Sentec V-Sign Sensor 2 Manual

Warning: The measurement of SpO2and PR with SenTec TC Sensors is

only defined on sites specified by the manufacturer (refer to the instrument`s

manual). In order to avoid erroneous readings and false alarms of SpO2and PR,

ensure that the appropriate patient type (Adult) is selected. Ensure to disable

the parameters SpO2/PR for sensor application on other measurement sites.

Warning: The use of temperatures higher than 41°C requires special

attention to patients with susceptible skin, e.g. neonates, geriatric patients, burn

victims, patients with skin diseases.

CAUTION: A flat, well-perfused area of intact skin is needed (centrally

located sites are preferable). Avoid placement over large superficial veins or

areas of skin breakdown or edema.

Cleaning and Disinfection

CAUTION: The use of other cleaning and disinfection procedures other

than those recommended here may result in permanent damage to the sensor.

CAUTION: Do not remove the membrane of the sensor for cleaning and

disinfection.

CAUTION: Wiping and/or the application of mechanical force in general

can damage the sensor membrane or the sensor cable mechanically. Wipe the

sensor carefully and inspect the condition of the membrane and sensor cable

after cleaning and/or disinfection.

The V-Sign™ Sensor 2 must be cleaned before inserting it into the docking

station in order to remove any gel residues or other soils such as blood, protein,

or mucous that could contaminate the docking station, cause cross-infections

between different patients and/or gas leakage during calibration.

In order to remove all foreign substances, the sensor should be cleaned prior

disinfection.

Important: The cleaning and disinfection solutions listed here have been tested

for their suitability for the V-SignTM Sensor. The below listed name brand products

for cleaning and disinfection may be substituted by other name brand products of

equivalent composition. However, as there are many factors (contact time, force

applied during wiping etc.) that can influence the functionality of the sensor, it is

the responsibility of the user to test the functionality of the sensor after cleaning

and/or disinfection. SenTec recommends using 70% Isopropanol.

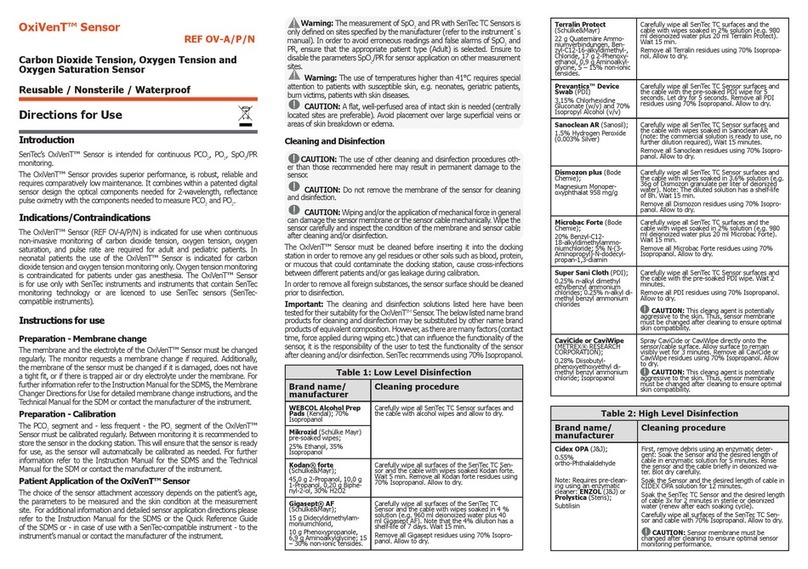

Table 1: Low Level Disinfection

Brand name/

manufacturer Cleaning procedure

WEBCOL Alcohol Prep

Pads (Kendal)

; 70%

Isopropanol

Carefully wipe all SenTec TC Sensor surfaces

and the cable with alcohol wipes and allow to

dry.

Mikrozid (Schülke Mayr)

pre-soaked wipes;

25% Ethanol, 35%

Isopropanol

Kodan® forte

(Schülke&Mayr);

45,0 g 2-Propanol, 10,0 g

1-Propanol, 0,20 g Biphenyl-

2-ol, 30% H2O2

Carefully wipe all surfaces of the SenTec TC

Sensor and the cable with wipes soaked Kodan

forte. Wait 5 min. Remove all Kodan forte resi-

dues using 70% Isopropanol. Allow to dry.

Gigasept® AF

(Schülke&Mayr);

15 g Didecyldimethylammoni-

umchlorid,

10 g Phenoxypropanole, 6,9

g Aminoalkylglycine; 15 –

30% non-ionic tensides.

