SENTRY II 959TA14 Series User manual

Twin Alternating Metered Water Softening System

Operation and Maintenance Manual

Series 959TA14

2

3

Table of Contents

System Specifications and Warnings .............................................................................. 4

Introduction ........................................................................................................................ 5

Assembly and Installation Instructions ........................................................................... 9

Plumbing Diagram .....................................................................................................13

General Installation ...................................................................................................14

Series 959 Control Valve Programming ......................................................................... 15

User Information Displays ............................................................................................... 19

Volume Calculator ............................................................................................................ 20

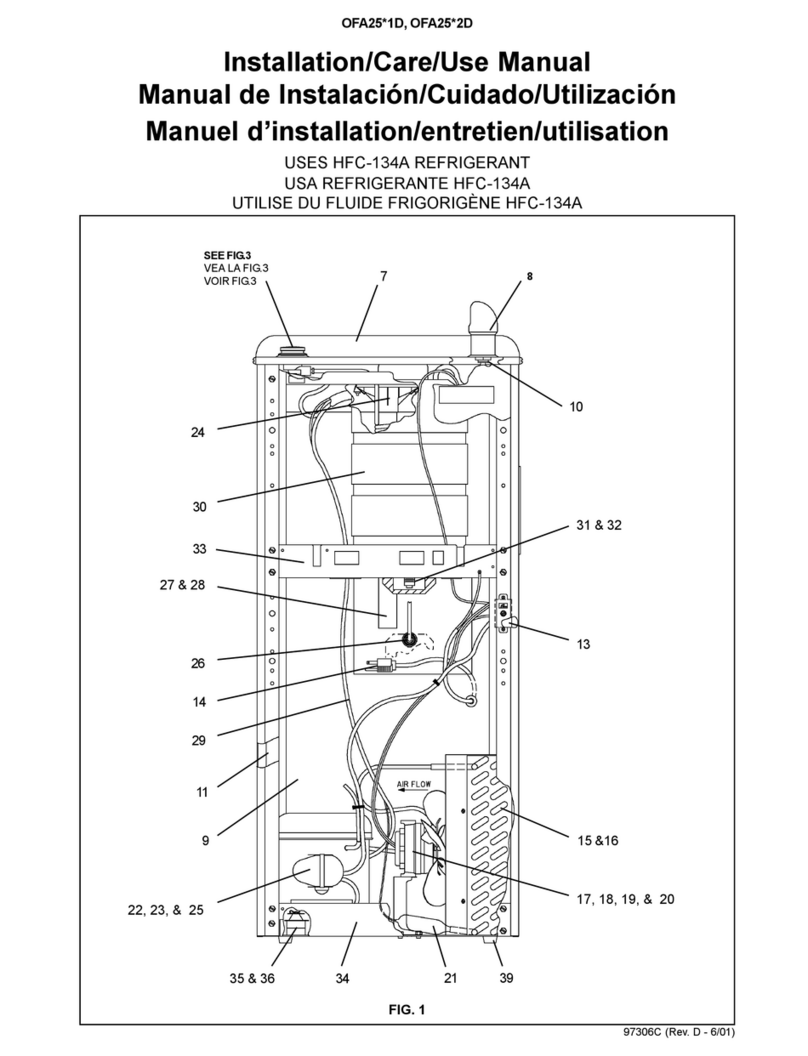

Parts Breakdown .............................................................................................................. 23

Front Cover and Drive Assembly ........................................................................... 25

Main Body Internal Parts ......................................................................................... 26

Injector Housing Assembly...................................................................................... 27

Water Meter .............................................................................................................. 28

Motorized Alternating Valve (MAV) .........................................................................29

Brine Tank Assembly .............................................................................................. 30

System Specifications ..................................................................................................... 31

Troubleshooting ............................................................................................................... 33

Water Softener Log .......................................................................................................... 40

Manufacturer’s Warranty .................................................................................................43

4

System Specifications

Water pressure: 40 psi minimum 100 psi Maximum

Water Temperature: 40°F to 110°F

Electrical Requirements:

Supply Voltage: 120V

Supply Frequency: 60Hz

Output Voltage: 24V AC

Output Current: Maximum 3.0 Amps

Water Meter:

Pipe Size: 3”

Accuracy: ± 5%

Minimum Flow: 3.5 GPM

Control Valve to Tank Connection: 6’’ Flange

Control Valve Distributor Pipe Connection: 3”

