0

0

14

0

1

1

1

0

23

1

1

1

0

1

6

0

1

1

0

0

15

1

1

1

1

0

24

0

0

0

1

1

7

1

1

1

0

0

16

0

0

0

0

1

25

1

0

0

1

1

8

0

0

0

1

0

17

1

0

0

0

1

26

0

1

0

1

1

3.1.3 Digital Outputs

The instrument is equipped with 7 digital outputs. Via software every out-

put can be assigned to different functions (see 5.4 Device configuration)

The state of the digital outputs can be adjusted:

NO (normally open): outputs have in active state 24 volts to the pins and

in inactive state 0 V (output max. 100 mA, load min. 300 Ω).

NC (normally closed): outputs have in active state 0 volts to the pins

and in inactive state 24 V (output max. 100 mA, load min. 300 Ω).

Additionally a verification time and hold time in ms can be set (see 5.4 De-

vice configuration):

The verification time defines how long an event is active until the out-

put is activated (for example, the temperature is exceeded).

The hold time defines the time how long the output is hold at least. This feature is useful e.g. if a

PLC error signal requires a signal time of at least 10 ms for a proper recognition.

Selectable Functions

No function

Output is always set to logic 0

Limit value output

If activated a temperature value can be entered from where a contact has to be active (LEDs on the

Regulus show the active state. Additionally outputs A-D are switching the relays). The hysteresis is

the value at how many degree below the limit value the output is switched back. Additionally it can be

selected if the contact is active with exceeding the temperature value or if the contact is inactive (logic

NO or NC).

Message controller active

Output is active if controller is active (in manual mode, program mode or open loop mode).

Message controller ready

Activates the output if a pyrometer or thermocouple is found or the analog input detects a 4 mA signal

(indicates that without connection error the controller is ready to use).

Setpoint limit 1 / Setpoint limit 2

The setpoint limit is a limit temperature above or

below the setpoint temperature that should not

exceeded or to be below. Two setpoints can be

defined. The output is activated if the measured

value exceeds the defined setpoint value. The

output is also activated if the measured value

falls below the defined value. Entry of the set-

point value has to be done relative to the set-

point, positive or negative, e.g. 20°C if the setpoint value is 800°C and the output should be active at

820°C.

Example

Setpoint limit 1

Setpoint band

Setpoint limit 2

Measured value

Selectable functions:

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

Commissioning

11

Setpoint band

The setpoint band is composed of the 2 setpoint limits and defines a range within the temperature

has to be. The output is activated if the measured value is outside the defined value.

Control of generator

Allows to enter generator-specific settings for shutdown the generator if the control output falls below

a limit value and reclosing (see under 5.4 Device configuration control of generator).

Message error

Output is active in case of an device error (see 6.2.1 Status Messages / Error codes)

Message control successful

Output is active if control process is finished:

- in manual control: if ramp time and/or hold time is finished

- program mode: if the complete program is executed (with all optional replays)

Note: The output signal is not set if a new controller start is faster than an adjusted verification time.

Control of heating process (belongs to "peak detection“, see under 5.4.2 Create Program Se-

quences Peak detection): Activates the output during the verifying period.

State of input A (not selectable on output G): Detects the state of input A and activates the output

accordingly.

3.1.4 Analog Outputs

2 analog outputs are available:

Control output: According to the requirements the control output can be set to

0-20 mA, 4-20 mA, 0-10 V, 0-5 V or 10 V PWM mode.

Actual value output: According to the requirements the actual value output can be set to

0-20 mA, 4-20 mA, 0-10 V, 0-5 V.

4 Commissioning

4.1 Operation Modes

Different operation modes can be executed with the Regulus (further explanations are to find in the cor-

responding sections of the software descriptions):

Manual mode

In manual mode an actual value and the required PID parameters are set.

Manual mode can be started directly on the device, per remote push button or via software.

Program controlled

When operating as a program controller, the controller starts predefined program sequences created

via software. Up to 26 programs with a maximum of 256 steps each can be created (limitation: pro-

grams + steps max. 990).

A program start can be done via software or directly on the Regulus. Programming itself only can be

done via software SensorTools.

Open loop mode

Starts a control process without feedback from a connected sensor. Anyway, a pyrometer or sensor

can be used to display the current measuring temperature.

