Sensorex TX100 Specification sheet

PRODUCT INSTRUCTION MANUAL

TX100 - pH/mV

2-Wire Loop-Powered

Transmitter

Form: INSTRTX100-Rev G

©2011 Sensorex Corporation

Thank you for choosing the TX100 pH/mV transmitter. This transmitter is a user-friendly microprosser based transmit-

ter for pH and mV measurement. As with all electronic instruments, it is essential to follow all directions for optimal

performance. In particular, you must properly install, use and maintain the TX100 to ensure that it will continue to

operate within its specications.

• Follow all warnings, cautions and instructions marked on and supplied with the transmitter. Please contact your sup-

plier with any product questions or concerns.

• Install the transmitter as specied in this manual, following all applicable local and national codes.

• Do not attempt to repair your TX100 transmitter or use any replacement parts from any other supplier.

• If you nd any errors in this manual, please report them to Sensorex by fax 714-894-4839 or via e-mail at

TECHNICAL AT SENSOREX.COM

• Please complete the WARRANTY REGISTRATION located at the back of this manual and fax to Sensorex at

714-894-4839 or scan and e-mail to TECHNICAL AT SENSOREX.COM

PRODUCT INSTRUCTION MANUAL

TX100 pH/MV Transmitter ESSENTIAL INSTRUCTIONS

READ THIS BEFORE USING YOUR TX100 pH/mV TRANSMITTER!

About This Document

This manual contains instructions for the installation, operation and care of the TX100 pH/mV transmitter. The following list provides notes concerning revisions of

this document.

Rev Level Date Notes

A 8/2007 1st revision of manual. Removed lightning protection graphic on pg. 15 and “DO NOT REMOVE NOTE”

B 10/2007 Added “Essential Instructions”. Fixed drawing in “Quick Start Guide”. Added bold text to “Cord Grip installation” section.

Fixed Figure references Section 8.1 and 8.2. Fixed drawing Figure 11-1. Fixed drawing Figure 11-3. Added

bold text to Section 9.7. Added EMI/RFI specs in TX100 Specications. Revised Figure 10-1. Re-numbered all pages.

C 12/2007 Fixed Figure 11-3 and 11-4 (removed top an bottom holes from mounting plate)

D 3/2009 Corrected ORP range specication from +/-1999mV to +/- 1000mV revised Figure 2-1 to used athead screwdriver at

edge of knockouts.

E 4/28/10 Claried NEMA, IP ratings

F 6/23/11 Added European Declaration of Conformity Certicate to inside cover

G 10/12/11 Correct ORP Range in Specications

H 01/2013 Updated product photo on cover.

