ITV1-TFK02-A

Installation and Maintenance Manual

Electro-Pneumatic Regulator with negative

terminal of power line separated from signal

line.

Series ITV1000-DIK00137

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution Indicates a hazard with a low level of risk, which if

not avoided, could result in minor or moderate injury.

Warning Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

• Electromagnetic compatibility:

This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted as

well as radiated disturbances.

• The compatibility of pneumatic equipment is the responsibility of

the person who designs the pneumatic system or decides its

specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed

by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

• Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

• When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

• Before machinery/equipment is re-started, ensure all safety measures

to prevent sudden movement of cylinders etc. (Supply air into the

system gradually to create back pressure, i.e. incorporate a soft-start

valve).

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

• Conditions and environments beyond the given specifications, or if the

product is to be used outdoors.

• Installations in conjunction with atomic energy, railway, air navigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

• An application, which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

• Ensure that the air supply system is filtered to 5 microns.

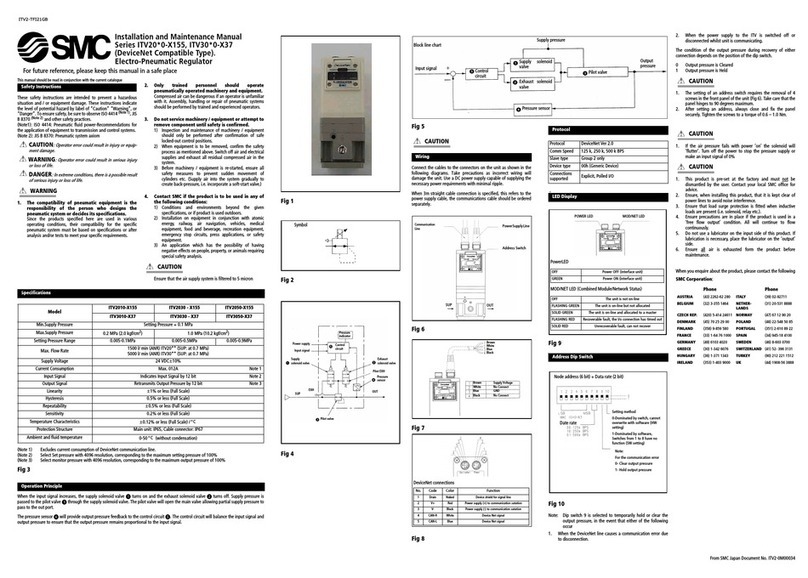

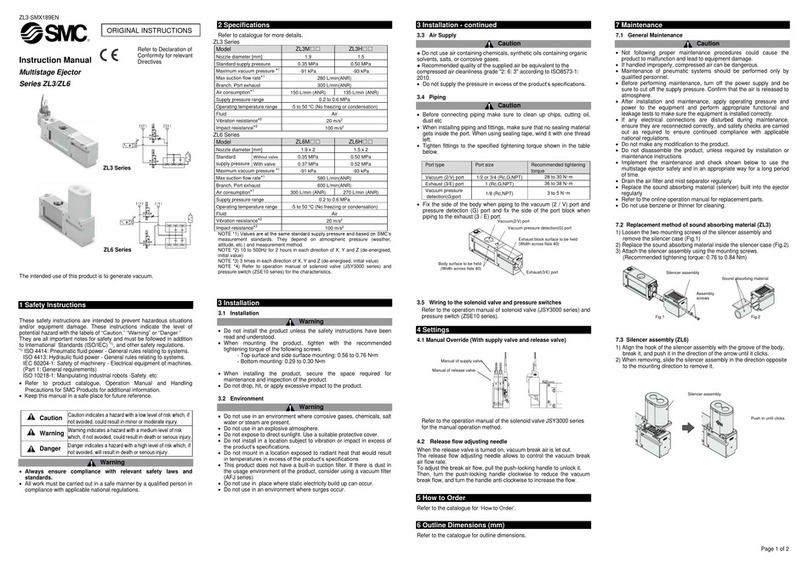

2 Specifications

Model ITV1010 ITV1030 ITV1050

Min. supply pressure (Set pressure) + 0.1 MPa

Max. supply pressure 0.2 MPa 1.0 MPa

Set pressure range 0.005 ~ 0.1 MPa 0.005 ~ 0.5 MPa 0.005 ~ 0.9 MPa

Supply voltage 24 VDC±10%

Current consumption Max. 120 mA

Input signal Note1 4-20 mADC

Input impedance Max. 250 Ω

Linearity Max. ±1%F.S.

