Sensorex TX3100 User manual

TX3100

Microprocessor

pH/ORP

Transmitter

Operation

Manual

TX3100

2

CONTENTS

Precautions for Installation

Brief Instructions ................................................................................................................................. 4

1. Specifications .................................................................................................................................... 7

2. Assembly and Installation

2.1 Transmitter Installation ................................................................................................................ 8

2.2 Panel Mounting Illustration ......................................................................................................... 8

2.3 Wall Mounting and Pipe Mounting Illustration ........................................................................... 9

2.4 Electrode and Housing Assembly .............................................................................................. 10

2.5 Round Junction Box Illustration and Description ...................................................................... 13

2.6 Rectangular Junction Box Illustration and Description ............................................................. 16

3. Overview of pH/ORP Transmitter TX3100

3.1 Rear Panel Illustration ............................................................................................................... 19

3.2 Terminal Function Illustration ................................................................................................... 19

3.3 Terminal Function Description .................................................................................................. 20

3.4 Accessorial Transmitter PH-300T Installation (Optional) ......................................................... 21

3.5 Transmitter and Accessorial Transmitter PH-300T Connection ................................................ 22

3.6 Wiring Illustration ...................................................................................................................... 23

3.7 Electrical Connection Illustration .............................................................................................. 24

3.8 Online pH/ORP Measurement System (Optional) ..................................................................... 25

4. Configuration

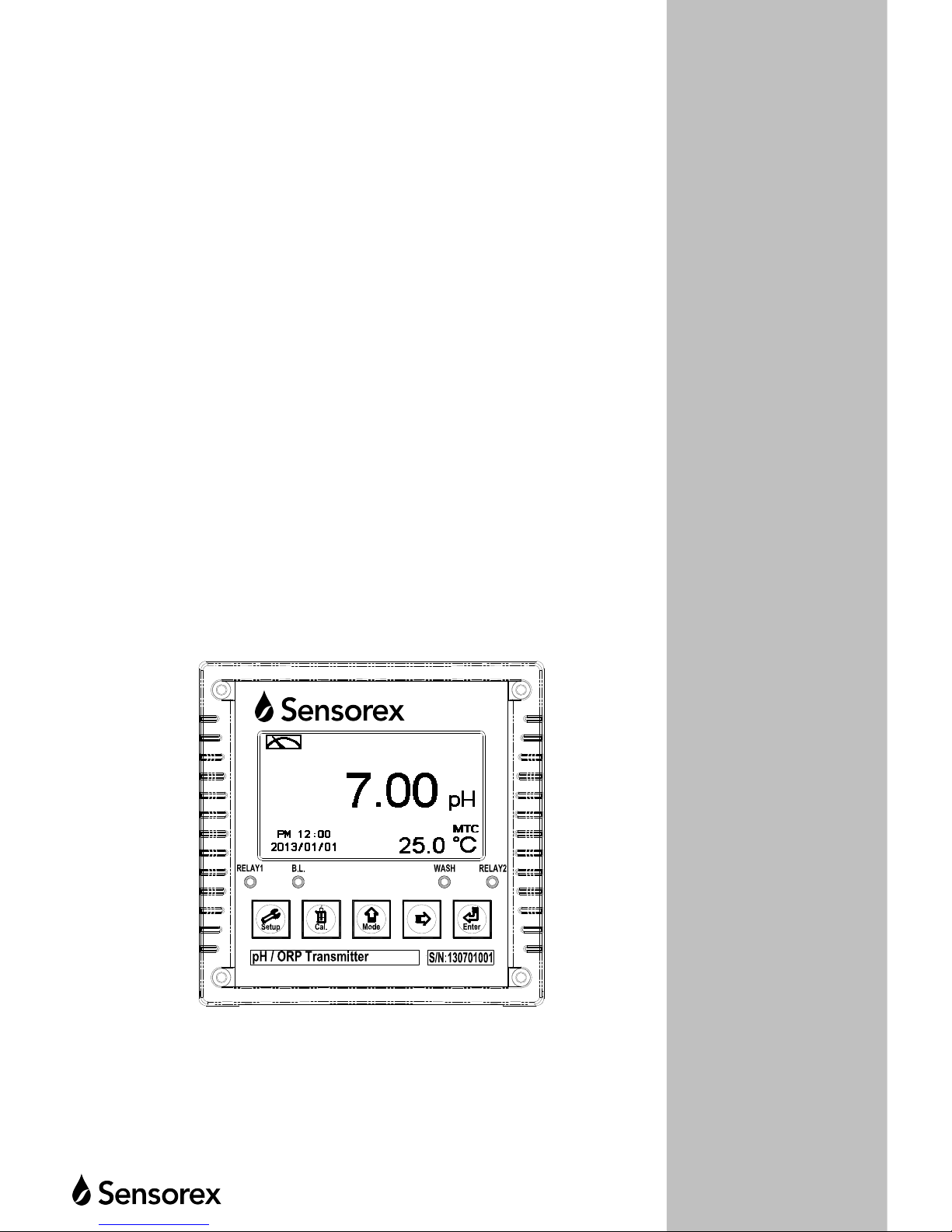

4.1 Front Panel Illustration .............................................................................................................. 26

4.2 Keypad ....................................................................................................................................... 26

4.3 LED Indicators ........................................................................................................................... 26

4.4 Display. ...................................................................................................................................... 27

5. Operation

5.1 Measurement Mode ................................................................................................................... 28

5.2 Settings Menu ............................................................................................................................ 28

5.3 Calibration Menu ....................................................................................................................... 28

5.4 Shortcuts .................................................................................................................................... 28

5.5 Default Values ............................................................................................................................ 28

