Distech Controls GS-AQOPM Series User manual

Installation Guide

Product Description

The Outside Particular Matter Sensor uses an optical sensor based on laser scattering principles and features innovative

contaminationresistance technology to perform highly accurate and reliable PM measurements. With a continuous-oper-

ation lifetime of more than 8 years, the sensor will provide long-term reliability and high-resolution particle size binning for

the detection of environmental dust and other particles.

The sensor is housed within a weatherproof enclosure to monitor outside PM levels. The sensor achieves excellent per-

formance characteristics, including high accuracy and low power consumption to ensure stable long-term operation. The

outside particulate sensor features both 4-20 mA and voltage outputs (0-5 / 0-10 Vdc) for simple integration into any build-

ing automation system to assure good air quality. The device is also available with an RS-485 MS/TP network connection

including either Modbus or BACnet®protocol.

General Installation Recommendations

Use electrostatic discharge precautions during installation and do not exceed the device ratings.

Read these installation instructions carefully before commissioning the PM Sensor.

Failure to follow these instructions may result in product damage.

Do not use in an explosive or hazardous environment, with combustible or ammable gases, as safety or emergency

stop devices or in any other application where failure of the product could result in personal injury.

GS-AQOPM Series

GS-AQOPM Series

2/7

Device Information

Mounting Instructions

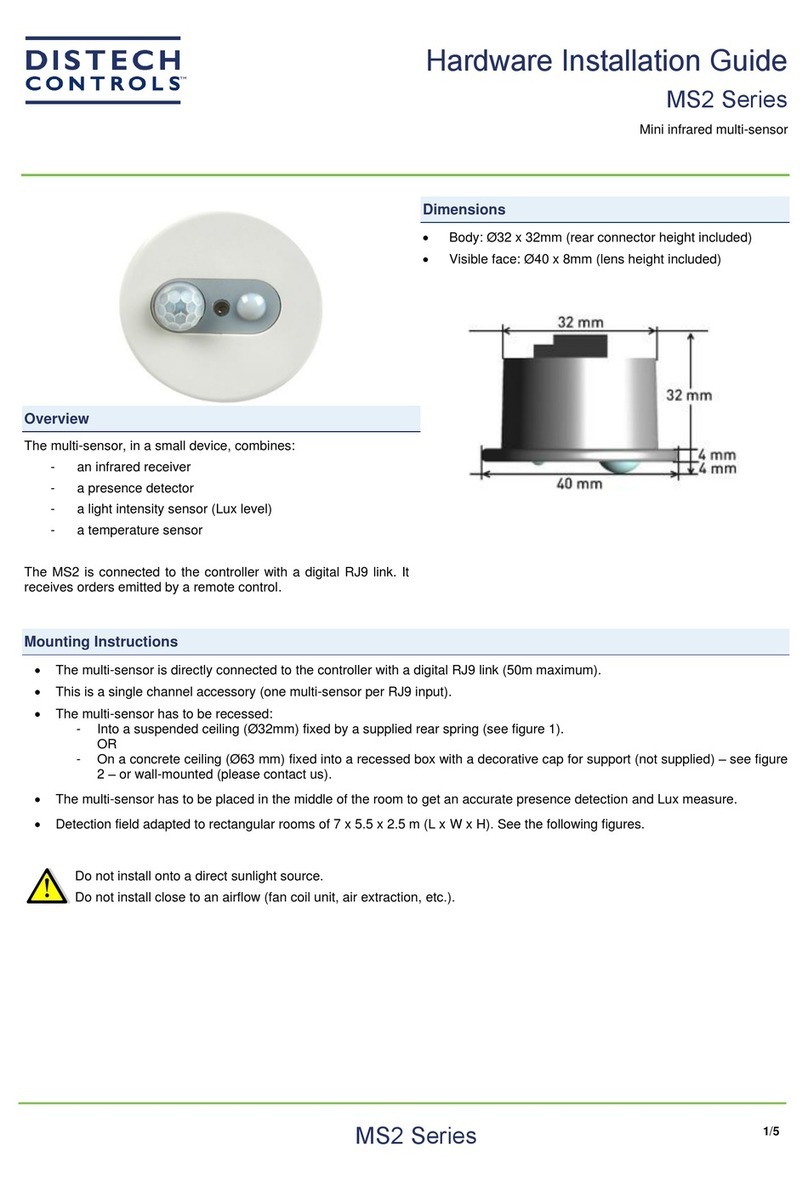

Select a suitable mounting spot on an exterior wall where the sensor

is best protected from direct exposure to sunlight, wind, etc. preferably

on a north facing wall. Do not mount the sensor near opening windows,

supply/exhaust air louvres or other known air disturbances. Avoid areas

where the sensor is exposed to vibrations or rapid temperature chang-

es. It is recommended that the enclosure be mounted so conduit or ca-

ble-gland connections be made on the bottom of the enclosure. See

Figure 1.

Remove the cover by using a standard or Phillips screwdriver to loosen

the four screws as shown in Figure 2. As the screws are captive type,

complete removal of the screw from the cover is not required.

Install a conduit connector or cable gland as shown in Figure 3. It is

recommended that weatherproof conduit or cable gland ttings be used.

The outside mount particulate sensor installs directly on an exterior wall

using the four integrated mounting holes provided on the enclosure. See

gure 4.

Select the best mounting technique based on the exterior wall materi-

al. The 4 mounting holes will facilitate a #10 size screw (not supplied).

Mount the base by screwing directly to the wall. After the base is secure-

ly fastened to the exterior wall, connect conduit to conduit connector or

