Senztek SolaSmart Plus User manual

INSTALLATION GUIDE

SolaSmart Plus™

www.senztek.com

© Senztek Holdings Ltd. 2011

SolaSmart™ Plus Installation Guide

Version 1.1 – March 2012 Table of Contents

Table of Contents

Before You Begin Installation.................................................................................... 1

Installing the SolaSmart™ Controller......................................................................... 5

Mounting the Sensors and Connecting Wiring........................................................... 7

Powering Up............................................................................................................ 10

Plumbing Tips ......................................................................................................... 14

About the Pump Settings......................................................................................... 16

BioSafe, Reheat, and Boost Functions.................................................................... 18

Operational Settings................................................................................................ 20

Tariff Table.............................................................................................................. 21

Display and Diagnostics.......................................................................................... 22

Sensor Maintenance ............................................................................................... 25

Trouble Shooting Guide .......................................................................................... 27

Specifications.......................................................................................................... 29

For technical help contact your distributor.

Distributor Details:

www.senztek.com

Senztek Holdings Ltd. 2009

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 1

BEFORE YOU BEGIN INSTALLATION

Assemble the

Components

You Will Need

The SolaSmart™ Controller is supplied with the following components:

Plug In Roof sensor

Tank sensor

Inlet sensor

Mains cable

Pump cable

Associated screws

Screw covers

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 2

BEFORE YOU BEGIN INSTALLATION,CONTINUED

Assemble the

Tools You

Will Need

You will need the following tools to install the SolaSmart™:

Philips1 screwdriver for lid screws.

Pozi 2 screwdriver for mounting screws.

NOTE: These tools are needed to mount the SolaSmart™ only, and other

tools may be needed for the remainder of the installation including the

sensors.

READ THESE SAFETY PRECAUTIONS and LIMIT OF LIABILITY BEFORE YOU BEGIN

The following pages contain instructions for qualified personnel only. They involve potentially

hazardous adjustments and high voltage mains wiring information.

General

Safety

Precautions

The following general safety precautions should be noted:

This installation guide is for the installation of SolaSmartTM

The complete installation should be checked at least annually for damage or

malfunction.

Controllers only

and is not an installation guide for any other part.

All servicing must be carried out by an authorised service agent only.

All aspects of the installation must comply with local electrical and plumbing

regulations (and any special solar hot water regulations).

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 3

BEFORE YOU BEGIN INSTALLATION,CONTINUED

Installation

Precautions Installers need to ensure the following:

The controller must be installed away from water sources such as rain,

leaking pipes, or wet floors; and must not be installed in damp areas like

bathrooms. The controller must have a waterproof enclosure if it is installed

outside.

Make sure the controller is installed away from direct sunlight, flammable

liquids or radiant heat sources.

Power leads must face directly down, not sideways or upwards.

Ensure the controller is in a safe environment for users to inspect display

panel.

Follow instructions carefully when mounting sensors. Incorrect sensor

mounting can lead to a poorly controlled solar hot water system with safety

issues (e.g. overheating; over pressure damage to the plumbing; freezing

damage to the solar collector).

The unit settings are factory programmed to optimise efficiency and safety.

Alteration of the programmed values can lead to dangerous conditions and/or

damage to parts of the solar hot water system.

CAUTION:

Dangerous Voltages may be present. The SolaSmartTM

Protective enclosure must only be opened by qualified personnel.

has no user

serviceable parts.

Remove ALL power sources before removing protective cover.

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 4

BEFORE YOU BEGIN INSTALLATION,CONTINUED

Electrical

Precautions When undertaking electrical installations, please note the following:

All mains voltage electrical work must be carried out by a qualified

electrician, especially external power outlet socket installation.

A readily accessible disconnect device, over current device and RCD

Protection rated to suit the size of the pump plus 5VA must be incorporated

in the power supply wiring. The over current device for a 1500W, 240Vac

pump must not exceed 10Amps.

Sensor leads should be kept 300mm (12 inches) away from mains and

comms cables.

Do not use mains power extension cords unless approved by the

manufacturer. Water resistant plugs and sockets should be used.

