Senstar Stellar Flash User guide

Flash™ System Installation Manual

Personal Emergency Alarm System

Flash

System Installation Manual

T1DA0302-001, Rev. A

January 27, 2004

Company

Name:

Senstar-Stellar

Corporation

Senstar-Stellar Senstar- Stellar Ltd. Senstar GmbH Senstar-Stellar Latin

America

Address: 119 John Cavanaugh

Dr.

43184 Osgood Rd. Orchard House,

Evesham Rd.

Reidheimer Str. 8 Pradera No. 214,

Col. Pradera

Carp, Ontario Fremont, CA Broadway, Worc. 88677 Markdorf Cuernavaca,

Morelos

Canada K0A 1L0 USA 94539 U.K. WR127HU Germany 62170, Mexico

Phone: +1 (613) 839-5572 +1 (510) 440-1000 +44 (1386) 834433 +49 (7544) 95910 +52 (777) 313-0288

Toll Free: 1-800-676-3300

Fax: +1 (613) 839-5830 +1 (510) 440-8686 +44 (1386) 834477 +49 (7544) 959129 +52 (777) 317-0364

Website: www.senstarstellar.com

E-mail: [email protected]

All material, including technical data, designs, knowledge, and

ideas contained in this document are considered proprietary, and

the exclusive property of Senstar-Stellar Corporation, and shall

not be used, disclosed, reproduced, or transmitted in any form or

by any means, electrical or mechanical, including photocopying,

recording, or by any information storage or retrieval system,

without permission in writing from Senstar-Stellar Corporation.

T1DA0302-001, Rev A Page 1

Flash™ System Installation Manual

Senstar-Stellar Life Safety Division

22611 Markey Court, Unit 110

Sterling, VA, USA 20166-6903

Tel: 703.421.2086 Fax: 703.421.2149

Revision History

January, 2003 A76309 1A Initial Release

January 27, 2004 T1DA0302-001 Rev A Company name and Logo change, new document number

T1DA0302-001, Rev A Page 2

Flash™ System Installation Manual

Table of Contents

1.0 INTRODUCTION .............................................................................................................5

1.1 System Introduction .........................................................................................................5

1.2 Installation Overview........................................................................................................5

1.3 Reference Documents .....................................................................................................6

2.0 SYSTEM ARCHITECTURE.............................................................................................7

2.1 Transmitters.....................................................................................................................8

2.2 Sensor..............................................................................................................................8

2.3 Monitoring Post Equipment..............................................................................................9

2.3.1 Computer .........................................................................................................................9

2.3.2 Uninterruptible Power Supply (UPS) .............................................................................10

2.3.3 Printer ............................................................................................................................10

2.3.4 Audio Output..................................................................................................................10

2.3.5 Interface Unit (IU) ..........................................................................................................10

2.4 Optional Serial Interfaces...............................................................................................10

3.0 UNPACKING and INSPECTION ...................................................................................11

4.0 INSTALLATION PLANNING..........................................................................................12

4.1 RF Coverage..................................................................................................................13

4.1.1 Single Building Facility...................................................................................................13

4.1.2 Small, Multi-Building Site ...............................................................................................14

4.1.3 Large Facility .................................................................................................................15

4.2 Communications Wiring .................................................................................................16

4.2.1 Daisy-Chained Wiring ....................................................................................................16

4.2.2 Star Wiring .....................................................................................................................17

4.3 AC Wiring.......................................................................................................................18

4.4 Antennas........................................................................................................................18

4.4.1 Antennas Overview........................................................................................................18

4.4.2 Antenna Guidelines .......................................................................................................19

4.5 Summary - Sensor Location Requirements ...................................................................19

5.0 PRE-INSTALLATION TEST ..........................................................................................20

5.1 Software installation.......................................................................................................20

5.2 Configure Sensor and Software.....................................................................................20

5.3 Sensor Preparation ........................................................................................................21

5.3.1 Data Connection ............................................................................................................21

5.3.2 Communication Selector Switch ....................................................................................21

5.4 Test Setup......................................................................................................................21

T1DA0302-001, Rev A Page 3

Flash™ System Installation Manual

6.0 SENSOR INSTALLATION .............................................................................................23

6.1 Disassemble Sensor ......................................................................................................23

6.2 Mount Sensor Housing ..................................................................................................23

6.3 AC Power.......................................................................................................................23

6.4 Install Sensor Electronics...............................................................................................24

6.5 Install Antenna ...............................................................................................................24

6.5.1 Mount Antenna ..............................................................................................................24