Circuit Board Memory: NonVolatile EEPROM (Electrical Erasable Programmable Read Only Memory)

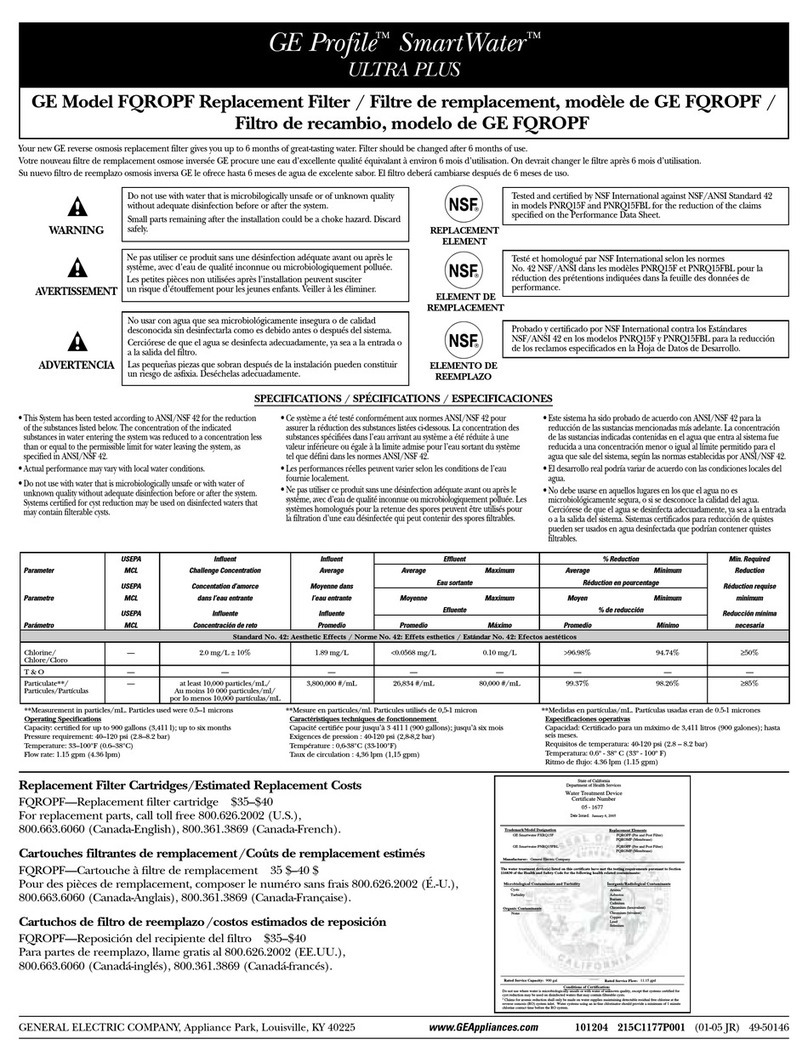

Compatible with the following typical concentrations of regenerant chemicals: Sodium Chloride, Potassium

Chloride, Potassium Permangenate, Sodium Bisulfite, Chlorine and Chloramines

Warnings

The control valve and fittings are not designed to support the weight of the system or the

plumbing.

Do not use Vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A

silicone lubricant may be used on black o-rings.

Hydrocarbons such as kerosene, benzene, gasoline, etc., may damage products that

contain o-rings or plastic components. Exposure to such hydrocarbons may cause the

products to leak. Do not use the product(s) contained in this document on water supplies

that contain hydrocarbons such as kerosene, benzene, gasoline, etc.

The water meter should not be used as the primary monitoring device for critical or health

effect applications.

Do not use pipe dope or other sealants on threads. Teflon tape is recommended to be

used on all threads. Use of pipe dope may break down the plastics in the control valve.

System Specifications and Warnings

5

Introduction

1. INTRODUCTION

Long term, successful operation of any water softening system depends upon the care and attention it

receives. Ordinarily, water treatment systems will provide uniform performance after the initial start-up

period and operation is stable. Gallonage delivery between regenerations and treated water purity

usually do not vary appreciably over the life of the resins--as long as the mineral content of the

incoming water does not change.

This manual is intended to be a practical reference guide for all operating personnel. In view of the

fact that system performance can change very dramatically throughout the year, a discussion of "ion

exchange" theory is included in addition to basic information relative to equipment operation and

regeneration procedures. Thorough understanding of the simple chemical reactions will help to

determine if some equipment malfunction has occurred, or if the system is simply responding to

changing water conditions. For this reason, all operation and supervising personnel are encouraged

to study Section 2, which define terminology and the simple chemistry associated with this system.

