Sensorex TX10 1/8 DIN User manual

pg.1

Operation Manual

TX10 1/8 DIN

Microcomputer Based pH/ORP Controller

11751 Markon Drive Garden Grove, CA. 92841 U.S.A.

pg.2

CONTENTS

GENERAL INTRODUCTION………………………………………..………....................3

INITIAL INSPECTION……...………………..................................................................3

USING THE Sensorex MODEL TX10………...….....................................................................3

A. Mounting procedure.....................................................................................3

B. Front panel....................................................................................................4

C. LCD screen....................................................................................................5

D. Rear connectors...........................................................................................6

E. Measure mode.............................................................................................7

F. Setting mode................................................................................................7

G. pH calibration mode...................................................................................10

H. RmV calibration mode................................................................................11

I. 4~20mA output............................................................................................11

ERROR DISPLAY AND TROUBLESHOOTING……………..……….........................13

pH BUFFERS……………..………..............................................................................15

SPECIFICATIONS……………..………………………………………........................16

WARRANTY……………..………...............................................................................17

pg.3

GENERAL INTRODUCTION

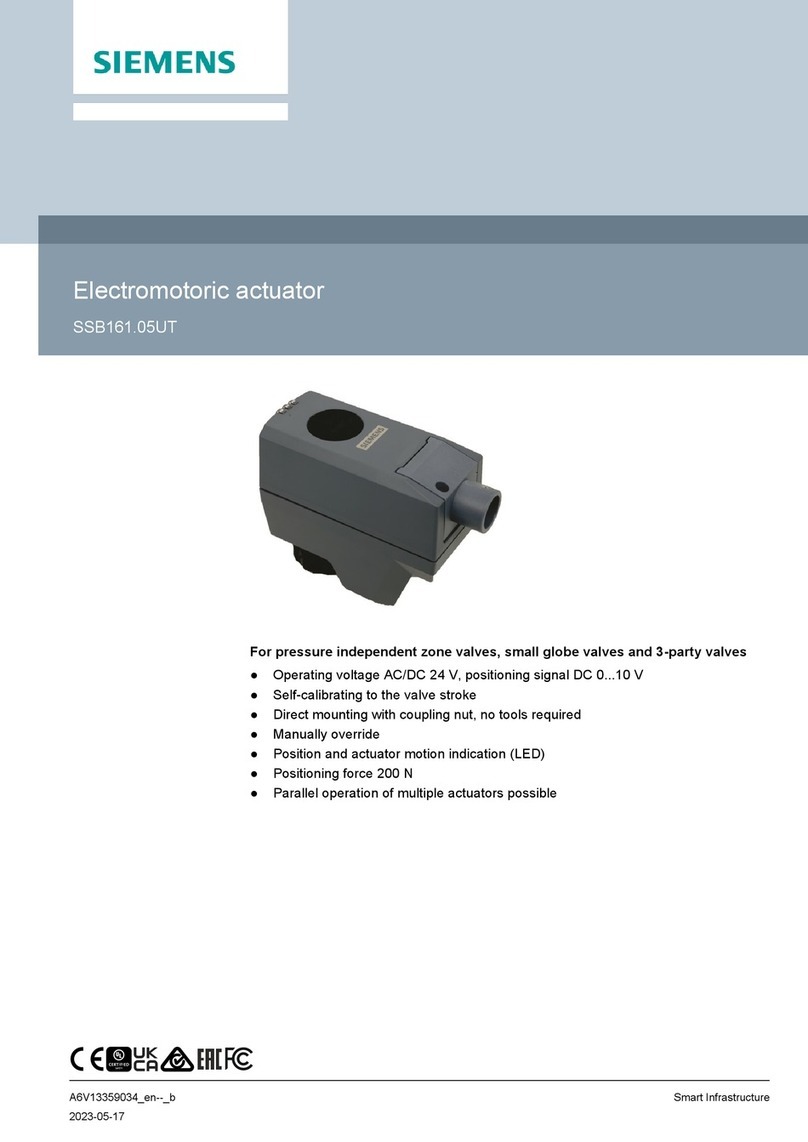

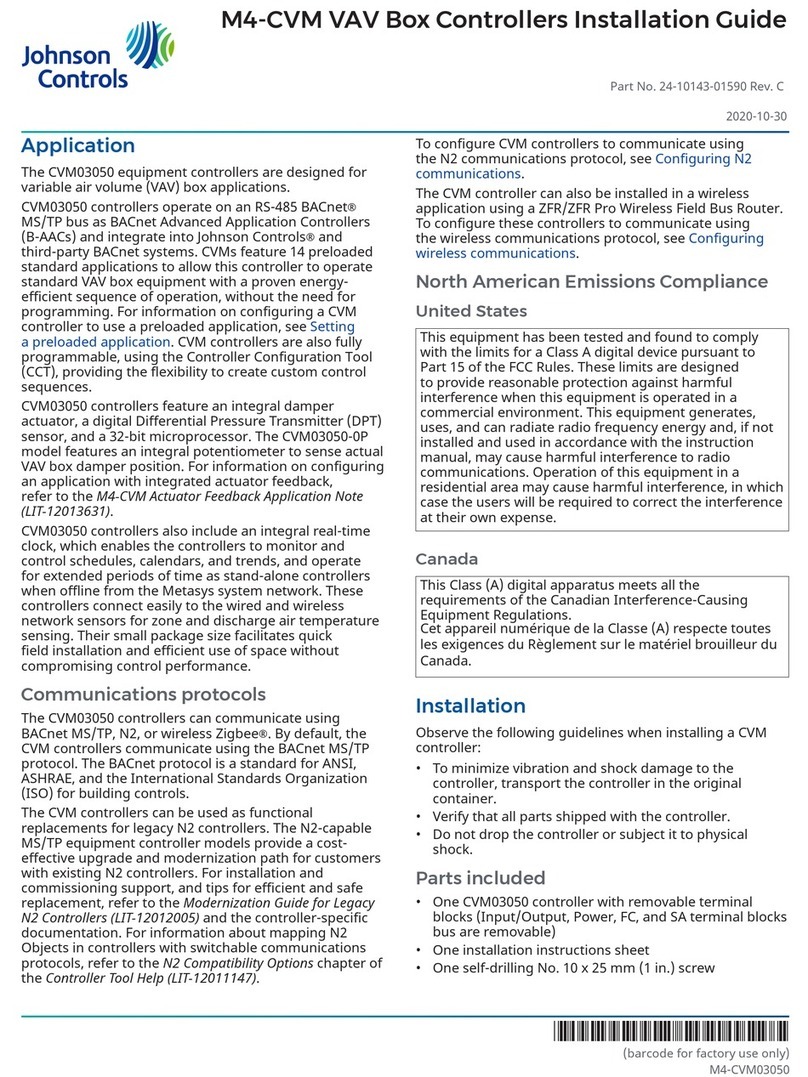

Thank you for selecting the Sensorex Model TX10. The TX10 pH/ORP transmitter is a rugged

microprocessor based instrument assembled in a watertight 1/8 DIN case, designed for use in

laboratories and process control applications.

The system displays pH or ORP or Temperature status in one large LCD screen.