feed cable through the cable gland and tighten. Make wire connections

as per the “Wiring” illustrations. Once wiring and set up are complete,

re-install cover and secure by tightening the four screws using a at

screwdriver. See Figure 5.

3/7

GS-AQOPM Series

Wiring Instructions

The sensor has standard screw block connectors and easy wire access to facilitate wiring. It is recommended that

shielded twisted pair wiring at least 22 AWG be used for all connections and that the device wires not be run in the

same conduit with wiring used to supply inductive loads such as motors. Disconnect the power supply before making

any connections to prevent electrical shock or equipment damage. Make all connections in accordance with national

and local electrical codes.

The device should be connected to a 24Vac/dc, class 2 power supply. The PWR terminal is used for the positive DC

voltage or the hot side of the AC voltage. The device is reverse voltage protected and as such will not operate if con-

nected backwards.

The common of the power supply is connected to the terminal marked COM. Note that this device has a half-wave type

power supply which means the power supply common is the same as the output signal common. Therefore, several

devices may be connected to one power supply and the output signals all share the same signal common. Use caution

when grounding the secondary of an ac transformer or when wiring multiple devices to ensure that the circuit ground

point is the same on all devices and the controller. In general, the transformer should not be connected to earth ground

when using devices with an RS-485 network connection.

The analog output signal is available on the OUT terminal. This signal is jumper selectable for either voltage or 4-20 mA

output signal type. See Figure 6. The voltage output signal defaults to 0-5 Vdc but may be changed to 0-10 Vdc via the

menu. These options are clearly indicated on the device PCB. The analog output signal is typically connected directly to

the Building Automation System (B.A.S.) and used as a control parameter or for logging purposes. Check the controller

Analog Input type to determine the correct connection and signal type before applying power. The device generates

the analog output signal (sourcing) and must not be connected to a

powered input or device damage may occur.

For voltage type output signal the device has a minimum load that

it is able to drive, similarly for current type output signal the device

has a maximum load that it is able to drive with a particular power

supply voltage. Observe and follow these ratings in the Specica-

tion section or inaccurate reading may result. The 4-20 mA output

signal can easily be converted to a 1-5 Vdc signal for controllers

accepting this type of input. Simply insert a 250 ohm (0.1% is best)

resistor between the “+” and “-” inputs of the controller. This will

convert the 4-20 mA signal to the desired 1-5 Vdc. See Figure 7.