Ion exchange (i.e., the softening process) is a reversible reaction. Ion exchange softening resins have

only a limited capacity for removing calcium and magnesium minerals. If the volume of water put

through a resin bed exceeds its capacity, some hardness will start sloughing off into the treated water.

Therefore, service runs must be terminated before this breakthrough occurs. When a run is over, the

resins are treated with sodium chloride salt to displace the hardness and restore its removal capacity

again. This process is termed "regeneration".

The degree of softening that can be accomplished depends upon several factors. The primary

influences are the incoming water composition, type of resins used and amount of salt used.

Secondary influences are the concentrations and flowrates at which NaCl is applied.

2. PRINCIPLES OF ION EXCHANGE IN THE SOFTENING PROCESS

2.1 ION EXCHANGE SOFTENING PROCESS

In order to understand what happens in the ion exchange softening process, it will first be

necessary to understand the meaning of the terms which are used in the explanation. HARD

WATER, CATION EXCHANGER, and BRINE are therefore defined below and then used to

show how the ion exchange process works.

A. Hard Water - All natural waters contain much the same dissolved impurities, but in

widely varying amounts. There are always enough ANIONS (-) present to balance the

CATIONS (+), but anions have no effect on the ion exchange softening process.

Water will be HARD, if it contains large amounts of Calcium (Ca++) and/or

Magnesium (Mg++) ions.

B. Brine - water in which SALT has dissolved. SATURATED brine contains as much salt

as it is possible to hold in solution (approx. 26% to 27%).

SALT -SODIUM CHLORIDE (NaCl). When dissolved in water it splits up (ionizes)

into Sodium (Na+) ions and Chloride (Cl-).

SATURATED BRINE -contains a very great number of Na+ and Cl-ions

(concentration is over 200,000 ppm). When used to regenerate a CATION

EXCHANGER, only the Sodium ions (Na+) are put to use. The Chloride ions (Cl-) do

not work in the process.

C. Cation Exchanger - a solid material which has a very large number of "REACTION

POINTS". These reaction points have NEGATIVE (-) electric charges, and are able to

attract and hold CATIONS, which are POSITIVELY (+) charged (much the same way

as the way opposite poles of a magnet attract each other).

6

Introduction

D. The Softening Process - When most of the reaction points have been occupied by

Ca++ or Mg++ ions, hardness will begin to slip through the bed in increasing amounts.

This rise in hardness in the effluent is an indication that the effective capacity of the

CATION EXCHANGER has been reached. The CATION EXCHANGER must then be

regenerated to restore it to its original condition.

E. Regeneration - A solution of NaCl is applied to the CATION EXCHANGER at a

controlled rate and the softening process is reversed. The Ca++ and Mg++ ions are

driven off of the CATION EXCHANGER and replaced with Na+ ions. At the end of

regeneration, the "spent" brine is rinsed away and the REGENERATED CATION

EXCHANGER, with its reaction points again occupied by sodium ions -is again able to

soften HARD WATER.

2.2 QUALITY OF EFFLUENT

If the hard water contains less than 500 ppm (about 30 grains) of Calcium, Magnesium and

Sodium salts, all expressed as CaCO3, it will be found that the effluent from a softener will

contain an average of not more that 2 ppm actual total hardness (Zero hardness by the SOAP

TEST). However, as the total CATION concentration in the hard water increases above 500

ppm, the average hardness in the effluent will also increase proportionately.

The reason for this is that when the sodium salt -those present in the raw water plus those

formed by the exchange reactions -are present in high enough concentrations, they cause a

"back-regeneration" effect at the same time as the softening process is taking place. This

effect prevents as complete a removal of calcium and magnesium as would otherwise be

possible.

It is often possible to reduce the average hardness in the effluent below normally expected

concentrations, by using a greater amount of salt than usual for regeneration.

Normal Softening Cycle -At the start of a normal softening cycle, the hardness in the effluent

drops rapidly as the residue of hardness ions left in the bed at the end of the rinse are forced

out. The effluent hardness reaches a certain minimum value and remains at approximately

this concentration for the major part of the softening run.

