Pfeiffer Vacuum ASM 380 User manual

Other Pfeiffer Vacuum Security Sensor manuals

Pfeiffer Vacuum

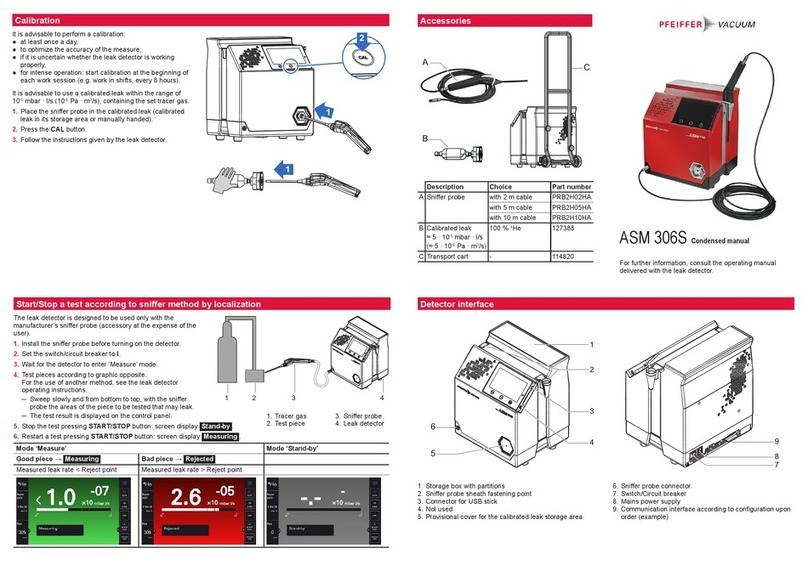

Pfeiffer Vacuum ASM 306S User manual

Pfeiffer Vacuum

Pfeiffer Vacuum adixen ASI 30 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASI 35 User manual