PRODUCT INSTRUCTION MANUAL

1.1 General 1

1.2 Features 1

1.3 TX100 Specications 2

1.4 Quick Start Guide 3

2.1 Cord Grip Installation 5

2.2 Wall Mounting 6

2.3 Panel Mounting 7

2.4 DIN Rail Mounting 8

2.5 Pipe Mounting 9

3.1 General 10

4.1 General 11

4.2 Power 11

4.3 4-20mA Loop wiring 12

5.1 General 13

5.2 Direct Sensor Connection 13

6.1 Keypad Function 14

6.2 LCD Display 15

7.1 General 16

8.1 Getting Started 17

8.2 2-Point pH calibration 17

8.3 Temperature Calibration (with ATC) 19

Part 1 Introduction

Part 2 Transmitter Mounting

Part 3 Sensor Mounting

Part 4 Transmitter Electrical Installation

Part 5 Sensor Electrical Connection

Part 6 Keypad Function and LCD Display

Part 7 Transmitter Programming

Part 8 Calibration

Table of Contents

PRODUCT INSTRUCTION MANUAL

9.1 Probe Select Menu 20

9.2 Calibration Oset 21

9.3 Range Menu 22

9.4 Limit Menu 23

9.5 Hold Menu 24

9.6 Clean Probe Menu 25

9.7 Factory Reset 26

9.8 Manual Temperature Compensation (without ATC) 27

9.9 Temperature Unit Menu 28

10.1 General 29

10.2 Troubleshooting Guidelines 29

10.3 Troubleshooting Chart 29

11.1 Overview 30

11.2 Replacement Parts 30

12.1 Product Warranty 34

12.2 Return of Items 34

Part 10 Troubleshooting

Part 11 Maintenance

Part 9 Setup Functions

Part 12 Warranty and Product Returns

Table of Contents

Figure 2-1 Conduit port Knockout removal 5

Figure 2-2 Cord grip Mounting 5

Figure 2-3 Wall Mount 6

Figure 2-4 Panel Mount 7

Figure 2-5 DIN RAIL Mount 8

Figure 2-6 3/4” Pipe Mount 9

Figure 4-1 Power connections (schematic) 11

Figure 4-1a 4-20mA loop wiring (schematic) 12

Figure 5-1 Electrode connections (TBM1) 13

Figure 6-1 Transmitter Keypad 14

Figure 6-2 LCD Denition 15

Figure 7-1 Transmitter Main Menu 16

Figure 8-1 2-Point pH Calibration 18

Figure 8-2 Temperature Calibration 19

Figure 9-1 Probe Select Menu 20

Figure 9-2 Calibration Oset 21

Figure 9-3 Range Menu 22

Figure 9-4 Limit Menu 23

Figure 9-5 Hold Menu 24

Figure 9-6 Clean Probe Menu 25

Figure 9-7 Factory Reset Menu 26

Figure 9-8 Manual Temperature Compensation 27

Figure 9-9 Temperature Unit Menu 28

Figure 10-1 Troubleshooting Chart 29

Figure 11-1 Wall Mount Parts - Exploded View 30

Figure 11-2 Panel Mount Parts - Exploded View 31

Figure 11-3 DIIN- Rail Mount Parts - Exploded View 32

Figure 11-4 Pipe Mount Parts - Exploded View 33

Diagrams and Illustrations

PRODUCT INSTRUCTION MANUAL

PRODUCT INSTRUCTION MANUAL

Part 1 Introduction

1.1 General

The Model TX100 is a microprocessor-based, loop-powered monitoring system, designed for the continu-

ous measurement of pH, mV (ORP) and temperature. The full scale operating range of the transmitter may

be user adjusted to any value between 0-14 pH or -1999 to + 1999mV. All transmitter features are selectable

via the silicone keypad. Please read this manual thoroughly before operating the transmitter. For quick use,

please read the “Quick Start” Instructions supplied with your transmitter.

1.2 Features

- The TX100 is designed to be a fully isolated, loop powered pH/mV instrument for two-wire DC

applications.

- Can be user-adjusted for specic application span from 0-14pH or -1999mV to + 1999mV.

- Automatic temperature compensation via Pt1000 RTD.

- Instrument supplied in rugged NEMA 4X (IP65) enclosure.

- Built-in programmable sensor cleaning reminder.

- Probe select menu allows user to scale in pH or mV units.

- Calibration Oset menu allows user to calibrate transmitter to match another reference pH meter.

- Several preprogrammed pH buer selections available for calibration.

Page 1 of 35

PRODUCT INSTRUCTION MANUAL

Page 2 of 35

1.3 TX100 Specications

Measuring Range (pH) 0.00 to 14.00pH, 0.01 pH resolution,

+/- 0.01 accuracy

Measuring Range (ORP/mV) -1999mV to 1999mV, 1mV resolution,

+/- 2mV accuracy

Measuring Temperature Range -20 degC to 110 degC /-4 degF to 230degF,

0.1degC/F resolution

Current Output Range 2.00mA to 24mA (4-20mA galvanically isolated) , 0.01mA

resolution,+/-0.005mA accuracy

Enclosure NEMA 4X, IP65, ABS case with silicone keypad

HWD: 3.8” (96.52 mm) x 3.8” (96.52 mm) x 2.8” (71.5mm)

Weight approx. 1lb (.45kg)

Mounting Options Wall mount, panel mount, pipe mount and DIN rail (rail not

included)

Conduit Openings Standard: 2 - 3/8” openings cordgrips included.