The model TX10 microprocessor performs a self-diagnostic routine every time you turn on the

unit providing you with basic information on the stability of the instrument.

The model TX10 has an isolated 4-20mA analog output, offset and span configurable for the

pH or ORP display.

INITIAL INSPECTION

Carefully unpack the unit and accessories. Inspect for damages made in shipment. If any

damage is found, notify your Sensorex representative immediately. All packing materials

should be saved until satisfactory operation is confirmed.

USING THE SENSOREX TX10 pH/ORP TRANSMITTER ERVIEW

A. Mounting Procedure

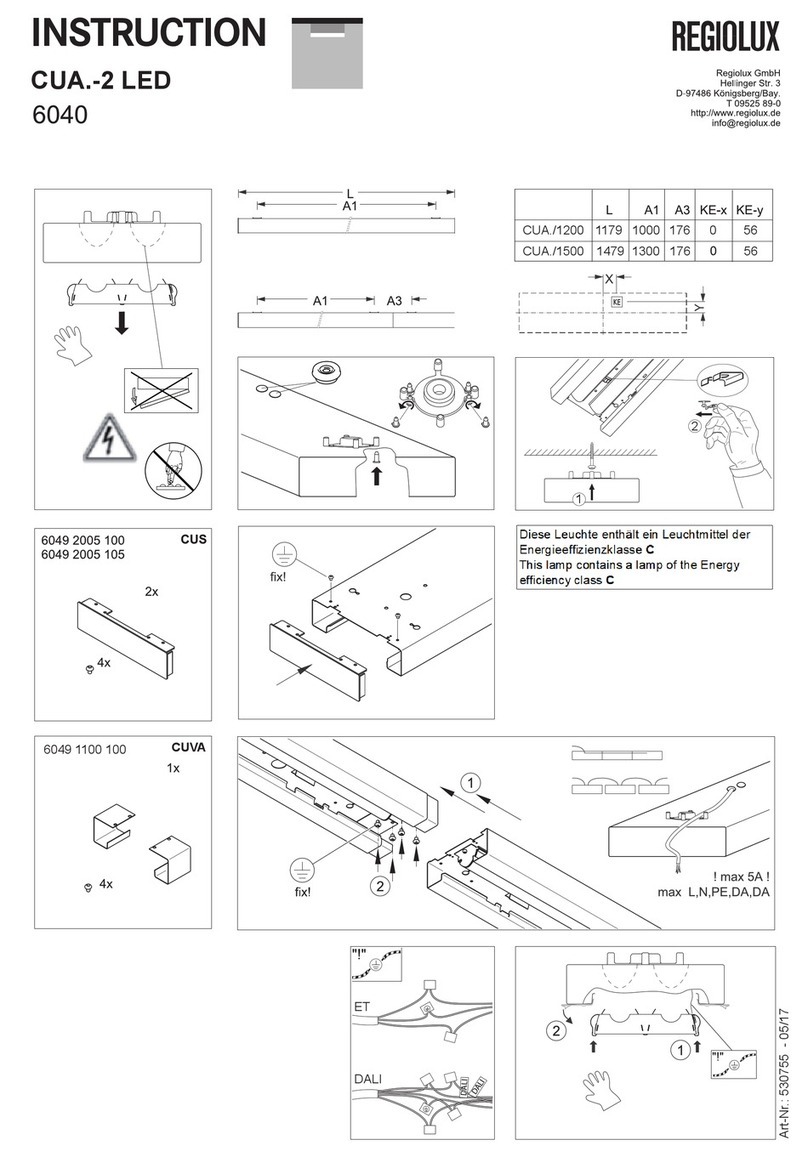

1. Make a cutout on any panel, with a thickness of 1/16 inch (1.5mm) to 3/8 inch

(9.5mm). Refer to FIG 1

Figure 1

2. Remove the mounting bracket from the controller and insert the controller into the

cutout. Refer to FIG 2.

Mounting Brackets

Figure 2

pg.4

3. Replace the mounting bracket assembly onto the controller and secure the controller

to the mounting panel. Refer to FIG 3.

Panel Mounting brackets

Figure 3

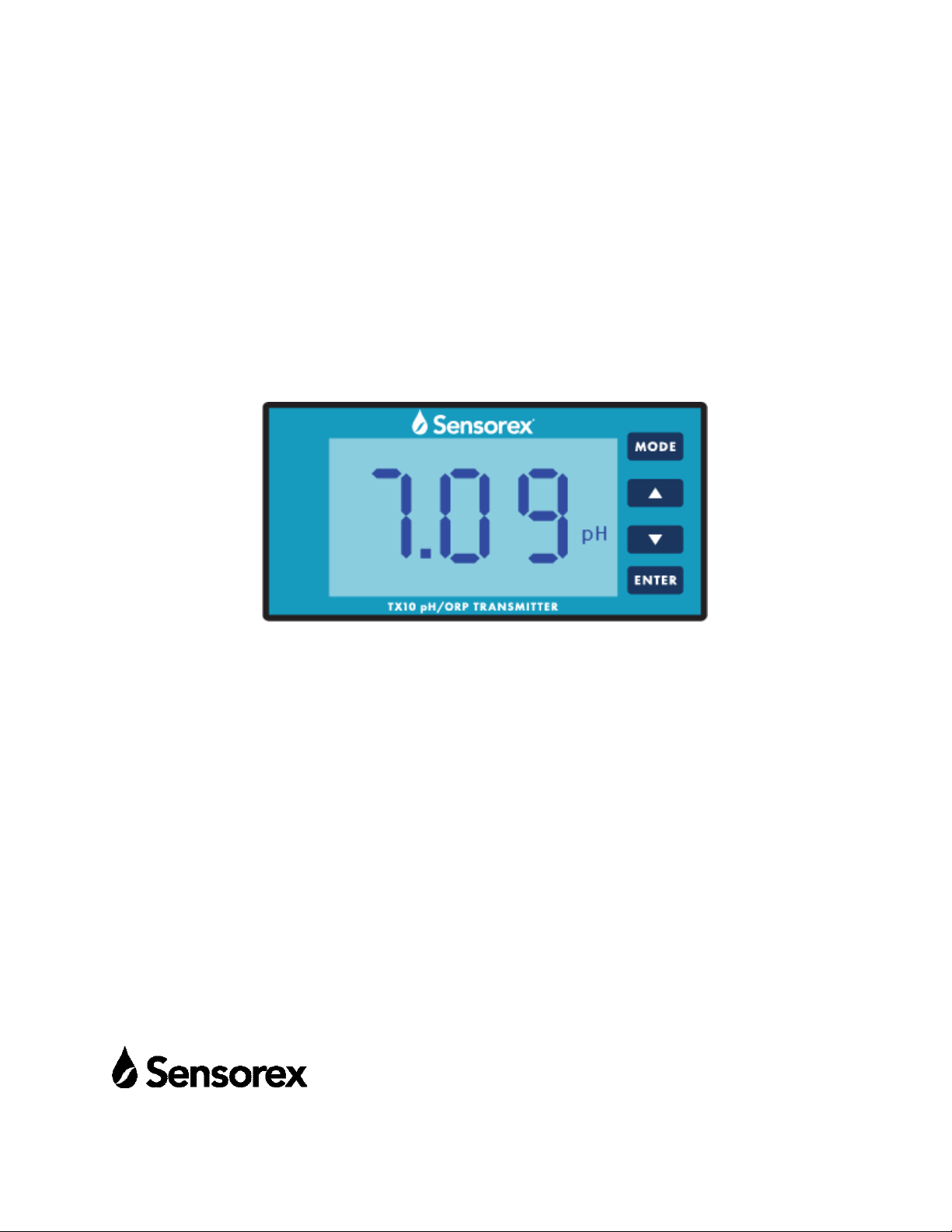

B. Front Panel

The front panel consists of a 4-digit LCD display and 4 keys.