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

12

5 SensorTools Software

5.1 Installation

With the minimum requirements devices can be connect and configured. When capturing or recording

data, the performance is potentially impaired, that is errors or interruptions in data transfer can occur.

With the recommended requirements all software features should be fully available.

Min. system requirement: Pentium IV processor with min. 1.6 GHz and 2 GB RAM

20 MB hard drive capacity for the program

RS232 or RS485 interface or USB2 (use of an RS232 or RS485 to USB in-

terface converter is required)

Recommended: i7 multi-core processor with 3 GHz and 16 GB RAM

20 MB hard drive capacity for the program

RS485 interface

Screen resolution min. 1024x768

Operation system: Windows Vista Ultimate, 7, 8, 8.1, 10

To install, start the setup program. It can be found on the supplied CD or can be downloaded from

sensortherm.de/en/download-section. If the setup program is on USB stick, it should be copied first to

hard disk.

Follow the on-screen instructions

INFO: There are regularly provided software and firmware upgrades available that add function-

ality or fix bugs. It is recommended always to install the latest software and firmware (available

on the home page in the download area under www.sensortherm.de/en/download-section).

In SensorTools can be checked to a new version, see 5.7).

5.2 Program Start

Starting the software opens

the main window of the pro-

gram. The Regulus is not con-

nected automatically.

5.2.1 Connecting the Regulus

For successful communication with the Regulus it has to be connected first. The status line on bottom of

the software window shows the current connection status:

Select the computer’s com port the device is connected to. Also a COM port must be

selected when connecting via an USB converter.

Note: Ensure the interface used at the PC is selected on the Regulus. If necessary

change the setting directly at the Regulus, changing via software is not possible (see

6.2 Menu setting <COM Interface > RS).

Press the search button if the com port is unknown. The Regulus will be connected

automatically if the port is found.

Press the connect button to connect the Regulus to the software. All controller set-

tings and programs will be read out and displayed in the software.

The button changes to “Diconnect” when connected. Click to disconnect.

The status line informs about device and connection status.

A detected Regulus shows temperature information, the type of operation mode and a (preset) setpoint.

Follow the instruction to setup the Regulus.

INFO: a Regulus connected to the software has blocked push buttons.

"Keylock" appears when pressing a key.

Select PC

interface

or search

automatically

Connect with

software

Status line

Homepage link

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

13

Software Window –Overview

5.3 General Settings

5.3.1 Select / Combine Measuring Devices

The connected pyrometer(s) or temperature probes have to be selected and configured be-

fore temperature measurement is successful.

Select connected

measuring devices

Combine multiple

measuring devices

and set as selection

to be used for meas-

urements later

Measurement data

and information field

Operating mode

(manual mode /

program selection))

Direct access to

control parameters in

manual mode

Controller start /stop

Device configuration

Create control programs

Select / combine

measuring devices

Main window

Control window

Graph window for displaying measurement and control data

Time axis settings

Tempera-

ture scale

Time axis

(current

time)

Data recording, data

recording settings, data

playback

Information to sample time

and control time

Select display graphs

(right click to change the

color settings of the

graph), activates or deac-

tivates graphs

Control value scale

Measuring temperature or

underflow / overflow of

sensor‘s temperature range

Setpoint temperature in

manual mode or

program selection

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

14

A Sensortherm pyrometer (digital sampled) is connected via serial interface and the temperature

range is automatically read out.

A Sensortherm pyrometer (analog sampled) is connected via serial interface and analog input, but

the analog output of the pyrometer used as signal transmitter. This connection can be selected if a

very rapid evaluation is necessary which does not work via interface, for example, at long interface

cables or when using high-speed pyrometers.

"Sensor settings" is used to configure pyrometer settings

For analog sampled devices the current output and temperature range must be set. The Regulus

can handle temperature ranges from 0-3300°C, the entered “temperature range” is the range of the

analog output range.

Thermocouples are available depending on the model.

At measurement errors, the temperature curve can be provided with an

offset.

Combine measuring devices:

All connected measuring devices can be combined as a unit and a transfer temperature are defined.

Two measuring devices can measure sequentially, for example, a thermocouple for the lower tem-

perature range and a pyrometer for the higher.