2.3 CAPACITY OF ION EXCHANGER

The capacity for the removal of calcium and magnesium depends mainly upon the type of ion

exchanger which is used. It is further influenced by the amounts of hardness and sodium ions

in the raw water, and by the amount of salt used for regeneration.

A. Raw Water - The effect of the amounts of hardness and sodium ions in the raw water,

is expressed in terms of COMPENSATED HARDNESS. The hardness of the raw

water is considered to be greater than it actually is for capacity determinations,

whenever: (a) the total hardness is greater than 400 ppm (as CaCO3), or (b) the

sodium salts are over 100 ppm as (CaCO3). This "greater-than-actual" hardness is

referred to as COMPENSATED HARDNESS.

B. Salt Dosage - The capacity which will be obtained from a cation exchanger is also

determined by the amount of salt used during regeneration. The Kilograins (kgr) of

hardness which can be removed by each cubic foot of ion exchanger between

regenerations, increases as more salt is used for regeneration.

At the same time, the efficiency of salt usage decreases with the higher regenerant

dosages. That is, a greater number of Kilograins of hardness are removed for each

pound of salt used at the lower salt dosages, (and consequently, at the lower

capacities). Thus, greater economy may be obtained at the expense of the number of

gallons of water softened between regenerations.

7

Introduction

3. NORMAL OPERATOR RESPONSIBILITIES

Long term, reliable system performance depends upon how conscientiously the equipment is operated

and maintained. Operator responsibilities to assure operation should include the following

recommended practices:

3.1 MAINTAIN OPERATING LOGS

Operators should maintain close control of the process by monitoring system performance

daily. Effluent purity, hardness leakage, service run lengths and pressure drop across the bed

must be recorded faithfully. Since resins are subject to fouling, decrease in product quality or

run length could be the result of fouling. In addition to operating data, log notations should

include chemical delivery dates, equipment design changes, or modifications in program

settings. This information can be invaluable if troubleshooting is ever required.

The daily log should be updated once or twice a shift and should include the following

information:

1. Date and Time

2. Which Softener is Online

3. Inlet and Outlet pressure gauge readings; calculated pressure drop

4. Influent hardness

5. Effluent hardness

6. Gallon capacity remaining

7. Record salt usage

8. Any equipment design changes, or modifications in programmed cycle settings or capacity

settings

4. OPERATING & REGENERATION PROCEDURES

4.1 DESCRIPTION OF OPERATION

The system is designed for fully automatic operation. Each unit is equipped with a NHWBP

(No Hard Water Bypass) valve that controls the In-Service and Standby modes. Service runs

will automatically switch to the stand-by tank when the meter set point has been reached,

initiating the regeneration cycle. The stand-by tank then becomes the service tank and the

exhausted tank begins a regeneration cycle.

4.2 REGENERATION CYCLE

A. SERVICE

During service flow, raw water passes through the inlet of the control valve and

downflow through the resin bed, through the lower hub and lateral distribution system,

up the distributor pipe and exits through the outlet of the control valve and into the

service lines. Service flow continues until the preset gallonage has been used,

initiating the regeneration process.

B. BACKWASH

Raw water passes through the inlet of the control valve and is directed down through

the distributor pipe to the bottom of the tank. Water flow passes through the lower hub

and lateral distribution system and travels upflow through the resin bed. The water

expands the bed scrubbing the resin beads and washing any entrapped dirt out

through the control valve drain port and out to drain. Backwash sequence lasts

approximately 10 minutes.

8

Introduction

C. BRINE AND SLOW RINSE

Raw water is directed through the injector built into the main regeneration control. A

venturi action in the injector draws the required amount of brine into the softener. The

solution of salt water then passes downflow through the resin bed, through the lower

hub and lateral distribution system, up the distributor pipe and exits through the drain

port of the control valve and out to drain. The level of water in the brine tank should be

drawn down from the preset level. The brine float air check valve shuts off air when

the preset drawdown is reached. Raw water continues to the drain through the main

control valve slow rinsing the resin for the remainder of the cycle. Brine and slow

rinse sequence lasts approximately 60 minutes.

D. SECOND BACKWASH

Water flow is the same as the first backwash. This step in the regeneration process

helps to remove iron that was released from the resin during the Brine cycle. The

second Backwash sequence lasts approximately 6 minutes.

E. FAST RINSE

Raw water passes through the inlet of the control valve and downflow through the

resin bed, through the lower hub and lateral distribution system, up the distributor pipe

and exits through the drain port of the control valve and out to drain. This sequence

removes all remaining brine from the resin bed. The Fast Rinse sequence lasts

approximately 10 min.

