Sentek HD 912 Quick start guide

SENSO

HD 912 Rate of Rise with Fixed Temperature Detector

Installation Wiring Diagram

Before Installing

The heat detector must be installed in compliance with

the control panel manual and meet the requirements of

the NFPA

TYPICAL WIRING DIAGRAM

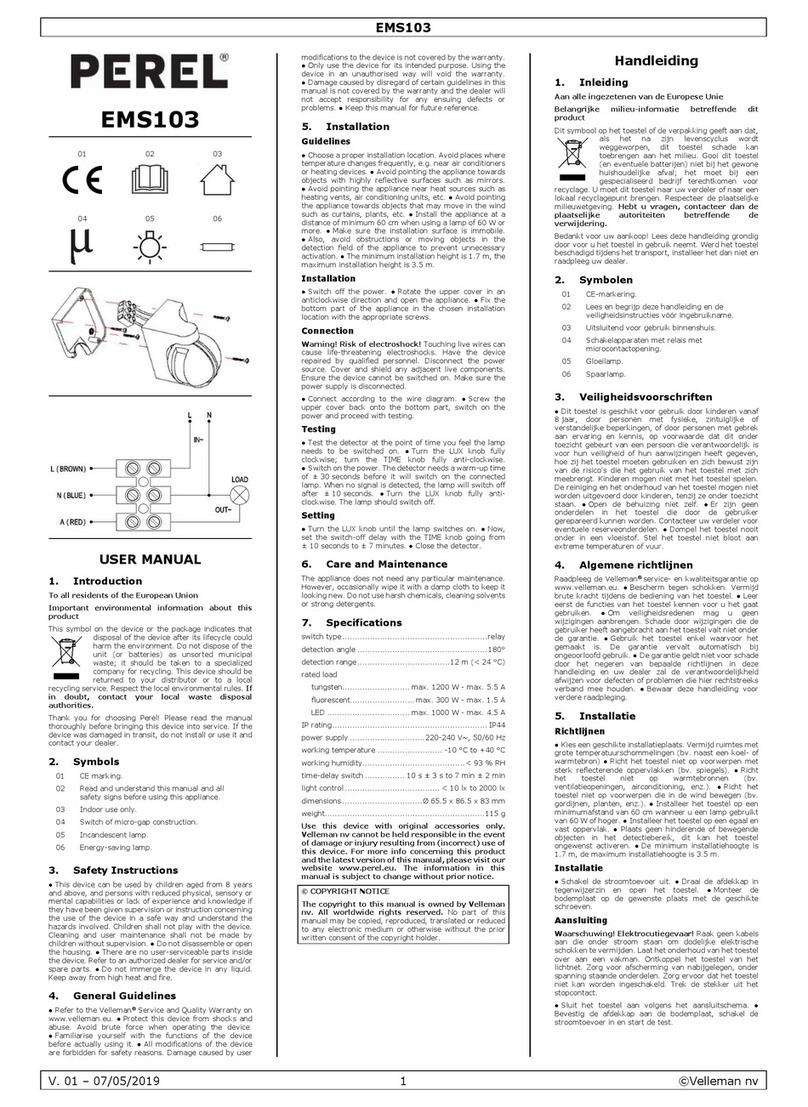

Figure 1(a) shows the typical wiring diagram of the 2-wire

multiple-station heat detector system.