6.5.2 Lightning Arrestor ..........................................................................................................29

6.5.3 Connect Antenna to Sensor...........................................................................................29

7.0 INSTALL PC EQUIPMENT............................................................................................30

7.1 PC System Setup...........................................................................................................30

7.2 Install UI (Modem)..........................................................................................................30

7.3 Install Flash Software.....................................................................................................30

7.5 Configure Flash Software ..............................................................................................30

7.6 Communications Test ....................................................................................................31

8.0 SYSTEM PROBLEMS ...................................................................................................32

T1DA0302-001, Rev A Page 4

Flash™ System Installation Manual

1.0 INTRODUCTION

This document provides complete instructions for the setup, installation, and configuration of a

SSC Flash, Personal Alarm System.

NOTE

This manual is specific to Flash software version 2.0.0.5 and Higher

1.1 System Introduction

The Senstar-Stellar Flash system is designed to monitor Personal Portable Alarms (PPA) and

notify the system operator when alarm activation occurs. Flash is intended for use with the SSC

Personal Protection Device (PPD) Transmitter; however, it also functions with other PPA/PPD

devices such as the common Digilarm PPD. Throughout this manual we will use the term PPD.

The Senstar-Stellar personal protection device (PPD) is a body-worn radio transmitter, which

emits a radio frequency alert signal when activated. The PPD is intended to be worn on the belt

of the user. When used in a facility equipped with the Senstar-Stellar Flash system, the

transmitter notifies security personnel an alarm has occurred and shows the ID of the transmitter

on a display screen. A unique ID code identifies each PPD unit during an alarm.

1.2 Installation Overview

System installation consists of several main steps:

• Equipment Unpacking and Inspection

• Installation Planning (determining location of equipment)

• Pre-Installation Testing

• Sensor Installation

• Computer Equipment Installation

• Software Installation and Set-Up

• System Testing

Section 2 of this manual provides an overview of the Flash system architecture. Subsequent

chapters provide detailed instructions for each of the installation steps listed above.

T1DA0302-001, Rev A Page 5

Flash™ System Installation Manual

1.3 Reference Documents

The following manuals and reference documents have been provided with the system. These

documents are contained within the three-ring ‘Flash Documentation Binder’.

• Flash ™ Software Manual – Flash ™ software operation

• Flash ™ Technical Manual – System Maintenance for the Flash ™ system

• PPD User Instructions – Care and Use of the SSC PPD

• PPD Technical Manual – PPD Maintenance

• PSU Mounting Instructions

• Antenna Mounting Instructions

T1DA0302-001, Rev A Page 6

Flash™ System Installation Manual

2.0 SYSTEM ARCHITECTURE

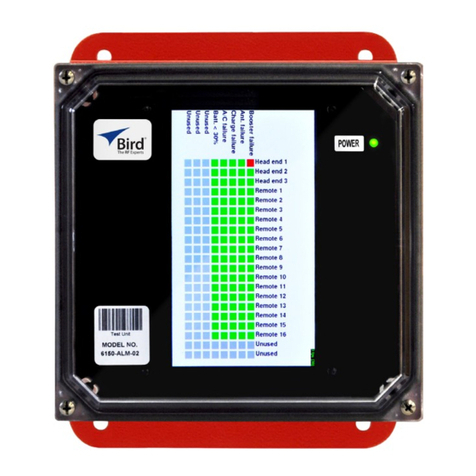

The Flash ™ system consists of a PC (Monitoring Post), Interface Unit (Modem), and one or

more Sensor Receivers. Throughout the remainder of this document the term Interface Unit (IU)

will be used. A block diagram of the system is shown in Figure 2.0.

UPS

IU

Sensor Receiver

Sensor Receiver

Sensor Receiver

PC

Twisted-PairRS-232

Additional receiv ers

as required to achiev e f ull f acility

cov erage

Printer

Optional SerialInterf ace

to otherThird Party

Head-EndSy stems

Figure 2. 0 Flash System Block Diagram

T1DA0302-001, Rev A Page 7

Flash™ System Installation Manual

2.1 Transmitters

The transmitter, also called a personal protection device (PPD) or personal portable alarm (PPA),

is a small, rugged unit that is activated by pushing a red button. It is worn in a holster on the belt

of the person to be protected. It uses a disposable 9-volt battery which lasts for at least one-year

under normal use (e.g. one transmission per-shift, 3 shifts per-day).

