Sentec WS303U User manual

"

!

WS303U Ultrasonic Wind Speed & Direction Sensor

Product Manual

!

WORKING PRINCIPLE

Ultrasonic wind measurement is an application of ultrasonic detection technology in the gas medium. It uses the

influence of air flow (wind) on the propagation speed of ultrasonic in the air to measure the wind speed. Compared with

the conventional wind cup or rotor anemometer, the most important feature of this method is that the whole wind

measuring system has no mechanical rotating parts and belongs to non inertial measurement, so it can accurately

measure the high frequency component of gust pulsation in natural wind.

Ultrasonic wind speed and direction transmitter uses four ultrasonic probes to send and receive ultrasonic waves in

two-dimensional plane circularly. The principle that ultrasonic waves are affected by wind speed and thus increase or

decrease is used to measure wind speed and direction.

INTRODUCTION

WS303U small ultrasonic wind speed and direction sensor is a wind speed and direction measuring instrument based

on the ultrasonic principle. It uses the acoustic pulse sent to measure the phase difference of the receiving end to

calculate the wind speed and direction. The sensor can measure the instantaneous value of wind speed and direction

at the same time. It is widely used in the fields of meteorology, ocean, environment, airport, port, laboratory, industry,

agriculture and transportation.

The equipment with built-in electronic compass no longer has the requirement of orientation during installation. It only

needs to ensure the horizontal installation. The whole machine shell is made of high-quality ABS material, which has

the characteristics of light weight, no moving parts, strong and durable.

FEATURES

•No angle limit, wind speed and direction data can be measured at the same time

•No moving parts, small wear and long service life

•The random error identification technology can ensure the low discrete error of measurement and make the output

more stable under strong wind

•Using ABS engineering plastic shell, the design is light, portable, easy to install and disassemble

•Analog signal output, 4 ~ 20mA, 0 ~ 5V, 0 ~ 10V optional

•485 communication interface, standard Modbus RTU communication protocol, communication address and baud rate

can be set, and the farthest communication distance is 2000 meters

•The equipment with built-in electronic compass can be installed horizontally without direction requirement