Carefully wipe all surfaces of the SenTec TC

Sensor and the cable with wipes soaked in 4%

solution (e.g. 960 ml deionoized water plus 40

ml Gigasept AF). Note that the 4% dilution has

a shelf-life of 7 days. Wait 15 min.

Remove all Gigasept residues using 70% Iso-

propanol. Allow to dry.

V-Sign™ Sensor 2

REF VS-A/P/N

Carbon Dioxide Tension and

Oxygen Saturation Sensor

Reusable / Nonsterile / Waterproof

Directions for Use

Introduction

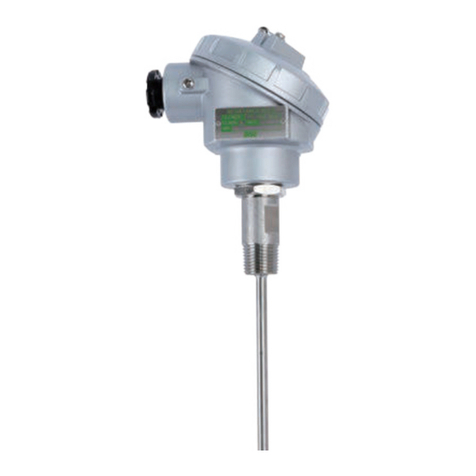

SenTec’s V-Sign™ Sensor 2 is intended for continuous PCO2, SpO2/PR monitoring.

The V-Sign™ Sensor 2 provides superior performance, is robust, reliable and

requires comparatively low maintenance. It combines within a patented digital

sensor design the optical components needed for 2-wavelength, reflectance pulse

oximetry with the components needed to measure PCO2.

Indications/Contraindications

The V-Sign™ Sensor 2 (VS-A/P/N) is indicated for use when continuous non-

invasive monitoring of carbon dioxide tension, oxygen saturation, and pulse rate

are required for adult and pediatric patients. In neonatal patients the use of the

V-Sign™ Sensor 2 is indicated for carbon dioxide tension monitoring only. The

V-Sign™ Sensor 2 is for use only with SenTec instruments and instruments that

contain SenTec monitoring technology or are licenced to use SenTec sensors

(SenTec-compatible instruments).

Instructions for use

Preparation - Membrane change

The membrane and the electrolyte of the V-Sign™Sensor must be changed

regularly. The monitor requests a membrane change if required. Additionally, the

membrane of the sensor must be changed if it is damaged, does not have a tight

fit, or if there is trapped air or dry electrolyte under the membrane. For further

information refer to the Instruction Manual for the SenTec Digital Monitoring

System (SDMS), the Membrane Changer Directions for Use for detailed

membrane change instructions, and the Technical Manual for the SDM or contact

the manufacturer of the instrument.

Preparation - Calibration

The PCO2segment of the V-Sign™Sensor 2 must be calibrated regularly. The

monitor requests a sensor calibration if required. Between monitoring it is

recommended to store the sensor in the docking station. This will ensure that the

sensor is ready for use, as the sensor will automatically be calibrated as needed.

For further information refer to the Instruction Manual for the SDMS and the

Technical Manual for the SDM or contact the manufacturer of the instrument.

Patient Application of the V-Sign™ Sensor

The choice of the sensor attachment accessory depends on the patient’s age, the

parameters to be measured and the skin condition at the measurement site. For

additional information and detailed sensor application directions please refer to the

Instruction Manual for the SDMS or the Quick Reference Guide of the SDMS or - in

case of use with a SenTec-compatible instrument - to the instrument’s manual or

contact the manufacturer of the instrument.

Terralin Protect

(Schülke&Mayr)

22 g Quaternäre Ammonium-

verbindungen, Benzyl-C12-

16-alkyldimethyl-, Chloride,

17 g 2-Phenoxyethanol, 0,9 g

Aminoalkylglycine, 5 – 15%

non-ionic tensides.

Carefully wipe all SenTec TC surfaces and the

cable with wipes soaked in 2% solution (e.g.

980 ml deionoized water plus 20 ml Terralin Pro-

tect). Wait 15 min.

Remove all Terralin residues using 70% Isopro-

panol. Allow to dry.

Prevantics™ Device Swab

(PDI);

3.15% Chlorhexidine Gluco-

nate (w/v) and 70% Isopro-

pyl Alcohol (v/v)

Carefully wipe all SenTec TC Sensor surfaces

and the cable with the pre-soaked PDI wipe

for 5 seconds. Let dry for 5 seconds. Remove

all PDI residues using 70% Isopropanol. Allow

to dry.