NOTE: IF REMOTE INDICATOR IS NOT USED, POLARITY TO DETECTOR MAY BE REVISED

Fig. 1.a. Installing the 2-wire heat detector base

DO NOT PLACE LINKS BETWEEN THE WIRING POSITIONS

OF TERMINALS 2 AND 5 TO PROVIDE POWER

SUPERVISION

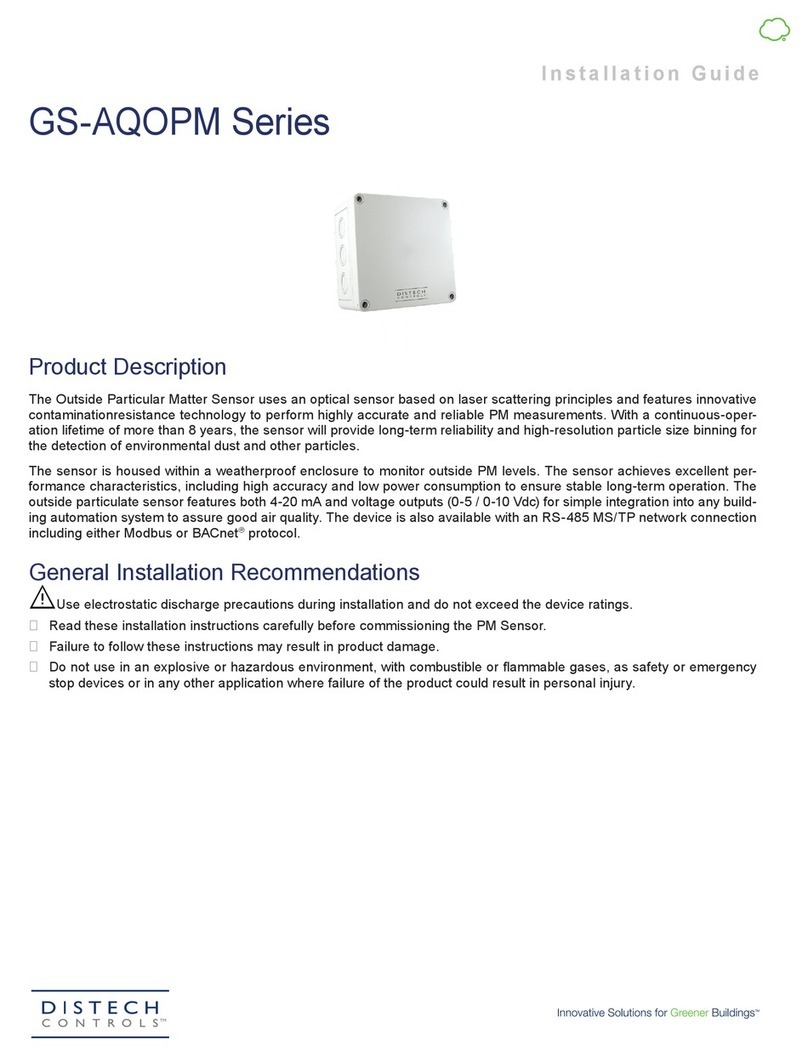

Figure 1(b) shows the typical wiring diagram of the 4-wire

multiple-station heat detector system.

Fig. 1. b. Installing the 4-wire heat detector base

DO NOT PLACE LINKS BETWEEN THE WIRING POSITIONS

OF TERMINALS 2 AND 5 TO PROVIDE POWER

SUPERVISION

WARNING

TO PREVENT DETECTOR CONTAMINATION AND

SUBSEQUENT WARRANTY CANCELLATION, THE

SMOKE DETECTOR MUST REMAIN COVERED UNTIL

THE AREA IS CLEAN AND DUST FREE.

INSTALLING THE BASE

1. To insure proper installation of the detector head to the

base, all the wires should be properly addressed at

installation:

(A) Position all the wires flat against terminals.

(B) Fasten the wires away from connector terminals.

2. If you use a jumper wire to connect the poles of

terminal 2 and 5 when testing the detector loop

continuity, be sure to remove the jumper wire prior to

the installation of the detector head.

3. The end-of-line device shown in fig. 1(a) and 1(b)

should be compatible with the control unit. The

end-of-line supervisory relay used should be rated for

the DC power voltage used.

4.Open area heat detectors are intended for mounting on

a ceiling or a wall in accordance with the fire standard

in your country.

5. The base of the heat detector can be mounted directly

onto an electrical junction box such as an octagonal

(75mm, 90mm or 100mm), a round (75mm), or a

square (100mm) box without using any type of

mechanical adapter.

INSTALLING THE HEAD

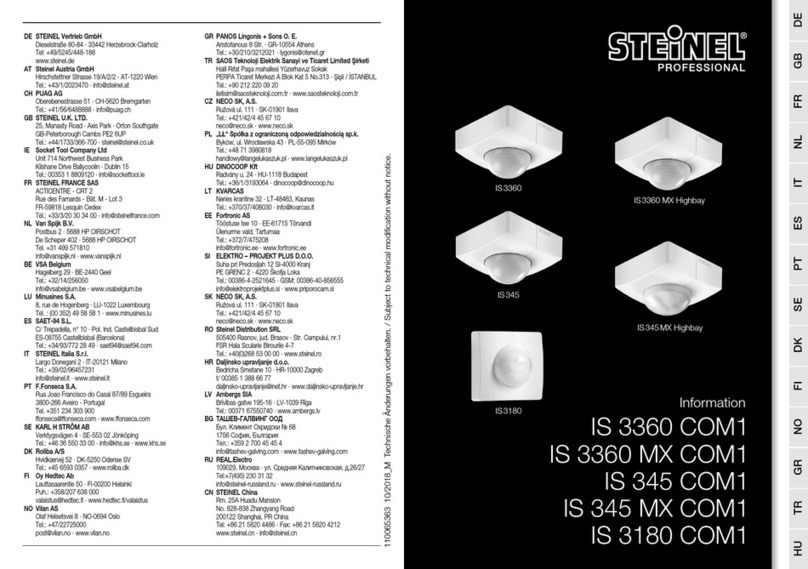

1. Align the components as shown in Figure 2.

2. Mate the detector head onto the base and twist

clockwise to secure it.

3. Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

The maximum number of smoke detector installed in

the same loop is 30 units.