1. [ MODE ] key:

1a. In the Measure mode, this key will switch the display in sequence from pH,

Temperature, ORP absolute mV, ORP relative mV and back to pH again.

1b. In the Calibration/Setting mode, pressing this key for three seconds will move you

back to the previous parameter in the case when recalibration / resetting is required.

2. [ UP ] key:

2a. In the Calibration mode, pressing this key will show the next possible option. In the

Setting mode, pressing this key will show the next possible option and increases the

numeral increment.

2b. In the Measure mode, pressing this key and [ENTER] key at the same time, the unit

will enter the Calibration mode.

3. [ DOWN ] key:

3a. In the Calibration mode,pressing this key will show the next possible option. In the

Setting mode, pressing this key will show the next possible option and decreases the

numeral increment.

3b. In the Measure mode, pressing this key and [ENTER] key at the same time, the unit

will enter the Setting mode.

4. [ ENTER ] key: In any mode where the user can change the settings, pressing this key

will save the new settings. If no change has been made then pressing this key will just

move the user to the next setting.

pg.5

C. LCD screen

STAND SLOPE

RmV

CAL

6.86 7.00 ATC MAN

pH

12 3 45

12

11

10

9876

C

mA

1. Major LCD display.

2. CAL – This icon will be displayed if the meter is in the Calibration/Setting mode.

3. mA – This icon, when displayed, indicate in the 4 mA or 20mA Setting mode.

4. Ԩ– Temperature and unit display.

5. pH – Unit indicator.

6. STAND – This icon will blink before Buffer 1 calibration. The icon will stay on while

Buffer 1 is being calibrated.

7. SLOPE – This icon will blink before Buffer 2 calibration. The icon will stay on while

Buffer 2 is being calibrated.

8. 6.86 – The 6.86 buffer group: 6.86, 4.00, 9.18.

9. 7.00 – The 7.00 buffer group: 7.00, 4.01, 10.01.

10. ATC –This icon will be displayed when a temperature probe is connected.

11. MAN –This icon will be displayed when a temperature probe is not connected.

12. RmV – Unit indicator

pg.6

D. Rear connectors

100~230VAC

LNE

mA

+-

+V -V 10k TH Pt 1000

GND

INPUT RFF

1. Connect the AC line to the rear of the instrument. The model 3631 can be used with

100~240V AC at 50/60 HZ. Make sure the EARTH connector is connected to the earth lead

of the AC power line.

2. Set the proper load to the 4-20mA-output connector. Make sure that the load impedance

is less than 500 Ohms.

3. V+ (5VDC) and V- (5VDC) output to provide excitation voltage for pH/ORP pre-amplifier

only.

【

Note

】

:

(1) Make sure that the power is unplugged before wiring your probes etc.

(2) Make sure you connect the AC power cord to the correct AC terminals. Connecting

incorrectly may damage the unit permanently.

pg.7

Measure mode

Turning on the unit will always display the Measure mode. This instrument is designed to

provide 4 distinct measurements:

7.00 ATC

pH

ATC

C

mV

RmV

MODE MODE

MODE

MODE

1. pH – The degree of acidity or alkalinity of the solution.

2. Temperature – Current temperature of the solution.

3. ORP mV – A measurement of absolute ORP mV.

4. ORP RmV– A measurement of relative ORP mV. The offset value at the RmV calibration

will be added to the ORP absolute value to display the ORP relative value.

【

Note

】

:

ORP relative value range: ORP absolute value - 1000mV to ORP absolute value + 1000mV

Pressing [MODE] key in the Measure mode will cycle the display from the four modes above.

E. Settings mode

Pressing [DOWN] key and [ENTER] key at the same time, the meter will enter into the Setting

mode.

1. Temperature compensation select:

+ENTER

ENTER ENTER ENTER

pH buffer 1 select

CAL

ATC

CAL

ATC

CAL

MAN

Pressing [UP] key or [DOWN] key in this screen will cycle the display from 01 (Thermistor:

10k ohm), 02 (Resistor: PT1000), 03 (Manual) modes above.

Select the preferred temperature compensation mode, press [ENTER] key to save, and

enter the next setting screen.

pg.8

2. pH buffer 1 select:

Pressing [UP] key or [DOWN] key in this screen will cycle the display from 7.00, 6.86 buffer

above.

Select the preferred buffer, press [ENTER] key to save, and enter the next setting screen.

Temperature compensation select

pH buffer 2 select

ENTER

ENTER ENTER

CAL

6.86

pH

CAL

7.00

pH

Buffer 1 7.00

Relay control parameters select

ENTER

CAL

7.00

pH

CAL

7.00

pH

ENTER ENTER

Buffer 2 6.86

Relay control parameters select

ENTER

ENTER ENTER

CAL

6.86

pH

CAL

6.86

pH

Pressing [UP] key or [DOWN] key in this screen will cycle the display from 4.01, 10.01 (or

4.00, 9.18) buffer above.

Select the preferred buffer, press [ENTER] key to save, and enter the next setting screen.

【

Note

】

: The pH buffer 2 is either 4.01 or 10.01 if select 7.00 buffer at pH buffer 1 select

screen. The pH buffer 2 is either 4.00 or 9.18 if select 6.86 buffer at pH buffer 1 select

screen.

pg.9

3. 4 mA output setting:

mA output parameters select

20mA output setting

ENTER

ENTER

CAL CAL

mA

pH

Pressing [UP] key or [DOWN] key in this screen to adjust the 4 mA value, this value is used

for scaling the 4-20mA analog output.

Pressing [ENTER] key to save, and enter the next setting screen.