The SolaSmart™ controlled output (PUMP) will be connected to the input

power supply wiring and is not isolated from it. Supply voltages will be output

through that outlet during activation.

The HWC outlets are isolated contacts. A supply wire and an output wire will

need to be wired to each HWC outlet.

Always use the unit within specified voltage and load ranges. Never use with

damaged leads, plugs or sockets.

Do not allow the sensor cable to come within 10mm of the high voltage

connectors or components inside the enclosure.

The electric element should have a fuse that is rated within the stated

maximum of the relay driving the element.

Do not connect the mains or the pump to a circuit that could be switched off

by your electricity supplier to manage peak loads (ripple control).

Comply with all local and relevant electrical regulations.

Warning These products are not designed for use in, and should not be used for,

applications which are in conjunction with items that are critical to any

person’s health (e.g. life support systems).

In any critical installation, an independent fail-safe back-up system must

always be implemented.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 5

INSTALLING THE SOLASMART™CONTROLLER

Overview The diagram below shows how the SolaSmart™ is connected to the hot

water cylinder (HWC), the collector, and the three sensors (ROOF, TANK

and INLET).

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 6

INSTALLING THE SOLASMART™CONTROLLER,CONTINUED

Where to

Mount the

SolaSmartTM

The SolaSmartTM should be mounted so that:

1. It is against a flat surface with sufficient strength to hold the enclosure

and any additional weight from the plugs, sockets and cables,

2. Power Leads face down not sideways or up,

3. It is safe for users to inspect, and

4. Allowance is made for cable runs, location of power outlets and lengths

of wires.

Mounting the

SolaSmartTM Follow these steps:

1. Allow for the enclosure dropping 5mm (1/5 inch) from screw centres once

mounted (keyhole mounting).

2. Place the drill guide template against the wall, checking for level

alignment. Four screws are supplied: two chipboard screws and two

combination plasterboard/wood screws.

All four mounting holes should be used with at least two firmly secured

into wood.

The outer plastic plasterboard anchors will self tap into plasterboard and

their inner metal screws fix into the centre of the plastic anchors.

3. Mark and drill/screw as appropriate leaving the heads of the screws

above the surface by approximately 3mm (1/8 inch).

4. Place the unit over the four screw heads. The unit should slide down

5mm into the ‘key’ slots and become secured to the wall. You will need to

adjust the screw height to obtain a secure fit.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 7

MOUNTING THE SENSORS AND CONNECTING WIRING

Introduction The locations and way that the sensors are mounted is critical to ensure the

SolaSmart™:

Operates correctly and at greatest efficiency;

Protects the system against damage from extreme temperatures, and

If the Tank (Upper Tank) and/or Inlet (Lower Tank) sensors are not mounted

correctly:

There may be an inaccurate Topout sensing, which could lead to damage to

the hot water cylinder or other components.

There may be an inaccurate BioSafe sensing, which could increase the risk

of biological contamination.

If the ROOF sensor is not correctly mounted:

The unit may not be able to detect FROST settings (this can lead to the

collector panel bursting).

Please follow the instructions below carefully.

Positioning

the ROOF

Sensor

The ROOF sensor should be fitted into a metal immersion ‘pocket’ in the hot

water outlet pipe.

Apply plenty of heat transfer compound (available from your distributor)

between the sensor and the lining of the hot water outlet pipe.

Seal the sensor with neutral cure sealant and install external lagging. The

cable should also be insulated from the bare pipe.

Ensure that the sensor cable is NOT in contact with the solar collector or any

other exposed metallic surface on the roof.

Secure the ROOF sensor cable so it cannot move in strong winds. This is

important to stop wire fatigue breakages.

To prevent physical damage to the cable by birds and vermin it is

recommended that the cable is run in appropriate electrical conduit that will

prevent damage to the sensor cable. The conduit needs to be run from the

collector to the controller such that all cable is protected. Make sure the

conduit is not in contact with the collector such that heat damage could occur

to the conduit.

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 8

MOUNTING THE SENSORS AND CONNECTING WIRING,CONTINUED

Positioning

the Tank

(Upper Tank)

Sensor

Positioning

the Inlet

(Lower Tank)

Sensor

The Tank (Upper Tank) Sensor must always be fitted above the Solar

Collector return pipe. Labelled ‘TANK’ on the circuit board.