Sanoclean AR (Sanosil);

1.5% Hydrogen Peroxide

(0.003% Silver)

Carefully wipe all SenTec TC Sensor surfaces

and the cable with wipes soaked in Sanoclean

AR (note: the commercial solution is ready

to use, no further dilution required), Wait 15

minutes.

Remove all Sanoclean residues using 70% Iso-

propanol. Allow to dry.

Dismozon plus (Bode

Chemie);

Magnesium Monoper-

oxyphthalat 958 mg/g

Carefully wipe all SenTec TC Sensor surfaces

and the cable with wipes soaked in 3.6% solu-

tion (e.g. 36g of Dismozon granulate per liter of

deionized water). Note: The diluted solution has

a shelf-life of 8h. Wait 15 min.

Remove all Dismozon residues using 70% Iso-

propanol. Allow to dry.

Microbac Forte (Bode

Chemie);

20% Benzyl-C12-18-alkyldi-

methylammoniumchloride;

5% N-(3-Aminopropyl)-N-

dodecylpropan-1,3-diamin

Carefully wipe all SenTec TC surfaces and the

cable with wipes soaked in 2% solution (e.g.

980 ml deionoized water plus 20 ml Microbac

Forte). Wait 15 min.

Remove all Microbac Forte residues using 70%

Isopropanol. Allow to dry.

Super Sani Cloth (PDI);

0.25% n-alkyl dimethyl ethyl-

benzyl ammonium chlorides

0.25% n-alkyl dimethyl ben-

zyl ammonium chlorides

Carefully wipe all SenTec TC Sensor surfaces

and the cable with the pre-soaked PDI wipe.

Wait 2 minutes.

Remove all PDI residues using 70% Isopropa-

nol. Allow to dry.

CAUTION: This cleang agent is potentially

aggressive to the skin. Thus, sensor membrane

must be changed after cleaning to ensure opti-

mal skin compatibility.

CaviCide or CaviWipe

(METREX® RESEARCH

CORPORATION)

0.28% Diisobutyl-phenoxye-

thoxyethyl dimethyl ben-

zyl ammonium chloride;

Isopropanol

Spray CaviCide or CaviWipe directly onto the

sensor/cable surface. Allow surface to remain

visibly wet for 3 minutes. Remove all CaviCide

or CaviWipe residues using 70% Isopropanol.

Allow to dry.

CAUTION: This cleang agent is potentially

aggressive to the skin. Thus, sensor membrane

must be changed after cleaning to ensure opti-

mal skin compatibility.

Table 2: High Level Disinfection

Brand name/

manufacturer Cleaning procedure

Cidex OPA (J&J) (*);

0.55% ortho-Phthalaldehyde

Note: Requires pre-cleaning

using an enzymatic cleaner:

ENZOL (J&J) or Prolystica

(Steris);

Subtilisin

First, remove debris using an enzymatic deter-

gent: Soak the Sensor and the desired length of

cable in enzymatic solution for 5 minutes. Rinse

the sensor and the cable briefly in deionized

water. Blot dry carefully.

Soak the Sensor and the desired length of cable

in CIDEX OPA solution for 12 minutes.

Soak the SenTec TC Sensor and the desired

length of cable 3x for 2 minutes in sterile or de-

ionized water (renew after each soaking cycle).

Carefully wipe all surfaces of the SenTec TC

Sensor and cable with 70% Isopropanol. Allow

to dry.

CAUTION: Sensor membrane must be

changed after cleaning to ensure optimal sensor

monitoring performance.

Sani Cloth Bleach (PDI);

Sodium Hypochloride 0.63%

Approx. 6000 ppm available

free chlorine

Carefully wipe all SenTec TC Sensor surfaces

and the cable with the pre-soaked PDI wipe.

Wait 4 minutes

Remove all PDI residues using 70% Isopropanol.

Allow to dry.

CAUTION: Do not use bleach cleaners on

sensor surfaces without or with defect mem-

brane. This may damage the PCO2unit.

CAUTION: Bleach is potentially aggressive

to the skin. Thus, sensor membrane must be

changed after cleaning to ensure optimal skin

compatibility.

Clorox Healthcare Bleach

Germicidal Wipes;

5500 ppm Sodium

Hypochloride

Mikrozid® PAA wipes

(Schülke & Mayr);

0.07% Per-Acetic acid; Hy-

drogen Peroxide, Acetic acid

Carefully wipe all SenTec TC Sensor surfaces

and the cable with the pre-soaked Mikrozid PAA

wipes, Wait 15 min. Remove all Mikrozid PAA

residues using 70% Isopropanol. Allow to dry.