F. BRINE REFILL

When the regeneration cycle is finished, fresh water flows through the brine line and

into the brine tank refilling it to the preset level. The brine valve float will control water

makeup level.

A WORD OF CAUTION -- DON'T ARBITRARILY MAKE CHANGES, IF YOU WISH

TO MAINTAIN EFFICIENT REGENERATIONS.

9

Assembly and Installation Instructions

Assembly

and

Installation

Instructions

10

Placement of Water Treatment Equipment

Locating the proper place for your water softener is important. Here are some important

considerations before the placement of the system.

1. The unit should be located as close to the point of use of the treated water as is

possible. Verify that the water pressure does not exceed 100 psi before installing the

system. The water pressure of the system should range between 50 psi and 100 psi

maximum. Damage may occur to the system and/or control valve if the pressure is

allowed to exceed 100 psi and the manufacturer’s warranty will be void.

2. The system must be provided with an open (gravity) drain of sufficient size to handle

the maximum flow rate of waste-water (See System Specifications for the flow rates)

without overflowing or splashing. The drain lines must not be smaller than the size of

the drain port located on the control valve.

3. It is important that a clean power supply, that originates from a fused non-

interruptible 120 V AC 60 cycle source, sufficient to operate the controller during

normal operating conditions, is provided. An electrical surge protector or UPS

(Uninterruptible Power Source) is recommended.

4. Do not place system in a location where particularly corrosive fumes are present or

heavy equipment and/or traffic is present. (However, the system is constructed to

handle normal industrial atmospheric and vibrational conditions.)

5. The system must be located on a sturdy, level floor. Otherwise a platform must be

built that is capable of supporting the complete assembly including the weight of the

water in the tanks.

6. The system should be installed within twenty feet of a suitable drain that is capable of

handling the backwash requirements of the system.

7. Some systems are quite large. Entrances to the desired location must be large

enough to accommodate the size of the largest component of the system. Also,

there must be adequate space for the system before installation. (For measurements

of the system check the model spec sheet.)

8. The system must be placed in a location where it will not freeze.

11

Loading the Mineral Tank with Media

Below is a list of instructions for loading the mineral tank with media:

1. Remove the disposable retainer plug in the top of the mineral tank. This retainer plug is

used to secure the distributor assembly inside the tank and protect it from damage during

shipping and handling.

2. Inspect the distributor assembly located at the bottom of the mineral tank before

loading the media. Center the distributor in the bottom of the tank.

WARNING: DO NOT LOAD THE TANK IF THE DISTRIBUTOR APPEARS TO BE

DAMAGED IN ANY WAY!

3. Place the mineral tank where you want to install the system.

•Careful consideration of the proper position of the empty mineral tank is necessary

since the system will be difficult to move once it is completely loaded.

4. Plug the top opening of the distributor pipe to keep any media from entering the pipe

while loading the mineral tank. Fill the tank approximately 1/3 full of water. The water will

aid as a cushion to protect the lower distributor assembly from gravel impact.

Note: The enclosed funnel has been added to aid the media installation.

5. Load the gravel into the mineral tank first. After the proper amount of gravel has been

placed in the tank make sure the gravel bed is level so that distributor laterals are

completely covered.

6. Load the water softening resin into the mineral tank. After loading the resin, fill the

remainder of the mineral tank with water.

Note: Care should be taken when installing the gravel and resin that internal piping and

tank lining is not damaged.