WARNING: Damage to the Hot Water Cylinder can occur if the Upper Tank

sensor is not mounted correctly.

The Upper Tank sensor should be fitted into a metal immersion ‘pocket’ in

the upper region of the hot water cylinder (HWC) (typically 1/3 of the way

down from the top of the HWC).

If a ‘pocket’ is not available, then bond the sensor against the metal wall of

the tank (not the outside cladding or insulation). Senztek has an ‘S3’

mounting option

Apply plenty of heat transfer compound (available from your distributor)

between the sensor and the lining of the ‘pocket’ (or between the tank and

the sensor).

If the tank is outdoors then seal where the cable exists the hot water tank

with neutral cure silicon.

The Inlet (Lower Tank) sensor should be fitted into a metal immersion

‘pocket’ above the HWC electric element near the bottom of the tank (usually

just above the element). Labelled ‘INLET’ on the circuit board.

If a ‘pocket’ is not available, then bond the sensor against the metal wall of

the tank (not the outside cladding or insulation). Senztek has an ‘S3’

mounting option

Apply plenty of heat transfer compound (available from your distributor)

between the sensor and the lining of the ‘pocket’ (or between the tank and

the sensor).

Precautions Please note:

Removing or cutting the cladding may void the hot water tank warranty.

The sensor must not be immersed in water.

Unless the temperature probe is designed for immersion in water,

temperature probe pockets need to be completely dry before you insert the

probe; and the pocket must be protected against moisture entry after the

probe is fitted.

Sensor leads should be kept 300mm (12 inches) away from the mains and

communications cables.

Make sure the right sensors are mounted in the right places!

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 9

MOUNTING THE SENSORS AND CONNECTING WIRING,CONTINUED

Connect the

Wiring The SolaSmart™ is supplied pre-wired with mains plug and pump socket,

tank and inlet sensors.

1. Connect the wiring from the SolaSmart™ Controller to the ROOF sensor,

the TANK sensor and the INLET sensor.

2. Connect the mains wiring.

3. Connect the wiring for the hot water cylinder element.

4. Connect the wiring from the SolaSmart™ Controller to the pump.

2. Connect the

wiring from the

controller to the,

the TANK sensor

and the INLET

sensor (as

labelled).

Plug in the ROOF

sensor.

1.

Connect the

mains wiring.

Do NOT

connect the

mains wiring

to a circuit

that could be

switched off

by your

electricity

supplier to

manage peak

loads (ripple

control)

3. Single Element HWC:

Connect the wiring from the controller to the hot water

cylinder element. Lower element or single element

Make sure that the electric element has a fuse that is

rated within the stated maximum of the relay driving the

element.

This is a simple (clean) set of normally open contacts

that interrupt the Active/Phase wire that powers the

element.

Do not bypass any thermostats or cut-outs.

Ensure mechanical thermostat is adjusted to maximum

so controller can operate HWC.

NOTE:WIRING OF HWC MUST BE DONE BY A REGISTERED

ELECTRICIAN.

4. Dual Element HWC:

Connect the wiring from the controller to the hot water

cylinder element. Upper element in a dual element tank

Make sure that the electric element has a fuse that is rated

within the stated maximum of the relay driving the element.

This is a simple (clean) set of normally open contacts that

interrupt the Active/Phase wire that powers the element.

Do not bypass any thermostats or cut-outs.

Ensure mechanical thermostat is adjusted to maximum so

controller can operate HWC.

NOTE:WIRING OF HWC MUST BE DONE BY A REGISTERED

ELECTRICIAN.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 10

POWERING UP

Before you

Connect the

Power

Before you power up, make sure you have:

Read the safety instructions, warnings and liability statements.

Completed installation.

Securely mounted the unit in place before you connect power to the unit.

Checked that no water, metal shavings or other electrical hazards are

anywhere near the plug, socket and/or surrounding environment.

NOTE:

The power outlet socket must be installed by a registered electrician.

The SolaSmart™ must be installed by a qualified person.

Ensure suitable over-current protection and RCD protection for the

SolaSmart™ is in place.