Applying force, e.g. during wiping, can damage the sensor cable and sensor

membrane mechanically. After cleaning, verify that the membrane is not dam-

aged and that there are no air bubbles between membrane and sensor surface.

The membrane ring must be securely seated on the sensor. In case of damages,

trapped air or loose fit the membrane must be changed. Do not use the sensor if

there is any visible damage.

Important: Always calibrate the sensor after cleaning and/or disinfection.

Note: For further information please refer to the Instruction Manual for the SDMS

or contact the manufacturer of the instrument.

Compatibility of V-Sign™ Sensor 2 with dierent instru-

ments

Before starting a measurement, please check the sensor’s compatibility with the

connected instrument.

Conntection to SDM: The V-SignTM Sensor 2 requires firmware versions SMB

V07.00.4 and MPB V05.00.06 or newer. The SMB and MPB version of the monitor

may be found in the SDM menu “System Information”. Please contact your local

SenTec representative for firmware upgrade information.

Other SenTec-compatible instruments: Consult individual manufacturers

for compatibility of of particular instruments and sensor models. Each manufac-

turer of SenTec-compatible instruments is responsible for determining whether

and under what conditions its instruments are compatible for safe and effective

use with each SenTec sensor model. This may include different specifications and/

or warnings, cautions, or contraindications. Refer to the intrument’s manual or

consult manufacturer for complete instructions for use of this sensor with their

SenTec-compatible instrument.

Accuracy

For accuracy specifications of the V-Sign™ Sensor 2 when used with SenTec

monitors refer to the Technical Specifications in the Technical Manual of the

SenTec Digital Monitor. For accuracy specifications of the V-Sign™ Sensor 2 when

used with SenTec-compatible instruments refer to the instrument`s manual or

contact the instrument manufacturer.

Useful life

Under normal wear and tear the expected life time of the V-Sign™ Sensor is

typically 18 months.

WARNINGS

• Sensors are designed for use with specific monitors. The user and/or operator

must verify the compatibility of the monitor, sensor, and cables before use or

patient injury may result.

• Failure to handle/apply the V-Sign™ Sensor 2 properly may cause inaccurate

measurements.

• Keep the V-Sign™ Sensor 2 (as well as any discarded parts) out of reach of

children under the age of 5 years. The sensor is small enough to be swallowed

and may block the trachea.

• Ensure that the V-Sign™ Sensor 2 is physically intact, with no broken or

damaged parts. Discontinue use immediately if any defects are noted.

• Do not touch the V-Sign™ Sensor 2 membrane with any sharp-edged objects

or your fingernails. Damage of the sensor membrane will cause inaccurate

measurements.

• Do not alter or modify the V-Sign™ Sensor 2.

• To ensure accurate data verify that the sensing elements on the V-Sign™ Sensor

2 membrane-face are completely covered by the measurement site.

• Carefully route and fix sensor cables to reduce the possibility of patient

entanglement or strangulation.

• Do not use the V-Sign™ Sensor 2 during MRI scanning. Conducted current may

cause burns. Also, the V-Sign™ Sensor 2 may affect the MRI image, and the

MRI unit may affect the accuracy of oximetry measurements.

• The sensor can be kept on the patient during defibrillation, burns are possible

under very rare circumstances.

• Physically separate the sensor and cables from electro-surgical equipment

during electro-surgery. Do not place the sensor between cutting and counter

electrode.

• Any change in cutaneous PcCO2may be due to either a change in arterial PCO2,

or due to a change in skin blood flow under the V-Sign™ Sensor 2. Cutaneous

PcCO2only reflects arterial PCO2at relatively high local blood flow.

• Do not expose the V-Sign™ Sensor 2 to strong ambient light such as direct

sunlight, surgical lamps, infrared warming lamps, and phototherapy lights

during clinical use. This may cause inaccurate measurements. In such cases,

cover the sensor with an opaque material.

• Excessive motion may compromise the performance of the V-Sign™ Sensor 2.

• SpO2readings may be falsely low in the presence of tricuspid valve insufficiency

(mixture of arterial and venous values) due to retrograde venous pulsations.

• The pulsations from intra-aortic balloon support can be additive to the pulse

rate on the oximeter pulse rate display. Verify pulse rate against ECG heart rate.

• Intravascular dyes may lead to inaccurate SpO2measurements.

• Elevated levels of Methemoglobin (MetHb) and/or Carboxyhemoglobin (COHb)

will lead to inaccurate SpO2measurements.

