Sensorex TX3000 User manual

PRODUCT INSTRUCTION MANUAL

TX3000 - pH/mV

Transmitter/Controller

Form: INSTRTX3000-Rev A

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Thank you for choosing the TX3000 pH/mV transmitter. This transmitter is a user-friendly microprocessor based trans-

mitter for pH and mV measurement. As with all electronic instruments, it is essential to follow all directions for optimal

performance. In particular, you must properly install, use and maintain the TX3000 to ensure that it will continue to

operate within its specications.

• Follow all warnings, cautions and instructions marked on and supplied with the transmitter. Please contact Sensorex

with any product questions or concerns.

• Install the transmitter as specied in this manual, following all applicable local and national codes.

• Do not attempt to repair your TX3000 transmitter or use any replacement parts from any other supplier.

• If you nd any errors in this manual, please report them to Sensorex.

• Please complete the WARRANTY REGISTRATION located at the back of this manual and fax or e-mail to Sensorex at

fax: 714-894-4839, e-mail: [email protected]

TX3000 pH/mV Transmitter ESSENTIAL INSTRUCTIONS

READ THIS BEFORE USING YOUR TX3000 pH/mV TRANSMITTER!

About This Document

This manual contains instructions for the installation, operation and care of the TX3000 pH/mV transmitter.

The following list provides notes concerning revisions of this document.

Rev Level Date Notes

A 9/2012 1st revision of manual.