The mechanical hot water thermostat for the electric element should be set

to the maximum for the HWC Control Mode to operate correctly. (The hot

water thermostat is only used as a failsafe feature and normally will not

operate.)

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 11

POWERING UP,CONTINUED

What you will

see Before you power up, make sure you have:

Read the safety instructions, warnings and liability statements.

Completed installation.

Securely mounted the unit in place before you connect power to the unit.

Checked that no water, metal shavings or other electrical hazards are

anywhere near the plug, socket and/or surrounding environment.

NOTE:

The power outlet socket must be installed by a registered electrician.

The SolaSmart™ must be installed by a qualified person.

Ensure suitable over-current protection and RCD protection for the

SolaSmart™ is in place.

The mechanical hot water thermostat for the electric element should be set

to the maximum for the HWC Control Mode to operate correctly. (The hot

water thermostat is only used as a failsafe feature and normally will not

operate.)

Continued on next page

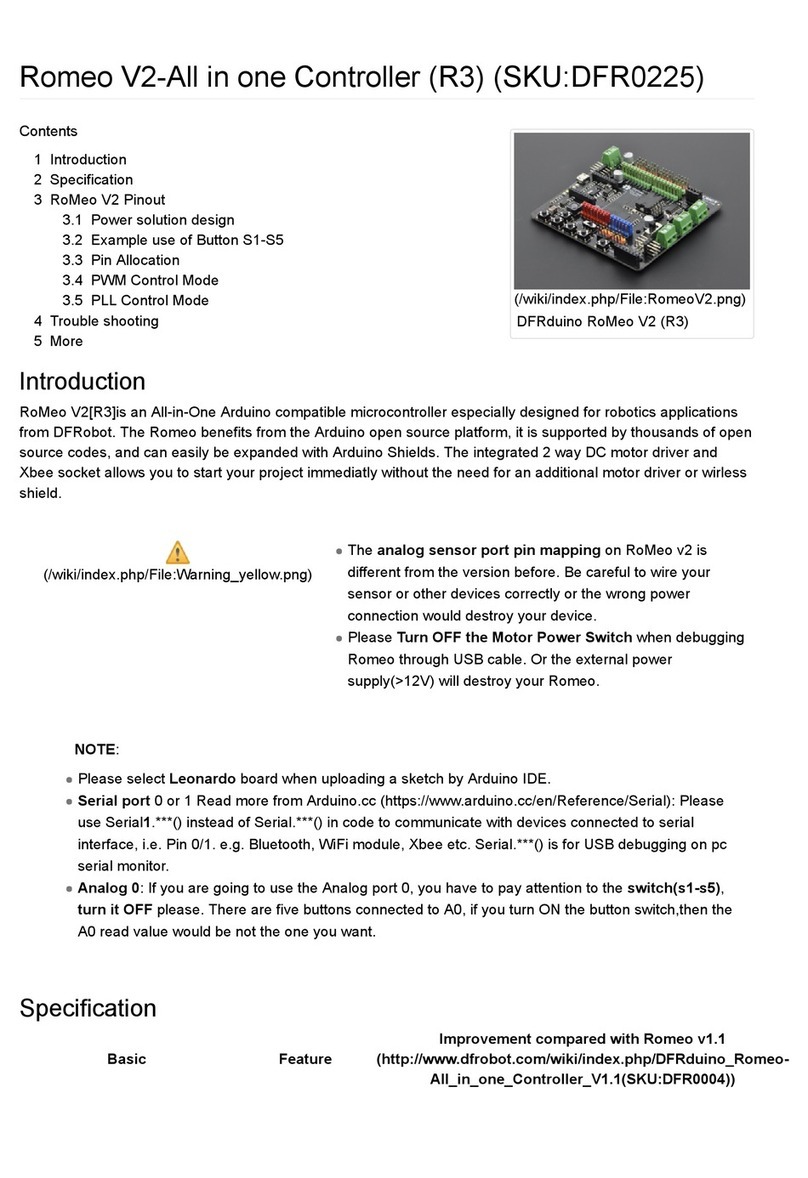

The CONTROLLER OK

light is on when the

controller is operating

correctly.