•No maintenance and field calibration required

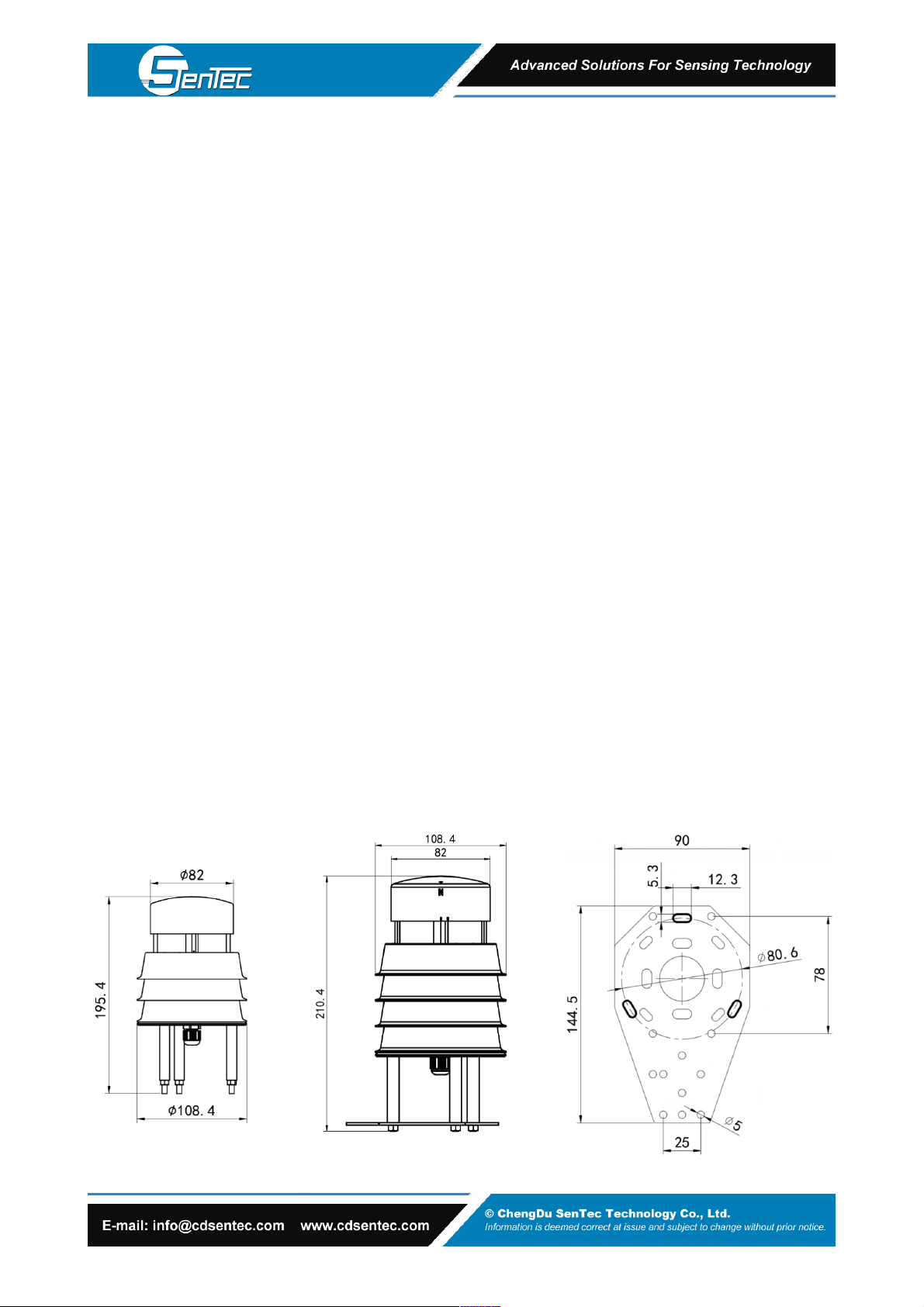

APPEARANCE SKETCH

RS485 Type

Analog Type

!

INSTALLATION INSTRUCTION

1. Inspection before equipment installation

Equipment list:

1 sensor equipment

Certificate and warranty card

One white bracket, two M4 * 10 screws and nuts, and three M5 nuts

2. Installation method

Beam installation (optional)

The installation of the device without electronic compass is shown in the figure below. The device with built-in

electronic compass only needs to be installed horizontally.

Supply voltage

10-30V DC (0-10V output is powered by 24 V)

Power consumption

485:0.12W

4~20mA/0~5V/0~10V:1.2W

Range

Wind speed

0 ~ 40m / S (customizable),0.5m starting wind speed

Wind direction

0~360°

Accuracy

Wind speed

±0.5+2%FS

Wind direction

±3°

Resolution

Wind speed

0.01 m/s

Wind direction

1°

Working environment

-40~80℃,0~95%RH

Wind resistance

75 m/s

Response time

1S

IP grade

485 type: IP65, analog type: IP54

Signal output

485 (Modbus RTU protocol)"

4 ~ 20mA current output"

0 ~ 10V, 0 ~ 5V voltage output

Load ability

Current output

≤600Ω

Voltage output

Output resistance ≤250 Ω

TECHNICAL SPECIFICATION

!

Line color

Explain

Power

brown

Power supply positive

black

Power supply negative

Output

yellow

Wind speed signal positive

white

Negative wind speed signal

blue

Wind direction signal positive

green

Negative wind direction signal

ANALOG OUTPUT

1. Interface description

Wide voltage power supply input 10-30V DC power supply. For 0 ~ 10V output equipment, the power supply is 24 v

2. Example of connection mode

sensor

sensor

Analog signal collector

Analog signal collector

4-wire wiring diagram

3-wire wiring diagram

!