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Table of Contents

1. Specications 1

2. Precautions for installation 2

3. Assembly and installation

3.1 Transmitter installation 2

3.2 Cable set-up 3

4. Overview of TX3000 pH/ORP transmitter

4.1 Illustration of rear panel 4

4.2 Illustration of terminal function 5

5. Conguration

5.1 Illustration of front panel 6

5.2 Function Key Description 7

5.3 LED indicators 8

5.4 Display icons 9

6. Operation

6.1 Measurement mode 10

6.2 Set-up mode 10

6.3 Calibration mode 10

6.4 Reset 10

6.4.1 Master reset 10

6.4.2 Calibration reset 10

7. Settings

7.1 Entry into set-up mode 11

7.2 Security code settings 11

7.3 Measurement parameters 12

7.4 Temperature Settings 13

7.5 Stand by Mode 14

7.6 Hi Alarm Relay 15

7.7 Lo point Alarm Relay 16

7.8 Wash time Relay 17

7.9 Analog output 1 (pH/ORP) 18

7.10 Analog output 2 (temperature) 19

7.11 Sample average of measurements (Digital Filter) 20

7.12 Backlit LCD 21

8. Calibration

8.1 Security code of calibration 22

8.1.2 Setting Code 22

8.2 Entry of calibration mode 22

8.3 Any Buer calibration (2-point) 23

8.4 Calibration of pre-set TECH. buer (Ct1) 24

8.5 Calibration of pre-set NIST. buer (Cn1) 26

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Table of Contents

8. Calibration (cont)

8.6 ORP calibration 26

9 Error messages (Error code) 27

10. Warranty

10.1 Warranty 28

10.2 Return of Product 28

Warranty Registration 29

Warranty Terms and Conditions 29

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

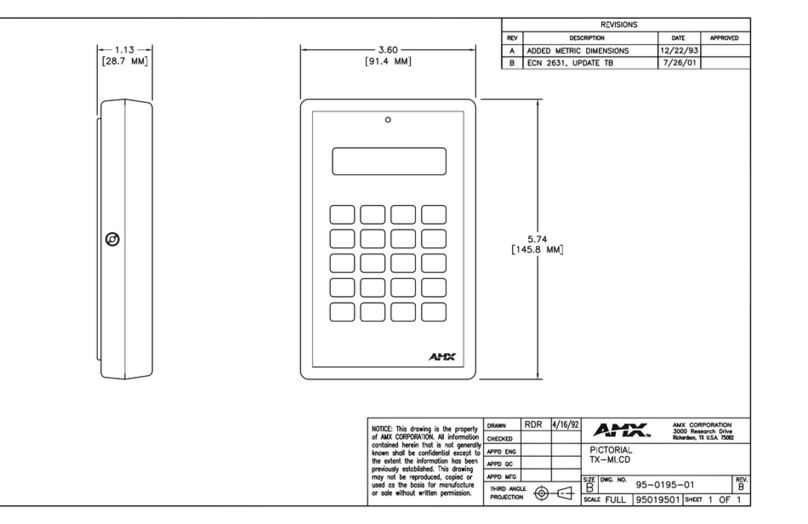

Figure 3-1 Panel Mount Cut Out 2

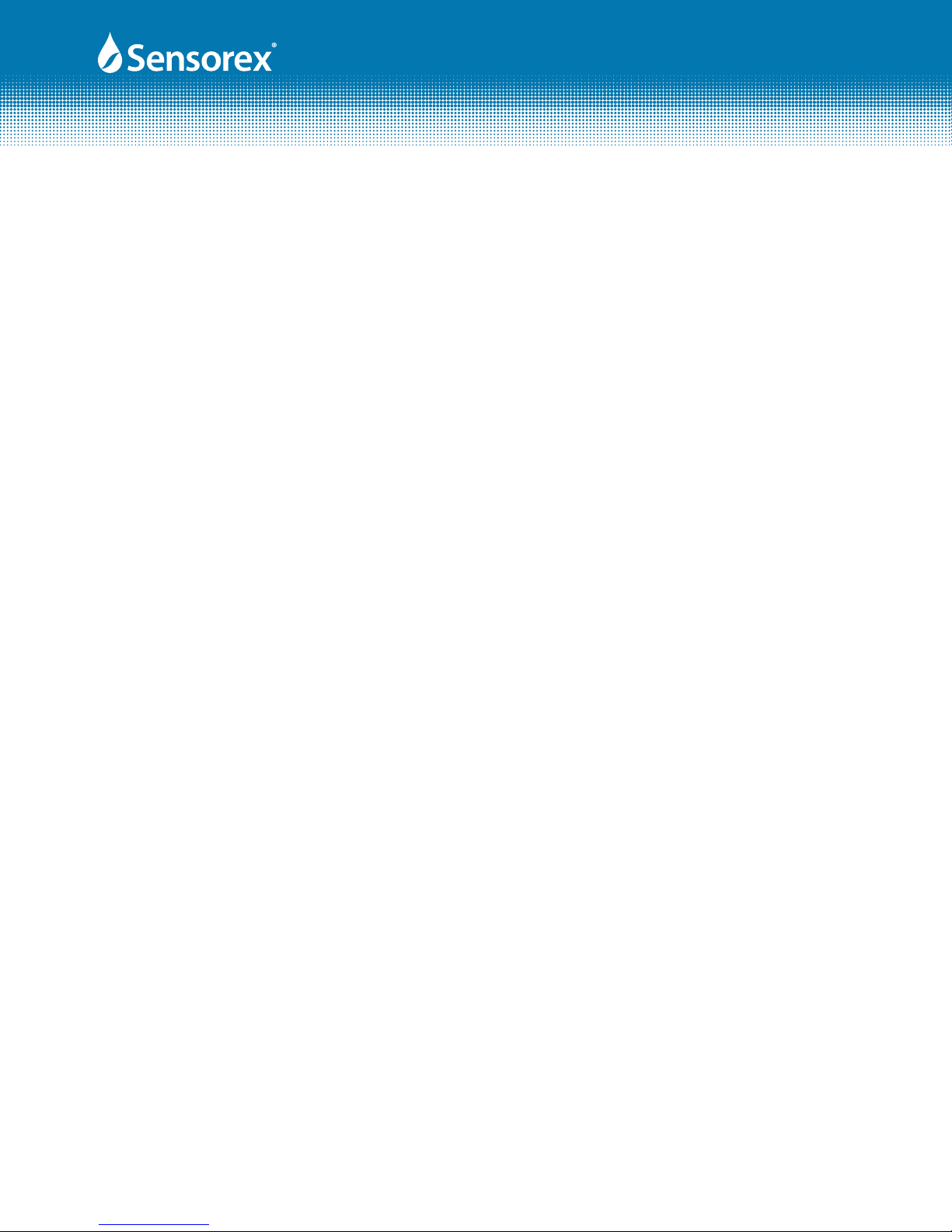

Figure 3-2 Wall Mounting 3

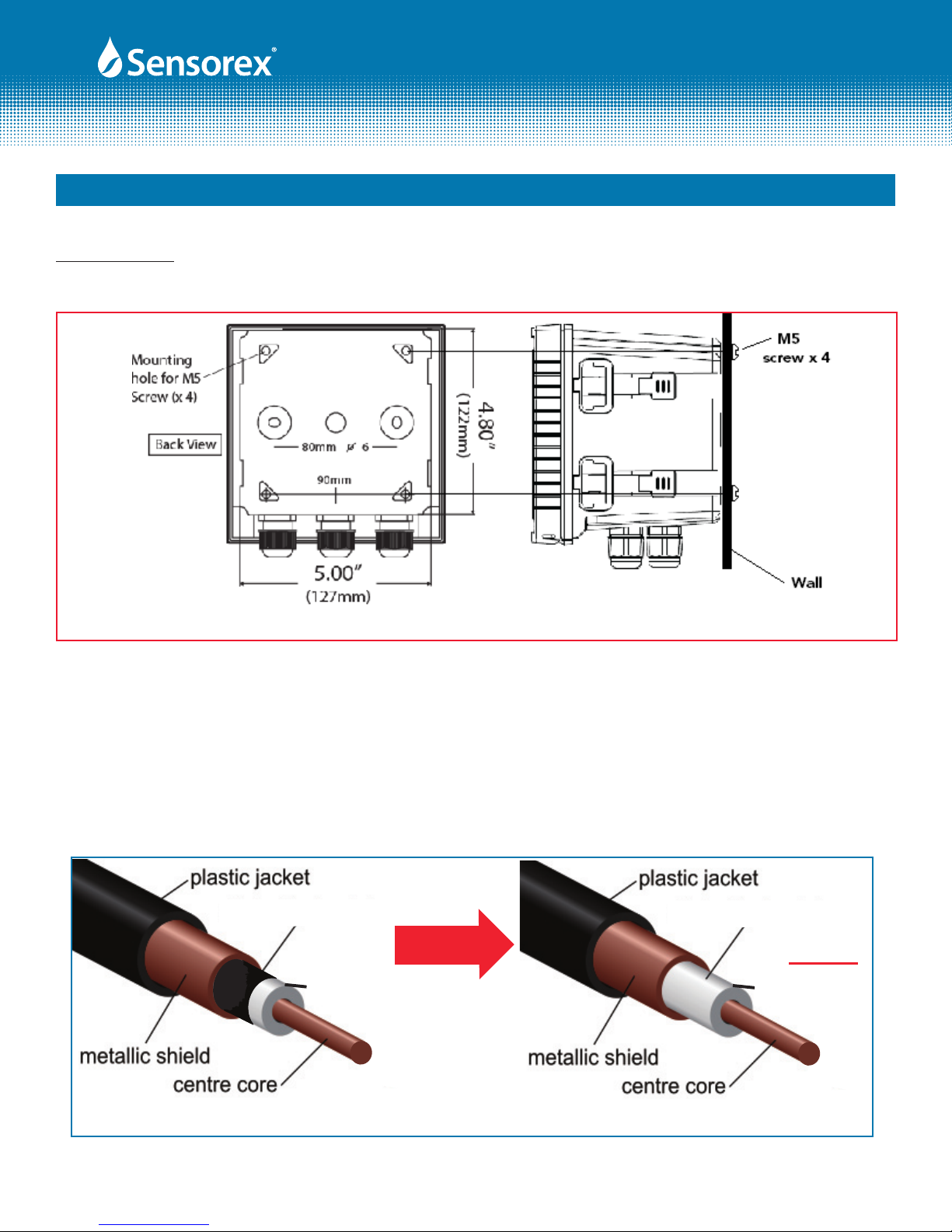

Figure 3-3 Coaxial Cable Preparation 3

Figure 4-1 Rear Panel Illustration 4

Figure 4-2 Terminal Functions 5

Figure 5-1 Front Panel 6

Figure 5-2 Displaty Icons 9

Figure 7-1 Security Settings 11

Figure 7-2 Measurement Parameters 12

Figure 7-3 Temperature Settings 13

Figure 7-4 Standby Mode 14

Figure 7-5 HI Alarm 15

Figure 7-6 LO Alarm 16

Figure 7-7 Wash Alarm 17

Figure 7-8 Analog Output 1, 4-20mA (pH/ORP) 18

Figure 7-9 Analog Output 2, 4-20mA (Temperature) 19

Figure 7-10 Sample Averaging 20

Figure 7-11 LCD Backlight 21

Figure 8-1 Entering Calibration Mode 22

Figure 8-2 2-Point Calibration Mode 23

Figure 8-3 2-Point Calibration Mode Ct1 (Preset buers) 24

Figure 8-4 ORP Calibration 26

Figure 9-1 Troubleshooting Chart 27

Form: INSTRTX3000-Rev A

Table of Contents

PRODUCT INSTRUCTION MANUAL

Part 1 Specications

Page 1 of 29

Measuring Range (pH) -2.00 to 16.00pH, 0.01 pH resolution,

+/- 0.01 accuracy, +/- 1 digit

Measuring Range (ORP/mV) -1999mV to +1999mV, 1mV resolution,

+/- 1mV accuracy, +/- 1 digit

Measuring Temperature Range -30 to 130° C, 0.1° C resolution,

+/- 0.2° C accuracy +/- 1 digit

Calibration Mode Any Tech or NIST buers up to 2 points

Analog Output 1 Isolated DC 0/4-20mA corresponding to pH or ORP,

maximum load 500Ω

Analog Output 2 Isolated DC 0/4-20mA corresponding to temperature,

maximum load 500Ω

Display Large LCD display with environment light sensor auto/manual

illumination function

Weight approx. 1.75lb (0.8kg)

Dimensions 5.7"(144mm) x 5.7"(144mm) x 4.5"(115mm)

Mounting Options Wall mount, panel mount, pipe mount

Panel Cut Out Dimensions 5.4"(138mm) x 5.4"(138mm)

Relays 1(HI) - Contact 110,240 VAC, 0.5A Max - programmable ON/OFF