Ambient Temperature Transmitter Service, 0 degC to 60 degC / 32 degF to 140 degF

Sensor Service – Refer to Sensor specications

Ambient Humidity 0 to 95% (non-condensing)

Location Designed for non-hazardous areas

Temperature Input 2-wire Pt1000 RTD with automatic compensation

Max. Sensor-to-Transmitter Distance 30 feet (9.1 meters)

Power 12-24 V .DC, 8 amp maximum current

EMI/RF EN 61326-1

Supply Voltage ( V DC) Max Resistance Load (Ohms)

12 150

16 350

20 550

24 750

PRODUCT INSTRUCTION MANUAL

Page 3 of 35

1.4 TX100 pH/MV Transmitter - QUICK START GUIDE

The TX100 is supplied with the following preset programming:

Factory Calibrated Values

pH Manual Oset = 0

mV Manual Oset = 0

Temperature Manual Oset = 0

Without TC, Default 25oC or 77oF

Range Mode [ - ] OFF

Range Mode Lo mV reset to -999 mV

Range Mode Hi mV reset to 999 mV

Range Mode Lo pH reset to 0.00

Range Mode Hi pH reset to 13.99

Hold Mode HLd Lr

Limit Mode O.r. OFF

Clean Probe Timer C.P. OFF

To change any of these parameters, please refer to the specic section in this manual (See Table of Contents).

a. Refer to Section 2 for installation instructions.

b. Connect electrode to transmitter as shown below.

c . Remove front cover from transmitter case by unscrewing four screws in rear corners of transmitter.

Connect a 12-24V DC, 8 amp maximum power supply as shown above. See page 6 for resistance load vs.

voltage.

d. Transmitter Programming/Setup

PRODUCT INSTRUCTION MANUAL

Page 4 of 35

e. If installed electrode is pH, move to step f.

If ORP/mV electrode is installed see Section 9.1 for Probe Selection programming.

f. Temperature Calibration is done at the factory before shipping. For temperature recalibration follow steps

shown in Section 9.8.

g. Factory preset temperature units are oC. To change to oF, follow instructions in Section 9.9.

h. For pH, perform Two-Point pH calibration as outlined in Section 8.2.

First buffer is pH 7.00 or 6.86 (NIST), second buffer choices are 4.01, 10.00 or 9.18 (NIST). A two-point

calibration must be performed. Three-point calibration is not necessary with the TX100.

PRODUCT INSTRUCTION MANUAL

Page 5 of 35

Part 2 Transmitter Mounting

2.1 Cord Grip Installation

Turn transmitter upside down with display facing you. Punch out either one or two conduit knockouts with

a small hammer and punch as shown below for cord grip mounting. Ensure back cover is installed to provide

mechanical support for the enclosure walls. BE CAREFUL NOT TO DAMAGE THE INTERNAL ELECTRONICS OR

CRACK THE TRANSMITTER CASE while performing this action.

Figure 2.1

Figure 2.2

PRODUCT INSTRUCTION MANUAL

Page 6 of 35

2.2 Wall Mounting

INCHES

(MILLIMETERS)

Figure 2.3

PRODUCT INSTRUCTION MANUAL

Page 7 of 35

2.3 Panel Mounting

INCHES

(MILLIMETERS)

Figure 2.4

PRODUCT INSTRUCTION MANUAL

Page 8 of 35

2.4 DIN Rail Mounting

INCHES

(MILLIMETERS)

Figure 2.5

PRODUCT INSTRUCTION MANUAL

Page 9 of 35

2.5 Pipe Mounting

INCHES

(MILLIMETERS)

Figure 2.6

4

PRODUCT INSTRUCTION MANUAL

Page 10 of 35

Part 3 Sensor Mounting

3.1 General

Select a location within the maximum sensor cable length (30 ft) for mounting of the sensor ow cell. If

there is more than 30 ft distance from the electrode to the transmitter, you should purchase a battery-

powered preamplier model PHAMP-1, or use an amplied pH or ORP electrode. Locate sensor away from

pumps, adjustable frequency drive systems, or other sources of high frequency EMI if possible. Refer to the

installation manual for your electrode for mounting requirements.

PRODUCT INSTRUCTION MANUAL

Page 11 of 35

Part 4 Transmitter Electrical Installation

4.1 General

The TX100 loop-powered instrument is a 12-24 VDC loop-powered pH/mV transmitter.

WARNING: Do not connect AC line power to the 2-wire module. Severe damage will result.

Important Notes:

1. Use wiring practices that conform to all national, state, and local electrical codes.

2. DO NOT run sensor cables or instrument 4-20 mA output wiring in the same conduit that contains AC

power wiring. AC power wiring should be run in a dedicated conduit to prevent electrical noise from

coupling with the instrumentation signals.