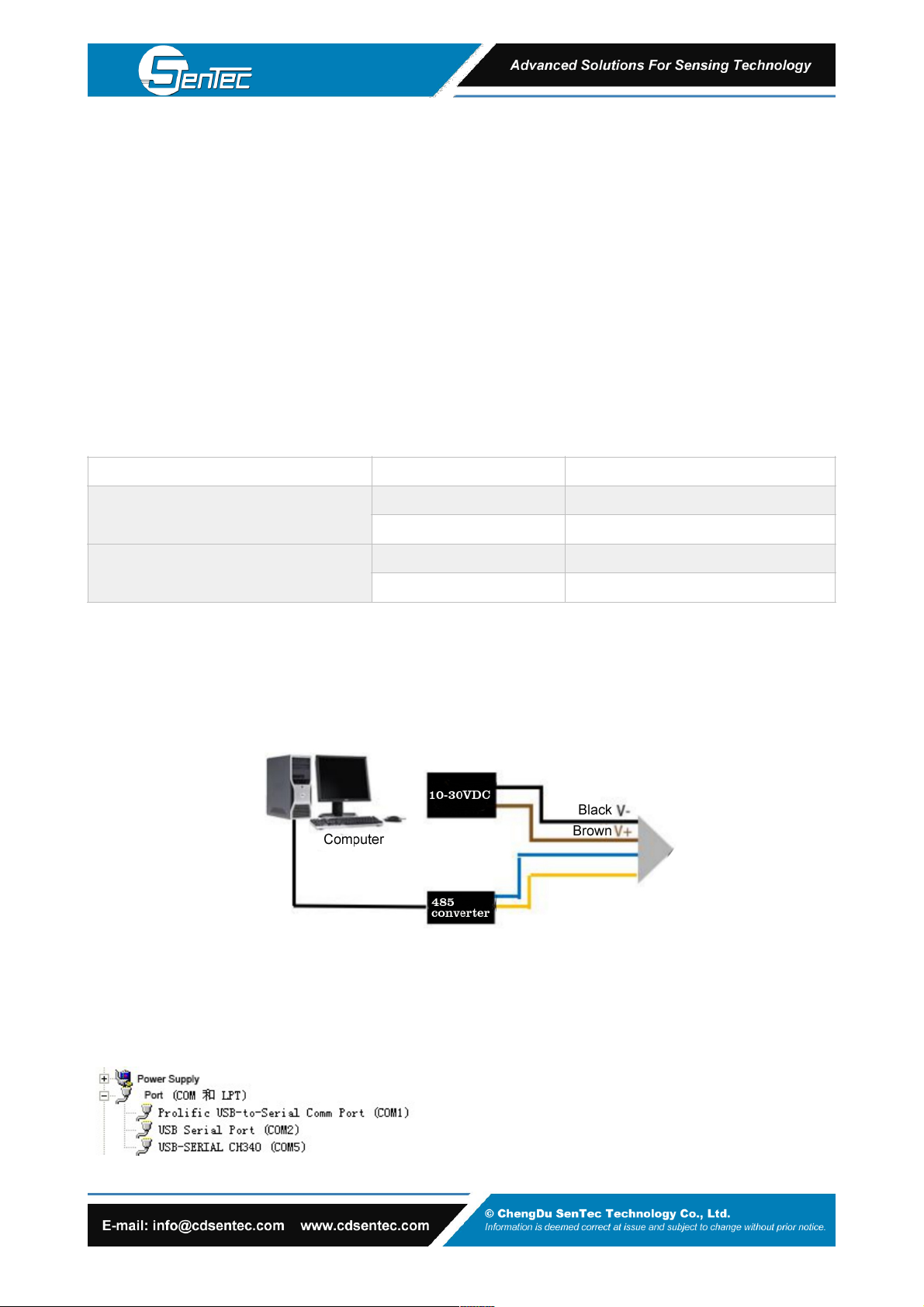

RS485 COMMUNICATION OUTPUT TYPE

1. Interface description

Wide voltage power supply input 10-30V DC power supply. When connecting 485 signal line, it is noted that the two

lines a and B cannot be connected reversely, and the address between multiple devices on the bus cannot conflict.

Line color

Explain

Power

brown

Positive power supply (10 ~ 30V DC)

black

Power supply negative (GND)

Output

yellow

485-A

blue

485-B

2. Installation and use of configuration software

2.1. Software selection

Open 485 data package, select "debugging software" - "485 parameter configuration software", find (Parameter

configuration tool.exe) and open it.

2.2. Equipment connection

2.3. Parameter setting

(1) Select the correct COM port (check the COM port in my computer - properties - Device Manager - port). The

following figure lists the driver names of several different 485 converters.

3. Computing method

3.1 conversion calculation of current mode output signal

The measuring range is 0 ~ 40m / s, 4 ~ 20mA output. When the output signal is 12mA, the current wind speed is

calculated. The span of wind speed range is 40m / s, which is expressed by 16mA current signal. 40m / S / 16mA =

2.5m/s/ma, that is, the current changes 1mA, and the wind speed changes 2.5m/s. Then the measured value can be

calculated. The measured value 12ma-4ma = 8Ma. 8Ma * 2.5m/s/ma = 20m / S, and the current wind speed = 20m / s.

3.2 calculation of voltage mode output signal conversion

The measuring range is 0 ~ 40m / s. take 0-10V output as an example, when the output signal is 5V, the current wind

speed is calculated. The span of wind speed range is 40m / s, which is expressed by 10V voltage signal. 40m / S / 10V

= 4m / S / V, that is, every 1V change of voltage corresponds to 4m / s change of wind speed. The measured value is

5v-0v = 5V. 5V*4/m/s/V=20m/s。The current wind speed is 20m / s.

Table of contents

Other Sentec Accessories manuals