6. Settings

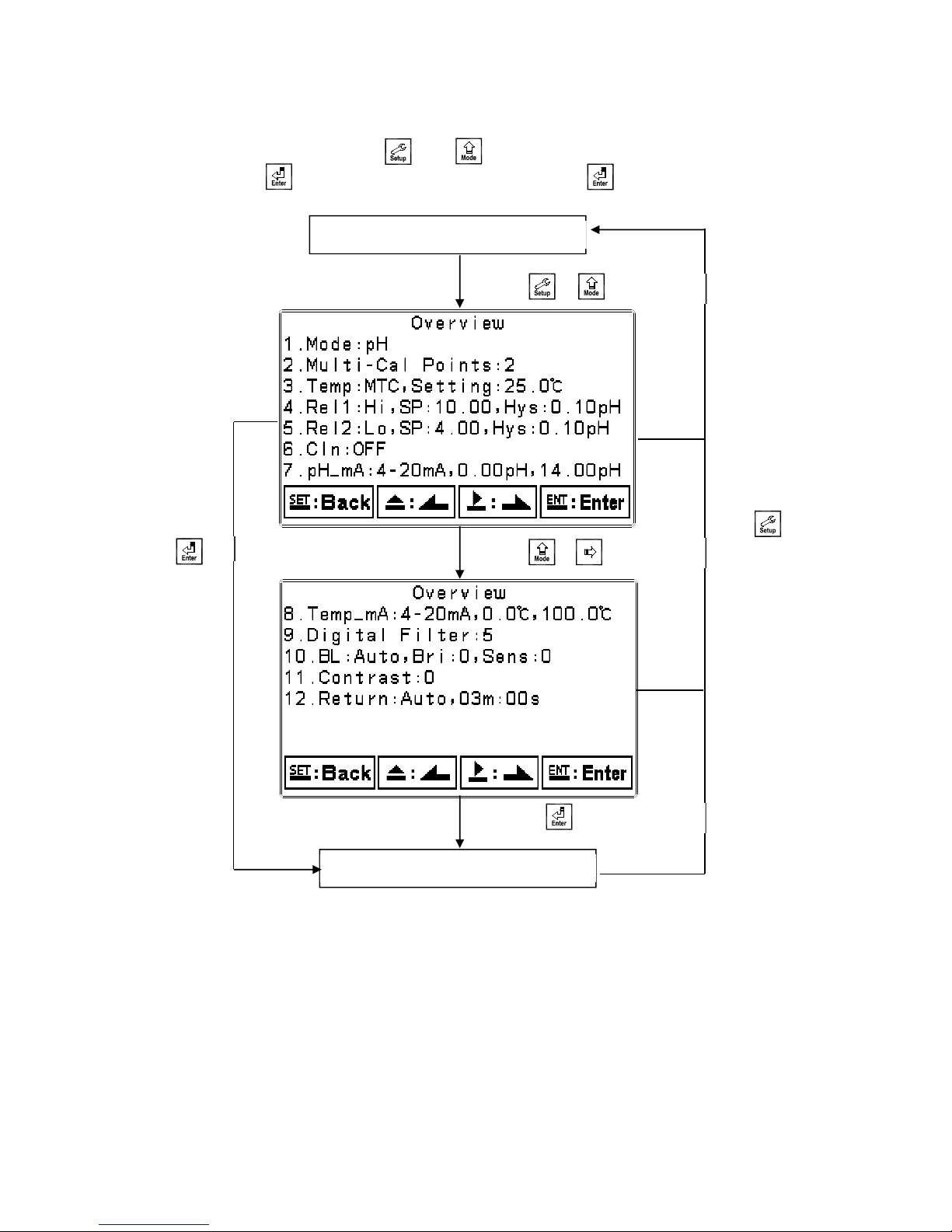

Settings Block Diagram ................................................................................................................... 30

6.1 Settings Menu ............................................................................................................................ 32

6.2 Settings Security Code (Code) ................................................................................................... 33

6.3 Language .................................................................................................................................... 34

6.4 Measurement Parameter (Mode) ............................................................................................... 35

3

6.5 Multi-Point Calibration (Multi-Cal) .......................................................................................... 36

6.6 Temperature ............................................................................................................................... 37

6.7 Relay 1 ....................................................................................................................................... 38

6.8 Relay 2 ....................................................................................................................................... 39

6.9 Clean .......................................................................................................................................... 40

6.10 Analog Output 1 (pH/ORP) ..................................................................................................... 41

6.11 Analog Output 2 (Temperature) ............................................................................................... 42

6.12 Date/Time (Clock) ................................................................................................................... 43

6.13 Sample Measurement Average (Digital Filter) ........................................................................ 44

6.14 Back Light ................................................................................................................................ 45

6.15 Contrast .................................................................................................................................... 46

6.16 Automatic Return (Return) ...................................................................................................... 47

7. Calibration

Calibration Block Diagram .............................................................................................................. 48

7.1 Calibration Menu ....................................................................................................................... 49

7.2 Calibration Security Code (Code) .............................................................................................. 50

7.3 pH Calibration ............................................................................................................................ 51

7.4 ORP Calibration ......................................................................................................................... 55

7.5 Automatic Return (Return) ........................................................................................................ 56

8. Error Messages (Error Codes) ...................................................................................................... 57

9. Maintenance ................................................................................................................................... 58

Appendix ............................................................................................................................................. 59

4

Brief Instructions

◎Settings Menu Description (See Chapter 6 for Details)

Press and simultaneously to display settings information overview. Press_____to enter

settings menu. Press keypad according to the index bar at the bottom of the screen.

Keypad Index

Keypad Index Bar Description

Return to previous level or action

Left or left page

Increase digit

Right or right page

Decrease digit

Confirm and proceed to next step

Settings Items

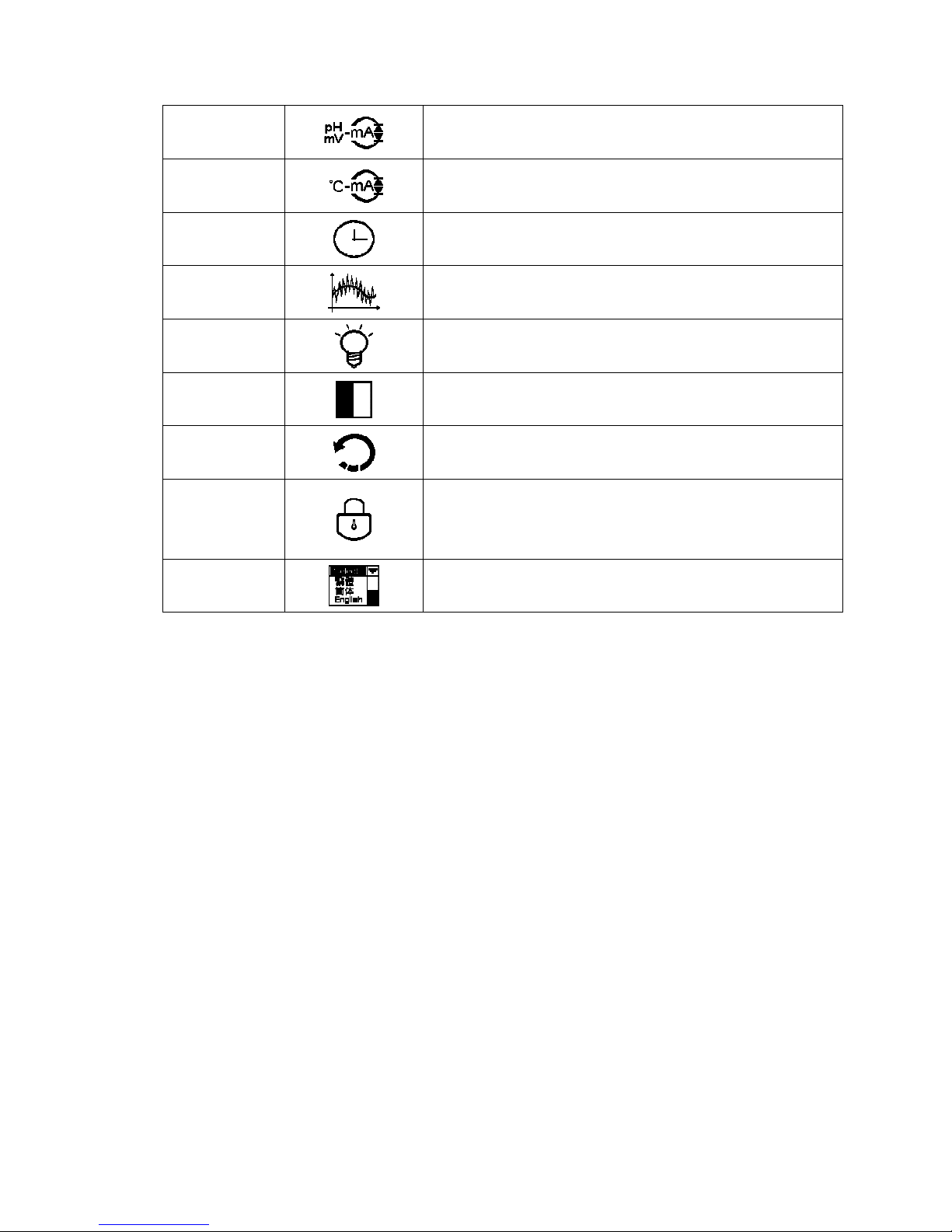

Function Icon Description

Mode Measurement mode, select pH or ORP measurement

Multi-Cal. Multi-point calibration, adjust number of points

(PC-3310 provides up to three point calibration)