Hysteresis Max. 0.5%F.S.

Repeatability Max. ±0.5%F.S.

Sensitivity Max. 0.2%F.S.

Temperature characteristics Max. ±0.12%F.S./°C

Operating temperature 0~50°C (without condensation)

Accuracy ±3%F.S

Pressure

display Min. Unit MPa: 0.01, kgf/cm2: 0.01, bar: 0.01,

PSI: 0.1Note 2, kPa: 1

Protection structure Main unit: IP65, Cable connector: IP67

Table 1.

Note 1: Two wire 4 to 20 mADC control. Negative terminal of power line is separated

from that of signal line.

Note 2: 1 PSI is the minimum unit on ITV1050.

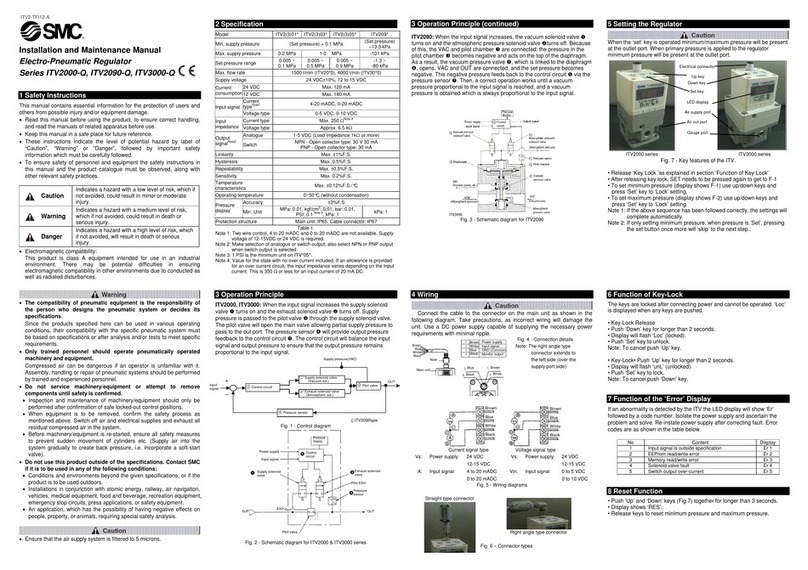

3 Operation Principle

When the input signal increases the supply solenoid valve nturns on and

the exhaust solenoid valve oturns off. Supply pressure is passed to the

pilot valve pthrough the supply solenoid valve. The pilot valve will open

the main valve allowing partial supply pressure to pass to the out port. The

pressure sensor qwill provide output pressure feedback to the control

circuit r. The control circuit will balance the input signal and output

pressure to ensure that the output pressure remains proportional to the

input signal.

Fig. 1 - Control diagram

Fig. 2 - Schematic diagram

4 Wiring

Connect the cable to the connector on the main unit as shown in the

following diagram. Take precautions, as incorrect wiring will damage the

unit. Use a DC power supply capable of supplying the necessary power

requirements with minimal ripple.

Fig. 3 - Connection details

Note: The right angle type

connector extends to

the left side (over the

supply port side)

Current signal type

Vs: Power supply 24 VDC

A: Input signal 4 to 20 mADC

Fig. 4 - Wiring diagram

Straight type connector

Right angle type connector

Fig. 5 – Connector types

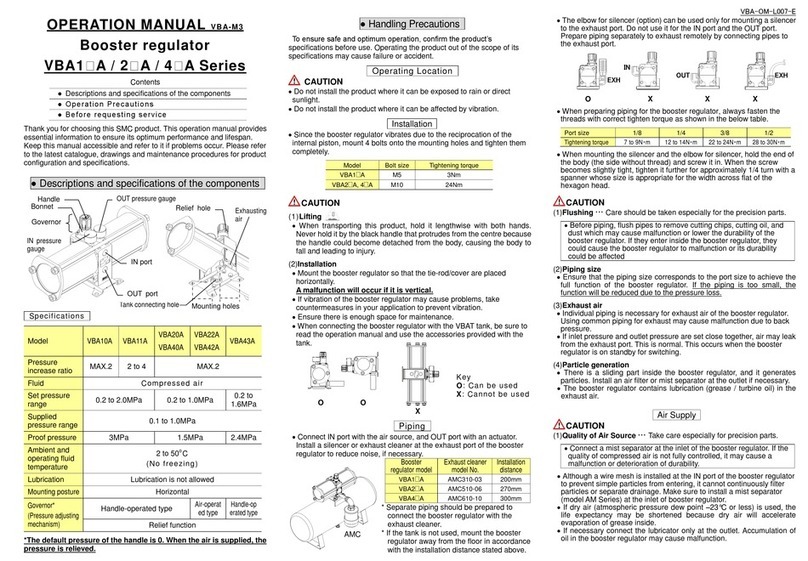

5 Setting the Regulator

When the ‘set’ key is operated minimum/maximum pressure will be present

at the outlet port. When primary pressure is applied to the regulator

minimum pressure will be present at the outlet port.