12

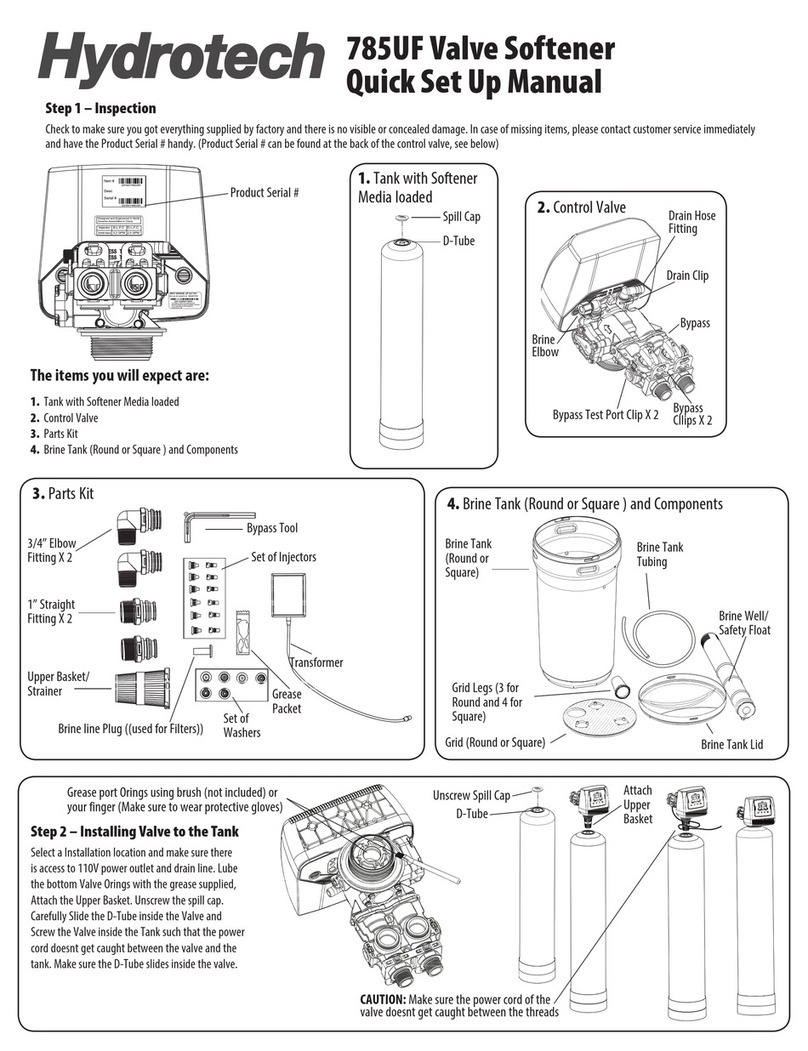

Loading the Media and Mounting the Control Valve

Mounting the Control Valves

1. Mount the flange adapter to the tank using the stainless steel, nut and bolt pack

that was packaged with the flange adapter. It is recommended that an anti-seize

lubricant be used on the threads of each bolt.

2. Push the flow disperser inside the flange adapter until it clips into the groove.

3. Grease the flange O-ring and the distributor pilot O-ring before mounting the

control valve.

Caution: DO NOT USE PETROLEUM BASED GREASES!

4. Guide the distributor pipe into the distributor pilot.

5. Special precaution is advised to avoid pinching or damaging the flange O-ring.

6. Lower and adjust the control valve until it rests square and flush with the flange

adapter.

7. Open the hinged clamp and fit over the flange adapter and control valve.

8. Close clamp and loosely attach the bolted clasp. This allows for proper alignment

of the control valve for installation.

9. Once control valve is properly aligned, tighten bolted clasp.

Repeat above steps to mount the control valve on each tank.

The system is now ready to install.

13

Plumbing Diagram

Plumbing Notes:

All plumbing should be done according to local plumbing codes. Dashed piping, fittings and

valves supplied by others.

1. Unions must be installed to facilitate removal of the control valve for servicing.

2. This system uses tanks that must not be subjected to a vacuum. A vacuum breaker

must be installed in an upright position per drawing.

3. Water meter must be installed in the horizontal position as shown in the drawing.

Note directional arrow on meter casting.

14

General Installation

Plumbing Connections

Note: All plumbing should be done in accordance with local plumbing codes.

Inlet and Outlet Connections:

Connect piping to unit using the Plumbing Diagram as a guide. Unions need to be installed

in the inlet, outlet and drain piping to facilitate removal of the control valve for servicing.

Connect the incoming untreated water line to the inlet connection on the left side of the

control valve and the outgoing treated water line to the outlet connection on the right side of

the control valve. Inlet and outlet connections are marked with directional arrows.

Drain Connections

Do not solder joints near the Drain Line Flow Controller (DLFC). The DLFC has rubber

components that could be damaged by heat. Soldering should be done prior to connecting

to the DLFC fitting.

Connect drain line to the DLFC located on the top of the control valve, making sure the

drain lines are properly supported and secured to prevent excessive vibration or strain.

Make the drain line as short as possible, leaving an air gap to visibly monitor the water flow

to the drain.

Option: Drain line may be run using Sch.80 PVC

Brine Tank

Make sure that the floor beneath the salt tank is both level and clean.