4 combinations are possible (selection A, B, C, D). Then, each selection can then be used for the

measurement process, in program mode even each program can be assigned another combination

(manual mode: see 5.4.1 Start a Control Process in Manual Mode -> “Sensor adjustment”. Pro-

gram mode: 5.4.2 Create Program Sequences setting field = Measuring device selec-

tion). is used to assign 2 connected measuring devices to a selection:

- Component 1 and 2: each selection will be done by the connected measuring devices. However,

component 1 is always defined by the lower temperature range.

Use the arrow key button to swap the measuring devices.

Example: Two sensors are connected, a NiCrNi thermocouple on X10 with a temperature range 0-

1350°C and a pyrometer connected to “X1” with a temperature range of 350-1800°C.

The bar graph shows the complete temperature range, the handover temperatures of both compo-

nents and the resulting hysteresis (temperature difference).

- The handover temperature / hysteresis defines the temperature at which the temperature meas-

urement is hand over from one measuring device to another at increasing or decreasing tempera-

ture. The difference is the hysteresis.

- Upper measuring limit component 1: handover temperature, where component 1 changes to

component 2 when the temperature is increasing.

- Lower measuring limit component 2: handover temperature, where component 2 changes to

component 1 when the temperature is decreasing.

Note: The handover temperature of component 1 has to be higher than of component. 2

Upper measuring limit component 1

Hysteresis

Selected temperature range component 1

Possible temperature range component 1

Lower measuring limit component 2

Temperature range component 2

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

15

5.3.2 Pyrometer Alignment

Precondition of a successful control process is a steady

temperature capturing. Align the pyrometer or sensor to an

area where a control process can be influenced (e.g. to a

faster heated border than a centered alignment).

5.4 Device Configuration

Here basic device settings are made.

Miscellaneous settings

- Setpoint deviation: The setpoint deviation is a global parameter that controls the program flow.

The setpoint level is the maximum deviation between actual value and nominal value to consider a

value as controlled successfully and start the next step.

- Range setpoint input: Defines the temperature range for the analog setpoint (possible range be-

tween 0 and 3300°C). The function is activated in the parameters control window.

- Key lock: To lock or unlock the key functions on the Regulus.

- None: All functions can be changed using the buttons on the unit.

- Active: The buttons on the unit are disabled.

- Menu lock: activates an input field for a 4-digit PIN code, which enables to protect changing of

parameters (PAR key) on the device. If activated, this code must be entered on the device be-

fore parameters with the PAR button can be changed.

Digital output

configuration

Digital input

configuration

Miscellaneous

settings

Analog outputs

configuration

Service functions,

and connection

settings

Example

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

16

Analog outputs (see 3.1.4)

- Measurement temperature (actual value output) / control output: Select the required output for

the connected device.

- PVM interval (period’s time) (only available if 10 V PWM is selected):Select the value corre-

sponding to your connected device.

- Adaptation: the temperature range span can be scaled down in order to adapt it to specific meas-

urement conditions.

Press the test button

to check the functionality of the

analog outputs.

Moving the slide control will set

values for the selected output.

The “On” button will transmit

the test setting to the controller

output, the Regulus shows the

result.

As notification on the Regulus a

blinking “Testfunction” text ap-

pears.

Digital input configuration (see 3.1.2)

Select the desired function in the list box for each (connected) input.

Digital output configuration (see 0)

Select the desired function in the list box for each (connected) output.

Every output has its corresponding settings in the line beside the output function.

- Setpoint: Values can be entered only if “Limit value output” is selected.

- Hysteresis: Only active if “Limit value output” is selected

- Logic: Sets the general functions of the output. NO: “Normally Open” or NC: “Normally Closed”

- Extended settings: Depending on the selection are either available:

Time settings: A verification time and a hold time can be set:

- Verification time: select “immediately” to activate the output function immediately when hap-

pening. A time between 1 and 65535 ms delays the activation accordingly.

- Hold time: A time can set to remain activated output for a desired time.

- None: signal is active as long as the function is active

- Process start: signal is active up to the next start (of a program or manual start)

- Time value between 1 and 65534 ms: signal is active for the entered time.

Reference: for selecting which measurement temperature to be used for the output control (which

pyrometer or which sensor or sensor combination).

Setting control of generator

Note: This output sets the time settings to 0):

- Control value limit: Defines the limit the control

output should be activated (minimum generator

power, if this cannot controlled continuously down

to 0%). Below the set value the control function is

switched off).