ADJUSTMENT THE RELAY POSITION

ADJUSTING THE RELAY FOR NO/NC

The normal condition for the relay is “normally open”

(NO).

1. To adjust the normal condition of the relay to “normally

closed”(NC), insert a screwdriver into the rectangular

hole located on the side between the front cover and base

and rotate to remove the front cover.

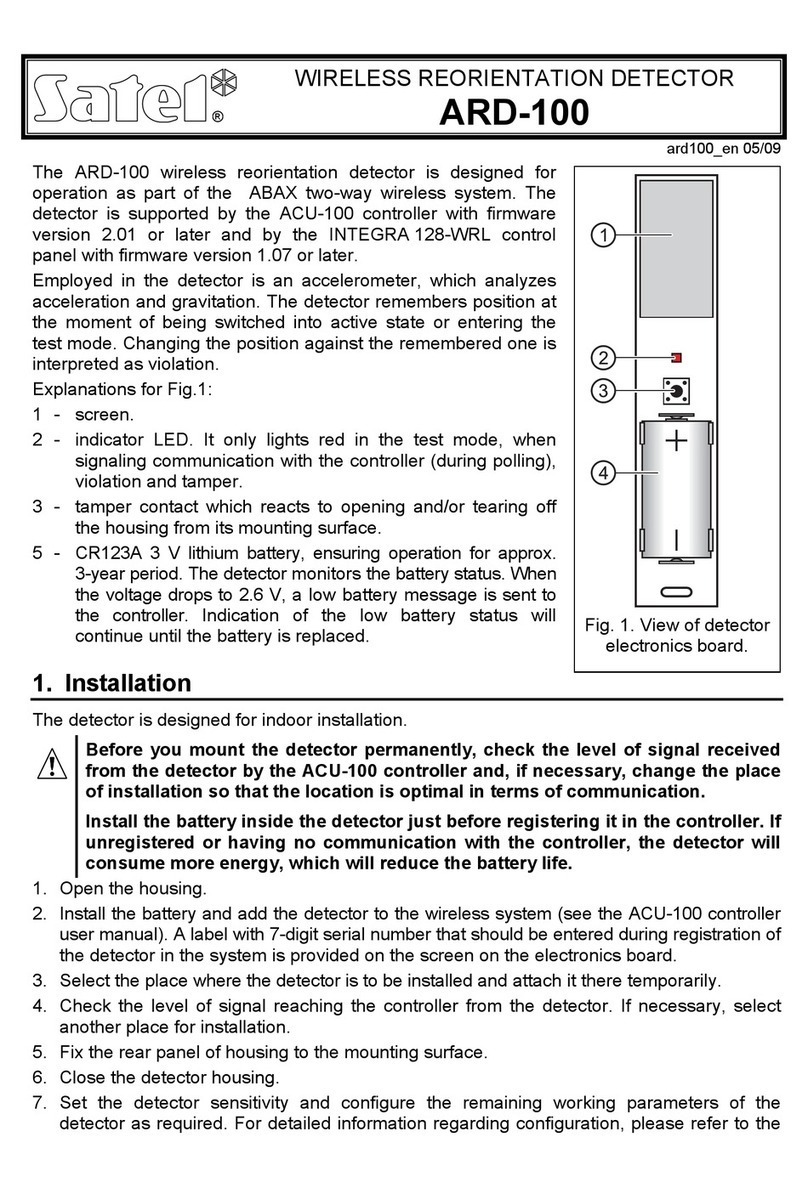

2. Refer to figure 3. There is a jumper head next to the

relay on the PCB. Remove the jumper head and reinsert it

in the NC position.

3. Carefully replace the front cover.

Relay contact rating:

1A@30VDC,

0.5A@125VAC.

TESTING

1.All the alarm signal services, releasing device and

extinguisher system should be disengaged during the

test period and must be re-engaged immediately at the

conclusion of testing.

2. After energizing the detector head for approximately 30

seconds, check to see the indicator red LED flashing

once every 1-3 seconds. If red LED fails to flash, it

indicates the non-functioning of the detector or faulty

wiring. Re-check the wiring or replace the detector if

necessary.

Fig. 3 Schematic of detector structure When

front cover is open.

Fig. 2 Mating detector head onto base

3. The detector to be tested should be subject to a flow of

warm air at a temperature of between 56°C and 80°C.

(This requirement can be met by some domestic hair

dryers).

Proceed as follows:

(1). Switch on the warm airflow and check that

temperature is correct and stable.

(2). From a distance of several inches, direct the

airflow at the guard protecting the thermistor. The

detector should alarm within 30 seconds.

(3). Upon alarm immediately remove the heat source

and check that the red LED of the detector is

illuminated. Reset the detector from the control

panel.

(4). If detector fails to go into alarm mode within 30

seconds it is too insensitive and needs to be

returned to the distributor for servicing.