Temperature

Temperature measurement and compensation,

MTC - Manual temperature compensation

PTC/NTC - Auto temperature compensation

Relay 1 First relay settings, select Hi/Lo alarm or OFF

Relay 2 Second relay settings, select Hi/Lo alarm or OFF

Clean Automatic wash time settings

Set cleaning relay ON/OFF duration

5

Analog 1 Current output corresponding to pH or ORP range

Analog 2 Current output corresponding to temperature range

Clock Time and date settings

Digital Filter Digital filter settings, adjust number of samples to be

averaged for each reading

Back Light Backlight settings, set backlight Auto/ON/OFF,

brightness, and sensitivity

Contrast Screen contrast settings

Return Measurement mode return settings

Code

Settings passcode setup, the settings passcode is

precedential to the calibration passcode and can be used to

bypass calibration lock

Language Available in English, Traditional Chinese, and Simplified

Chinese

6

◎Calibration Menu Description (See Chapter 7 for Details)

Press and simultaneously to display calibration information overview. Press_____to

enter calibration menu. Press keypad according to the index bar at the bottom of the screen.

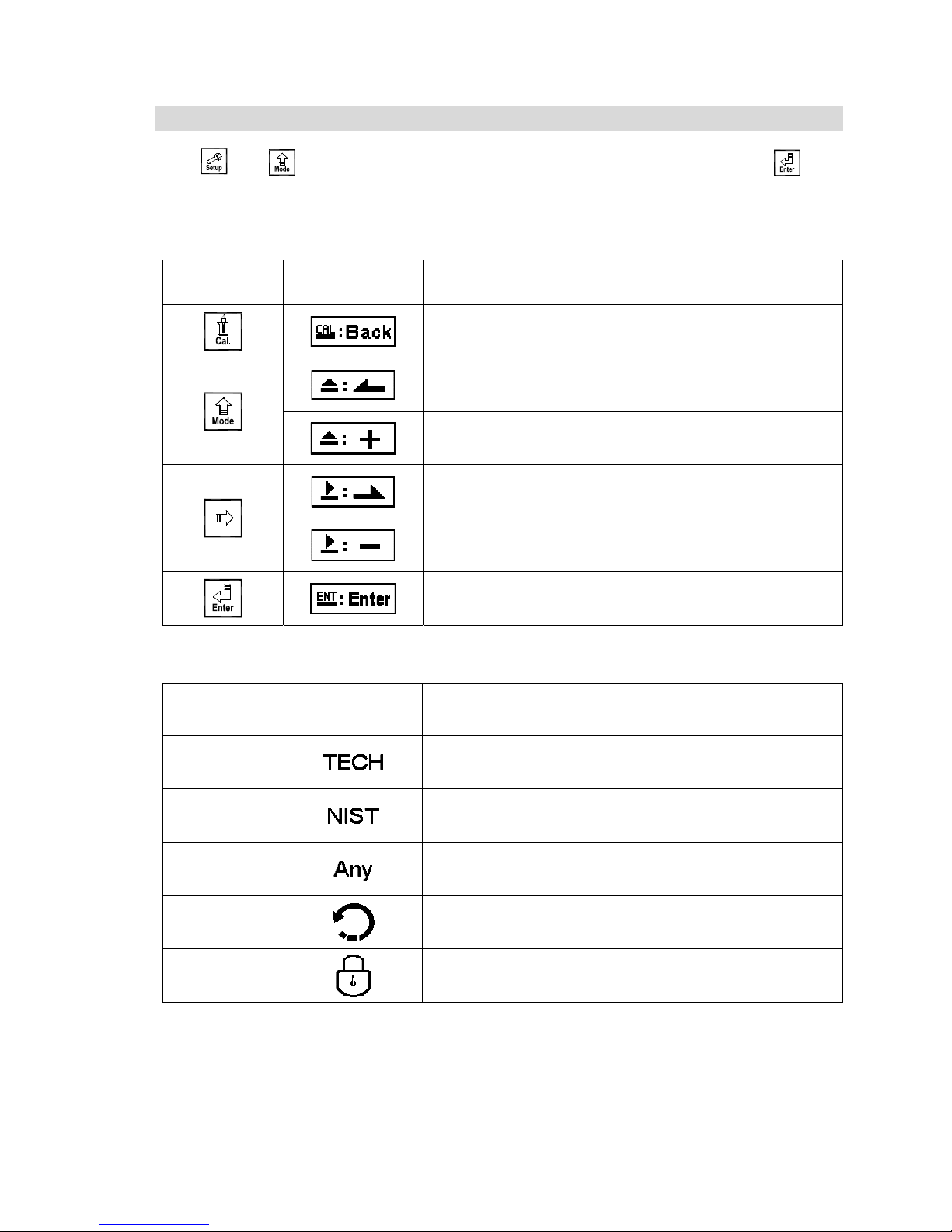

Keypad Index:

Keypad Accordingly item Description

Return to previous level or action

Left or left page

Increase digit

Right or right page

Decrease digit

Confirm and proceed to next step

Calibration Items:

Function Icon Description

TECH Use TECH buffers as standard solution for calibration

NIST Use NIST standard buffers (DIN 19266) as standard

solution for calibration

Any Use any buffer solution by users’ definition for calibration

Return Measurement mode return settings

Code Calibration passcode setup

7

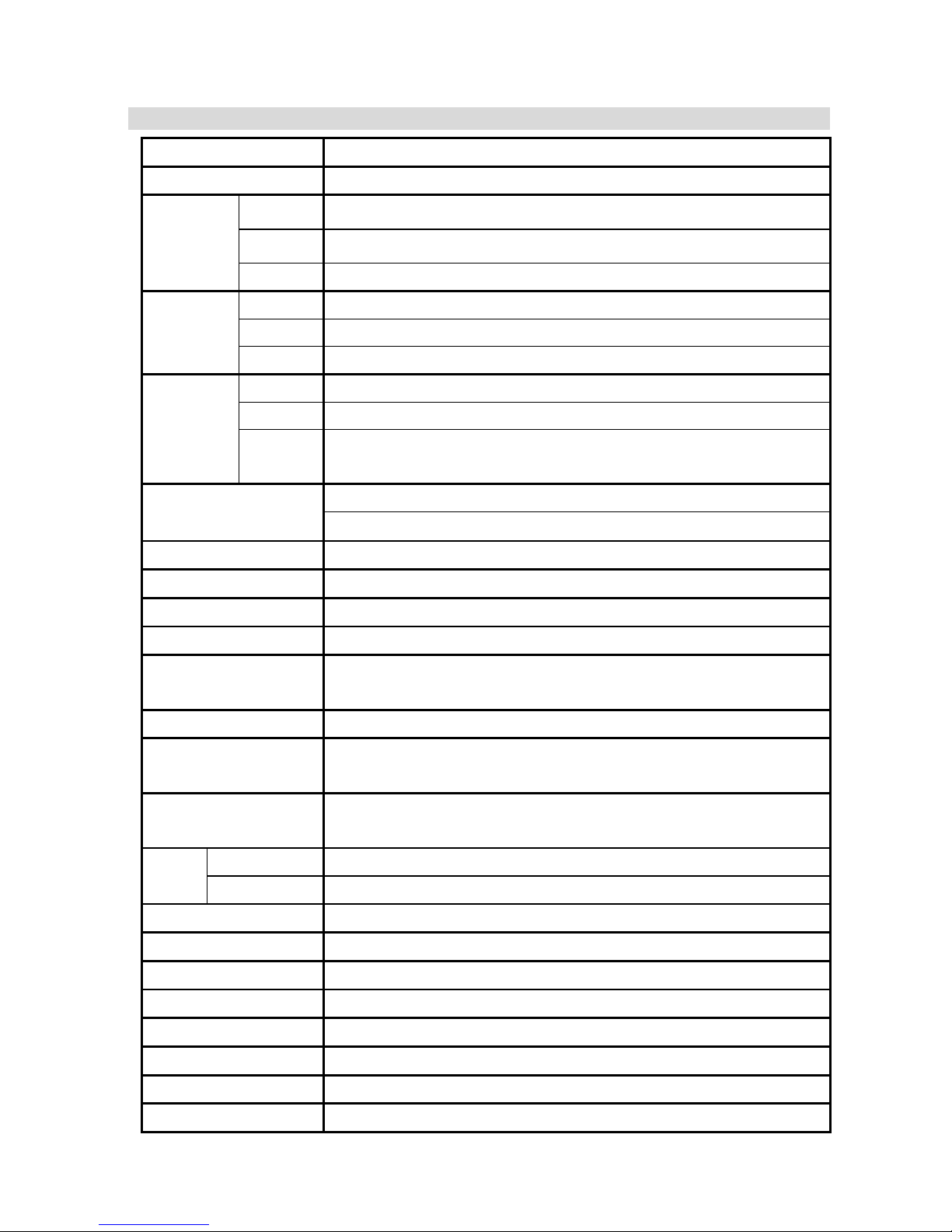

1.Specifications

Model TX3100

Measurement Modes pH/ORP/Temp

Range

pH -2.00~16.00 pH

ORP -1999~1999 mV

TEMP -30.0~130.0˚C

Resolution

pH 0.01 pH

ORP 1 mV

TEMP 0.1˚C

Accuracy

pH ±0.01 pH (±1 Digit)

ORP ±0.1% (±1 Digit)

TEMP ±0.2˚C (±1 Digit)

with temperature error correction

Temperature

Compensation

NTC30K / PT1K Auto temperature compensation

Manual temperature compensation

Calibration Mode TECH, NIST, Any Buffer, up to three point calibration

Ambient Temp. 0~50˚C

Storage Temp. -20~70˚C

Input Impedance > 1012Ω

Display Large LCM with backlight sensor and contrast adjustment;

Text mode

Language Available in English, Traditional Chinese, Simplified Chinese

Analog Output 1 Isolated DC 0/4~20 mA corresponding to main measurement,

Max load 500Ω

Analog Output 2 Isolated DC 0/4~20mA corresponding to temperature,

Max load 500Ω

Settings Contact RELAY ON/OFF contact, 240VAC 0.5A Max (recommended)

Activate Hi/Lo, Hi/Hi, Lo/Lo, selectable two limited programmable, ON/OFF

Wash RELAY contact, ON 0~99 min 59 sec / OFF 0~999 hr 59 min

Voltage Output DC±12V, 1W Max for PH-300T (Optional)

Protection IP65

Power Supply 100V~240VAC±10%, 6W Max, 50/60Hz

Installation Wall / Pipe / Panel Mounting

Dimensions 144 mm × 144 mm × 115 mm (H×W×D)

Cut off Dimensions 138 mm × 138 mm (HW)

Weight 0.8 kg

8

2. Assembly and Installation

2.1 Transmitter Installation

This transmitter can be installed by panel mounting, wall mounting, or 2” pipe mounting.

Panel Mounting:

Prepare a square hole of 138 mm x 138 mm on the panel box, then insert the controller directly

into the hole. Insert the accessorial mounting bracket from the rear, and fix into the pickup groove.

2.2 Panel Mounting Illustration

Min. 200 mm

Min. 200 mm

Hole distances on the panel box

Panel mounting illustration,

fixed with mounting bracket

138 mm

138 mm

Hole size

++

+

+

Mounting bracket

90 mm

10

Put heat-shrinkable

sleeve on coaxial shield

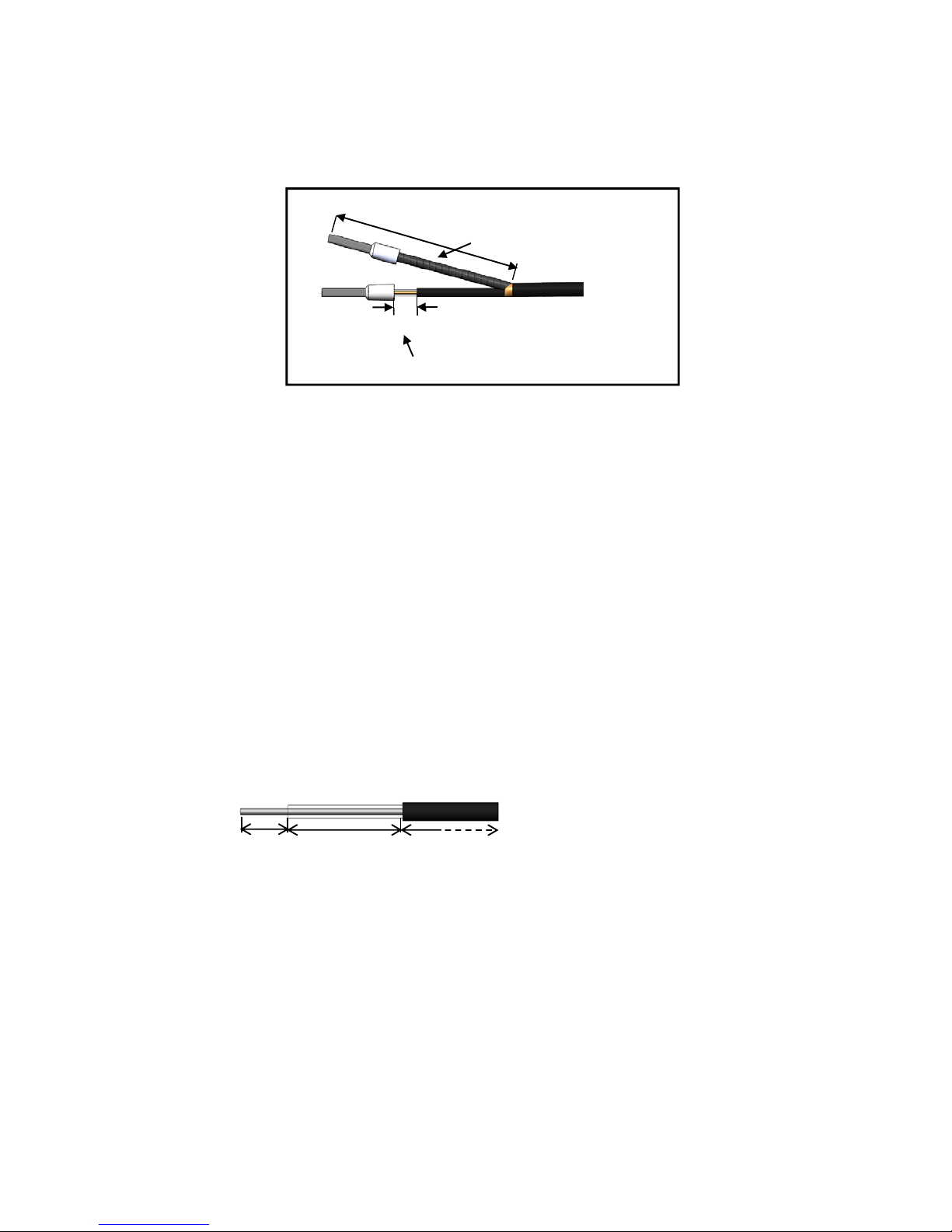

2.4 Electrode and Housing Assembly

2.4.1 Cable Preparation (Cable Stripping Procedure)

a. Strip off approximately 40 mm of the pH/ORP coaxial cable jacket; separate the coaxial inner

wire and coaxial shield wire as seen in the illustration above.