The PUMP light comes on when the

pump is on (in normal or FROST

operation or when the PUMP button

is pressed).

For Dual Element model:

The HWC2 light comes on when

upper element is on.

The HWC1 light comes on when

element is on.

HWC Button

Press for Boost; press again to

cancel boost.

The SENSORS OK light

is on when the sensors

are operating correctly.

Light off; check Roof

sensor.

Light flashing; check Tank

sensor.

PUMP Button

Press and hold this button to turn the pump

on, and release to turn the pump off.

To keep the pump running, press and hold

button until pump light is flashing; and press

again to turn pump off.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 12

POWERING UP,CONTINUED,CONTINUED

Setting the

Time and Date The display is accessed by taking the top cover off the unit. Care must be

taken in these conditions as there are dangerous voltages present around

the high voltage section of the PCB. There is a plastic sheath fitted around

this area under normal conditions. The Setting Time and Date procedure is

also printed on the plastic sheath.

Procedure:

1. Press the Set Button.

2. Press the Hour and Min buttons to adjust time.

3. Press the Set Button.

4. Press the Day and Month buttons to adjust date. Year not set.

5. Press the Set Button.

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 13

POWERING UP,CONTINUED,CONTINUED

Final Checks The SolaSmartTM is now fully installed and should be working.

It is best to observe some solar hot water pump cycles, but this will depend

on the sun shining.

Check all functions are working correctly before leaving the installation.

The SolaSmart™ settings have been factory set to the standard settings for

your area and requirements.

See ‘Trouble Shooting’ section on pages 27-28 of this guide if the system is

not working correctly.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 14

PLUMBING TIPS

Overview This section will help you to ensure the plumbing associated with the

SolaSmart™ will enable the system to be operated safety and to maximum

efficiency.

All plumbing installations should be carried out by registered and qualified

plumbers and all regulatory and local standards must be applied. Best

plumbing standards must be used for all plumbing work associated with

installation and maintenance.

All parts including the pump must be rated for the elevated temperatures

found in solar hot water systems.

The information provided here provides feedback from experienced solar hot

water professionals, but does not represent a complete guide to plumbing a

system.

Tempering

Valve Water from solar hot water collectors frequently reaches very high

temperatures. It may exceed 100°C (under pressure).

A tempering (or mixing) valve must be installed if required by local

regulations.

It is used to ensure the supply from the tank does not burn end users. The

tempering valve must be appropriately rated to handle extreme

temperatures.

Installation must be to best plumbing practice and the manufacturer’s

specifications.

Non Return

System Hot water rises and cold water falls. If the solar collector is colder than the

tank (e.g. at night) the hot water from the tank can thermo-siphon up to the

collector. The collector then radiates the heat to the cool night air and the

cooler water descends back to the tank.

To stop this loss of hot water at night or during cloudy skies, a ‘one way’ or

non-return valve or other non return solution needs to be fitted.

The failure of a non-return valve or heat loop is a common problem with solar

hot water systems. Some key points are:

It is critical to make sure that the orientation of the valve is as per the

manufacturer’s directions.

Make sure there are no debris caught in the valve as that could cause the

valve not to close.

The heat loop/trap is long enough.

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 15

PLUMBING TIPS,CONTINUED

Pressure

Relief Valves Solar hot water systems can run much hotter than standard domestic hot

water systems. Hotter water expands more, and needs high quality pressure

relief valves to ensure the tank or other components do not burst under

pressure.

A qualified plumber can recommend the best practice solution for each

installation for pressure relief valves, including the number and placement of

them.

Air Relief

Valves Air locks can occur within the piping system (as well as the pump). These

can increase the pressure that the pump is working against, to the point

where the pump can no longer circulate the water.

To avoid this, an air relief valve should be fitted (especially in low pressure

systems).

Your registered plumber should install the air relief valve to the highest point

of the return from the solar water collector.

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 16

ABOUT THE PUMP SETTINGS

Introduction The SolaSmart™ works by turning the pump on when the difference between

the temperature at the solar hot water collector (ROOF) and the INLET is at a

high level (i.e. the temperature at the solar hot water Collector is significantly

higher than the temperature at the bottom of the tank (INLET).