2(LO) - Contact 110,240 VAC, 0.5A Max - programmable ON/OFF

WASH - Contact 110,240 VAC, 0.5A Max - programmable ON (0-9999 sec),

OFF (0-999.9 hrs)

Ambient/Storage Temperature 0-50° C / -20-70° C

Temperature Compensation NTC 30K Ω or 2-wire Pt1000 RTD auto, manual

Power Requirement 100-240 VAC, 50/60 Hz, software selectable

Voltage Output DC +/-12V(to power external transmitter, if required)

Certication IP 65 (NEMA 4X), CE

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

pH / ORP Transmitter TX-3000

(144mm)

5.67”

(144mm)

5.67”

(125mm)

4.92”

(98mm)

3.74”

Cord grip x3

Panel mount

ttings x4

90mm

80mm o6

Front View Side View

(127mm)

5.00”

(122mm)

4.80”

Back View

Mounting

hole for M5

Screw (x 4)

TX3000 Specications - Dimensional Specs

PRODUCT INSTRUCTION MANUAL

Part 1 Specications (cont.)

PRODUCT INSTRUCTION MANUAL

Page 2 of 29

Wrong wiring will lead to breakdown or electrical shock of thetransmitter, please read this operation man-

ual clearly before installation.

• Make sure to remove AC power from the transmitter before wiring input and output connections and

before opening the transmitter housing.

• Install the transmitter in a well ventilated area. Avoid installing in areas receiving direct sunshine.

• The material of signal cable should be special coaxial cable. Strongly recommend using our coaxial

cable. Do not use normal wires instead.

• Avoid electrical surge when using power, especially when using three-phase power, use ground wire

correctly.

• The internal relay contact of the transmitter is for alarm or control function. You must connect to an

external relay which can withstand enough current to ensure safe operation of the transmitter. Please

refer to chapter 4.2“Terminal Functions”

Part 2 Installation Precautions

Part 3 Assembly and Installation

3.1 Transmitter installation: This transmitter can be installed by panel mounting, wall mounting and pipe

mounting.

Panel Mounting: Cut a square hole of 5.4"(138mm) x 5.4"(138mm) on the panel, and then insert the trans-

mitter directly into the panel. Attach the mounting bracket from the rear, so that it attaches to groove.

FIG 3-1

Form: INSTRTX3000-Rev A

Side View with

mounting brackets

Mounting

Bracket

4x

Panel

Panel Cutout

5.4"(138mm)

5.4"(138mm)

minimum distance between

TX3000 panel cutouts = 1.7"(42mm)

PRODUCT INSTRUCTION MANUAL

Page 3 of 29

FIG 3-2

Wall Mounting: Use 4 each M5 screws to attached to mounting holes shown below.

FIG 3-3

clear cover

black noise

reduction

layer

clear cover

black noise

reduction

layer removed

3.2 Coaxial Cable Preparation: Cut coaxial cable plastic jacket o. This will reveal the braided shield wire.

Twist the braid together to reveal black noise reducing layer. Remove the black noise reducing layer even

to the braid (See Fig 3-3). Cut some of clear layer away to expose copper center core.

Part 3 Assembly and Installation (cont.)

Form: INSTRTX3000-Rev A

Wall Mounting

PRODUCT INSTRUCTION MANUAL

Page 4 of 29

Part 4 TX3000 Overview

4.1 Rear Panel:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

100-240

AC

WASH REL 2 REL 1

NC

21

- +

4-20mA

- +

4-20mA

0/4-20mA Isolated MAx load 500Ω

Power: 100~240 VAC +/-10% 50/60Hz

Relay: 240 VAC Max 0.5A (REL1/REL2/WASH)

D-(A)

G

D-(A)

RS-485 Version Only

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

- 12V

+ 12V

T/P

SG

REF

NC

GLASS

Important!

Must remove the

jumper between no.