2.2 Sensor

The Sensor (sometimes referred to as PSU) is a high sensitivity radio frequency (RF) receiver

operating in the 420 to 450 MHz (Canada) or 450 to 470 MHz (U.S.A.) frequency band. A single

Sensor will detect a transmitter more than half a mile away if a clear line-of-sight path exists.

However, most facilities use concrete and steel structures which greatly limit the effective range.

More than one Sensor is often installed in a facility to provide alarm coverage. Sensors are

powered from 120VAC. They communicate to an interface unit over (shielded) twisted pair

wiring using the industry standard CEBus® spread spectrum protocol. Each Sensor has a (4)

four-hour backup battery to keep it running in the event of a power failure.

The Sensors use a dual-antenna design. Sensors are typically supplied with a pair of whip

antennas (also referred to as rubber duck); however, optional higher gain antennas are available

to extend the useful range of the Sensor. The particular antennas to be used with the Sensor(s)

are a function of the size of the facility, construction details, and Sensor location within the

facility (Refer to Section 4 for guidelines in determining the type and placement of Sensor

antennas).

CAUTION

Please note that there are no user-serviceable parts in any of the Flash ™

components. Flash components should be serviced only by a trained

technician. The interior of Flash components contain exposed high voltage

areas which can be hazardous to the untrained.

T1DA0302-001, Rev A Page 8

Flash™ System Installation Manual

2.3 Monitoring Post Equipment

Alarms detected Flash Sensors are annunciated and displayed on a ‘head end’ computer system.

This equipment is typically installed in the Control Center of the facility. The head-end

equipment consists of a combination of SSC proprietary hardware and software devices as well

as commercially available computer equipment, peripherals, and accessories. Many times, SSC

will supply a turnkey head-end package; however, often the customer chooses to procure the

computer equipment independently.

The following sections will provide an overview of the various components that comprise the

head-end equipment.

2.3.1 Computer

The computer provides a user interface to display transmitted alarms, selectively acknowledge,

and clear individual alarms. The basic operator interface is point-and-click (a keyboard is not

required). Icons appear in the alarm window indicating the PPD ID and status of each alarm.

The computer will emit an alarm sound that can be silenced by acknowledging the alarm. A text

window at the bottom of the screen keeps a chronological log of alarm events and any hardware

malfunctions. Text appearing in this window can not be cleared. However, the alarm logs are

archived on the computer's hard drive.

IMPORTANT: The Flash Application Must Run on a Dedicated PC System.

The computer runs in a WindowsTM operating system with the Flash software application.

Minimum PC Requirements

• Intel P4 – 1.2 GHz

• 256 MB RAM

• 1 Spare Serial Port

• Sound-Blaster or Equivalent Sound Card

• External Audio Speaker Package

• Windows 2000 or Windows XP Operating System

Optional PC Requirements

• CD Reader - Flash software is delivered on a CD

T1DA0302-001, Rev A Page 9

Flash™ System Installation Manual

2.3.2 Uninterruptible Power Supply (UPS)

The PC system should be equipped with a UPS of at least 400VA and the system should be

connected to a circuit fed by the facility emergency back-up power. The UPS is required to

assure that the PC system is operational during the brief time (30 seconds typical) that is usually

required for the facility power back-up system to activate in the event of a general power failure.

2.3.3 Printer

The Flash software supports hardcopy printout of alarm events. Flash was specifically designed

for use with ‘tractor feed’ type printers. The software utilizes the PC's parallel port for the printer

interface.

2.3.4 Audio Output

In the event of an alarm, the Flash system will annunciate an audible alarm signal using the PCs

external speaker system. The customer should select a PC speaker system and speaker placement

that is appropriate for their particular requirements.

2.3.5 Interface Unit (IU)

The interface unit is a device which converts CEBus protocol to an EIA-232C format used by PC

computers. The Interface unit is located near the PC and is powered from 120VAC. If an

uninterruptible power supply (UPS) is used, the interface unit and the computer will use the UPS

for power. The IU is a module manufactured by Senstar-Stellar. Do not attempt to substitute

units directly from any other company.

2.4 Optional Serial Interfaces

The Flash system can interface to other Control Center equipment via an optional serial interface

module. This would allow Flash alarms to be annunciated on other vendors' systems. Flash can

communicate with other systems via an EIA-232 serial port. Contact Senstar-Stellar for details

concerning the optional serial interfaces and/or for information about the development of a

customized interface for your particular third-party equipment.