4. 20mA output setting:

4mA output setting

Measure mode

ENTER

ENTER

CAL CAL

mA

pH

Pressing [UP] key or [DOWN] key in this screen to adjust the 20 mA value, this value is

used for scaling the 4-20mA analog output.

pg.10

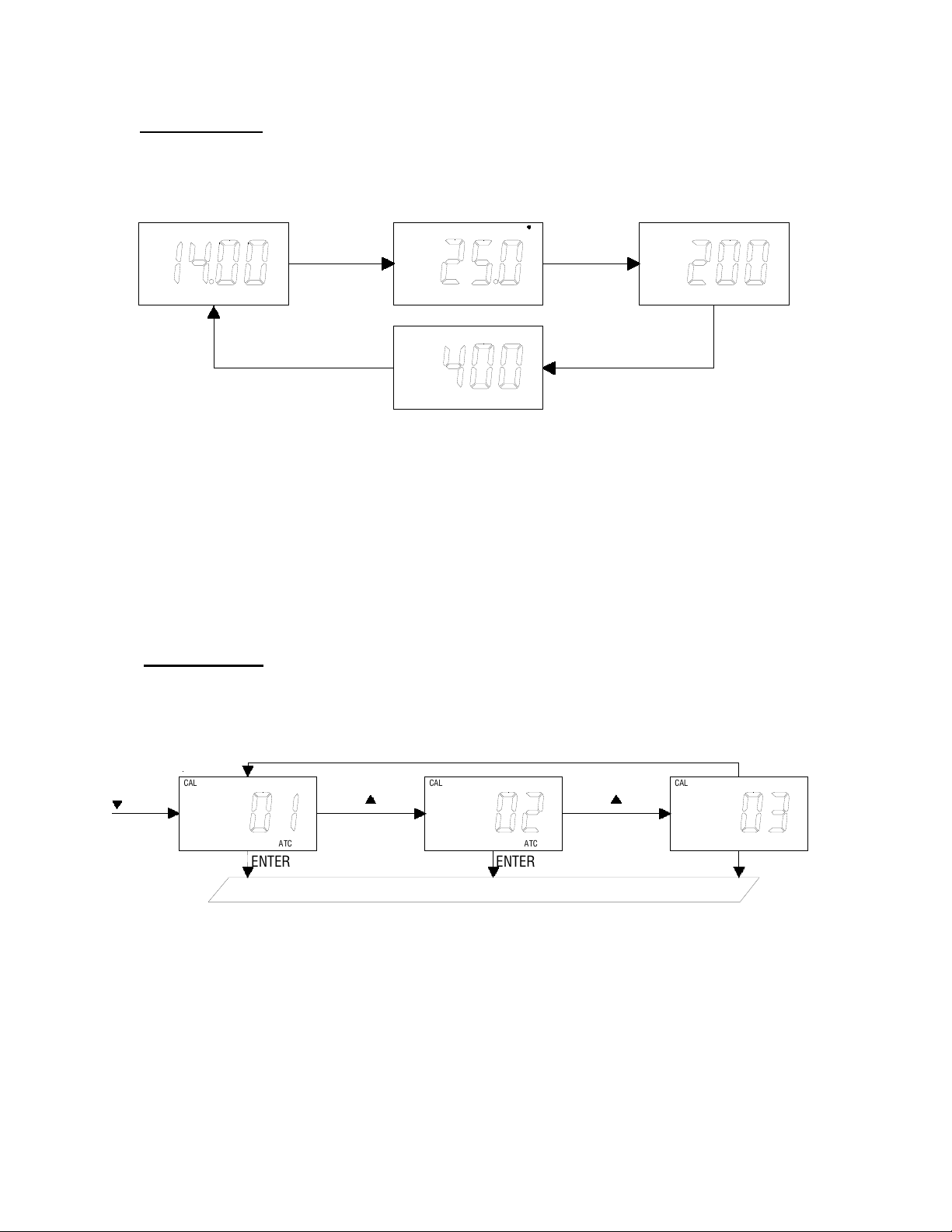

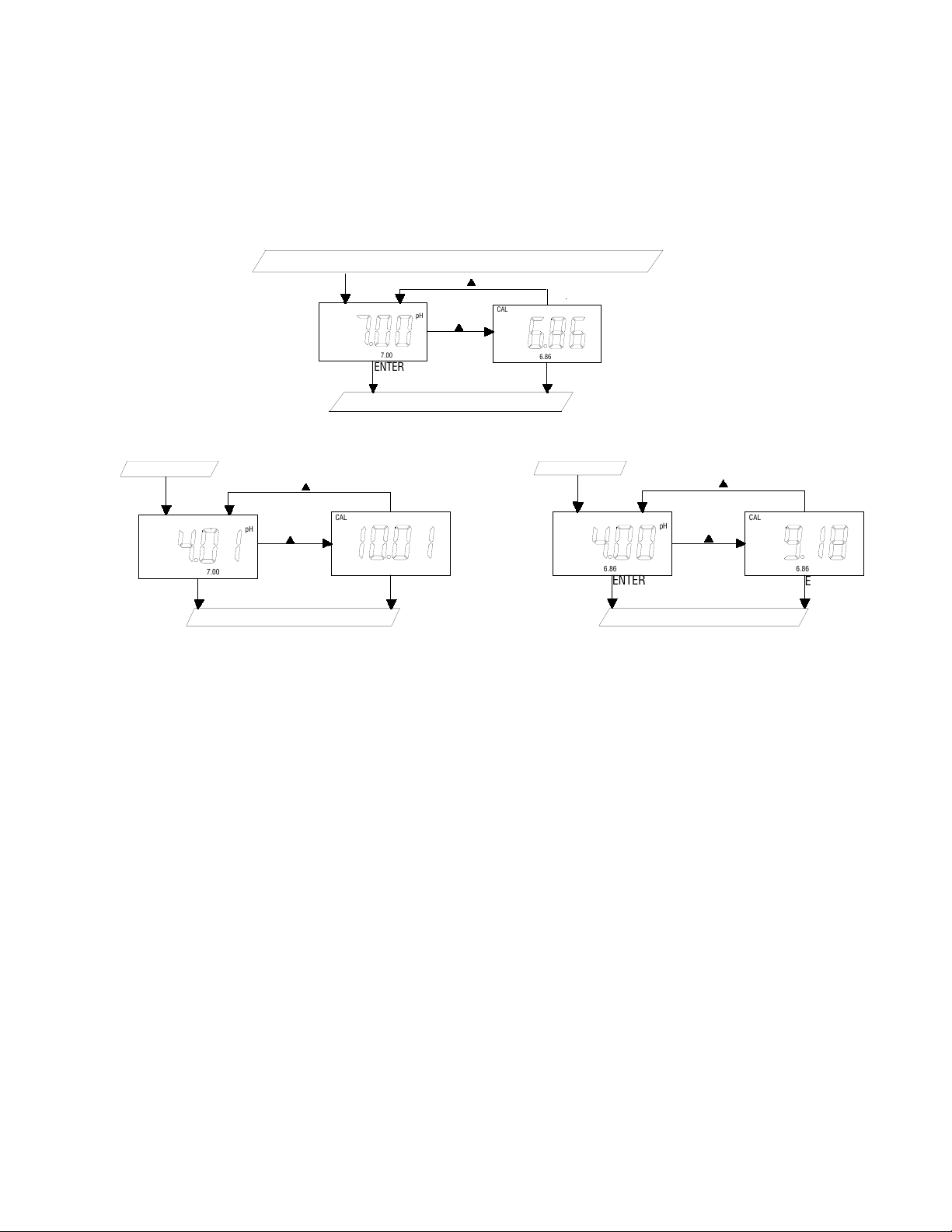

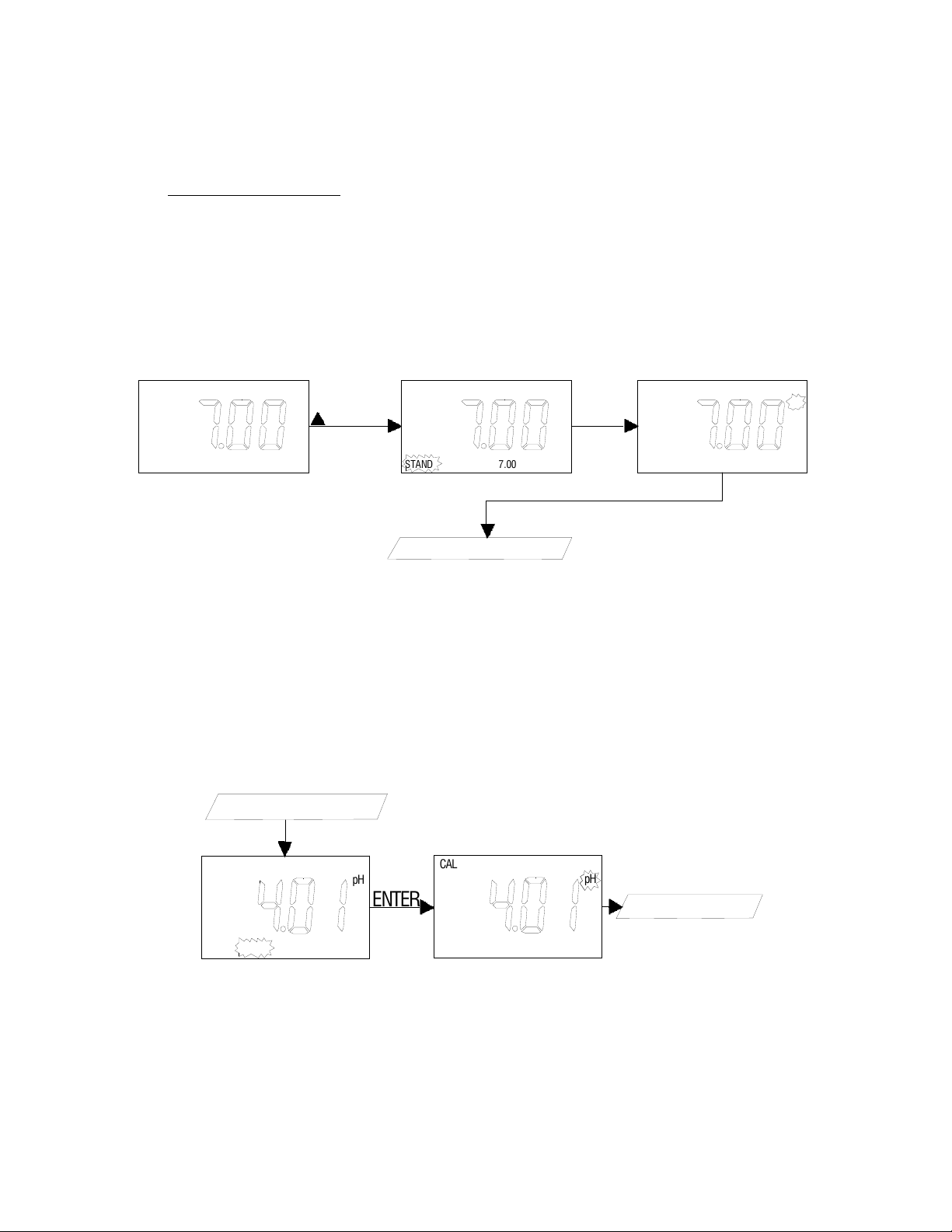

E. pH Calibration mode

The TX10 uses 2-point calibration for pH. The first point must be 6.86/7.00, and the second

point can either be 4.00/4.01 or 9.18/ 10.01.

In the pH Measure mode, pressing [UP] key and [ENTER] key at the same time to allow the

meter to go to the pH Calibration mode.

1. Buffer 1 (STAND) calibration:

Buffer 2 calibration

+ENTER ENTER

STAND

CAL

7.00

pH

STAND SLOPE 7.00

pH

HI2

STAND

CAL

7.00

pH

Enter into the pH calibration mode, the “STAND” icon will flash, the unit is ready to be

standardized at the first buffer. Rinse the pH and ATC/Temp probes in distilled water and

immerse them in the first buffer solution (either 7.00 or 6.86). Allow temperature reading

to stabilize, then press “ENTER” key to calibrate. The “pH” icon will flash until the unit

detects a stable reading. Once the unit calibrates the first point, the “SLOPE” icon will

flash. The unit is ready to be sloped at the second buffer.

2. Buffer 2 (SLOPE) calibration:

Rinse the pH and ATC/Temp probe in distilled water and immerse them in the second

buffer solution (either 4.00/4.01 or 9.18/10.01). Allow temperature reading to stabilize,

then press “ENTER” key to calibrate. The “pH” icon will flash until the unit detects a stable

reading. Once the unit calibrates the second point and the unit will automatically exit the

calibration mode and goes to the pH Measure mode. Dual point calibration is complete.

ENTER

Buffer 1 calibration

Measure mode

STAND SLOPE

CAL

7.00

pH

STAND SLOPE

CAL

7.00

pH

pg.11

【

Note

】

: In the Setting mode (1. Temperature compensation select), select 03 (Manual

temperature compensation mode) if no temperature probe is being used. Press the [UP]

key or [DOWN] key in the Manual temperature compensation mode to adjust the

value to that of the test solution temperature. Then calibrate buffer 1 and buffer 2.