- Pick up verification: specifies the time the controller output must reach the control value limit

without interruption, before the output is activated.

- Drop down verification: specifies the time the controller output must be less the control value lim-

it without interruption, before the output is deactivated.

- Start delay: Delays checking the control value limit at a controller start.

- Output activation by control start: Activates the output directly at the control start without check-

ing the pick-up verification and start delay time.

Settings de-

pending on the

connected

generator

Slide control

Output values

Activate Test

Control output

Test display

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

17

Setting heating control

The output switches at a detected temperature peak (see in 5.4.2

Peak detection function). Switching back of the output can be de-

layed.

With the Test function digi-

tal inputs and outputs can be checked for er-

rors.

Click on an “Output control” check box to acti-

vate the corresponding output. A green LED

symbol signalizes the activation.

Digital inputs are marked with a green LED

symbol if connected and active.

Activation of the outputs will also activate the

LEDs on the Regulus.

As notification on the Regulus a blinking “Test-

function” text appears.

CAUTION! Using the test function will activate the selected outputs.

All connected systems will start working.

Always pay attention to the security instructions of these systems!

Temperature unit

The temperature can be displayed and entered in °C or °F.

(Changing the mode will not change the entered values, no conversion will be done).

Service functions

To back-up, for printing or restore device parameters or cre-

ate service files for remote diagnosis of problems.

- Create configuration file: A configuration file includes all

device settings made by user. This can be used e.g. to

setup a new pyrometer with the same values and settings

or to save the current status in case of a device replace-

ment.

- Load configuration file: load a previously saved configu-

ration data in the pyrometer.

- Print parameters: Prints the parameters of the currently

connected device.

- Print configuration file: Prints a saved file.

- Factory settings: Resets the device to its factory defaults.

- Create service file: A service file includes all device data

and all software settings made by user. Creating such a file

can be useful if a controller problem can’t be solved and help from our service could be useful.

- Upload service file: Transmitting a (possibly modified) file to the device it was created from.

Serial Interface

For setting the baud rate (not with USB), device address and inter-

face delay (in the case of faulty data transfer).

Note: The serial interface type and the device address can be

changed directly on the Regulus (see 6.2 Menu settings under

<COM Interface>).

Device addresses from 00 to 97 are valid. Addresses 98 and 99 are

with special functions. The global address 99 can be used to com-

municate with every controller, independent of the set device ad-

dress. This allows communication with devices with unknown addresses. The address 98 is a group

address used for RS485 devices in bus operation. With this address devices do not answer, useful to

change parameters of all connected devices at the same time.

Output check

Input check

Activate output

Test display

Regulus LEDs

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

18

Data Collection (buffer mode) (Only available when connected via serial in-

terface. Not with USB, since this always runs with the highest possible speed).

The measurement data transfer from Regulus to the PC can vary depending on the requirements and

computing power. Speed and transferable amount of data are dependent on the baud rate and the

data mode. In the data collection window are shown the amount of measured values determined by

calculation for each baud rate and each mode. When set to "Auto. interval adjustment ", the corre-

sponding values of baud rate selection will be entered automatically in the field on bottom right. When

required, they still can be adjusted manually, for example, if the calculated values still give problems.

USB always works internally with the baud rate 921.6 kBd.

ASCII mode: The Regulus al-

ways transfers separate read-

ings to the software and shows

each in the graph as a pixel. In

addition to the transmission of

measured values, also regularly

status values are transmitted

(limit contacts or active laser

targeting light...), so that meas-

ured values do not always ar-

rive at the same time interval.

For most applications this

speed is sufficient, a modern

PC can transmit every 5 ms a

value at 921 Kbits.

With buffer mode: Measure-

ment data are temporarily

stored in the internal buffer of

the controller and periodically

transferred to the software in

blocks, additional control infor-

mation (I/O states, laser target-

ing active,...) will be transmitted

cyclically. The buffer interval

defines how fast the internal

FIFO buffer of the Regulus is

filled. The shorter the time, the

more data per communication block will be transferred.