(5). After testing, check that the system is set for

normal operation and notify the appropriate

authorities that the testing operation is complete

and the system is active again.

CAUTIONS

This heat detector is particularly designed to initiate and

activate emergency action, but will do so only when it is used

in conjunction with an authorized fire alarm system. This

detector must be installed in accordance with NFPA Standard

72.

The purpose of design of heat detectors is meant to

protect property, not life. The heat detectors do not provide

early warning of fire and cannot detect smoke, gas,

combustion particles, or flame. They will alarm when

temperature at the heat detector reach 57oC (135oF) or

above. Given the rapid growth of certain types of fires, heat

detectors cannot be expected to provide adequate warning of

fires resulting from smoking in bed, inadequate fire protection

practices, violent explosions, escaping gas, and improper

storage of flammable liquids like cleaning solvents, other

safety hazards, or arson.

Heat detectors do not always detect all fires because the

fire may be a slow-smoldering, low-heat type (producing

smoke), or because they may not be mean where the fire

occurs, or because the heat of the fire may bypass them.

Heat detectors will not detect smoke, gas, flames, or

combustion particles.

Heat detectors are components in professionally installed fire

alarm systems. They will not function if they have been

improperly wired into the fire alarm system or if power to

them is disconnected for any reason.

Heat detectors cannon last forever. They should be tested

and maintained following the instructions in this manual. To

be safe, they should be replaced after they have been

installed for ten years.

Refer to NFPA 72 for application.

CAUTION: DO NOT ATTEMPT TO DISASSEMBLY OF THE

FACTORY SEALED HEAT DETECTOR. THIS ASSEMBLY

IS SEALED FOR YOUR PROTECTION AND IS NOT

INTENDED TO BE OPENED FOR SERVICING BY USERS.

TO OPEN THE DETECTOR HEAD WILL VOID THE

WARRANTY.

REFER TO THE TECHNICAL BULTTIN ISSUE NO. STHD20080508S1,

REV.E, May 08, 2008.

SPECIFICATION

Model

2/4

wire

Voltage

DC

(Min./Max)

Standby

Current

(Max.)

Alarm

Current

(12 /24V)

Surge

Current

(Max.)

Temperature

Rating

Permissible

Current

(Max.)

Frequency

Alarm

contact

Base model

Safety

HD912-2

2

10.8~33V

40μA

20/50mA

100μA

135℉/57℃

80mA

1-3 Seconds

—

P/N852001

UL/CUL/CE

HD912-2L

2

10.8~33V

40μA

20/50mA

100μA

135℉/57℃

80mA

1-3 Seconds

—

P/N854001

UL/CUL/CE

HD912-4(12V)

4

12V

40μA

33mmA

100μA

135℉/57℃

80mA

1-3 Seconds

Form A

P/N854001

UL/CUL/CE

HD912-4(24v)

4

24V

40μA

46mA

100μA

135℉/57℃

80mA

1-3 Seconds

Form A

P/N854001

UL/CUL/CE

HD912-4B

4

12/24V

40μA

33mA/46mA

100μA

135℉/57℃

80mA

1-3 Seconds

Form A

P/N854001

—

HD912-4AR

4

12/24V

40μA

33mA/46mA

100μA

135℉/57℃

80mA

1-3 Seconds

Form A

P/N854001

—

HD912-4ARB

4

12/24V

40μA

33mA/46mA

100μA

135℉/57℃

80mA

1-3 Seconds

Form A

P/N854001

—

Remarks: AR-auto reset function/ L-remote LED indicator output/ B-Buzzer

HDMI912080528, REV H,05.28.2008.

Manufacturer:

Sentek Electronics Co., Ltd.

448 Yingchun Road, Wangchun Industrial Zone, Ningbo City 315175,

Zhejiang, China

Tel: 86-574-8715 5635 Fax: 86-574-8715 5951

email: sales@sentek.cc Web: www.sentek.cc

LIMITED WARRANTY STATEMENT

SENTEK ELECTRONICS INC. declares that this product is free from defects in material and workmanship. And it will repair or replace any

product or part thereof which proves to be defective in workmanship or material for a period of twelve (12) months from the date of purchase

but not to exceed eighteen (18) months after shipment by the manufacturer. For a full description of SENTEK’S LIMITED WARRANTY, which,

among other things, limits the duration of warranties of merchantability and fitness for a particular purpose and excludes liability for

consequential damages. Please read the entire LIMITED WARRANTY on the SENTEK quotation. Acceptance of order and/or original invoice

which will become part of your sales agreement. Please contact SENTEK directly for a return merchandise authorization (RMA) number before

returning goods to the factory . Shipment must be prepaid and SENTEK will repair or replace your returned detector.

This manual suits for next models

7

Other Sentek Security Sensor manuals