b. Make sure to remove the conductive rubber of the coaxial inner as seen in the following

illustration.

c. Put heat-shrinkable sleeve on the coaxial shield.

d. Attach connection tips on both ends of coaxial inner and coaxial shield.

e. Extend the cable to the transmitter without any joints except at the junction box. Connect the

transparent coaxial inner directly to the GLASS terminal on the back of transmitter, then

connect the metal coaxial shield to the REF terminal.

pH/ORP Signal Cable Preparation Instruction:

Refer to the cable preparation illustration above. Peel 5 mm of the black conductive rubber wrap

on the coaxial inner away from the connection tip.

The length of the separated coaxial inner and coaxial shield wires is suggested to be approx. 40

mm for the convenience of wiring.

6mm 12mm Conductive rubber

Coaxial Inner Stripping Illustration

Transparent coaxial inner

(Peel away conductive rubber)

5mm

40mm

pH/ORP Cable Preparation

19

3. Overview of pH/ORP Transmitter TX3100

3.1 Rear Panel Illustration

3.2 Terminal Function Illustration

POWER

WASH/Cln

2

4/20m

A

+

-

±12V

+

-

REL2REL1

AC

INPUT

POWER

1

4/20m

A

+

-

Temp

(T/PShield)

SG

T/P

GLASS

REF

pH/

ORP

20

3.3 Terminal Function Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

100~240 AC: Power supply terminal

WASH: Wash relay contact for an external relay

REL2: Second alarm control, contact for an external relay

REL1: First alarm control, contact for an external relay

NC / D-(A): No contact

4~20mA - terminal / G: Temperature current output terminal -, for external

recorder or PLC control

4~20mA + terminal / D+(B): Temperature current output terminal +, for

external recorder or PLC control

4~20mA - terminal: Master measure current output terminal -, for external

recorder or PLC control

4~20mA + terminal: Master measure current output terminal +, for external

recorder or PLC control

DC±12V: Output terminal of direct current voltage ±12V

T/P: Connect with one of cable end of temperature probe

SG: Solution ground wire. In a two-wire distribution system, the

terminals SG and REF should be short circuited with a terminal cross

jumper slice (included and attached as factory default).

