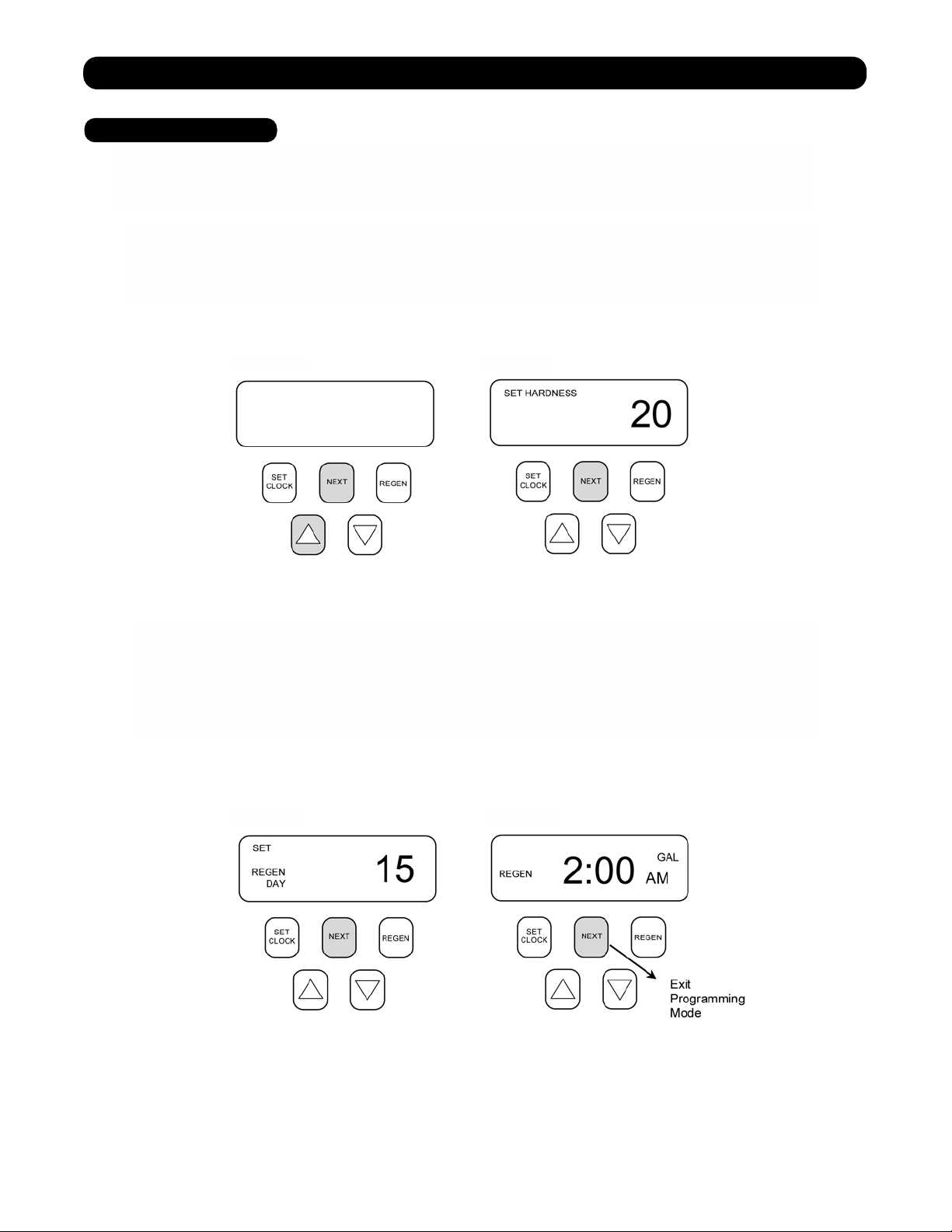

SENTRY II 950SM Series User manual

Table of contents

Other SENTRY II Water Dispenser manuals

SENTRY II

SENTRY II 952TA Series User manual

SENTRY II

SENTRY II 940ST Series User manual

SENTRY II

SENTRY II 962SM Series User manual

SENTRY II

SENTRY II 960SM Series User manual

SENTRY II

SENTRY II 954SM Series User manual

SENTRY II

SENTRY II 960 Series User manual

SENTRY II

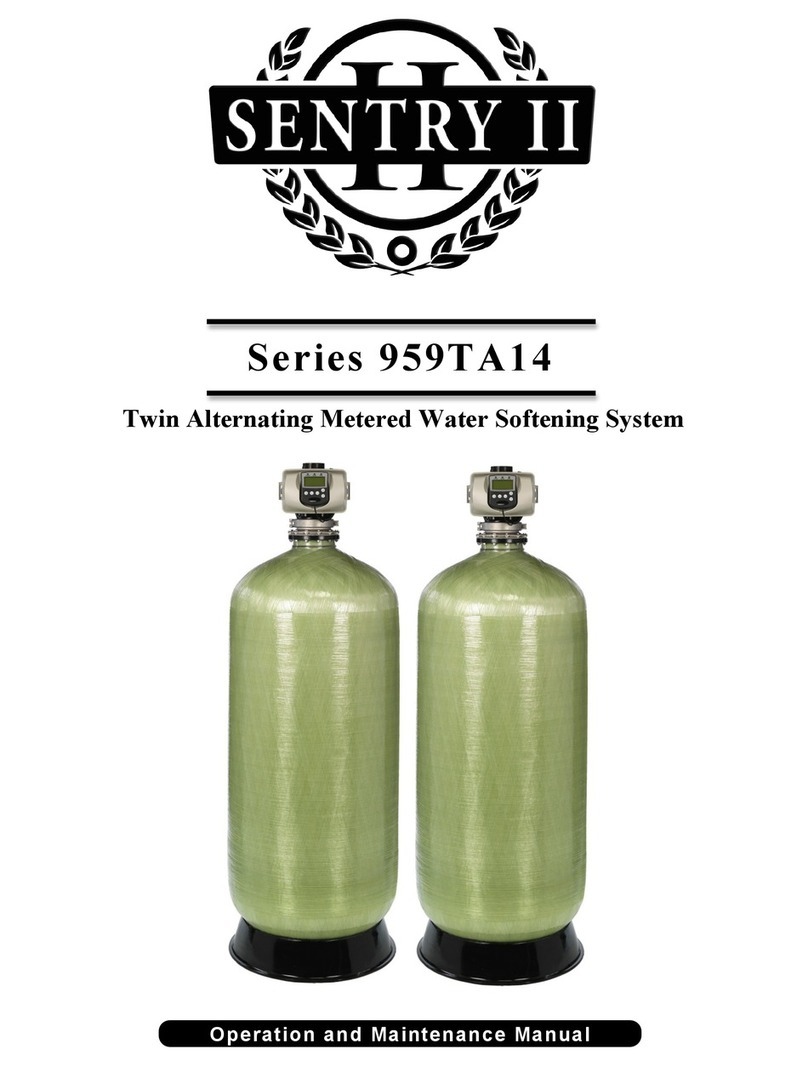

SENTRY II 959TA14 Series User manual

SENTRY II

SENTRY II 972SM Series User manual

SENTRY II

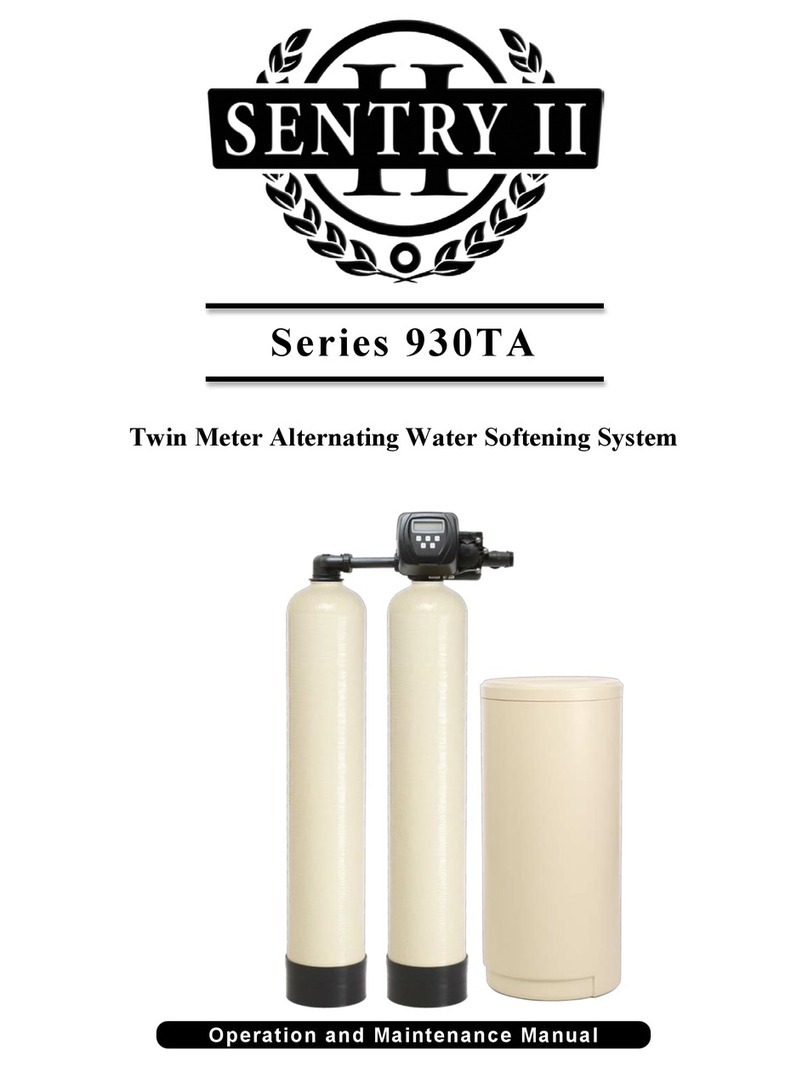

SENTRY II 930TA Series User manual

Popular Water Dispenser manuals by other brands

Osmio

Osmio EcoSoft PRIMO General installation guide

Ebac

Ebac SlimCool User instructions

Aqua Essentials

Aqua Essentials Borg & Overström B4 user guide

Avalon

Avalon A3F Use and care guide

Lincoln Electric

Lincoln Electric COOL ARC 55 Operator's manual

Zodiac

Zodiac ZXC Series Installation and operation manual

Pelican Water Technologies

Pelican Water Technologies PC1354 owner's manual

Borg & Overstrom

Borg & Overstrom E4 user guide

Watts

Watts PWSR Series Installation, operation and maintenance manual

Rheem

Rheem RHW42 Installation and operation manual

WaterGroup

WaterGroup 185HE SIMTAN owner's manual

icetro

icetro ID-0300-AN user manual

Elkay

Elkay FLEXI-GUARD EMABFDTL C Series Installation, care & use manual

KYOWA

KYOWA KW-1503 instruction manual

Canature WaterGroup

Canature WaterGroup 85HE owner's manual

Fleck

Fleck 9100SXT Meter Installation & start-up instructions

GE

GE GXSS20B Owner's Manual & Installation Instructions

Excalibur

Excalibur EWS S1590 Installation and user guide