3. DO NOT remove dessicant pack from inside transmitter case. This is necessary to control moisture.

4.2 Power

A12-24VDC power supply, eight amp maximum current must be used to power the instrument. See chart

below for Maximum load. The exact connection of this power supply is dependent on the control sys-

tem into which the instrument will connect. See Figure 4.1 for further details. Any twisted pair shielded

cable can be used for connection of the instrument to the power supply. Route signal cable away from AC

power lines, adjustable frequency drives, motors, or other noisy electrical signal lines. Do not run sensor or

signal cables in conduit that contains AC power lines or motor leads. The TX100 is supplied with a light-

ning protective component.

Note: Terminal block labels for power, electrode and temperature sensor connections are marked on the PCB next to their

respective terminal.

Figure 4.1

PB

RF

GD

TC

PWR

Supply Voltage( V DC) Max Resistance Load (Ohms)

12 150

16 350

20 550

24 750

TBM1 - Terminal Block

1. PB, pH wire (center wire of

coaxial cable)

2. RF, Reference wire (braid of

coaxial cable)

3. GD, Temperature Input 1

(Pt1000 RTD)

4. TC, Temperature Input 2

(Pt1000 RTD)

5. PWR (NO CONNECTION)

1. (L-) Power Supply -

2. (L+) Power Supply +

PRODUCT INSTRUCTION MANUAL

Page 12 of 35

Part 4 Transmitter Electrical Installation

Figure 4.1A

Supply Voltage( V DC) Max Resistance Load (Ohms)

12 150

16 350

20 550

24 750

4.3 4-20mA loop connection to PLC or other 4-20mA load device

Install loop wiring as shown below in diagram 4.1A, paying particular attention to maximum resistance load

shown in the chart. Note that PLC or 4-20mA device and power supply are customer supplied components.

PRODUCT INSTRUCTION MANUAL

Page 13 of 35

Part 5 Electrode Electrical Connection

5.1 General

The electrode cable can be quickly connected to the TX100’s terminal strip by matching the wire colors on

the cable conductors. Route signal cable away from AC power lines, adjustable frequency drives, motors, or

other noisy electrical signal lines. Do not run sensor or signal cables in conduit that contains AC power lines

or motor leads.

5.2 Direct Sensor Connection

The sensor cable can be routed into the enclosure through one of the provided cord-grip retainers, or

through a properly sized conduit connection. Connect electrode wires as shown below.

If the cord-grip devices are used for sealing the cable, ensure the cord-grips are snugly tightened after elec-

trical connections have been made to prevent moisture incursion.

Note: Terminal block labels for power, electrode and temperature sensor connections are marked on the PCB

next to their respective terminal.

Figure 5.1

PB

RF

GD

TC

PWR

PRODUCT INSTRUCTION MANUAL

Page 14 of 35

Part 6 Keypad Function and LCD

6.1 Keypad

The TX100 keypad is designed for ease-of-use. See graphic below for keypad function.

Figure 6.1

Table of contents

Other Sensorex Transmitter manuals

Sensorex

Sensorex CT-1000 User manual

Sensorex

Sensorex TX3000 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX3100 User manual