REF: Coaxial shield of pH/ORP electrode signal wire

NC: No contact

GLASS: Coaxial inner of pH/ORP electrode signal wire

23

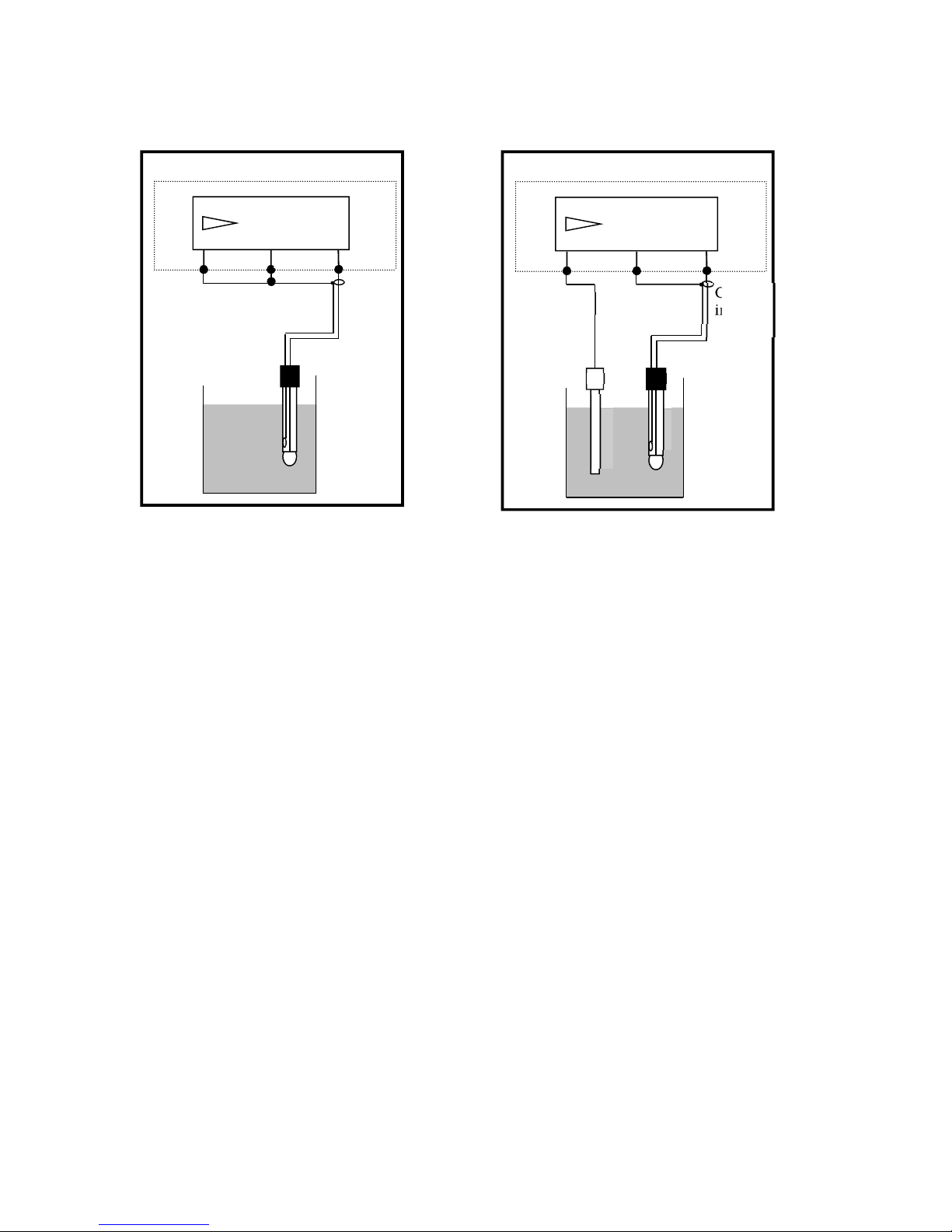

3.6 Wiring Illustration

Three-Wire Distribution

GND REF. GLAS

pH/

ORP

Coaxial

inner

Coaxial

shield

Black

Two-Wire Distribution

GND REF. GLAS

pH/

ORP

Coaxial

inner

Coaxial shiel

d

Short circuit slice

24

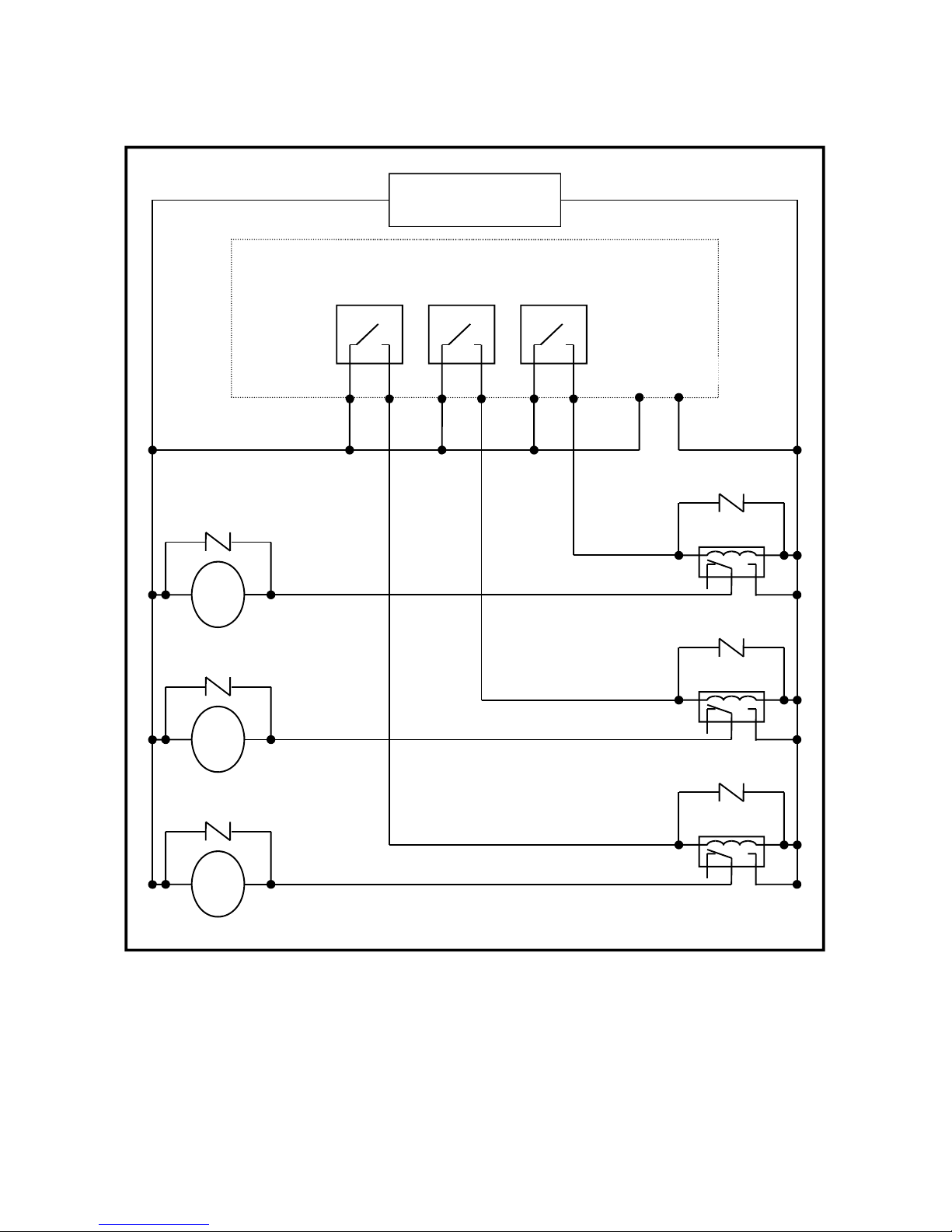

3.7 Electrical Connection Illustration

100V~240VAC

Relay 2 Relay 1 WASH/Cln

100V~240VAC

Transmitter

Cleaning device

Surge absorber

M

Surge absorber

External relay

Dose feeder

Surge absorber

M

Dose feeder

Surge absorber

M

Surge absorber

External relay

Surge absorber

External relay

Note: The transmitter’s built-in miniature relays are required to be repaired and replaced by professional

technicians. External relays (Power Relay) must be connected to activate external devices.

26

4. Configuration

4.1 Front Panel Illustration

4.2 Keypad

In order to prevent unauthorized operations, the transmitter utilizes multi-key and passcode functions

to enter parameter and calibration setting modes. Description of the key functions are as follows:

:When in settings menu, press this key to exit and return to measurement mode.

: When in calibration menu, press this key to exit and return to measurement mode.

:1. When in settings or calibration menu, press this key to move left or return to the

previous page.

2. When adjusting values, press this key to increase the digit.

:1. When in settings or calibration menu, press this key to move right or to advance to the

next page.

2. When adjusting values, press this key to decrease the digit.

:Key for confirmation; press this key to confirm data values or select menu items.

4.3 LED Indicators

WASH : Washing device operation indicator

RELAY1: Dosage control operation indicator (Relay 1)

RELAY2: Dosage control operation indicator (Relay 2)

B.L. : Light sensor; under automatic display backlight mode, the indicator will light up when

the surrounding brightness changes.