Pfeiffer Vacuum

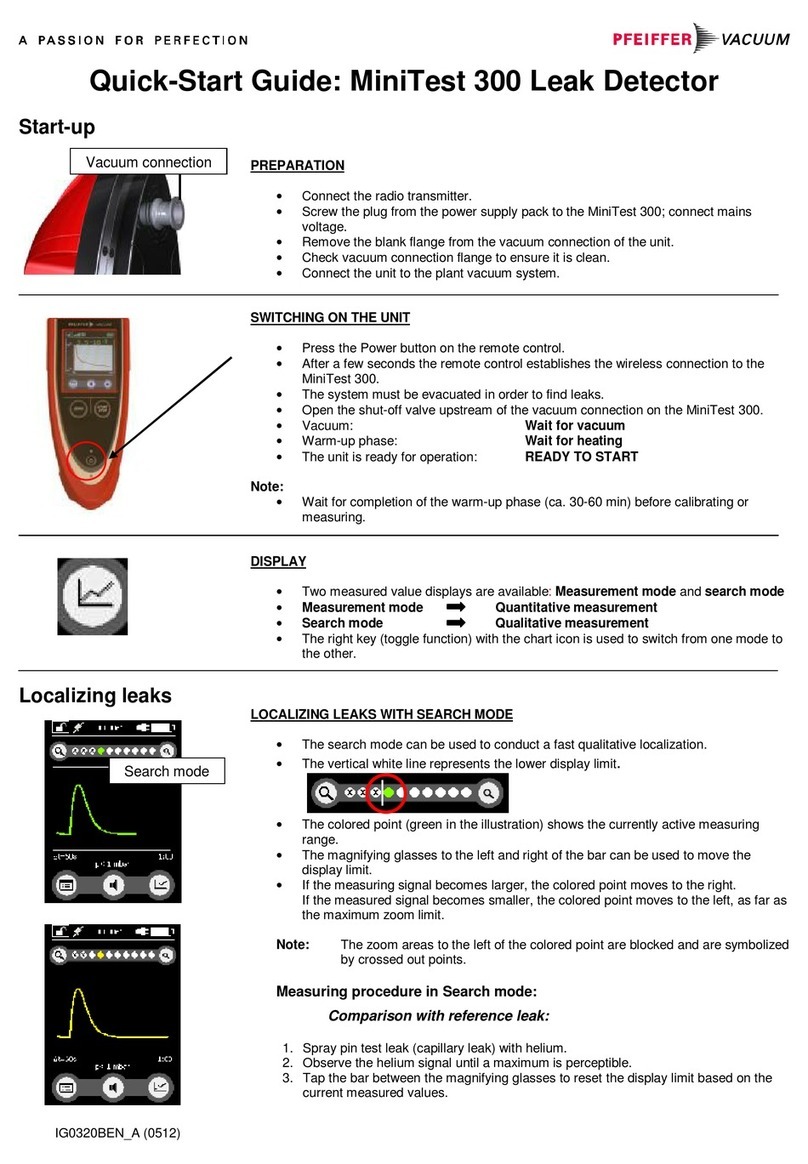

Pfeiffer Vacuum MiniTest 300 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum QualyTest HLT 260 Technical specifications

Pfeiffer Vacuum

Pfeiffer Vacuum ASI 35 Technical specifications

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 306S Manual

Pfeiffer Vacuum

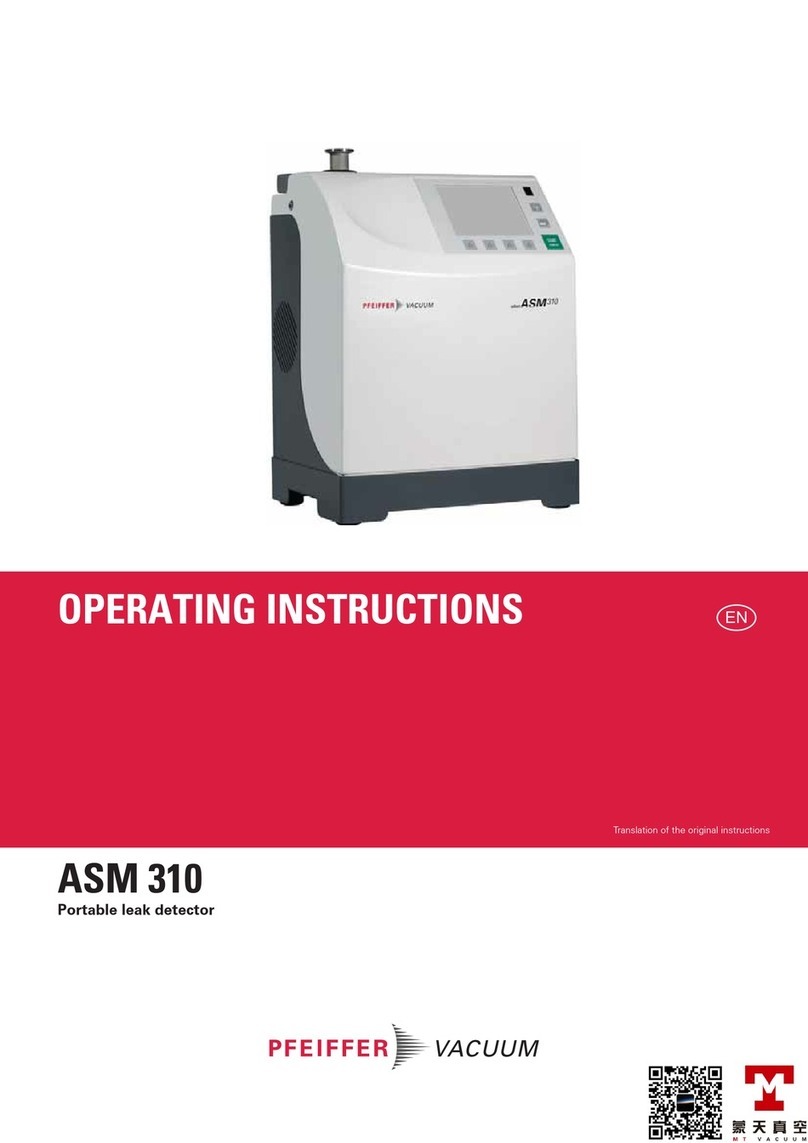

Pfeiffer Vacuum ASM 310 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 310 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 Technical specifications