Sensorex

Sensorex CX100 User manual

Sensorex

Sensorex CX105 User manual

Sensorex

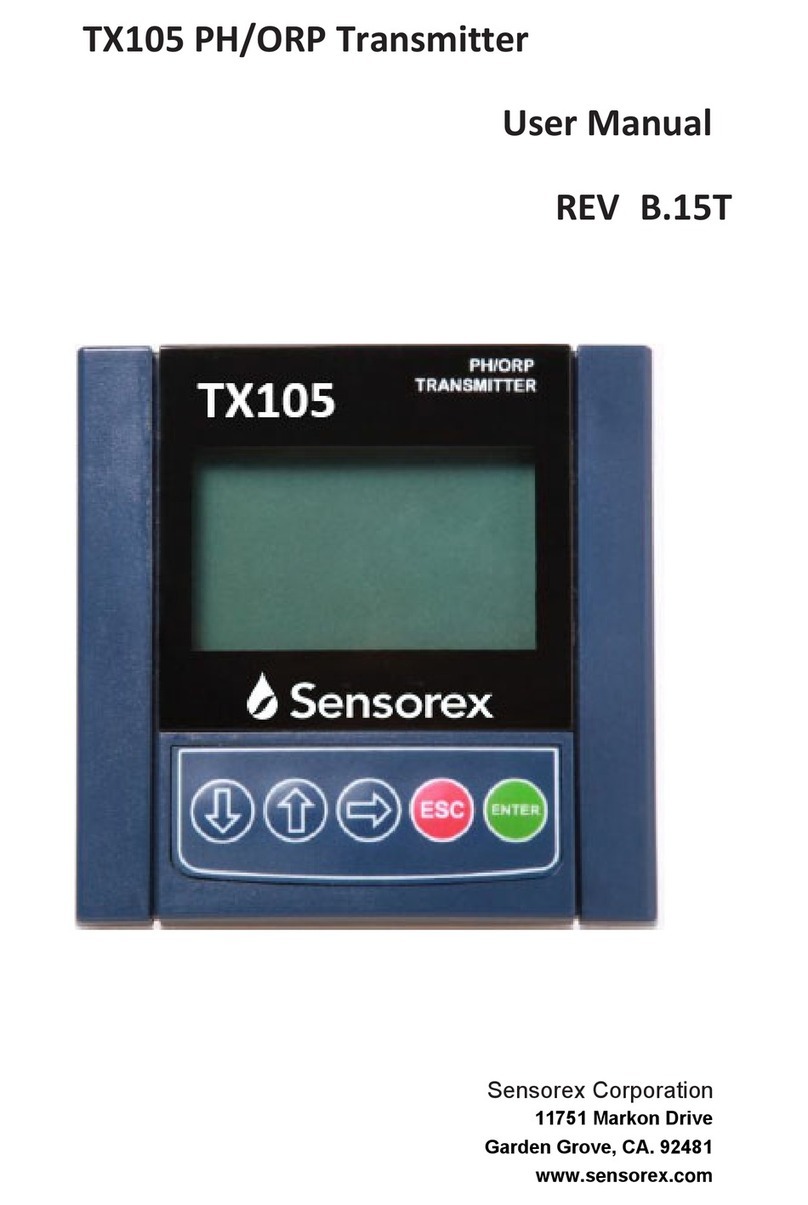

Sensorex TX105 User manual

Popular Transmitter manuals by other brands

RKI Instruments

RKI Instruments 65-2646XL-05-04 Operator's manual

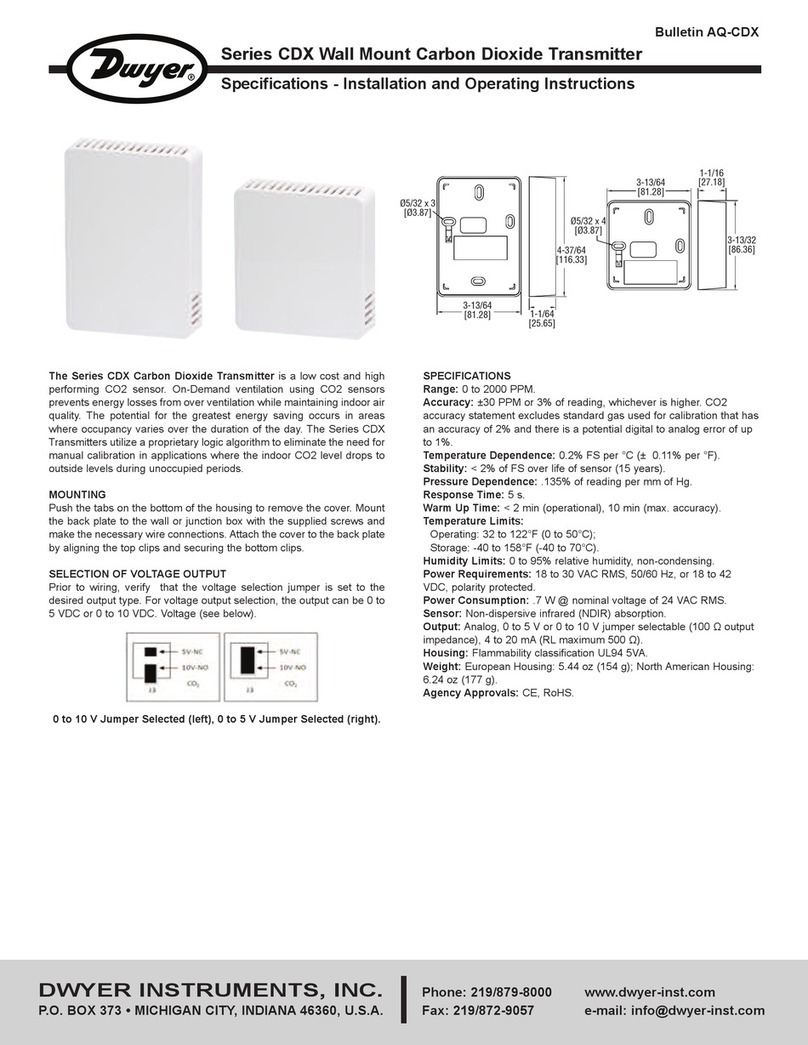

Dwyer Instruments