TX3100

27

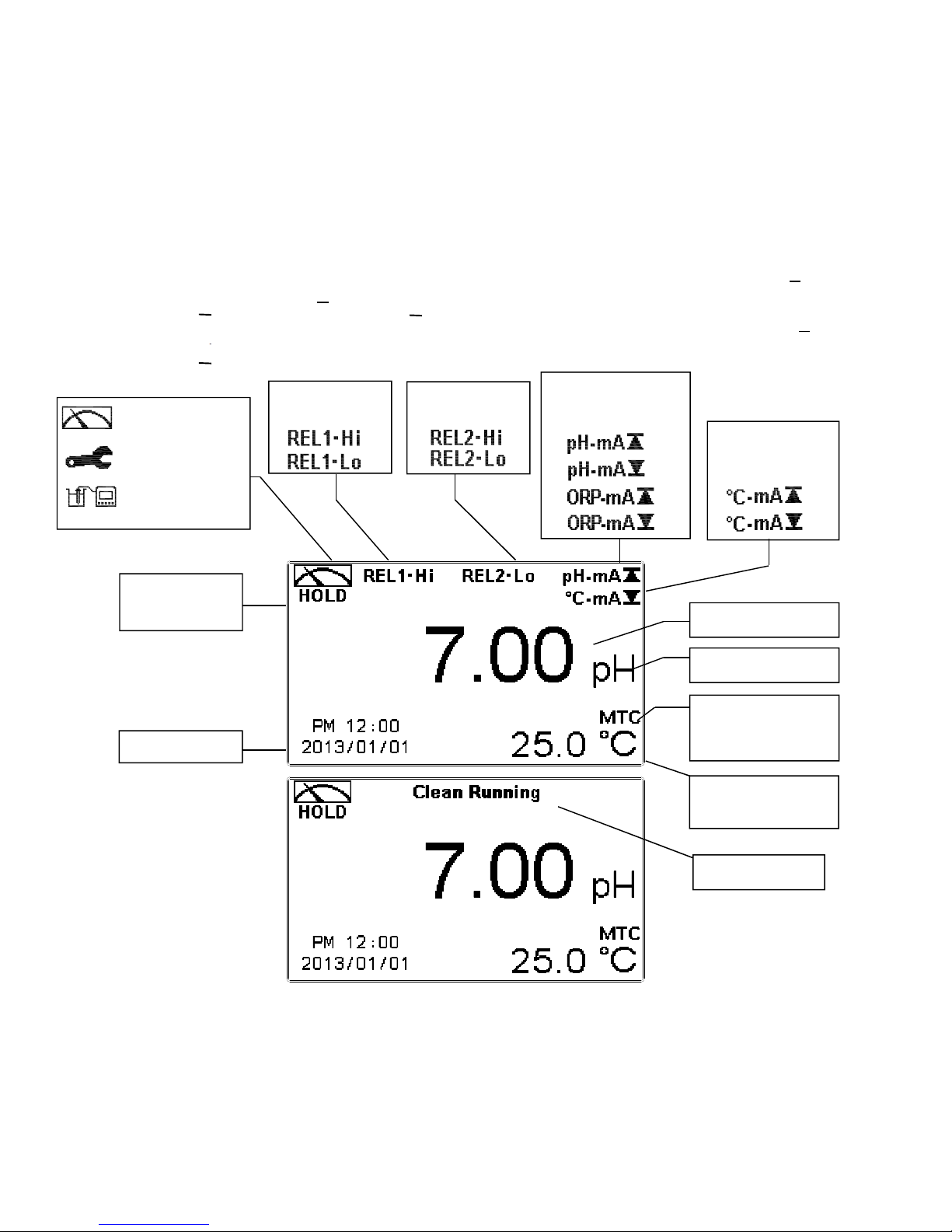

4.4 Display

1. When clean function is activated, the display will show “HOLD” and flash “Clean Running”. At the same

time, the WASH indicator LED will light up, and the transmitter will automatically turn off Relay 1 and

Relay 2 function. After cleaning is completed, both Relay 1 and Relay 2 will automatically return.

2. When Relay 1/Relay 2 Hi settings are activated, the display will flash “REL1-HI/ REL2-HI”, and the

RELAY1/RELAY2 indicator LED will light up. When Relay 1/Relay 2 Lo settings are activated, the

display will flash “REL 1-Lo/ REL 2-Lo”, and the RELAY1/RELAY2 indicator LED will light up.

3. When the Analog 1 current output exceeds the upper/lower limit, the display will flash “pH-mA / pH-

mA ” or “ORP-mA / ORP-mA ”.

4. When the Analog 2 current output exceeds the upper / lower limit, the display will flash “˚C-mA / ˚C -

mA ”.

Note: The “HOLD” warning text appears when clean function is activated, or when entering setup menu, or when

entering calibration menu. Under HOLD status, the corresponding display and output are as follows:

1. Both Relay 1 and Relay 2 cease from action. When entering settings menu or calibration menu under

clean status, the instrument will pause cleaning automatically.

2. The current output which corresponds to measurement value, will remain at the last output value before

HOLD status.

Analog 1 output

current over range

alarm

REL 2 high or

low point alarm

:

Measurement mode

:

Set-up mode

:

Calibration mode

Analog 2 output

current over range

alarm

Control function

on hold

REL 1 high or

low point alarm

Cleaning in action

Measurement Unit

Time and Date

Temperature

Compensation Mode

(MTC/ATC)

Temperature Value

Measurement Value

▲

▲

▼

▲

▼

▼

28

5.Operation

5.1 Measurement Mode

After all electrical connections are secured and tested, connect the instrument to the power supply

to turn it on. The transmitter will automatically enter measurement mode with the factory default

settings or the previous user settings.

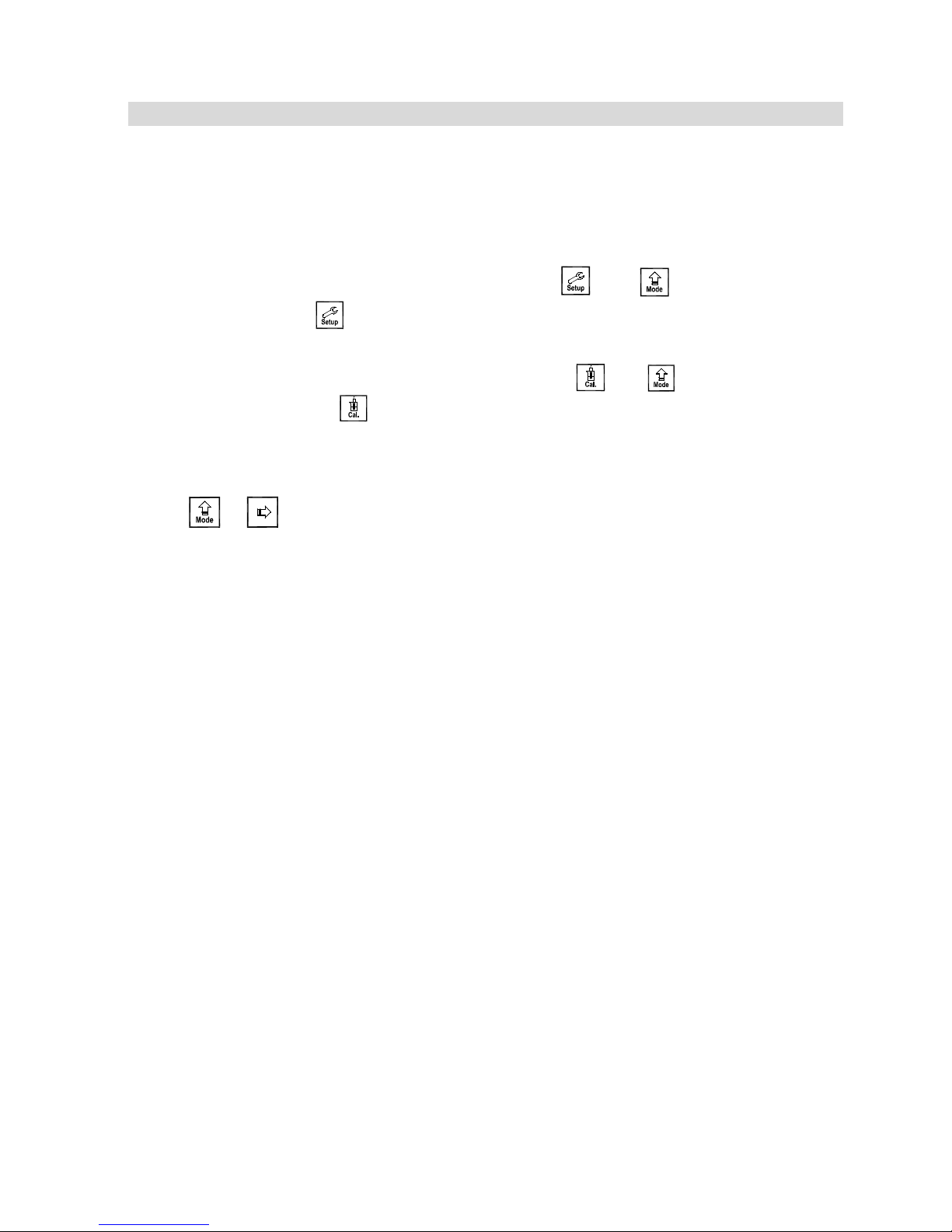

5.2 Settings Menu

Please refer to the settings instructions in Chapter 6. Press and simultaneously to enter

settings menu, or press to return to measurement mode.