Pfeiffer Vacuum

Pfeiffer Vacuum ASI 35 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 Manual

Pfeiffer Vacuum

Pfeiffer Vacuum MiniTest 300 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 380 MEMO User manual

Pfeiffer Vacuum

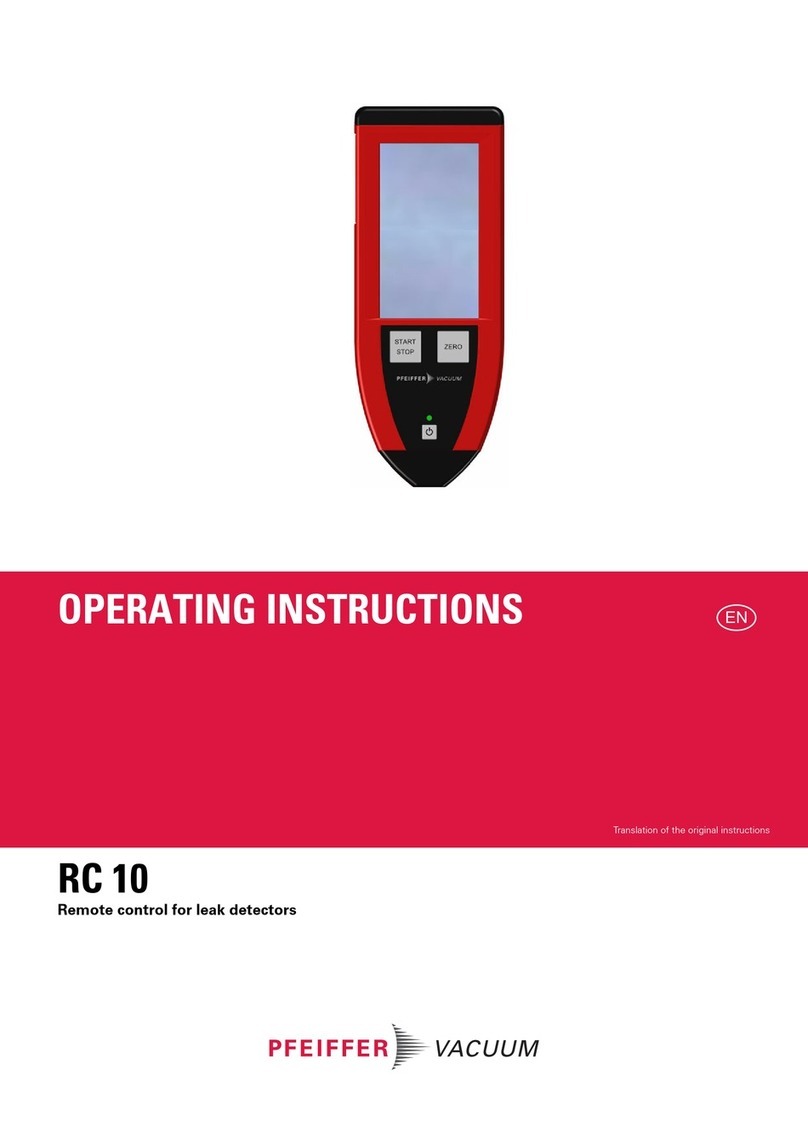

Pfeiffer Vacuum RC 10 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 340 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 310 Operating and maintenance instructions

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 390 User manual

Pfeiffer Vacuum

Pfeiffer Vacuum ASM 340 Technical specifications

Popular Security Sensor manuals by other brands

Shinko

Shinko SE2EA-1-0-0 instruction manual

Det-Tronics

Det-Tronics X Series instructions

ACR Electronics

ACR Electronics COBHAM RCL-300A Product support manual

TOOLCRAFT

TOOLCRAFT 1712612 operating instructions

Elkron

Elkron IM600 Installation, programming and functions manual

Bosch

Bosch WEU PDO 6 Original instructions