17 & 18 when using

solution ground (SG)

STD (2 Wires)

Meas.

SG (3 Wires) Meas.

ESD Shield cover removed

FIG 4-1

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Page 5 of 29

Part 4 TX3000 Overview (cont.)

GLASS

REF

GND

TP

TP

pH/

ORP

T

HI LO WASH

POWER

AC

INPUT

POWER

TX3000

only

2

4-20mA

4-20mA

1

+/-12V

+

+

+

-

-

-

-

4.2 Terminal Functions:

4.3 Description of terminal function:

1 & 2 - 100~240AC: Power supply terminal

3 & 4 - WASH: External wash relay terminal

5 & 6 - REL2: LO, External relay terminal low control

7 & 8 - REL1: HI, External relay terminal high control

9 - N/C

10 - 4~20mA – terminal /G: Temperature current output terminal -

11 - 4~20mA – terminal /G: Temperature current output terminal +

12 - 4~20mA - terminal: Master measurement current output terminal -

13 - 4~20mA - terminal: Master measurement current output terminal +

14 & 15 +/- 12V output

16 - T/P: temperature probe

17 - SG : Connect the other end of temperature probe, or used as ±12V ground potential. In two-wire distributing

system, there should be a short circuit between this terminal and REF (a short circuit jumper is attached from

the factory)

18 - REF: Coaxial shield connecting pH/ORP electrode signal wire

19 - NC: NC

20 - GLASS: Coaxial inner conductor= pH/ORP electrode signal wire

FIG 4-2

Form: INSTRTX3000-Rev A

Not

Used

PRODUCT INSTRUCTION MANUAL

Page 6 of 29

Part 5 Conguration

5.1 Front Panel:

FIG 5-1

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Page 7 of 29

Part 5 Conguration (cont.)

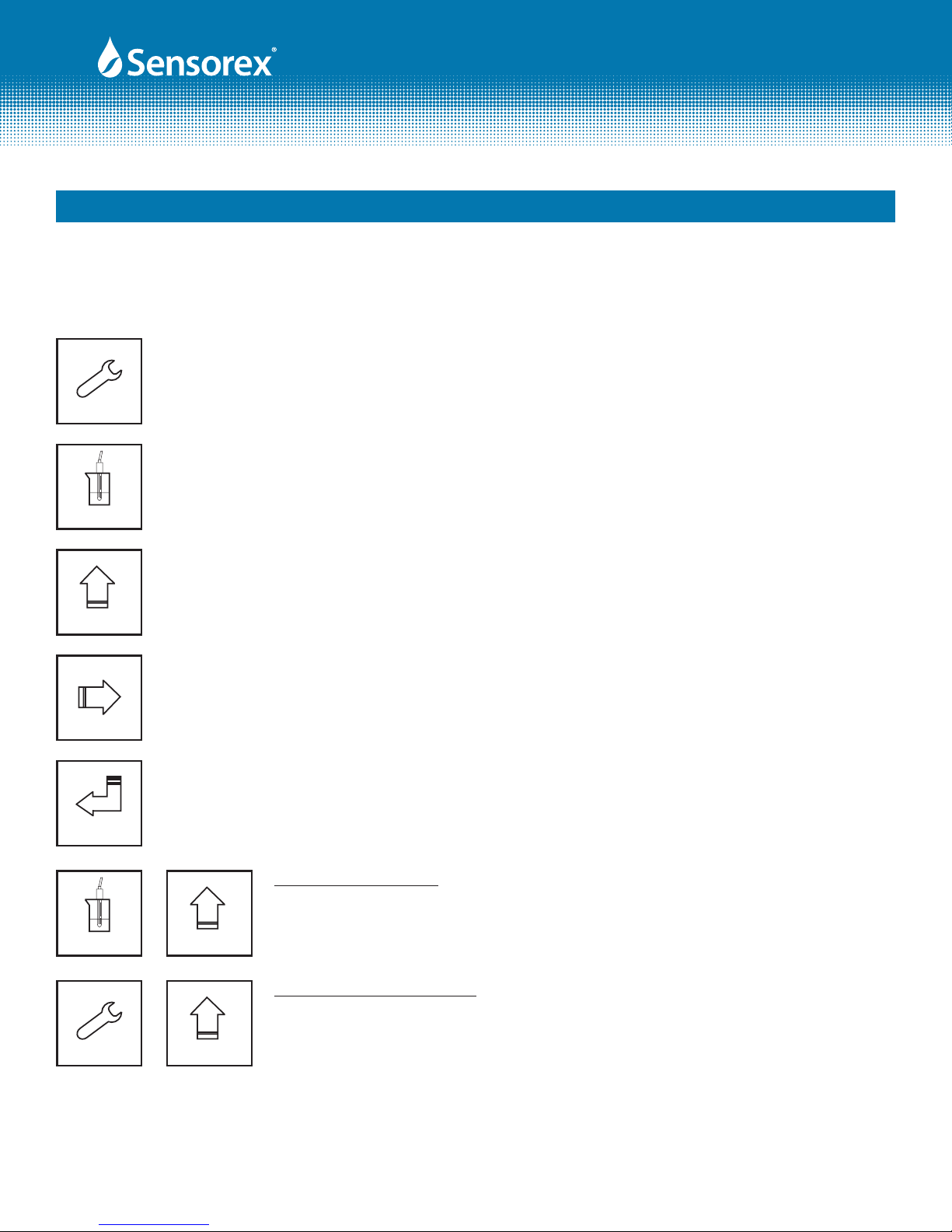

5.2 Function Keys:

Setup

In the parameter set-up mode, pressing this key allows you to exit parameter set-up mode

and go back to Measurement mode.

Cal.

In the Calibration mode, pressing this key allows you exit Calibration mode and back to Mea-

surement mode.

Mode

In the parameter set-up mode and Calibration mode, press this key to increase the value or to

scroll to other function.

In the parameter set-up mode and Calibration mode, press this key to decrease the value or to

scroll to other function.

Enter

Key for conrmation; pressing this key is essential when modifying data value or selecting the

parameter setting items in the window.