5.3 Calibration Menu

Please refer to the calibration instructions in Chapter 7. Press and simultaneously to enter

calibration menu, or press to return to measurement mode.

5.4 Shortcuts

Under measurement mode, if MTC is selected for temperature compensation mode, you may

press_____or_____to adjust the MTC temperature value.

5.5 Default Values:

5.5.1 Settings Default Values

Measurement Mode: pH

Multi-Cal: 2 points

Temperature Compensation: MTC 25˚C

Relay 1: High point alarm: AUTO, SP1 = 10.00 pH, Hys = 0.10 pH

Relay 2: Low point alarm: AUTO, SP2 = 4.00 pH, Hys = 0.10 pH

Wash Time: OFF

Analog 1 current output (pH/ORP): 4~20 mA, 0.00~14.00 pH

Analog 2 current output (Temp): 4~20 mA, 0~100.0˚C

Date & Time: 2013/1/1 00:00:00

Digital Filter: 5

Backlight: Off

Contrast: 0

Return: Auto, 3 minutes

Code: OFF

29

5.5.2 Calibration Default Values:

Calibration Type: TECH-No Cal

Slope: -59.15 mV/pH @ 25.0˚C

Asy: 0 mV

Sensitivity: 100.0%

Determination:1.0000

Calibration Value: None data

Return: Auto, 3 minutes

Codep: OFF

Note: The factory default calibration setting is “No Cal”, and the calibration value is “None”. This means

that the user has not yet calibrated the sensor with the transmitter. After every calibration, the display

will show the calibration type and the calibration value. However, if the transmitter has not yet been

calibrated, it takes the pre-set Asy and Slope into measurement.

30

6.Settings

Settings Block Diagram – Part 1

Overview

Mode

Setting

Code

Setting

Temperature

Setting

Relay 1

Setting

Relay 2

Setting

Multi-Cal.

Setting

Input

Code

OFF ON

New

Code

Select

pH/ORP

Mode

MTC NTC

Relay 1

SP Input

Relay 1

Hys. Input

Select

Relay 1

On/Off

Relay 1

Test

Relay 2

Hys. Input

Select

Relay 2

On/Off

Relay 2

Test

Relay 1

SP Input

Select

No. of

Points

PTC

Value

Input

Value

Correct

Value

Correct

Select

Relay 1

Hi/Lo

Select

Relay 2

Hi/Lo

English

Tradi-

tional

Chinese

Simpli-

fied

Chinese

Clean

Setting

Auto

Return

Setting

Auto Auto

Language

Setting

:

:

:

:

Return to previous

level/action

Continue on next page

31

Settings Block Diagram – Part 2

Clean

Setting

Analog 1

pH/ORP

Output 1

Analog 2

Temp.

Output 2

Clock

Setting

Digit Filter

Setting

Input

Shut down

Time

Input Clean

Hys. Time

Clean

Test

Input

Clean

Active Time

Value corr. to

0 or 4mA

Value corr. to

20mA

Value corr.

to 0 or 4mA

Value corr.

to 20mA

Select

0~20mA or

4~20mA

Set Year

Set Date

Set Time

Number of

Signal

Average

Select

0~20mA or

4~20mA

Back Light

Setting

Contrast

Setting

Contrast

Return

Setting

Return

Timer

Auto Manual

Exit

Auto On Off

Input

Bright-

ness

Input

Sensi-

tivity

Input

Bright-

ness

Relay2

Setting

Code

Setting

Select

Clock

On/Off

ON

:

:

:

:

Return to previous

leve

l

/actio

n

Select

Clean

On/Off

Auto

Connected with previous page

32

6.1 Settings Menu

Under measurement mode, press_____and_____simultaneously to display current settings

overview. Press_____to return to measurement mode or press_____to enter settings menu.

Enter Settings Menu

“Measurement (Mode)”

Press or

Press

Press

Press to confirm it

Press or

Table of contents

Other Sensorex Transmitter manuals

Sensorex

Sensorex CX105 User manual

Sensorex

Sensorex CX100 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX105 User manual

Sensorex

Sensorex TX100 Specification sheet

Sensorex

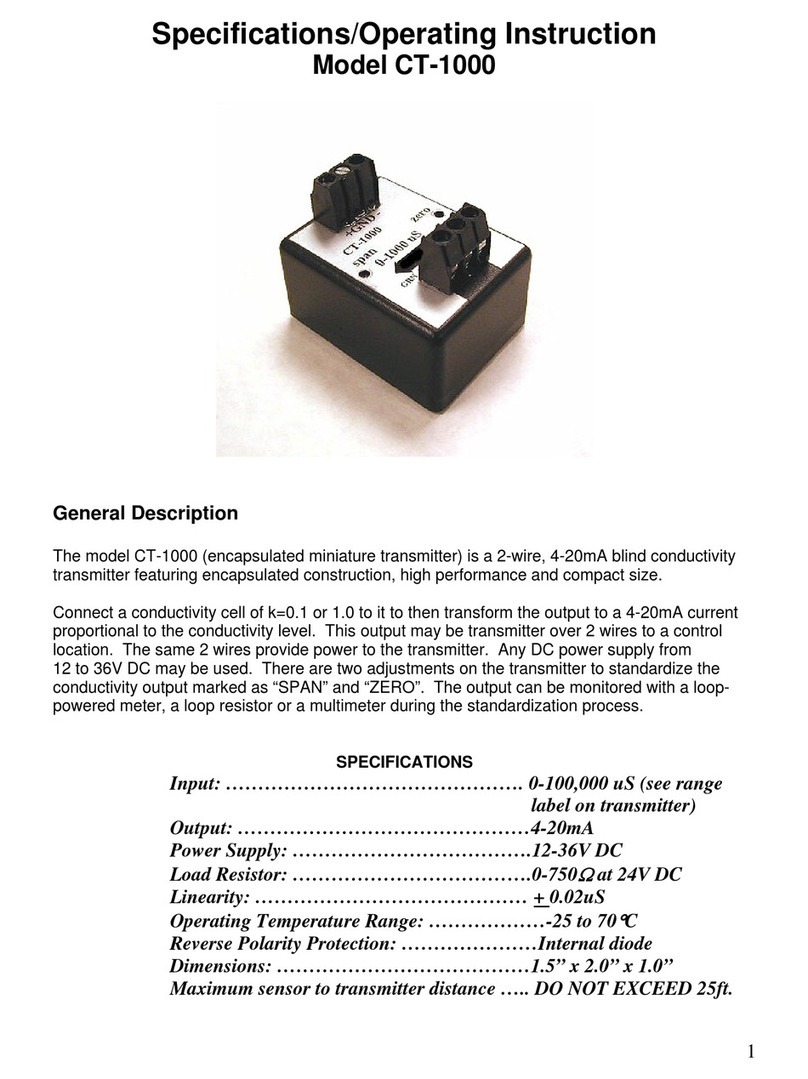

Sensorex CT-1000 User manual

Sensorex

Sensorex TX3000 User manual

Popular Transmitter manuals by other brands

Interphone

Interphone BTSplitter35 instruction manual

Honeywell

Honeywell oneWireless XYR 6000 user manual

MSA

MSA General Monitors S4100T instruction manual

AMC

AMC WiFi Wireless Transmitter TR1a Instructions for installation and operation

Evikon

Evikon PluraSens E2648-N2O user manual

Microsensor

Microsensor MPM4730 Operation manual