Dwyer Instruments CDX Series Installation and operating instruction manual

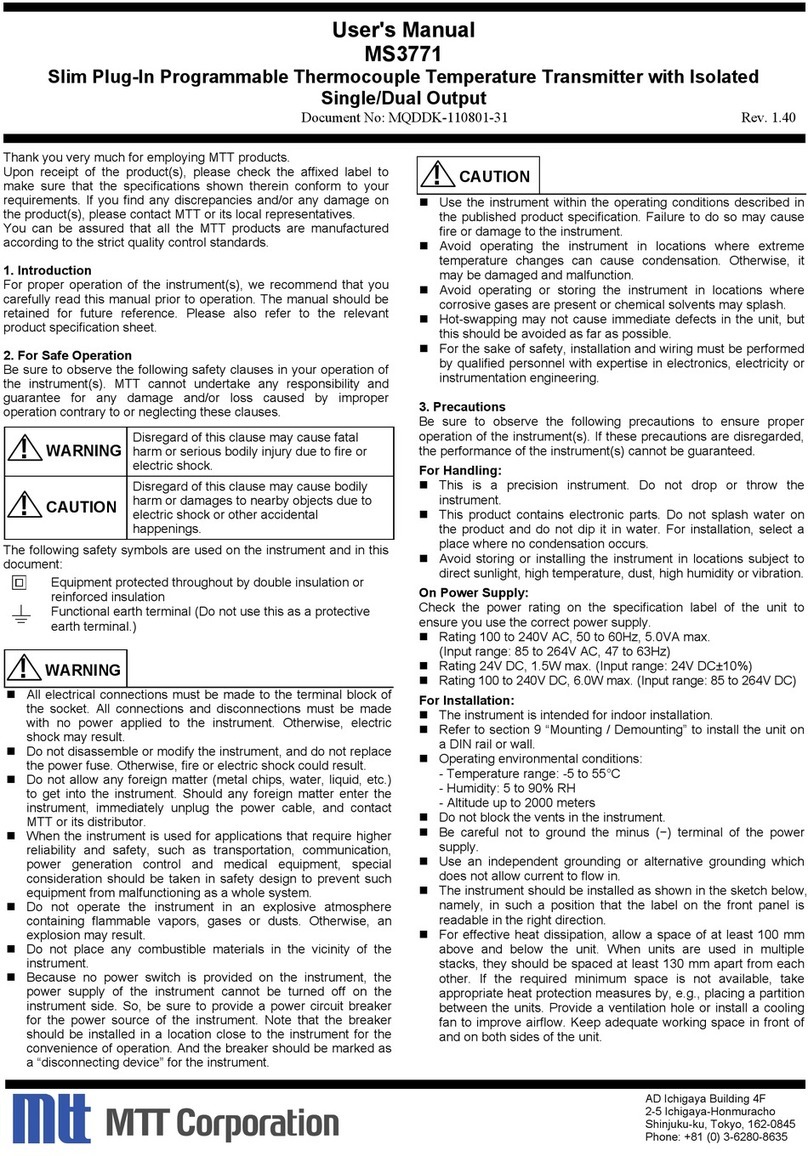

MTT

MTT MS3771 user manual

FISCHER

FISCHER ECO-LINE DE80 operating manual

Crestron

Crestron DigitalMedia DM-TX-200-2G Operations & installation guide

Burkert

Burkert SE56 quick start guide