Fig. 6 - Key features of the ITV.

• Release ‘Key Lock ’as explained in section ‘Function of Key-Lock’

• After releasing key lock, SET needs to be pressed again to get to F-1

• To set minimum pressure (display shows F-1) use up/down keys and

press ‘Set’ key to ‘Lock’ setting.

• To set maximum pressure (display shows F-2) use up/down keys and

press ‘Set’ key to ‘Lock’ setting.

Note 1: If the above sequence has been followed correctly, the settings will

complete automatically.

Note 2: If only setting minimum pressure, when pressure is ‘Set’, pressing

the set button once more will ‘skip’ to the next step..

6 Function of Key-Lock

The keys are locked after connecting power and cannot be operated. ‘Loc’

is displayed when any keys are pushed.

• Key-Lock Release

• Push ‘Down’ key for longer than 2 seconds.

• Display will flash ‘Loc’ (locked).

• Push ‘Set’ key to unlock.

Note: To cancel push ‘Up’ key.

Power supply +

Input signal +

Power supply –

Input signal –

Brown

White

Blue

Black

Brown

Blue

White

Blac

• Key-Lock• Push ‘Up’ key for longer than 2 seconds.

• Display will flash ‘unL’ (unlocked).

Note • Push ‘Set’ key to lock.

Brown

Blue

Main Note: To cancel push ‘Down’ key.

7 Function of the ‘Error’ Display

If an abnormality is detected by the ITV the LED display will show ‘Er’

followed by a code number. Isolate the power supply and ascertain the

problem and solve. Re-instate power supply after correcting fault. Error

codes are as shown in the table below.

No Content Display

1 Input signal is outside specification Er 1

2 EEProm read/write error Er 2

3 Memory read/write error Er 3

4 Solenoid valve fault Er 4

Table 2.

8 Reset Function

• Push ‘Up’ and ‘Down’ keys (Fig 6) together for longer than 3 seconds.

• Display shows ‘RES’.

• Release keys to reset minimum pressure and maximum pressure.

9 Installation & Maintenance

• If the electrical supply fails, settings are ‘held’ for a short period.

• If the air pressure fails with power ‘on’ the solenoid will ‘flutter’. Turn off

the power.

• This product is pre-set at the factory and must not be dismantled by the

user. Contact your local SMC office for advice.

• Ensure, when installing this product, that it is kept clear of power lines to

avoid noise interference.

• Ensure that load surge protection is fitted when inductive loads are

present (i.e. solenoid, relay etc.).

• Ensure precautions are in place if the product is used in a ‘free flow

output ’condition. Air will continue to flow continuously.

• Do not use a lubricator on the input side of this product. If lubrication is

necessary, place the lubricator on the ‘output’ side.

• Ensure all air is exhausted from the product before maintenance.

• Length of connector cable shall be 10 m maximum.

10 Contacts

AUSTRIA (43) 2262 62280 NETHERLANDS (31) 20 531 8888

BELGIUM (32) 3 355 1464 NORWAY (47) 67 12 90 20

CZECH REP. (420) 541 424 611 POLAND (48) 22 211 9600

DENMARK (45) 7025 2900 PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513 SLOVAKIA (421) 2 444 56725

FRANCE (33) 1 6476 1000 SLOVENIA (386) 73 885 412

GERMANY (49) 6103 4020 SPAIN (34) 945 184 100

GREECE (30) 210 271 7265 SWEDEN (46) 8 603 1200

HUNGARY (36) 23 511 390 SWITZERLAND (41) 52 396 3131

IRELAND (353) 1 403 9000 UNITED KINGDOM (44) 1908 563888

ITALY (39) 02 92711

URL : http// www.smcworld.com (Global) http// www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2009 SMC Corporation All Rights Reserved.

unit White

Black

Brown

Blue

White

Black

Electrical connector

Down key Up key

OUT

Pilot valve

SUP EXH

Control

circuit

Pressure

sensor

Supply solenoid

valve Exhaust solenoid

valve

Power supply

Input signal

Pilot EXH

Pressure

display

Set key

LED display

Gauge port