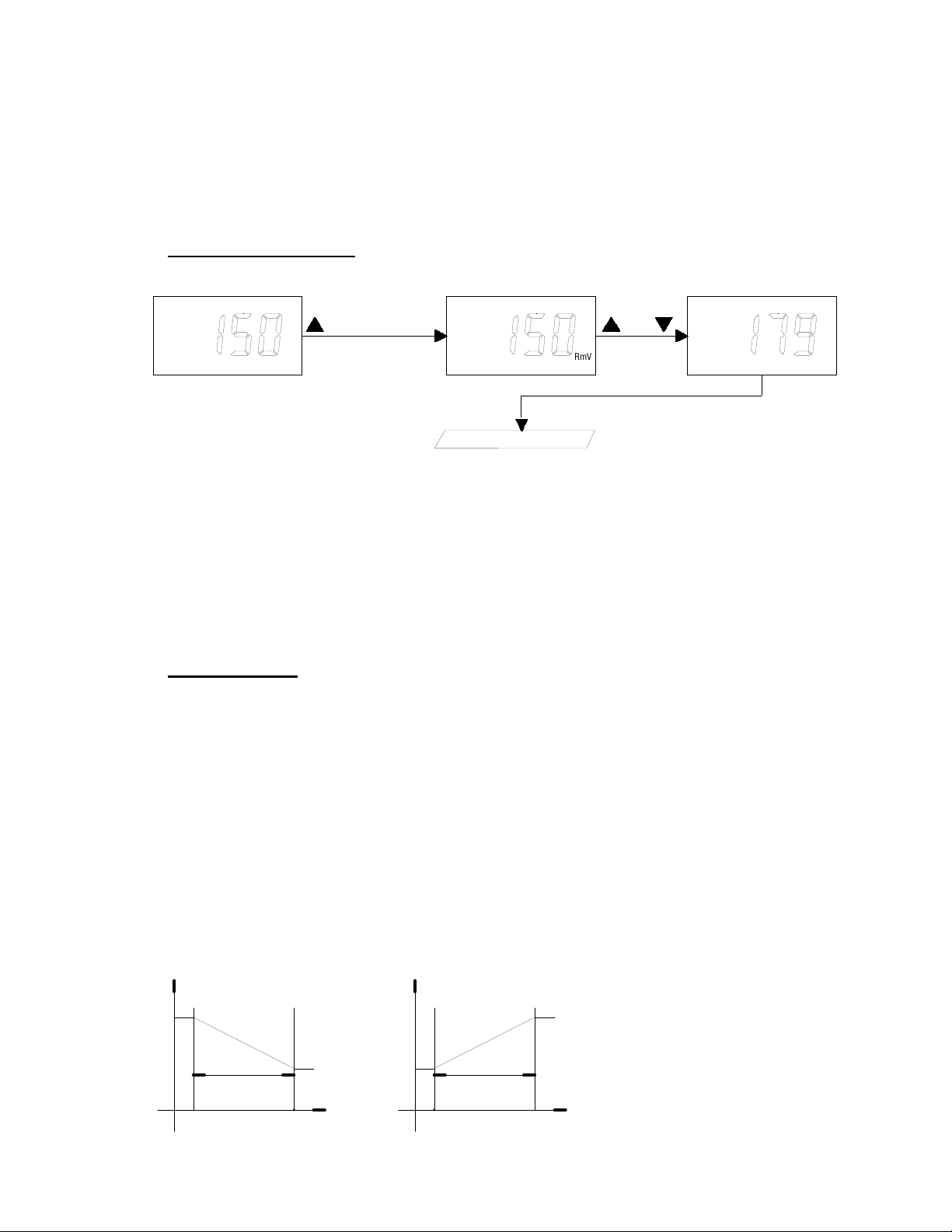

F. RmV Calibration mode

RmV normal mode

or

CAL

RmV

CAL

RmV RmV

+ENTER

The model TX15 uses 1-point calibration for RmV. In the RmV Measure mode, pressing [UP]

key and [ENTER] key at the same time, the meter will enter into RmV calibration mode.

Rinse the ORP probe in distilled water and immerse it in the ORP standard solution, then press

[UP] or [DOWN] key to adjust the ORP value to that the ORP standard. Press [ENTER] key to

save. The unit beeps to indicate a successful calibration. Calibration is now complete and the

unit will automatically switch to the ORP relative mV Measure mode.

【

Note

】

: When the ORP absolute mV reading is off, recalibrate RmV value.

G. 4-20 mA output

1. Isolation voltage:

The maximum isolation voltage of the 4-20mA output contacts is 500 VDC. The voltage

differential between the 4-20mA output contacts and the load should not exceed 500

VDC.

2. Output load:

The maximum load is 500 ohm. Output current inaccuracies may occur for load

impedance in excess 500 ohm.

3. The analog output will produce a linear analog output. The user can only bind the

ANALOG OUTPUT to one reading at a time. The user can change this anytime by

changing option at the Calibration/Setting mode screen.

The analog output will be restricted on the 4 mA setting, 20 mA setting and the current

bound display.

Adjustable

Bandwidth Bandwidth

Adjustable

Set

point point

Set

20mA

4mA 4mA

20mA

mA mA

Decreasing current for Increasing current for

pH/ORP pH/ORP

increasing pH or ORP increasing pH or ORP

pg.12

The above figure shows the relationship between Reading, U4mA & U20mA.

The analog output is based on the following equation:

mA(output) = 4mA+(16mA)*(D – U4mA ) / (U20mA- U4mA)

Where:

mA(output) = analog output

D = current bound display

U

4mA = user setting for 4 mA for current bound display

U

20mA = user setting for 20 mA for current bound display

【

Note

】

:

1. The ideal range of U4mA and U20mA for pH is -2.00 to 16.00 pH.

2. The ideal range of U4mA and U20mA for absolute mV is -2000 to 2000 mV.

3. The ideal range of U4mA and U20mA for relative mV is -3000 to 3000 mV.

pg.13

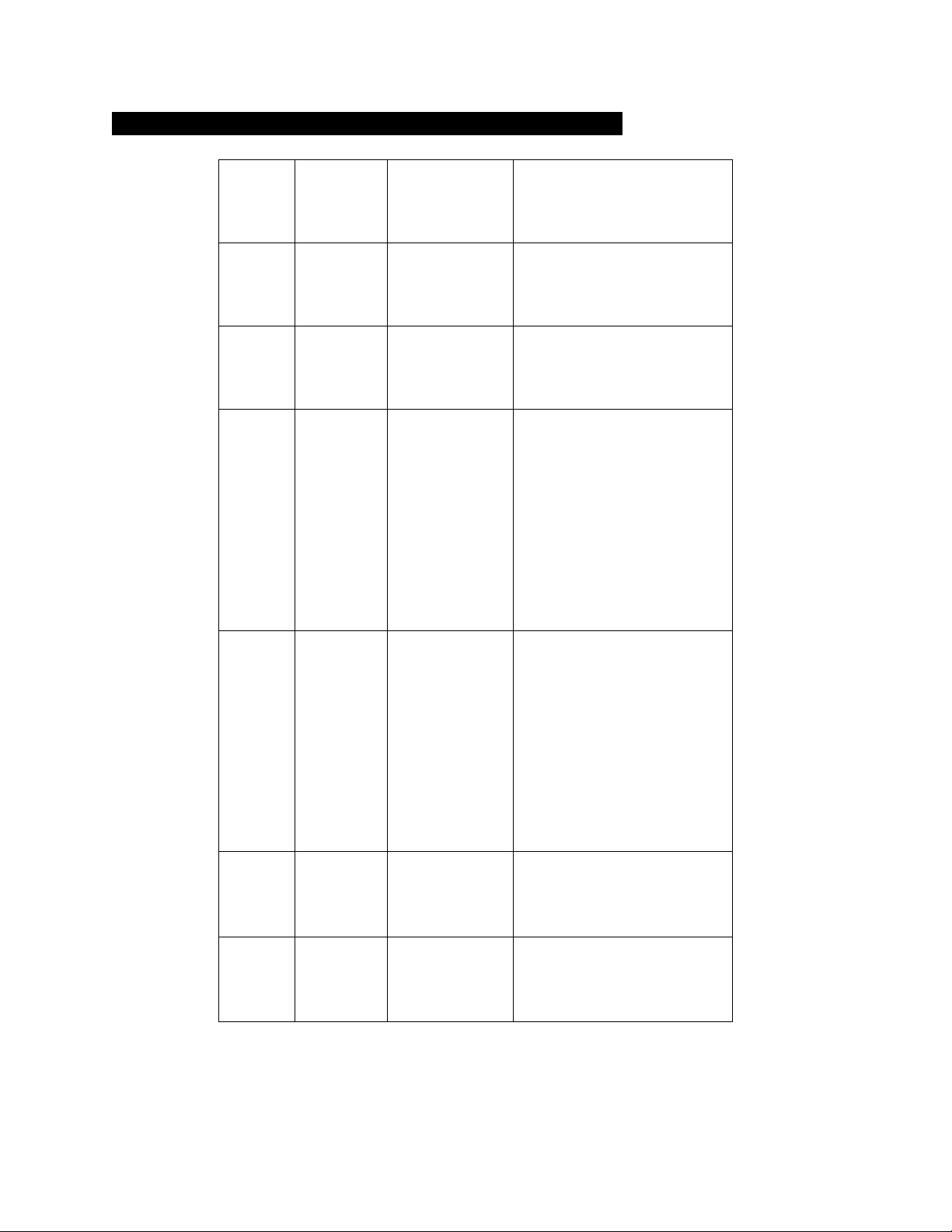

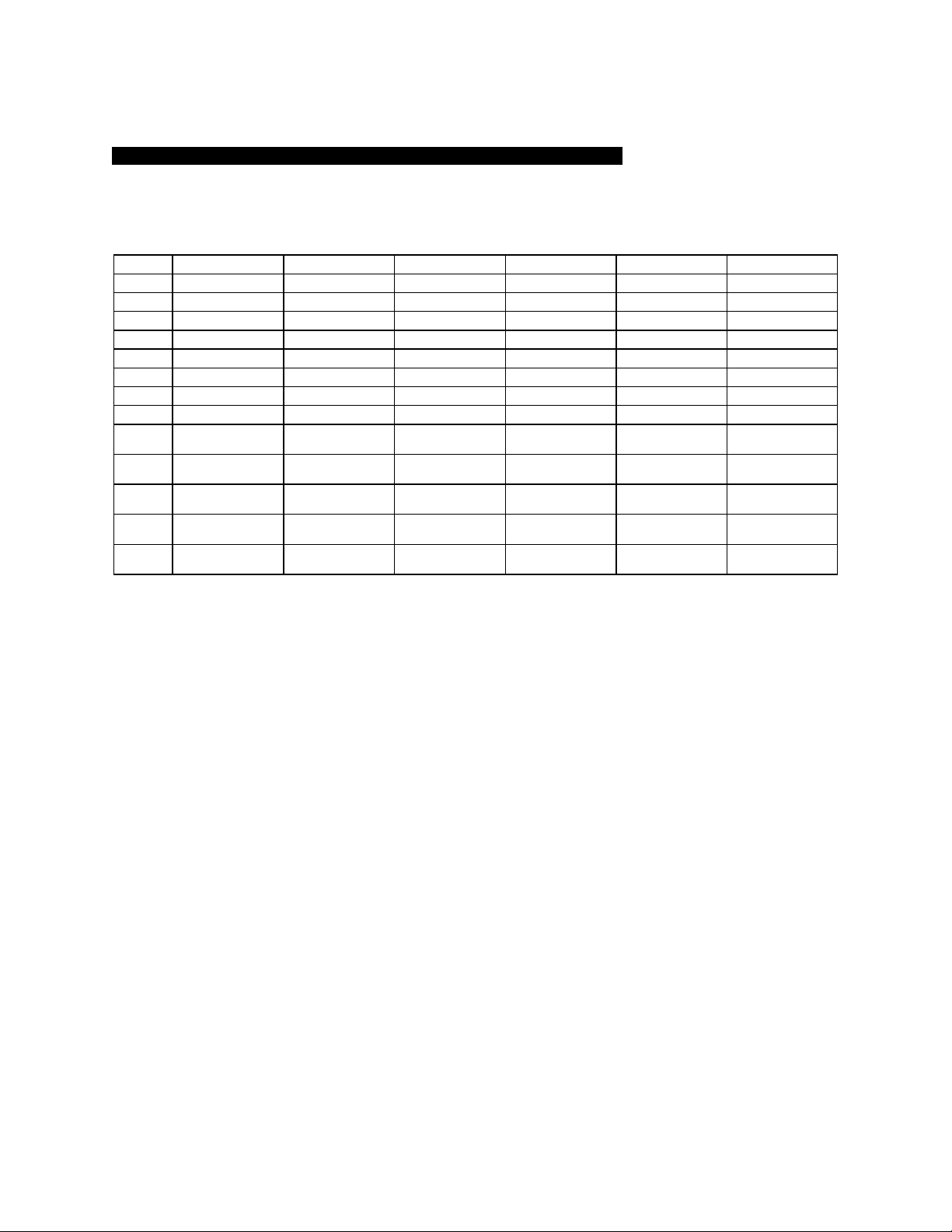

ERROR DISPLAY AND TROUBLESHOOTING ERVIEW

pH/ORP

Display

Temperature

Display

Display Mode

Possible cause(s)

[Action(s)]

"OvEr" -10.0~120.0°C pH measure mode pH > 16.00pH

[Recalibrate]

“Undr” -10.0~120.0°C pH measure mode pH < -2.00pH

[Recalibrate]

"OvEr" "OvEr" pH measure mode a. Temperature > 120.0°C.

[Bring buffer solution to lower

temperature.]

[Replace temperature probe.]

b. No temperature sensor.

[Adjust the manual temperature to -

10~120°C.]

"OvEr" “Undr” pH measure mode a. Temperature < -10.0°C.

[Bring buffer solution to higher

temperature.]

[Replace temperature probe.]

b. No temperature sensor.

[Adjust the manual temperature to -

10~120°C.]

"OvEr" Temperature

reading

Absolute ORP mV or

relative ORP

Absolute ORP mV > +1999 mV

[Bring solution to a lower ORP reading]

"Undr" Temperature

reading

Absolute ORP mV or

relative ORP

Absolute ORP mV < -1999 mV

[Bring solution to a higher ORP reading]

pg.14

pH/ORP

Display

Temperature

Display

Display Mode

Possible cause(s)

[Action(s)]

ORP

reading

"OvEr" Absolute ORP mV or

relative ORP

a. Temperature > 120.0°C.

[Bring buffer solution to lower

temperature.]

[Replace temperature probe.]

b. No temperature sensor.

[Adjust the manual temperature to -

10~120°C.]

ORP

reading

"Uder" Absolute ORP mV or

relative ORP

a. Temperature < -10.0°C.

[Bring buffer solution to higher

temperature.]

[Replace temperature probe.]

b. No temperature sensor.

[Adjust the manual temperature to -

10~120°C.]

"OvEr" 0~60°C a. pH calibration

mode-Buffer 1

(STAND)-7.00

b. pH calibration

mode-Buffer 1

(STAND)-6.86

c. pH calibration

mode-Buffer 2

(SLOPE)

a. Offset < -100 or > 100 mV

b. Offset < -91.7 or > 108.3 mV

c. Slope > ideal mV by 30%

[Use a new buffer solution.]