T1DA0302-001, Rev A Page 10

Flash™ System Installation Manual

3.0 UNPACKING AND INSPECTION

Carefully unpack and inspect all of the equipment received. A site transmittal letter will be

included with your shipment. Compare the items received to the items listed on this document. If

there is any obvious physical damage to the unit or you believe you may be missing required

items, please contact:

Senstar-Stellar

Life Safety Division

Technical Services

703-421-2086 x205

T1DA0302-001, Rev A Page 11

Flash™ System Installation Manual

4.0 INSTALLATION PLANNING

As described in Section 2.0, the Flash system consists of a PC system interconnected to one or

more Sensors via twisted pair phone lines. If new wires are being pulled, it is suggested using

shielded twister pair. The critical factors in planning the system installation are:

RF Coverage

One of the primary objectives in system planning and installation is to assure that no

matter where in the facility a PPD is activated, at least one Sensor will ‘hear’ the RF

transmission and report the alarm to the PC. The quantity of Sensors used, their exact

placement within the facility, and the type and location of antennas used with the Sensors

are all critical to the goal of ‘100% coverage’.

Ease / Cost of Installation

The Sensor requires a source of AC power. A suitable source must be located within 6

feet of the Sensor. This requirement may impact Sensor locations in that it may be

difficult to route AC power to the desired Sensor location. Furthermore, and more

importantly, there needs to be a data path between the Sensor(s) and the PC system.

Installation costs can be greatly reduced if there is an available phone circuit (twisted

pair) between the PC and the desired Sensor location. If no phone lines are available, the

Sensor(s) location should be selected such that it is relatively easy to route new shielded,

twisted pair cable between the PC and Sensor.

Determining the optimum location for the Sensor(s) in a Flash system often involves a trade-off

between the objective of minimizing installation cost and assuring 100% facility coverage. In

one case, the ideal location from an RF coverage viewpoint may be a very difficult place from

which to get a data line between the Sensor and the PC system. Conversely, there may be an

available data path between two possible locations; however, if installed in either one of these

locations, the receiver may not provide adequate coverage.

Selecting the ‘perfect’ location for the Sensor(s) would be a very complex process involving

many factors including the size of the facility, exact locations of buildings, building materials,

construction details, and an understanding of RF propagation characteristics and antenna

transmission patterns.

Such concepts and knowledge are beyond the scope of this installation guide. However, because

of the sensitivity of the SSC Sensor and the relatively high power output from the PPDs,

determining the ‘perfect’ location for each Sensor is unnecessary except in particularly complex

site plans.

Under most circumstances, a competent technician can select a suitable location by following the

guidelines and examples presented below. Installers are encouraged to contact Senstar-Stellar

Technical Services to obtain assistance in selecting Sensor locations.

T1DA0302-001, Rev A Page 12

Flash™ System Installation Manual

4.1 RF Coverage

4.1.1 Single Building Facility

In a very small facility containing one building, a single Sensor should provide adequate

coverage regardless of its specific placement. Select a location where AC power is readily

available and it is easy to route a data cable between the Sensor and PC. In a very small facility

adequate coverage may be obtained simply using the ‘rubber whip’ (rubber duck) antennas

connected directly to the receiver.

Try this configuration first, however, if there are ‘holes’ in the facility coverage, try connecting a

higher gain antenna to the unit. Mount the antenna has high as possible within the building. This

has a dramatic effect on system coverage. Consult the factory for additional guidance on

selecting the appropriate antennae and antenna coaxial cables.

Figure 4.1.1 shows an example of a very small, single building facility. In this case, the Sensor is

installed in the back part of the ‘Administration’ area of the compound.

ADMIN

CellBlock

Figure 4.1.1

Small, Single Building Facility

Perimeter

Fence

RFCoverageArea

Sensor

Location

X

T1DA0302-001, Rev A Page 13

Flash™ System Installation Manual

4.1.2 Small, Multi-Building Site

In a small multi-building facility, and utilizing a single Sensor, it would be advantageous to

install the Sensor in the middle (approximately) of the facility and use the Sensor's internal

antennas. In a slightly larger single Sensor system it may be necessary to utilize one or more

external antennas. It may also be necessary to install the external antenna high on an outdoor

mast, where it will have a ‘view’ of the entire facility.

An example of a small, multi-building facility is shown in Figure 4.1.2. The Sensor is located in

the ‘Cell Block’ which is approximately the center of the facility's perimeter. Since the head-end

computer system is most likely to be installed in the Administration building, a data path

between the Cell Block Building and the Administration Building will be required.