The pump turns off again when the difference is lower (i.e. the water in the

tank has been heated up).

For example, using the standard settings:

PUMP ON = 12°C and PUMP OFF = 6°C:

When the solar hot water collector (ROOF) water temperature is 12°C higher

than the INLET, the pump turns on. This transfers hot water from the

collector to the tank, and transfers cooler water from the bottom of the tank to

the collector.

This makes the temperature in the Tank heat up; and the temperature in the

collector on the ROOF cool down.

When the difference in the two temperatures reduces to 6°C, the pump

switches off, allowing the water in the collector to heat up again.

FROST

Function

The FROST function is designed to protect your collector and hot water

system from freezing and bursting. When this temperature is reached, the

pump will come on just enough to raise the temperature of water by 2-3°C

Only a small amount of warm water is needed to protect the collector and

plumbing.

When the unit is in Frost Mode, the PUMP light will come on.

PWM Pump

Function

The PWM output is a signal that can communicate with an intelligent variable

speed pump such as the Grundfos Solar PM 15-85. This is a signal only and

not a power source.

A PWM pump uses less electricity to pump the same amount of water as a

standard induction pump and will harvest solar energy more efficiently with

the SolaSmart controller using a control method that self adjusts to maximum

energy transfer.

Continued on next page

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 17

ABOUT THE PUMP SETTINGS,CONTINUED

Advanced

TopOut

Function

The Topout temperature is the maximum temperature that you will allow in

the cylinder. Very high temperatures in the cylinder can cause damage

(especially for ceramic lined tanks) – both from heat, and from high

pressures on plumbing fittings.

This function is designed to stop hotter water from the collector entering the

cylinder if the temperature is already high – until the water in the cylinder has

cooled down to a safe level.

Senztek has also developed an advanced Topout method that delays the

onset of collector stagnation and facilitates early recovery if stagnation has

occurred.

This is achieved by using a three stage Topout where the tank is protected at

all times and the solar pumping control method is altered progressively.

If stagnation has occurred and the hot water tank is no longer at maximum

then recovery is achieved by pulsing water through the collector, dissipating

heat in the pipes such that steam should not be present when the water re-

enters the tank and thus avoiding steam implosions (loud banging noises in

tank).

SolaSmart™ Plus Installation Guide

Version 1.1 – Mar 2012 Page 18

BIOSAFE,REHEAT,AND BOOST FUNCTIONS

Collector

BioSafe During BioSafe the pump is run for two minutes once the tank is above the

target temperature.

BioSafe Mode

BioSafe runs periodically according to the settings. Only Inlet (Lower Tank)

Sensor is used and Lower Element will be turned on when the controller is in

the BioSafe Mode.

For installations where the Inlet (lower tank) sensor is below the electric

element, BioSafe must use the Tank (upper tank) sensor for control and

should be set to run every 24 hours to comply with AS 3498 Clause 7.1 (j)

BioSafe uses the Real Time Clock to determine when it should run and is

therefore immune to power outages less than 14 days.

BioSafe Target

The controller ensures that the whole tank is above this temperature during

BioSafe Mode.

BioSafe Holdup

The time BioSafe Target Temperature will maintain before exiting BioSafe

Mode. If Lower Tank Temperature drops below BioSafe Target Temperature,

the holdup timer is reset for the full BioSafe Holdup.

BioSafe Band

BioSafe can be specified to run at the start of any of the four Tariff band.

(Refer to “Tariff Table” on page 21)

BioSafe Period

It is the interval that BioSafe takes to repeat its operation, nominally every 7

days.

