iZ10000 Natural Gas Odorization System

Table of Contents

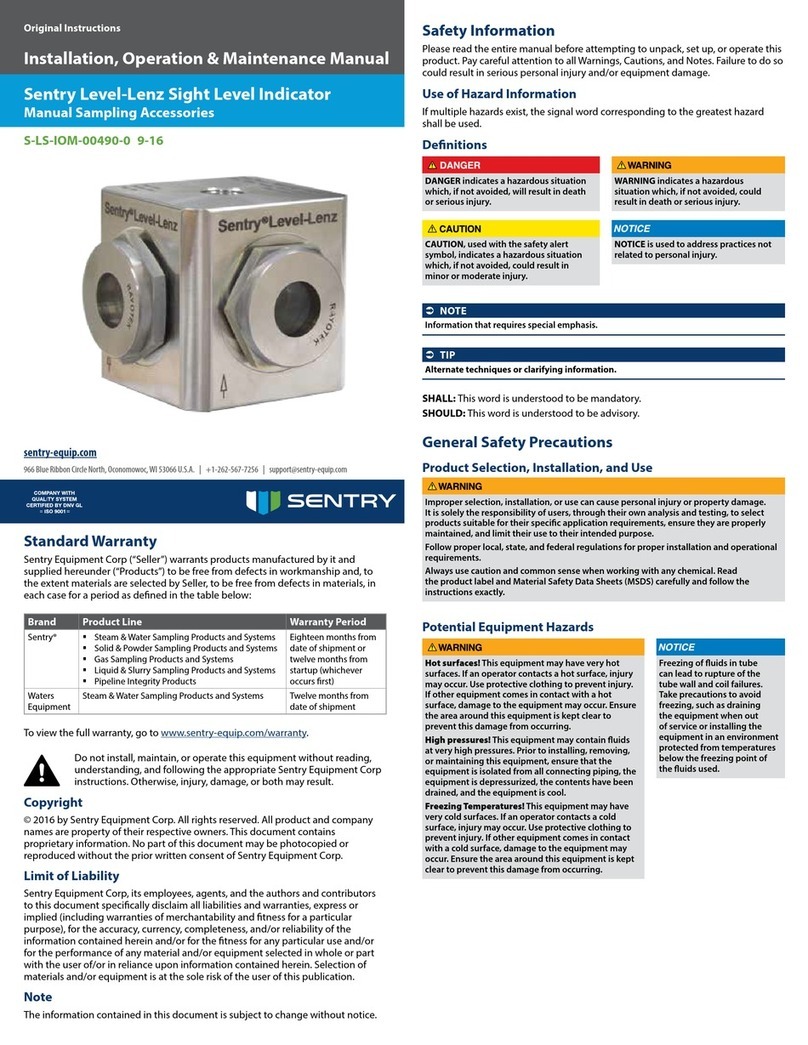

Safety Information........................................................ iii

General Safety Precautions ................................................ iv

Warning Labels............................................................v

1. Specications ...................................................................................................1

2. Overview..........................................................................................................2

2.1 Principles of Operation: ............................................................................2

2.2 Continuous Mode .....................................................................................2

2.3 Batch Mode ..............................................................................................2

2.4 System Components.................................................................................3

2.4.1 Z10000 Injector.............................................................................3

2.4.2 System Controller..........................................................................3

2.4.3 Odorant Storage Vessel .................................................................4

3. Installation.......................................................................................................5

3.1 Site Requirements ....................................................................................5

3.1.1 Unit Location.................................................................................5

3.1.2 Blanket Gas...................................................................................5

3.1.3 Electrical Power.............................................................................5

3.2 Equipment and Tools ................................................................................5

3.3 Tubing ......................................................................................................5

3.4 Wiring.......................................................................................................5

3.4.1 Electrical Connections ...................................................................5

3.4.2 Wiring Termination .......................................................................6

3.4.3 Flow Signal and Level Gauge Signal..............................................6

3.4.4 Modbus RS-485 Wiring .................................................................6

3.4.5 I/O Signal Verication ...................................................................6

3.4.6 External HMI (optional).................................................................8

3.5 Leak Testing..............................................................................................8

3.6 Unit Conguration....................................................................................9

3.6.1 Remote Conguration...................................................................9

3.6.2 TechView.......................................................................................9

3.6.3 External HMI .................................................................................9

3.7 Warm Start / Hydraulic Bleed .................................................................10

4. Mechanical Overview .....................................................................................11

4.1 Solenoid Isolation Valve..........................................................................11

4.2 Positive Displacement Flow Meter..........................................................11

4.3 Hydraulic Pump ......................................................................................12

4.4 Bellows Capsules ....................................................................................12