Setup

CALIBRATION MODE

In the Measurement mode, pressing these two keys simultaneously allows you

to enter Calibration mode.

+

Mode

Mode

Cal.

FUNCTION SET-UP MODE

In the Measurement mode, pressing these two keys simultaneously allows you

to enter parameter set-up mode.

+

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Page 8 of 29

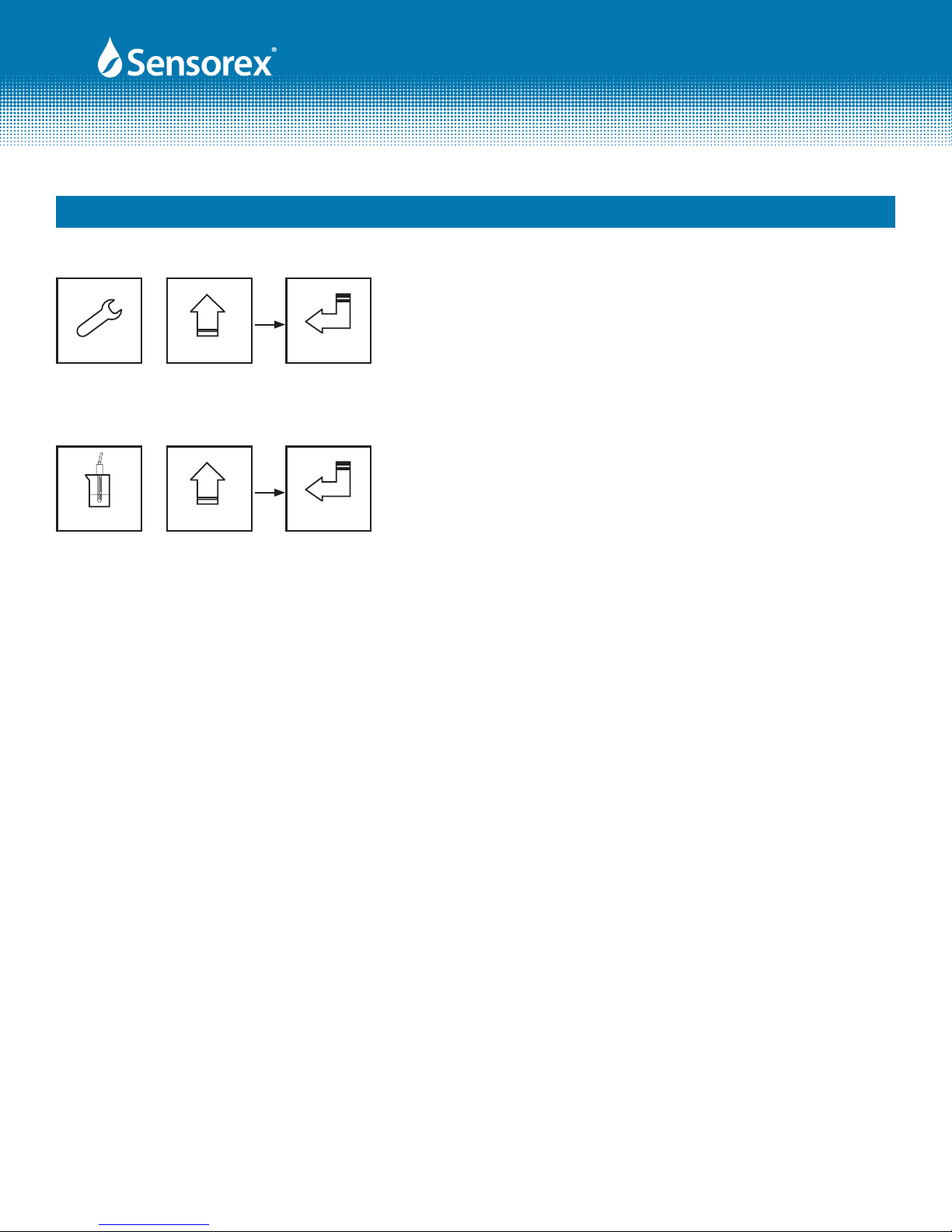

Master Reset-Restore factory default parameter’s settings

In the Measurement mode, press the "SETUP" and "MODE" keys

simultaneously for ve seconds, and then press the "ENTER" key

until you see a clock signal appearing on the display. Release all

keys and then factory default settings will be restored.

Setup Mode

+

Part 5 Conguration (cont.)

5 Seconds

Enter

Calibration Reset-Restore factory default calibration settings

In the Measurement mode, press the "CAL" and "MODE" keys

simultaneously for ve seconds, and then press the "ENTER" key

until you see a clock signal appearing on the display. Release all

keys and then factory default calibration settings will be restored.

Mode

+

5 Seconds

Enter

Cal.

5.3 LED indicators:

HI: High set point indicator light; when the high setting point is reached, the REL1 indicator will light.

B.L.: Light sensor; in the automatic display backlit mode, the lamp will light or go out depending on

environmental brightness.

WASH: Washing device indicator light; when the washing device is started up, the indicator will light.

LO: Low set point indicator light; when the high setting point is reached, the REL2 indicator will light.