Continued on next page

Other manuals for SolaSmart Plus

1

Table of contents

Other Senztek Controllers manuals

Popular Controllers manuals by other brands

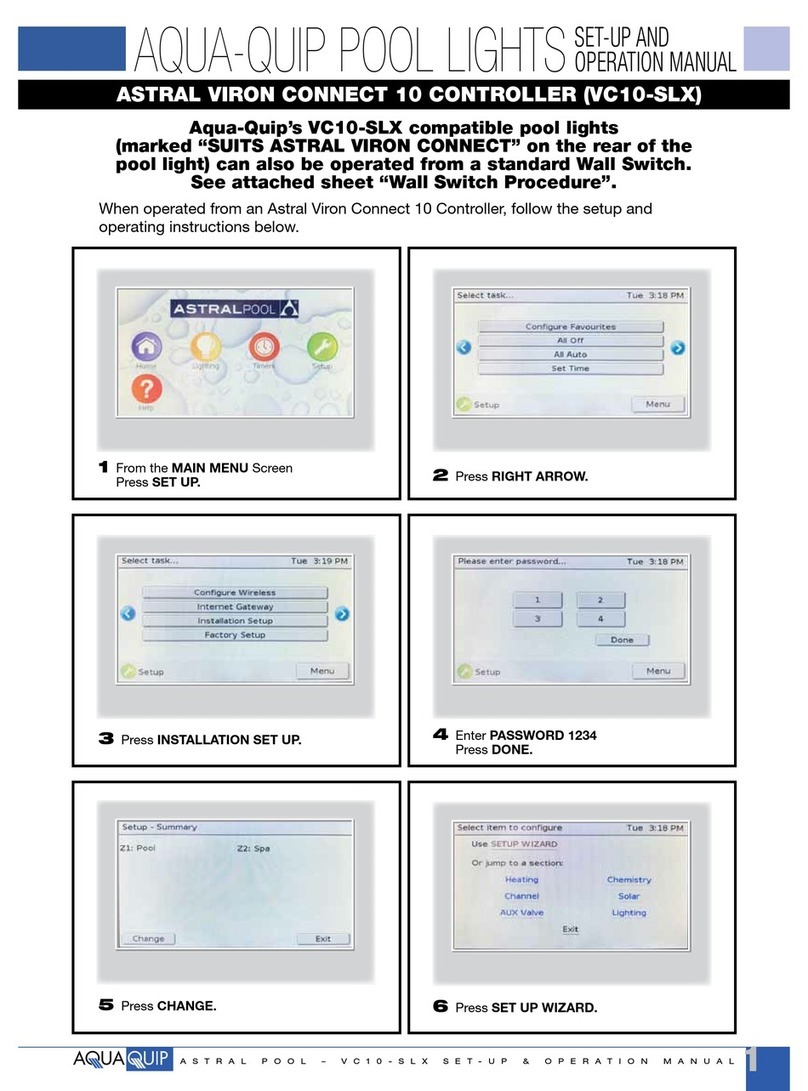

Astral Pool

Astral Pool ASTRAL VIRON CONNECT 10 Setup and operation manual

Contro l4

Contro l4 EA-5 installation guide

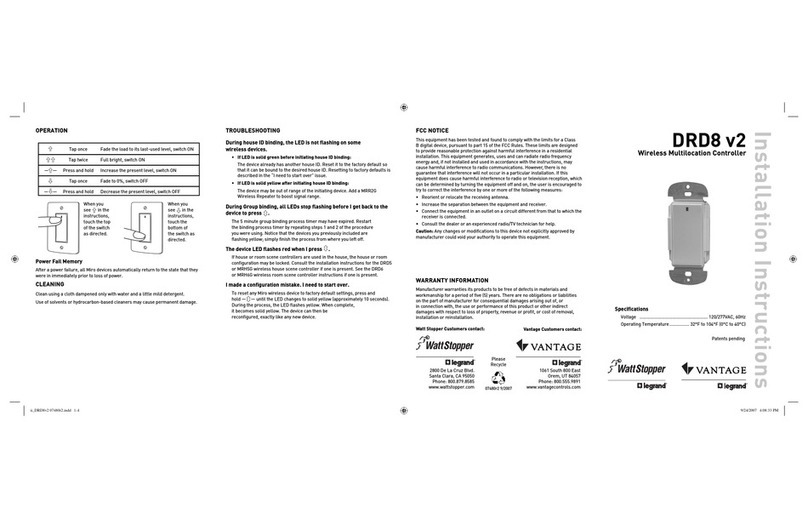

wattstopper

wattstopper DRD8 v2 installation instructions

Show Tec

Show Tec Showmaster 48 MKII manual

digitalview

digitalview HSP-1920v2 instructions

Kieback&Peter

Kieback&Peter DDC4400e Product description