If the device includes the optional network connection, use twist-

ed shielded pair to connect to the terminals marked A-, B+ and SH

(SHIELD). The positive wire connects to B+, the negative to A- and

the cable shield must be connected to the SH terminal on each

device. The shield wire should be connected to earth ground at one

end of the network only. If the device is installed at either end of

an RS-485 network, an end-of-line (EOL) termination resistor (121

Ω) should be installed in parallel with the A- and B+ terminals. See

Figure 8. This device includes a network termination resistor and

jumper that can be used to connect the EOL resistor on the PCB.

Simply move the jumper to the EOL position and no external resis-

tor is required. See Figure 9.

A network segment is a single shielded wire loop run between

several devices (nodes) in a daisy chain conguration. The total

segment length should be less than 1220 meters (4000 feet) and

the maximum number of nodes on one segment length is 128.

Nodes are any device connected to the loop and include controllers

but do not include the EOL terminators. To install more than 128

devices, or to increase network length, repeaters will be required

for proper communication. The maximum daisy chain length (seg-

ment) depends on transmission speed (baud rate), wire size and

number of nodes. If communication is slow or unreliable, it may be

necessary to wire two daisy chains to the controller with a repeater

for each segment.

GS-AQOPM Series

4/7

An optional signal is the alarm relay output available on the NO (NORMALLY OPEN), NC (NORMALLY CLOSED) and

R.COM (RELAY COMMON) terminals. The R.COM terminal is not connected to the power supply COM terminal, the

relay output is completely isolated. The relay contacts may be connected to a controller Digital Input (DI) for status mon-

itoring or used to directly control an alarm or ventilation fan. Do not exceed the device contact ratings. In some cases, a

separate control relay may be used between the PM sensor relay and a large fan for example. See Figure10.

Operation - Start Up

After applying power to the device, it will enter the start-up mode and the LCD will indicate the software version number, the

PM range, the PM alarm setpoint (if applicable) and the analog output type for two seconds each.

If the network option is installed, then the start-up sequence will also show the network protocol, the baud rate and the

device address. Then the device will start normal operation and display the PM concentration value.

5/7

GS-AQOPM Series

Operation - Normal

During normal mode the device reads the PM sensor and calculates the Air Quality Index based on a 24 hour time average.

The real time PM concentration value is displayed on the LCD and set as the output value for the analog output. The output

value is updated once per second. The LCD may be congured via the menu to display either the PM value or the AQI. If the

optional tri-color LED is installed, it will change color to indicate Good (Green), Moderate (Yellow) or Poor (Red) air quality.

On start-up when the rst readings are obtained, the Air Quality reading for the device averages the concentration level

as necessary until the required time base setting is reached. For example, if only 10 readings are available then the out-

put value is calculated as the average of those 10 readings. The next output value will be an average of 11 readings. This

short-averaging will continue until the unit has been running for 24 hours. Once 24 hours is reached then the AQI value will

always be the average of readings over the past 24 hours.

The device also monitors the keypad and takes appropriate menu actions for setup. The network version of the product

allows for conguration of settings via BACnet®or Modbus protocol and the BACnet®objects or Modbus registers are up-

dated with the appropriate values and alarm conditions are monitored.

Operation - Alarm

All models except for the analog output only without relay will have a PM setpoint alarm. The alarm will control the optional

relay or network variables as applicable to the model. The PM alarm setpoint, hysteresis and time delay may be congured

via the menu or network. The details of each setting and operation is explained in the Setup Menu section.

Operation - Setup Menu

The Setup Menu has several items as shown below. To enter the menu, press and release the <MENU> key while in nor-

mal operation. This will enter the Setup Menu step 1, pressing the <MENU> key a second time advances to step 2. Each

press of the <MENU> key saves the selection and advances the menu item. The <ROLL> key is used to make changes to

program variables by scrolling through the available options. If the Setup Menu is not active for 5 minutes (no key press),

then the menu will exit and the device returns to normal operation.