Form: INSTRTX3000-Rev A

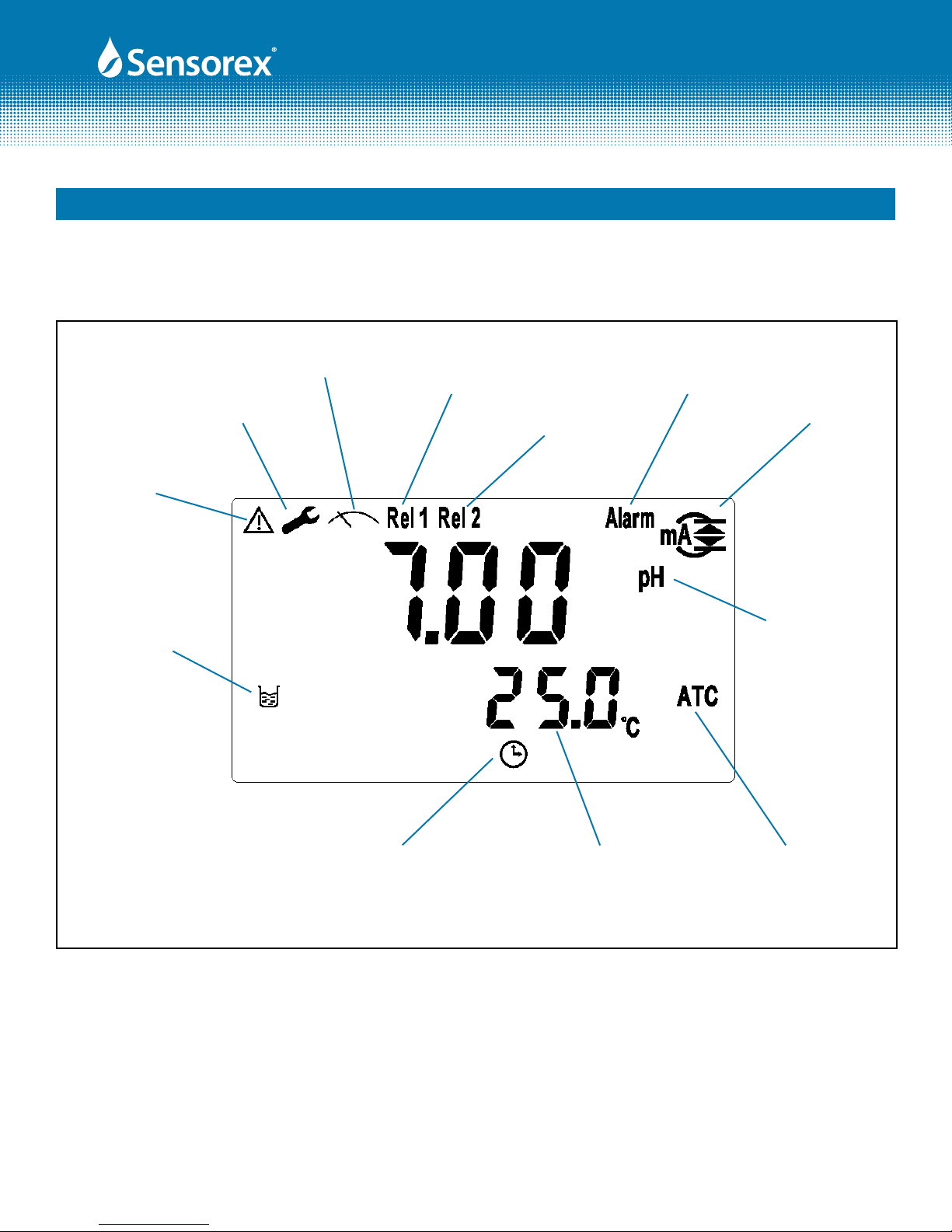

Set Up

Mode

Measurement

Mode Relay 1

Activated

Relay 2

Activated

Clean Device

Activated Output

Current

Over Range

Controller

Function Lock

Calibration

Mode

Temperature Automatic

Temperature

Compensation

Measurement

Units

PRODUCT INSTRUCTION MANUAL

Page 9 of 29

Reset Indicator

(factory/cal)

Part 5 Conguration (cont.)

FIG 5-2

Form: INSTRTX3000-Rev A

5-4 Display Icons:

PRODUCT INSTRUCTION MANUAL

Page 10 of 29

6.1 Measurement mode:

After all electrical connections are nished and tested, connect the transmitter to the power supply and turn

it on. The transmitter will automatically enter measurement mode with the factory default settings or the

last settings from user.

6.2 Set-up mode:

PRESS "SET UP" AND "MODE" SIMULTANEOUSLY

Please refer to the set-up instructions in Chapter 7, and press "SETUP" key to return to measurement mode.

6.3 Calibration mode:

PRESS "CAL" AND "MODE" SIMULTANEOUSLY

Please refer to the calibration instruction in Chapter 8, and press "CAL" key to return to measurement mode.

6.4 Reset:

6.4.1 Master reset:

In the Measurement mode, press the "SETUP" and "MODE" keys simultaneously for ve seconds, and then

press the "ENTER" key until you see a clock signal appearing on the display. Release all keys and then factory

default settings will be restored.

Factory defaults:

Measurement mode: pH

Temperature compensation: MTC 25°C

High point alarm: AUTO, SP1= 10.00 pH,db1= 0.10 pH

Low point alarm: AUTO, SP2 =04.00 pH,db2= 0.10 pH

Wash time: OFF

pH/ORP current output: 4~20 mA, 02.00~12.00pH

TP current output: 4~20 mA, 000.0~100.0˚C

Backlit Display: OFF

Code set-up: OFF

6.4.2 Calibration reset:

In the Measurement mode, press the "CAL" and "MODE" keys simultaneously for ve seconds, and then

press the "ENTER" key until you see a clock signal appearing on the display. Release all keys and then factory

default calibration settings will be restored.

Factory defaults:

OS value: 0 mV SLOPE value: 100.0 %

Calibration mode: Two-Point Calibration: Ct1

Part 6 Operation

Form: INSTRTX3000-Rev A

PRODUCT INSTRUCTION MANUAL

Page 11 of 29

Part 7 Settings

7.1 Set-up mode

In the measurement mode, pressing the "SETUP" and "MODE" keys

simultaneously allows you enter the parameter set-up mode. You can return to

the measurement mode at any time by pressing the key "SETUP" key.

Setup Mode

+

Mode

Enter

7.2 Security

In the set-up mode, you can set up the code by pressing the key "MODE" , and conrm by pressing the

"ENTER" key . The original code is 1111.

When the rst “0” of the digits 0000

ashes, press "MODE" (up arrow)

key or "right arrow" key to input

the code, and press "ENTER" to

conrm. Then, continue inputting

the second digit, the same way and

repeat until all digits are changed.

If you

input the

wrong

code, the

CODE will

ash

4X, and

then the

display

will

return

back for

another

input.