Connect the brine tubing from the brine tank to the control valve using the tubing and

fittings, (packaged inside the brine tank.) Brine connection on the softener is located on the

top rear of the control valve.

To prevent water damage in case of brine tank overflow, locate the overflow fitting on the

outside of the brine tank directly below the fittings for the tubing. Attach tubing to the

overflow fitting and position it so that the excess water flows to the drain.

If seismic straps are included secure to floor and brine tank.

Note: On very large systems the tubing and fittings are not included. The system requires

hard piping to the brine tank such as Sch.80 PVC.

Pressure Testing

Verify water pressure is within operating range.

The unit should be pressure tested prior to the initial operation.

•To begin pressure test, slowly open the inlet water valve to the unit.

•Allow pressure build up to line pressure and observe for leaks.

•Correct as necessary.

15

Control Valve Programming

Series 959

Control Valve Programming

16

17

Control Valve Programming

Press the SET CLOCK button.

The hour digit will begin flashing.

Use the UP and DOWN buttons

to adjust the hour setting.

Set the Clock

Press the SET CLOCK button

again. The minutes will begin

flashing. Use the UP and

DOWN buttons to adjust the

minutes setting.

After the minutes and hour settings have been adjusted press SET CLOCK to

complete setting the clock.

Set Gallons Between Regenerations

Before you can set the gallons between regenerations you will need to know the water

softener capacity and the water hardness. For your convenience a gallon calculator has

been provided on pages 20-22.

Note: To calculate the gallons between regenerations use the following formula.

Capacity multiplied by 0.8 divided by Hardness

To set gallons between regenerations press

and hold NEXT and UP buttons simultaneously

for approximately five seconds. The numbers

will begin flashing. To adjust the gallons use

the UP or DOWN buttons. Press NEXT to

complete setting the gallons between

regenerations and to advance to the DAY

OVERRIDE.

18

Control Valve Programming

Day Override

Press NEXT to advance to the Time of Regeneration

Time of Regeneration

This setting should be set to OFF. Twin systems do not require a day override.

The System regenerates when the volume remaining reaches 0. This setting is not

adjustable.

Press NEXT to exit programming.

19

User Information Displays

Time of Day Display

During normal operation one of three screens can be displayed.

Pressing the NEXT button alternates between these displays.

1. Current Time of Day

2. Current Flow Rate in Gallons per Minute

3. Totalizer (Total gallons used since installed)

4. Capacity Remaining in Gallons

Adjustments cannot be made from the user information displays.

See Examples Below

Current Flow Rate

Totalizer

Capacity Remaining in Gallons

20

A959SM-300

24,000

21,500

20,000

18,000

17,000

A959SM-450

36,000

32,500

30,000

27,500

25,500

A959SM-600

48,000

43,500

40,000

36,500

34,000

A959SM-750

60,000

54,500

50,000

46,000

42,500

A959SM-900

72,000

65,000

60,000

55,000

51,000

A959SM-

1050

84,000

76,000

70,000

64,500

60,000

A959SM-

1200

96,000

87,000

80,000

73,500

68,500

MODEL

NUMBER

WATER HARDNESS 10-14

10

11

12

13

14

MODEL

NUMBER

WATER HARDNESS 15-19

Volume Calculator

A959SM-300

16,000

21,500

20,000

18,000

17,000

A959SM-450

36,000

32,500

30,000

27,500

25,500

A959SM-600

48,000

43,500

40,000

36,500

34,000

A959SM-750

60,000

54,500

50,000

46,000

42,500

A959SM-900

72,000

65,000

60,000

55,000

51,000

A959SM-

1050

84,000

76,000

70,000

64,500

60,000

A959SM-

1200

96,000

87,000

80,000

73,500

68,500

15

16

17

18

19

This manual suits for next models

9

Table of contents

Other SENTRY II Water Dispenser manuals

SENTRY II

SENTRY II 940ST Series User manual

SENTRY II

SENTRY II 930TA Series User manual

SENTRY II

SENTRY II 952TA Series User manual

SENTRY II

SENTRY II 960SM Series User manual

SENTRY II

SENTRY II 960 Series User manual

SENTRY II

SENTRY II 950SM Series User manual

SENTRY II

SENTRY II 962SM Series User manual

SENTRY II

SENTRY II 972SM Series User manual

SENTRY II

SENTRY II 954SM Series User manual