<MENU> Press and hold to enter the setup menu. Once in menu release <MENU>.

1. Particulate matter range

The default PM Range is PM10. Use <ROLL> to change the range as required to either PM1.0,

PM2.5, PM4.0, or PM10.

<MENU> Press to advance to next menu item.

2. Voltage output signal

Use <ROLL> to set the voltage output signal type to 0-5 or 0-10 Vdc. The factory default is 0-5

Vdc.

<MENU> Press to advance to next menu item.

3. Analog output

The analog output defaults to Direct (4-20 mA, 0-5 Vdc or 0-10 Vdc). Use <ROLL> to change it to

Reverse (20-4 mA, 5-0 Vdc or 10-0 Vdc) if required.

<MENU> Press to advance to next menu item.

GS-AQOPM Series

6/7

4. Analog output scale

The default analog output scale is 0-1000 ug/m3. The maximum value can be changed from 500

to 1000 (resolution 100) using <ROLL> if required. For example, the output can be 4-20 mA =

0-700 ug/m3.

<MENU> Press to advance to next menu item.

5. Display information

The default analog output scale is 0-1000 ug/m3. The maximum value can be changed from 500

to 1000 (resolution 100) using <ROLL> if required. For example, the output can be 4-20 mA =

0-700 ug/m3.

<MENU> Press to advance to next menu item.

6. Backlight

The backlight operation defaults to Auto operation. It can be set to O or On using <ROLL>. Auto

means the LCD backlight only lights when a menu is accessed, o means it never lights and on

means it is always on.

<MENU> Press to advance to next menu item.

Only if Relay OR Network Option installed

7. Setpoint alarm Setpoint for PM alarm and relay (if installed) activation. Default setpoint

for alarm activation is 150 ug/m3. Use <ROLL> to adjust from 50-900 ug/

m3. Resolution is 10 ug/m3.

<MENU> Press to advance to next menu item.

8. Alarm

hysteresis

The default PM alarm hysteresis is 20 ug/m3. Use <ROLL> to change to

10, 15, 20, 25, 30, 35 or 40 ug/m3. If the PM Alarm setpoint = 150 and

hysteresis = 20, then the alarm will be set if the PM exceeds 150 and will

reset when it falls below 130.

<MENU> Press to advance to next menu item.

9. Alarm delay The default PM alarm delay is 0 minutes. Use <ROLL> to change from 0

to 10 minutes to prevent false alarms. Resolution is 1 minute.

<MENU> Press to advance to next menu item.

10. PM alarm The default PM alarm test is O. Use <ROLL> to toggle it O or On. When

set to On, an alarm condition is forced for testing purposes. If a relay is

installed it will also be activated. The alarm condition will be reset to O.

<MENU> Press to advance to next menu item.

Only if Network Option installed

11. Baud rate The default network baud rate is 9600. Use <ROLL> to select 9600,

19200, 38400, 57600, 76800 or 115200 as required.

<MENU> Press to advance to next menu item.

12. Address The default network address is 3 for BACnet®and 1 for Modbus. Use

<ROLL> to select 0-127 for a BACnet®device or 1-255 for a Modbus

device.

<MENU> Press to advance to next menu item.

GS-AQOPM Series_IG_10_EN

7/7

Specications subject to change without notice.

©, Distech Controls Inc., 2019. All rights reserved.

Global Head Oce - 4205 place de Java, Brossard, QC, Canada, J4Y 0C4 - EU Head Oce - ZAC de Sacuny, 558 avenue Marcel Mérieux, 69530 Brignais, France

Only if Modbus Option installed

13. Parity value The default network address is 3 for BACnet®and 1 for Modbus. Use

<ROLL> to select 0-127 for a BACnet®device or 1-255 for a Modbus

device.

<MENU> Press to advance to next menu item.

14. Stop bits Use <ROLL> to toggle the stop bits between 1 and 2. The default Modbus

stop bits is 1.

<MENU> Press to advance to next menu item.