• Furthermore, the following situations may result in reduced accuracy of the

V-Sign™ Sensor 2 readings: dysfunctional hemoglobins, anemia, intravascular

dyes, low perfusion at the measurement site, venous pulsations, certain

cardiovascular pathologies, skin pigmentation, externally applied coloring

agents, prolonged and/or excessive patient movement, exposure of the sensor

to high ambient light levels, defibrillation.

• Ensure to select the upper alarm limit for SpO2carefully and in accord with

accepted clinical standards. High oxygen levels may predispose a premature

infant to develop retinopathy.

• Always apply sensor on intact and closed skin sites. Pierced earlobes may

result in incorrect tcPCO2measurements. Do not apply to injured skin. Avoid

placement over large superficial veins.

• After observation of any skin irritations, do not apply the V-Sign™ Sensor 2

to the same measurement site. Unless the patient’s local skin perfusion and

physiological condition improved significantly do not apply the sensor to any

other measurement site.

• The recommended/ default application duration per measurement site (site

time) is 8 hours but longer site times are possible (up to 12 hours). Refer to the

Technical Manual for the SDM (when used with SenTec-compatible instruments

refer to the instrument`s manual) for further information. Exercise extreme

caution and assess the measurement site at least every 2 hours with poorly

SenTec AG, Ringstrasse 39, CH-4106 Therwil, Switzerland

www.sentec.com HB-005148-l

Date of release: 03/2019

perfused patients.

• Regularly inspect the sensor. Do not use the sensor if there is any visible damage

to the sensor housing, sensor membrane, sensor cable or if the color of the ring

around the glass electrode has a metallic luster. Change the sensor membrane if

it is damaged or missing, has a loose fit, or if there is trapped air or dry electrolyte

under the membrane.

• Check disposables monthly and replace any expired products.

• For additional warnings, cautions and/or contraindications when using the

V-Sign™ Sensor 2 with SenTec-compatible instruments, refer to the instrument’s

manual or contact the instrument manufacturer.

CAUTIONS

• Federal law (U.S.) restricts this device to sale by or on the order of a physician.

• WEEE Disposal: European consumers are obliged by law to dispose Waste

Electrical and Electronic Equipment (WEEE) according to the WEEE Directive:

1. All electrical and electronic waste must be stored, collected, treated, recycled

and disposed of separately from other waste. 2. Consumers are obliged by law

to return electrical and electronic devices at the end of their service lives to the

public collection points set up for this purpose or point of sale. Details to this

are defined by the national law of the respective country. Note: By recycling

materials or other forms of utilizing old devices, you are making an important

contribution to protecting our environment.

• Druing transport: store sensor with membrane and protected from light/

radiation.

• Do not clean the sensor in an ultrasonic cleaner.

• Do not immerse the connector of the sensor cable in any liquid solution.

• Do not sterilize any parts of the sensor by irradiation, steam, ethylene oxide,

plasma or autoclav method.

• Always clean the sensor surface before insertion into the docking station or the

Membrane Changer.

• Avoid bending and tearing the sensor cable or the application of any other me-

chanical force (e.g. during cleaning), mechanical damage could result.

Warranty

To obtain information about a warranty (and warranty exclusions), if any, for this

product, contact SenTec AG, your local SenTec representative or the manufacturer

or the manufacturer’s local representative of the SenTec-compatible instrument.

Patents/Trademarks/Copyright

International Industrial Design No. DM/054179, Japanese Design No. 1137696, U.S.

Design Patent No. D483488. Canadian Patent No. 2466105, European Patent No.

1335666, German Patent No. 50111822.5-08, Spanish Patent No. 2278818, Hongkong

Patent No. HK1059553, U.S. Patent No. 6760610. Chinese Patent No. ZL02829715.6,

European Patent No. 1535055, German Patent No. 50213115.2, Spanish Patent No.

2316584, Indian Patent No. 201300, Japanese Patent No. 4344691, U.S. Patent No.

7862698. SenTec™, V-Sign™, OxiVenT™, V-STATS™, V-CareNeT™, V-Check™,

Staysite™, Advancing Noninvasive Patient Monitoring™ and Illuminate VentilationTM are

trademarks of SenTec AG / © 2019 SenTec AG. All rights reserved. The contents of

this document may not be reproduced in any form or communicated to any third party

without the prior written consent of SenTec AG. While every effort is made to ensure

the correctness of the information provided in this document, SenTec AG assumes no

responsibility for errors or omissions. This document is subject to change without notice.

0123

Other Sentec Accessories manuals