An interval time set too fast in relation to the baud rate and computing power leads to buffer over-

flows, which are represented by vertical bars in the graph. A modern PC reaches intervals of about

0.3 ms at 921 Kbits without buffer overflow, at 57 Kbits intervals of approximately 3.6 ms. If buffer

overflows occur, the interval time can be increased, the baud rate can be increased or unnecessary

programs and background services be stopped. A minor impact also has the reduction of the maxi-

mum data records in memory (see under 5.6 Data recording settings).

- Display mode:

- Controller display: In the software window

the actual measured temperature, the setpoint

and the control mode are displayed.

- Sample display: The software settings win-

dow, the temperatures of all sensors and ac-

tual value and setpoint display. This can be

used to display the temperatures of all meas-

uring instrument combinations.

Active mode

Switching the display in the

measured values and the

info field (control window)

Current setting

(With USB port

always 921.6 kBd)

Open the settings

window

Transmission rate of

the serial interface in

Baud

Automatically take

over values/s

Manually adjust

buffer interval

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

19

5.4.1 Start a Control Process in Manual Mode

In manual mode, a setpoint temperature and necessary PID

control parameters can be entered directly into the software

or at the Regulus. Starting the process will start to control to

the setpoint temperature with the set parameters. The con-

trol process will be hold until is finished manually or automat-

ically if a hold time is entered which runs if the setpoint value

is reached.

Parameters can be changed during a running control pro-

cess and will be taken over by pressing “Enter” on the key-

board. Invalid values will be automatically corrected to the

next possible value.

Note: all values in this “Control parameters” window can also

be set directly at the Regulus (see 6Device Handling).

INFO: At control process where the temperature is

approached from a temperature higher than the

setpoint temperature should be optimized selecting

this field. If setpoint temperature is reached from

upper temperature the integration sum of PID con-

trol is set to 0. In this case undershooting the set-

point temperature is avoid in the control process.

Control mode : Switching between manual

mode and stored control programs. The mode is displayed once again in the upper display.

Measuring device selection :

To set, which measuring device selection is

used to carry out by the measurement (see

5.3.1 Select / Combine Measuring devices).

General parameters

- Setpoint: Setpoint specification

- Analog setpoint: when activated, the analog input is used to specify the setpoint externally via

voltage input (see under 3, Electrical Connection Connector X3 External Setpoint Settings).

- Ramp time (in 100 ms):The setpoint temperature will be approached by increasing the tempera-

ture with a uniform gradient of the temperature within the entered time.

- Hold time: to hold the reached control output value a hold time can be set. Control process is con-

tinuing automatically after reaching the setpoint temperature and expiring the hold time.

PID parameters

- Xp: The proportional band represents the reciprocal of the gain of the controller (Entering 0.1-

1000%, 0.1 = highest gain, 1000 = lowest gain).

- Ti:The integral time constant represents a kind of smoothing or delay (Note: Ti is a multiple of the

sampling time. Therefore, changes in the sampling time have an impact on this value).

- Td: The derivative time constant slowdowns the rapid rise to prevent overshooting (Note: Td is a

multiple of the sampling time. Therefore, changes in the sampling time have an impact on this val-

ue).

- Sampling time: Select how quick temperature values will be read out of the sensor. Select the pa-

rameter depending on the inertia of the heating process (Note: Ti and Td are a multiple of the

sampling time. Therefore, changes in the sampling effect changes in Ti and Td).

Current measuring

temperature, set-

point and control

mode

Select manual mode

Enter required val-

ues in the boxes.

Press “Enter” to take

over the values

Start the control

process

AutoTune for auto-

matic detection of Xp

and Ti values

Setpoint entry

Hide rarely used

parameters

Previously determined

measuring devices

selection

Channel selection for

ratio pyrometers

PID Program Controller Regulus RD / RDS / RDK / RDKS / RDKK / RDSS

SensorTools Software

20

Power adjustments

- P-min: The minimum control output power defines the power which is to the control output at least.

- P-max: The maximum control output limits the power to the entered value.

- P-zsc: Limits the control output power as long as the beginning of the sensor’s or pyrometer’s

temperature (zero scale temperature) range is reached. This is useful to avoid a too fast start of a

heating process because the object temperature is out of the pyrometer’s temperature range.

Threshold values (values in this field are not available directly in the parameters menu of the Regu-

lus):

- Setpoint limit 1 and 2: Activates every selected “setpoint limit” output 1 or 2 (see 0Digital Outputs

and 5.4 Device configuration) if the set temperature is exceeded or falls below. The required tem-

perature has to be set relative to the setpoint temperature (in the control parameter field), not as

absolute value.