[Replace electrode.]

pg.15

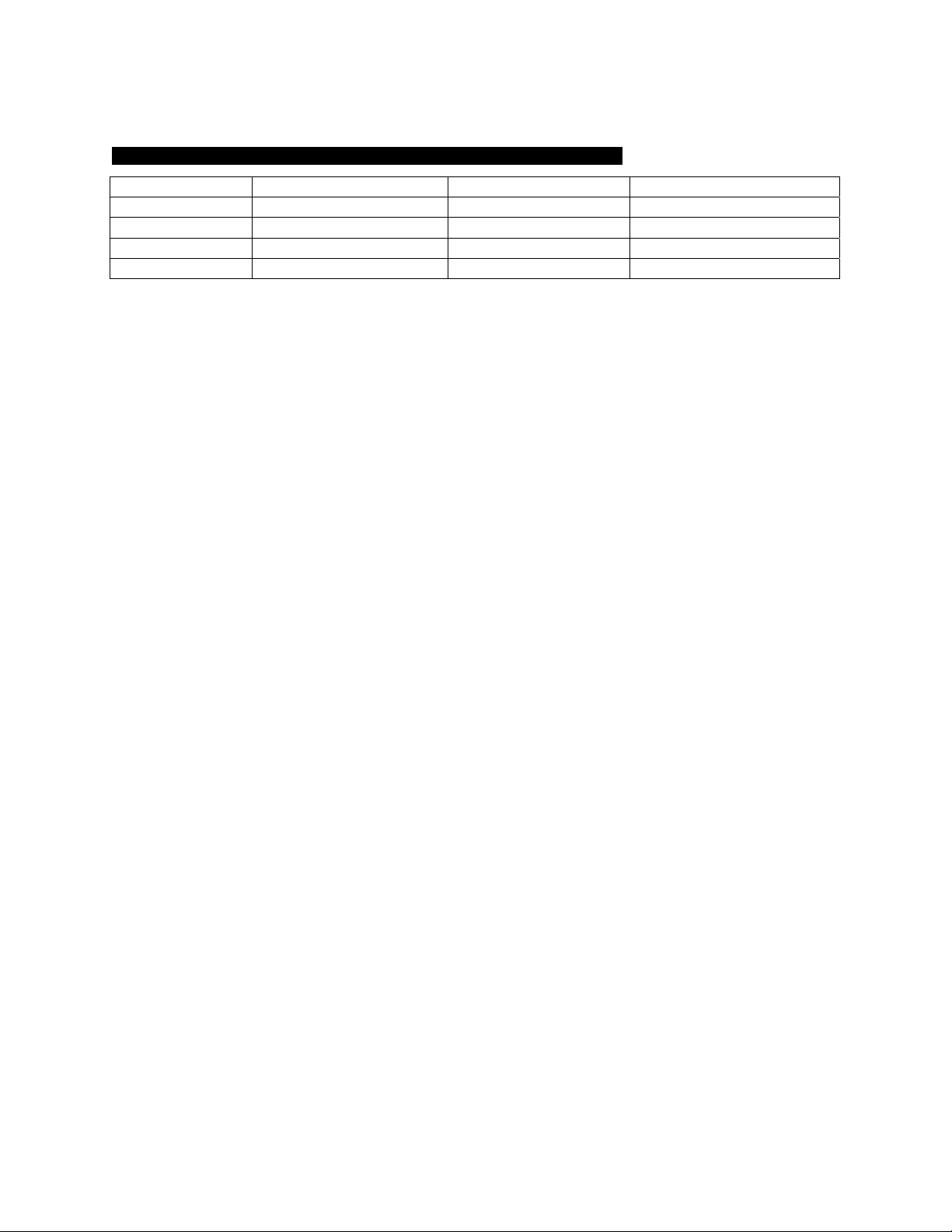

pH BUFFERS

The temperature characteristics of pH calibration buffers pH4.00, pH4.01, pH6.86, pH7.00,

pH9.18 & pH10.01 are stored inside the instrument. The buffers used to calibrate the

instrument must exhibit the same temperature characteristics as the stored values.

°C 4.00 6.86 9.18 4.01 7.00 10.01

0 4.01 6.98 9.46 4.01 7.11 10.32

5 4.00 6.95 9.39 4.01 7.08 10.25

10 4.00 6.92 9.33 4.00 7.06 10.18

15 4.00 6.90 9.28 4.00 7.03 10.12

20 4.00 6.88 9.23 4.00 7.01 10.06

25 4.00 6.86 9.18 4.01 7.00 10.01

30 4.01 6.85 9.14 4.01 6.98 9.97

35 4.02 6.84 9.10 4.02 6.98 9.93

40 4.03 6.84 9.07 4.03 6.97 9.89

45 4.04 6.83 9.04 4.04 6.97 9.86

50 4.06 6.83 9.02 4.06 6.97 9.83

55 4.07 6.83 8.99 4.08 6.97 9.80

60 4.09 6.84 8.97 4.10 6.98 9.78

【Note】: The actual reading of the instrument can differ from the values shown by ±0.01 pH.

pg.16

SPECIFICATIONS

Recognized pH buffers US (4.01, 7.00, 10.01) or NIST (4.00, 6.86, 9.18)

pH Temperature compensation Manual/Auto -10.0°C to 120.0 °C

pH Buffer Temperature range 0.0°C to 60.0 °C

pH Electrode Offset recognition +/-100 mV at pH 7.00 , +108.3 mV/-91.7 mV at pH 6.86

pH Electrode Slope recognition +/- 30% at pH 4.00, 4.01, 9.18, 10.01

Input impedance >1012 Ω

Calibration end point sensing Yes

Temperature sensor Thermistor: 10k ohm at 25 °C, (User selectable) Resistor ( PT1000) or

Manual

Current output range 4 to 20 mA (isolated)

Current output scale user programmable

Maximum load 500 Ω

Accuracy ±0.03 mA

Isolation voltage 500VDC

Keys Audiofeedbackinallkeys

Power: 100VAC to 240VAC , 50/60Hz

Ambient Temperature range 0.0 to 50.0 °C

Case IP65, 1/8DIN case, depth 90mm

Weight 290 g

Mode Range Resolution Accuracy

pH -2.00 to 16.00 pH 0.01 pH ±0.1% ± 1 digit

ORPAbsolute mV -1999 to 1999 mV 1 mV ±0.1% ± 1 digit

ORP Relative mV -2999 to 2999 mV 1 mV ±0.1% ± 1 digit

Temperature -10.0 to 120.0 °C 0.1 °C ±0.3 °C

pg.17

WARRANTY

Sensorex warrants this product to be free from significant deviations in material and

workmanship for a period of 1 year from date of purchase. If repair or adjustment is

necessary and has not been the result of abuse or misuse, within the year period, please

return-freight-prepaid and the correction of the defect will be made free of charge. If you

purchased the item from our Sensorex distributors and it is under warranty, please contact

them to notify us of the situation. Sensorex Service Department alone will determine if the

product problem is due to deviations or customer misuse.

Out-of-warranty products will be repaired on a charge basis.

RETURN OF ITEMS

Authorization must be obtained from one of our representatives before returning items for

any reason. When applying for authorization, have the model and serial number handy,

including data regarding the reason for return. For your protection, items must be carefully

packed to prevent damage in shipment and insured against possible damage or loss.

Sensoex will not be responsible for damage resulting from careless or insufficient packing. A

fee will be charged on all authorized returns.

【

Note

】

:Sensorex reserves the right to make improvements in design, construction and

appearance of our products without notice.

Table of contents

Other Sensorex Controllers manuals