Figure 4.1.2

Small Multi-Building

Fac ility

ADMIN

CellBlock

Per imeter

Fence

Sensor

Location

X

RF Co v er age

Area

T1DA0302-001, Rev A Page 14

Flash™ System Installation Manual

4.1.3 Large Facility

In large, multi-building facilities, two (2) or more Sensors may be required to provide additional

coverage. The Sensors are positioned such that each provides coverage over a portion of the site.

Figure 4.1.3 provides one example of a multi-Sensor system.

ADMIN

CellBlock

Figure 4.1.3

Typical Tw o (2) Sensor System

Pe r i me t e r

Fence

CellBlock

CellBlock

Rec eiv er 1

CoverageArea

Rec eiv er 2

CoverageArea

CellBlock

Sensor#2

Location

Sensor#1

Location

ADMIN

CellBlock

CellBlock

CellBlock

Rec eiv er 1

CoverageArea

Rec eiv er 2

CoverageArea

CellBlock

X

X

T1DA0302-001, Rev A Page 15

Flash™ System Installation Manual

4.2 Communications Wiring

The PC System communicates with the Sensor(s) via a pair of twisted (or shielded) wires. This

pair can be a ‘spare pair’ in a telephone bundle, a dedicated pair of wires, or a CAT3 or CAT5

wire. Whenever possible, the communications path to the Sensor should be over a dedicated,

shielded cable. However, when assessing costs, using existing twisted pair is sufficient.

When multiple Sensors are used, the cable can be routed using a variety of topologies such as a

'daisy-chained' (point-to-point) or ‘star’ configuration. The figure below presents two of the most

common wiring scenarios for multiple Sensor systems.

4.2.1 Daisy-Chained Wiring

An example of ‘daisy-chained’ wiring is shown in Figure 4.2.1. In this case, a pair of wires is

routed from the PC system to the 1st Sensor. Another pair of wires is routed from the 1st Sensor

to the 2nd Sensor. When existing phone lines are not available and it is necessary to run new data

communications wire, this approach is frequently used.

PC Modem Sensor

1

Sensor

2

Admin Buildiing

Building #1

Building #2

Figure 4.2.1

Daisy-Chain

Wiring

T1DA0302-001, Rev A Page 16

Flash™ System Installation Manual

4.2.2 Star Wiring

An example of ‘star’ wiring is shown in Figure 4.2.2. In this case, a pair of wires is routed from

the PC to the 1st Sensor. A second pair of wires is routed from the PC to the 2nd Sensor.

This is the most typical form of wiring when using existing phone lines. Primarily, due to the

amount of un-used phone lines interconnecting the Administration building to other buildings

within the facility.

When utilizing existing phone lines, the installer first identifies available pairs between the

Admin Building and Buildings containing the Sensors. At the Admin building these pairs are

‘shorted together’ at the 66-Block (also referred to as Punch-Down Block) and then extended to

the location of the PC modem. At the Sensor end, the technician simply has to extend the lines

from the 66-Block (also referred to as Punch-Down Block) in that building to the specific

location of the Sensor.

PC Modem Sensor

1

Sensor

2

Admin Buildiing

Building #1

Building #2

Figure 4.2.2

‘Star’ Communications Wiring

T1DA0302-001, Rev A Page 17

Flash™ System Installation Manual

4.3 AC Wiring

The Sensor requires 110/120 VAC electrical power. The Sensor is typically fed from a dedicated

circuit connected to the facility’s emergency back-up generator. The circuit should be protected

with a maximum 20A breaker (the unit draws approximately .25 amps).

The Sensor is provided with a 6’ external power cord with a Leviton 4720C twist-lock AC plug.

In some instances, customers choose to provide power to the unit via conduits as opposed to the

power cord. In this case, follow the instructions and drill templates provided in document

A77003 for locations of conduit penetrations.

4.4 Antennas

The type of antenna(s) used with the Flash system and their specific location and orientation

within the facility, have a major impact on the performance of the system. Therefore, when

planning a location for the Sensor, special consideration to antenna placement must be given.

The following sections describe the attributes of the different antennae that may be used with

Flash and provide guidelines for selecting an appropriate antenna and antenna location.

4.4.1 Antennas Overview

The Sensor utilizes a dual-antenna design and antennas must be connected to both inputs in order

to provide maximum RF coverage. In many installations, the unit will use two different types of

antennae to maximize the coverage area. The following briefly describes the types of antennas

typically used with the Flash system:

‘Whip Antenna’ (e.g. ‘rubber duck’)

The SSC Sensor is supplied with two (2), whip antennas. These antennas have a TNC

connector and can be mounted directly to the Sensor or they can be 'remoted' via coaxial

cable. Whip antennas are the least sensitive; however, they have an omni-directional

receive pattern (that is, they can ‘see’ in all directions) and they are very easy to install.