- P dynamic: Limits the power, the control output can control suddenly (standard 100%).

AutoTune settings

- The AutoTune target temperature defines the temperature that is used for Xp and Ti determina-

tion. The entry occurs in % and defines the difference between setpoint and actual value (example:

setpoint is 1000°C, the measurement object is cold which means the actual value is the pyrome-

ter’s beginning of temperature range and thus, for example, 500°C, then the target temperature is

750°C at 50% factory setting). Only a value below 100% prevents a temperature exceeding during

P-I-determination and thus a possibly material destruction due to overheating.

- Next start with AutoTune: Starts the AutoTune function prior to the next control start, then imme-

diately the control process starts with the found PI parameters. This also works with an external

control start. The function is only active for one controller start and will be deactivated (unchecked)

with the next control start.

- Controller start always with AutoTune: starts AutoTune prior to every control start, then the con-

trol process directly starts with the found PI parameters (also works with an external controller

start).

The AutoTune function enables to detect automatically useful values for the proportional

band Xp and integral time constant Ti. The function tries to find the values Xp and Ti without over-

shooting the setpoint temperature.

NOTE:

AutoTune usually results in only a guide, their further optimization is necessary then.

Starting the Controller

Press Start to start the control process. Pressing the start button at

the Regulus will also start the procedure in the software.

Press stop to quit the process.

Press the red record button to store temperature and control values to the PC’s hard disc.

Note: Recording can be started simultaneously with controller start if corresponding setting is made

(see Data recording settings under 5.6: under “automatic recording by active control” and if required

“automatic end of recording by inactive control”).