To cancel

security

code,

press

"MODE"

2X

Enter

Enter

GO TO "MEASUREMENT SETUP,

SECTION 7.3

FIG 7-1

Form: INSTRTX3000-Rev A

Enter

Setup

PRODUCT INSTRUCTION MANUAL

Page 12 of 29

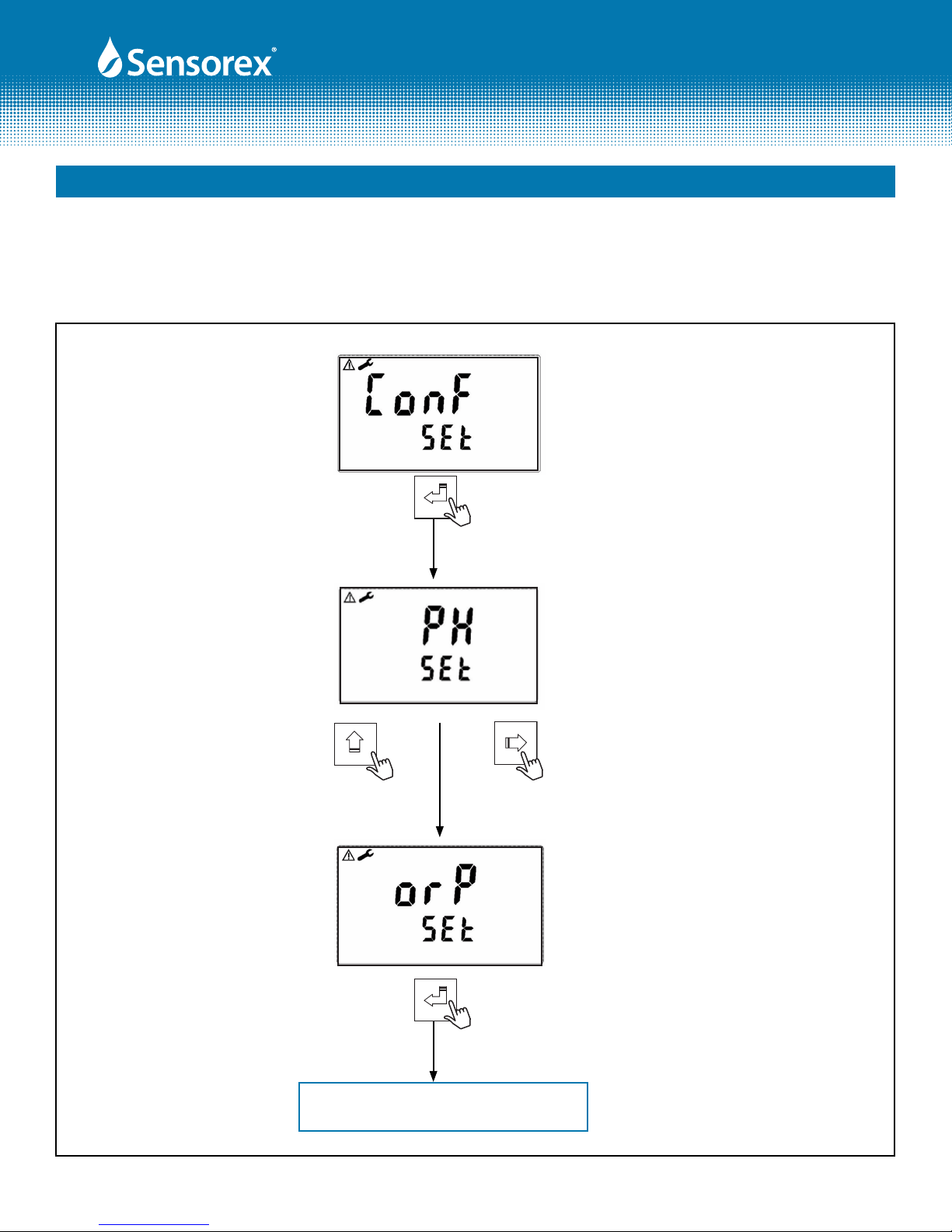

Part 7 Settings (cont.)

Enter

Mode

Select pH or ORP. pH is

the default setting.

Enter

GO TO "TEMPERATURE SETUP,

SECTION 7.4

7.3 Measurement Setting

In the measurement mode, you can choose between pH and ORP settings.