In a small facility, a single Sensor with two (2) whip antennas can provide sufficient

coverage. In larger systems, it is not uncommon to find a Sensor with whip antennas

installed in a remote corner of the facility which is providing coverage in a ‘blind-spot’ to

the other Sensors.

Co-Linear Phased Array (CPA) (also referred to as Omni Antenna)

These large antennas are much more sensitive (3 db) than the typical ‘rubber duck’. The

CPA (or Omni) antenna is omni-directional in the horizontal plane (e.g. parallel to the

ground) but is not very sensitive directly above or below the antenna. The CPA antenna is

typically used when a single Sensor, located centrally, is to provide full coverage for the

facility. In such situations, the CPA is mounted outdoors on a mast in a central location.

T1DA0302-001, Rev A Page 18

Flash™ System Installation Manual

A small whip antenna directly mounted to the Sensor's other antenna port, assures

coverage directly below the mast in the CPA antenna’s blind spot.

Yagi Antenna

The Yagi is the most sensitive antenna typically used with the Flash system. The Yagi

has a very wide beam width; but, it is more directional than the Whip or CPA described

above. The Yagi is typically used when the Sensor is installed at one end of the facility.

The antenna is positioned such that it ‘looks out’ over the compound.

4.4.2 Antenna Guidelines

1. Antennas should be located within 20’ of the Sensor when using RG-58 cable and 100’

when using RG-8 cable. The antennas can be located at greater distances than those

distances listed above; however, this would require more expensive ‘low loss’ coaxial

cables.

2. IMPORTANT - Antennas should be mounted as high as possible!

3. Coverage in large multi-building facilities will require one or more antennas to be

mounted in outdoor locations (e.g., on the roof of a building containing the Sensor).

4. When mounting antennas outdoors be sure to provide adequate lightning protection per

the manufacturer’s guidelines.

4.5 Summary - Sensor Location Requirements

1. Access to 110 VAC Emergency Back-Up power

2. Availability of phone lines of twisted-pair cable between the PC system and Sensor

3. Within 100’ of a suitable antenna location

4. Location from which antenna combination (Whip-whip, Whip-Yagi, CPA-Whip, etc.)

will provide coverage over the required area.

If there are any doubts concerning installation requirements and/or selecting an appropriate

location for the Sensor please contact:

Senstar-Stellar Life Safety Division

Technical Services

703-421-2086 Ext. 205

T1DA0302-001, Rev A Page 19

Flash™ System Installation Manual

5.0 PRE-INSTALLATION TEST

Before permanently installing Flash Sensors, it is strongly advised the system is setup in a

temporary configuration in order to test and ensure the selected Sensor locations will provide

adequate facility coverage. This step will also verify the equipment is configured correctly and is

in proper working order.

The following outlines the basic steps required to test a potential Sensor location prior to fixed

installation:

1. Install Flash software on a Laptop PC

2. Configure the Software and Flash Sensor unit

3 Prepare the Sensor for use

4. At the location to be tested:

Connect Flash Sensor to the Laptop via the IU and a Modular Phone cord.

Connect the desired antennae to the Sensor and provide some temporary means to

support them. Ideally, the antennae will be tested in a location that is as close as

possible to the actual, permanent locations.

Supply AC power to the Sensor (uses an extension cord if necessary to get the

Sensor as close as possible to its final position).

5. Conduct a series of PPD Alarm tests at various locations around the facility and

verify that the alarms are detected and reported by the system.

5.1 Software installation

Install the Flash software from the installation CD following the instructions detailed in the Flash

Software Manual (Section 3).

5.2 Configure Sensor and Software

Configure the Flash Software and Sensor following the procedures defined in Section 3 of the

Flash Software Manual.

T1DA0302-001, Rev A Page 20

Table of contents

Other Senstar Stellar Security System manuals

Popular Security System manuals by other brands

Wolf-Guard

Wolf-Guard YL-007M2G user manual

Inhep Digital Security

Inhep Digital Security IDS X Series user manual

LogicMark

LogicMark 37920 Setup instructions

Response

Response CENTURION SCOUT owner's manual

fadini

fadini MIRI 4 manual

Elektrotechnik Schabus

Elektrotechnik Schabus GX-HS operating instructions