15. CRC value Use <ROLL> to set the CRC value to A001 (CRC-16 reverse), 1021

(CITT), 8005 (CRC-16) or 8408 (CITT reverse). The default CRC poly-

nomial is 0xA001.

<MENU> Press to advance to next menu item.

15. Slave

response

Use <ROLL> to change the value from MIN (minimum) to 50, 100, 150,

200, 250, 300 or 350ms. The factory default slave response delay is min-

imum (minimum delay means just more than 3.5 character time delays,

4ms for 9600 baud rate, for example).

<MENU> Press to advance to next menu item.

Operation - Testing/Commissioning (Optional)

To perform testing or commissioning the unit should be congured to display PM reading since AQI reading requires op-

eration over 24-hour period. To verify sensor is reading properly a CO BUMP KIT can be used to generate particulates.

Hold wick close to inlet of sensor (bottom of cover).

Sensor PM reading should increase.

This will verify sensor is reading higher PM levels and is operational. If sensor readings do not increase with smoke then

sensor is faulty.

Table of contents

Other Distech Controls Security Sensor manuals

Popular Security Sensor manuals by other brands

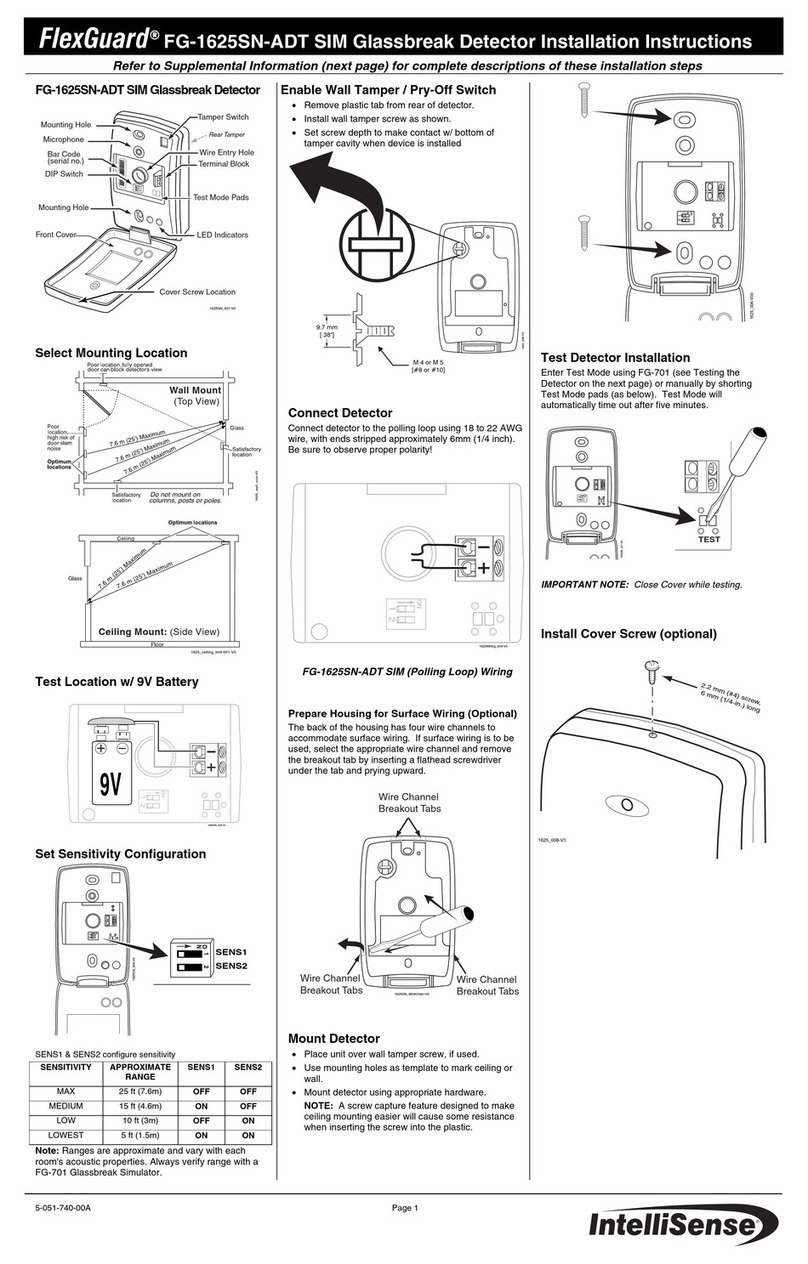

IntelliSense

IntelliSense FlexGuard FG-1625SN-ADT installation instructions

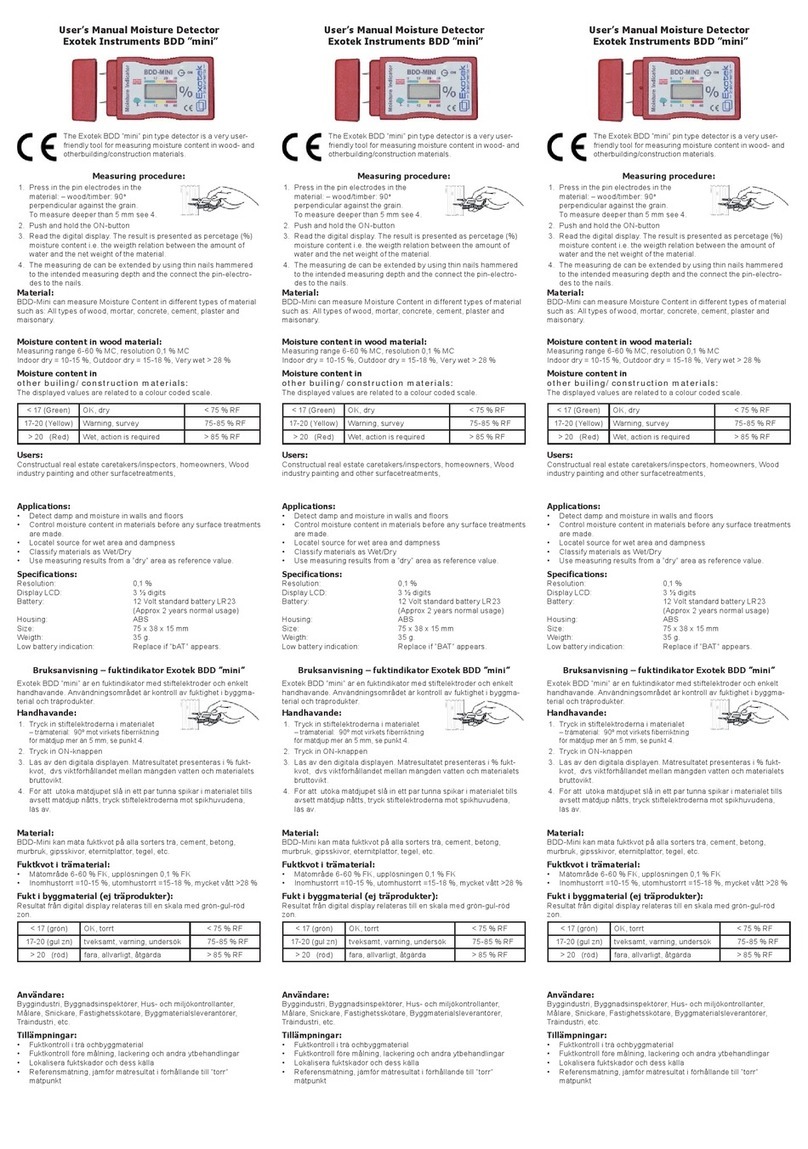

Exotek Instruments

Exotek Instruments BDD mini user manual

Jung

Jung HOME BT 17181 Series operating instructions

ensto

ensto LYNX 4400 Installation and operation manual

System Sensor

System Sensor B110RLP Installation and maintenance instructions

BEMKO

BEMKO SES15 Manual instruction