FIG 7-2

Form: INSTRTX3000-Rev A

OR PRESS "SET-UP" KEY

TO RETURN TO

MEASUREMENT MODE

PRODUCT INSTRUCTION MANUAL

Page 13 of 29

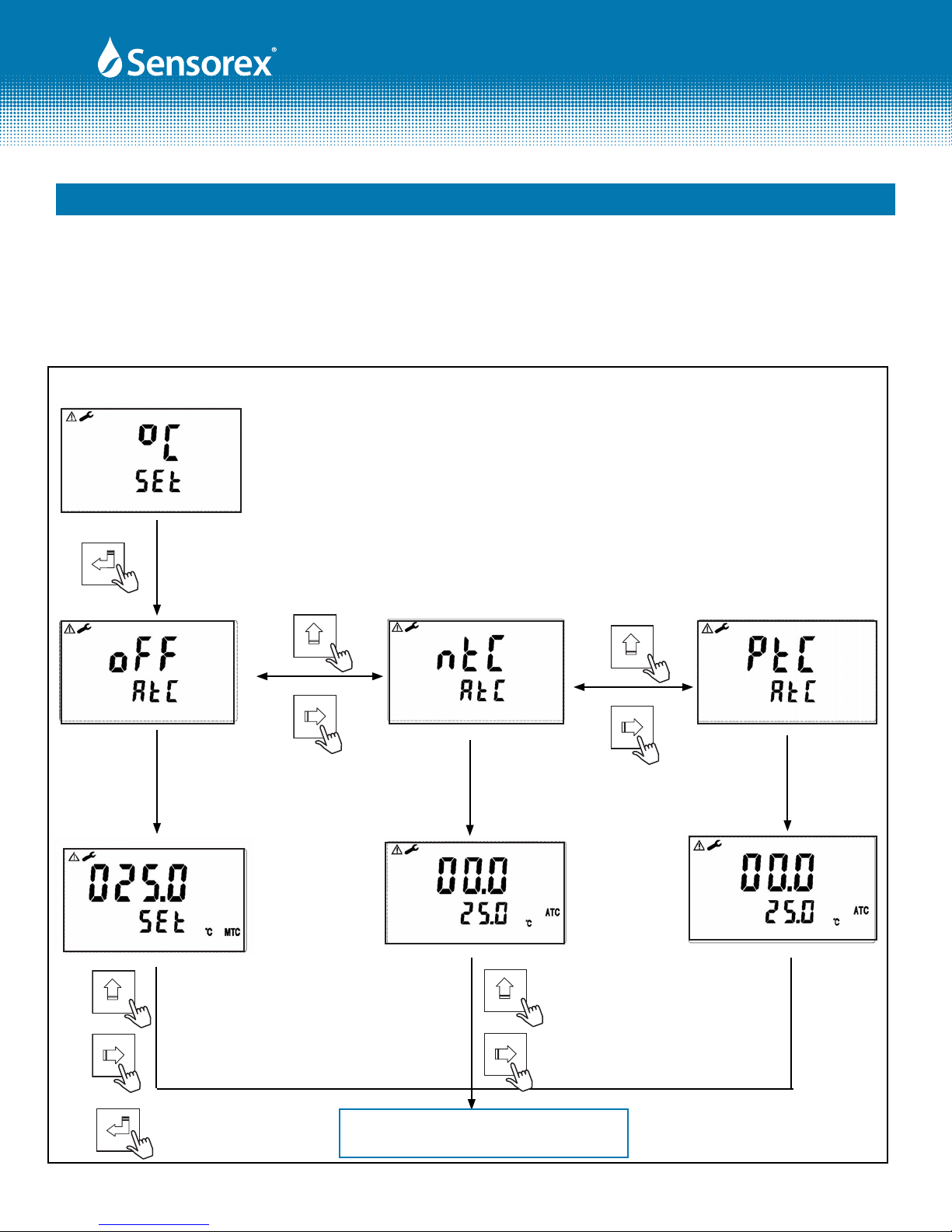

Part 7 Settings (cont.)

7.4 Temperature Settings

In the Temperature mode you will set the ATC, On or OFF, set the temperature sensor type (PTC or NTC) and

calibrate/adjust the temperature..

Enter

Mode

Mode

GO TO "STANDBY SETUP,

SECTION 7.5

Use a standard thermometer to test the

actual temperature of the solution, and

press "MODE" or "RIGHT ARROW" key to

input the correct temperature value. Press

"ENTER" to conrm.

Mode

If necessary, compare with the

actual temperature value tested by

standard thermometer. Press

"MODE" or "RIGHT ARROW" key to

input the modied value. Press

"ENTER" to conrm.

Mode

Enter

Follow same

steps to left.

FIG 7-3

Form: INSTRTX3000-Rev A

OR PRESS "SET-UP" KEY

TO RETURN TO

MEASUREMENT MODE

Table of contents

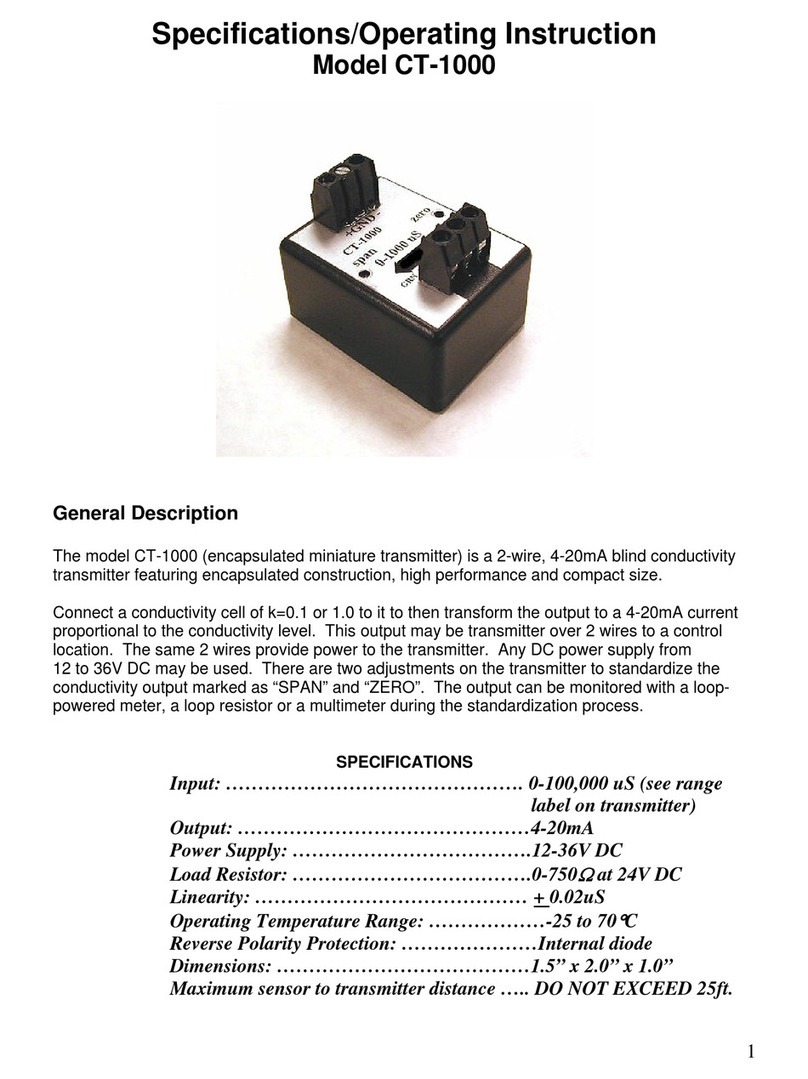

Other Sensorex Transmitter manuals

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex CT-1000 User manual

Sensorex

Sensorex CX105 User manual

Sensorex

Sensorex TX3100 User manual

Sensorex

Sensorex TX2000 User manual

Sensorex

Sensorex TX100 Specification sheet

Sensorex

Sensorex CX100 User manual

Sensorex

Sensorex TX105 User manual

Sensorex

Sensorex TX2000 User manual