This manual suits for next models

5

Table of contents

Popular Controllers manuals by other brands

Bernard Controls

Bernard Controls ST Series INSTRUCTIONS FOR START-UP

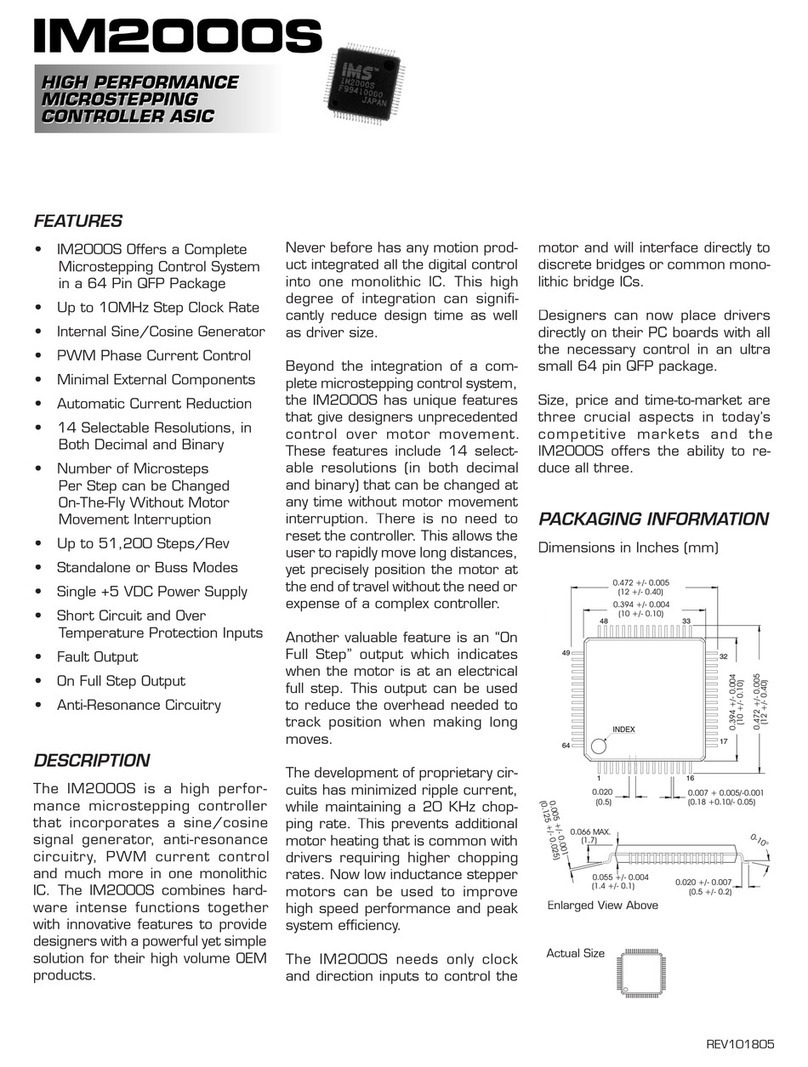

IMS

IMS IM2000 IM2000S datasheet

Spirax Sarco

Spirax Sarco BC1100 Installation and maintenance instructions

NSTHAI

NSTHAI NSC2024R instruction manual

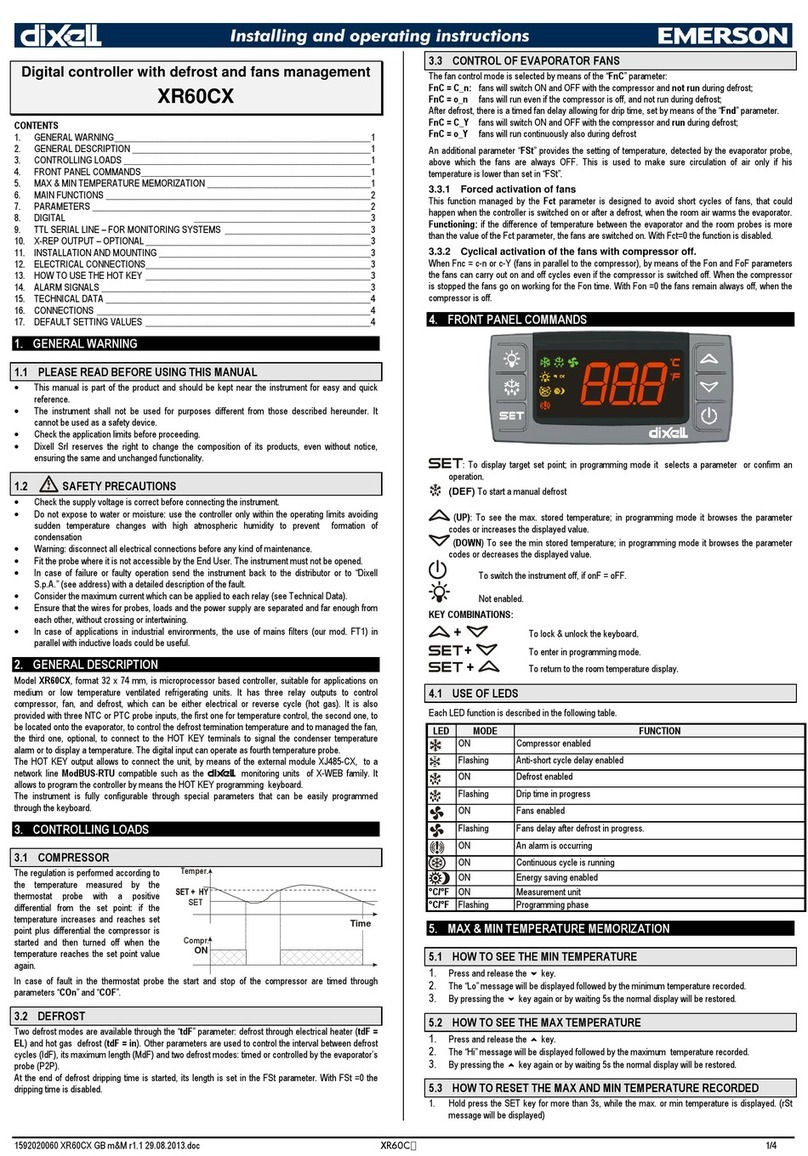

Emerson

Emerson dixell XR60CX Installing and operating instructions

Saten

Saten ST-1004-KI user manual

Axel Larsson

Axel Larsson AL 79-045U Installation, Maintenance and Operating Instruction Manual

SMC Networks

SMC Networks ITV1050 Installation and maintenance manual

Distech

Distech ECYPSE user guide

Siemens

Siemens Simatic S7-1500 manual

Mitsubishi

Mitsubishi MELSEC QJ71C24-R2 user manual

Omron

Omron F3SP-U4P-TGR datasheet